24 hour turnaround? That’s Impossible!

I met with a CNCROi.com client the other day and they told me after reading my business card, “24 hour turnaround? That’s Impossible!”

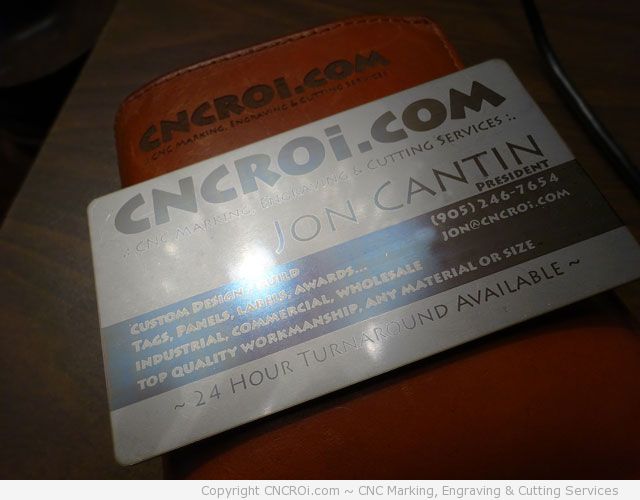

304 stainless steel plate fiber annealed using our dual-sourced Austrian CNC laser.

I believe the customer is always right, until they are proven wrong… and in this case, the client and the project they had for me to do was more than possible to achieve a 24 hour turnaround on.

They had been using another laser supplier for their metal tags which were done with a CO2 laser source which means they had to use Cermark. The results are NOT as good and long-lasting as with fiber so I knew right off the bat that we can not only produce things FASTER but actually CHEAPER than their current supplier. What would take the trophy shop about a day, we can get done in a few hours. Not only do we have a fiber lens with fiber tube but we also have the fastest CNC production laser on the market!

Why we don’t use Cermark for metal

Cermark is a ceramic paste that’s applied to a clean (meaning you need to clean it first) surface which you want to the hit with a CO2 laser source to “bake” it into/onto the material. Afterwards, you need to clean the surface again to remove this toxic paste.

Their process black on stainless steel using a CO2 laser source

- clean the metal

- apply the toxic Cermark paste

- wait 10 minutes (or longer) for it to dry

- stick the metal in the machine

- clean off the paste (still toxic and more often than not, sent right down the drain into our environment!)

- give to client (hope no residue was left, otherwise you are sharing this toxic paste with friends and family)

Us here at CNCROi.com? Make a jig (if we don’t already have one made), stick the metal in the bed and anneal away! Our platform is a meter wide by as long as you want which means we can do far more volume per “run” than the average business with a CNC laser.

By the way, our process is true annealing and doesn’t come off, Cermark isn’t viewable in as wide a variety of angles and doesn’t chip or fade over time.

Annealed 304 Stainless Steel business card, imagine having a thousand of these to do with Cermark! That’s an insame amount of work and the finish would be nowhere as clean as this!

Cermark isn’t all bad!

Cermark has it’s use, if you want to get black pictures and text on glass, that’s pretty much the only thing you can use but otherwise, I stay clear of it… and for glass, I suggest people use sand blasters if the detail they want to achieve isn’t high enough to justify a CNC laser. I do plan on getting a sand blaster in the shop once we move to a larger location btw as I believe in using the best machine for the application, not trying to Mickey Mouse my way into projects.

Why offer a 24 hour turnaround?

BECAUSE WE CAN! Seriously though, it’s highly dependent on the project, budget and inventory we have here if the client doesn’t have their own… we can’t guarantee it for everybody but it is a nice feature for those clients who are in an absolute hurry! Generally, we take a few days turnaround but to be completely honest, the faster we get the project in your hands COMPLETE, the faster we get paid, so it’s to our advantage – without cutting corners – to get a project done as efficiently and cleanly as possible.

24 hour turnaround? TOTALLY possible!

Now that you have a deeper understanding of how we are able to produce thousands of stainless steel (or other production materials) in as little as 24 hours, why not shift your steel production to a company that has invested Mucho Dineros (big money) into the best damn CNC laser in the marketplace! Give CNCROi.com a call!

Unwashed and used washer with fiber annealing down to font size of “1”… if we can write on this, imagine what we can write on the clean stuff!