Challenges with CNC Laser Engraving REAL Wood

Laser engraving REAL wood has a set of challenges not present with man-made alternatives like MDF or to a lesser extent plywood. CNCROi.com will review some of them here.

We often get customers asking us to engrave wood to a specific depth and the answer is that CNC lasers are really an unprecise challenge as there is no two way feedback between the material and the laser.

Unlike a CNC router, where, after set-up, the bit knows exactly where it is relative to the surface of the material, the laser has no idea where it is relative to anything other than the X and Y axis.

Put in another way, there is no Z axis feedback on a CNC laser relative to a CNC router. As such, the amount of material vaporized by the laser is relative to speed, power and material density.

Additionally, where a CNC router can power through knots and grain (where the material density is higher than other areas of the wood), the CNC laser, again, has no way of realizing that it’s all of a sudden engraving into higher density material.

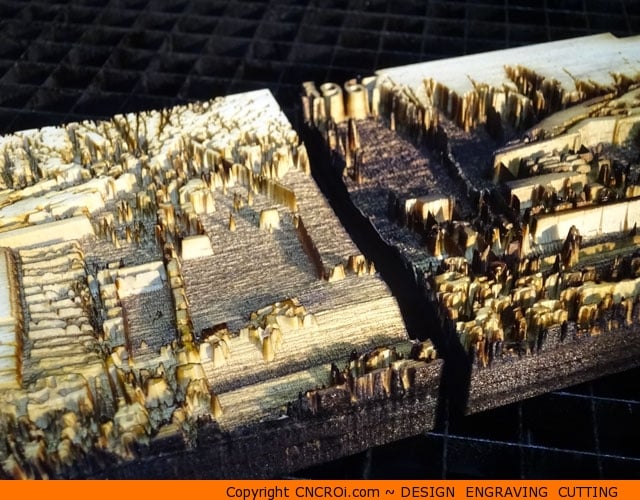

As such, then the laser hits higher density material, it reduces the depth of the engraving relative to lower density material. With wood, this poses a unique challenge. Wood is anything but even density throughout.

REAL wood can have HUGE density variances and as such, a customer requesting a specific depth are asking for something that the technology isn’t designed for.

On consistent material, such as acrylic, laminate, metal and to a certain extent, MDF and plywood, this isn’t as much of an issue. What do you see in common here? Well, they are all man-made material that are made in huge production runs to produce a consistent commercial product.

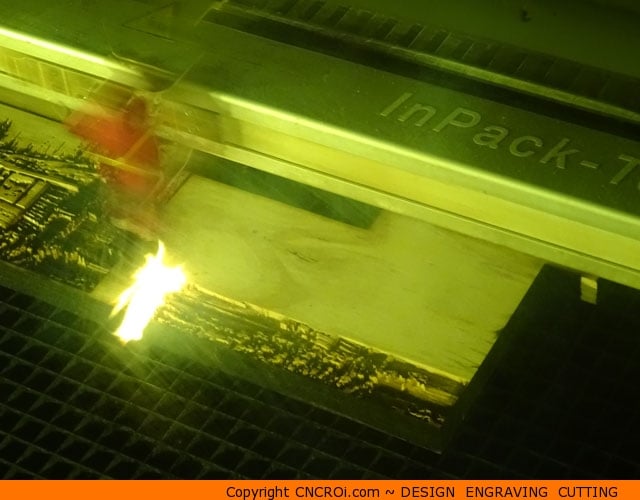

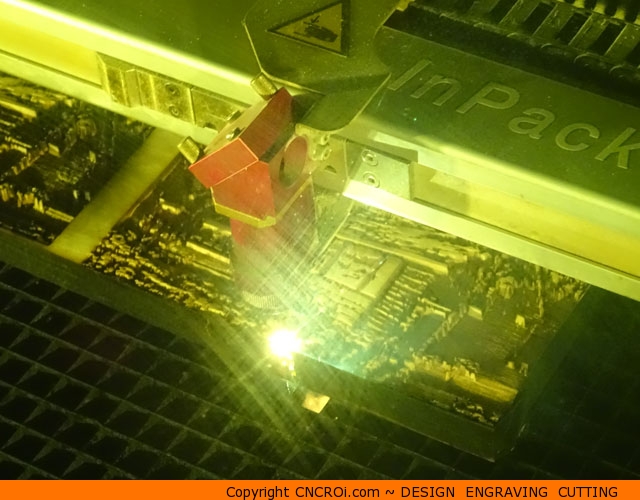

As you can see in the video above, going twice as fast doesn’t necessarily produce an engraving half as deep. Why? Because the laser has one more “hitch” called FOCUS.

For a CNC router, you have a spinning bit, so if the material hits anywhere on the spinning bit, it will be cut. For a laser, the extra complication is that the further you are from the focal point, the less power you have.

When it comes to laser engraving, you can see how much unique of a challenge getting a consistent depth with a CNC laser can be. There are a few ways around this but they aren’t really good.

The first is doing deep engraving using multiple passes, this is good because you are removing a lower amount of material per pass but the challenge here is that material inconsistencies build-up with each additional pass.

This is because it’s the “out of focus” that actually helps create a consistent depth result in the first place, it tends to equalize things over the entire board. Essentially, what is “bad” is actually “good” in a way.

So, how is a RELATIVELY even depth even achieved? One is to go with more consistent material, the other is just raw experience laser engraving and cutting wood.

We use a ton of different species and thicknesses of wood here at CNCROi.com and know the optimal material to use for particular applications.

Although a lot of different species can be used for signage, pine is tough to beat as it’s so easy to work with, relatively weight and produces a very nice contrast when engraved.

We also use woods in the shop for a variety of applications, from custom business cards to coasters, cutting boards and a bunch of other things like cake toppers and furniture.

As such, this broad range of items that we design and make for customers using wood specifically helps us build optimal material databases across a wide variety of applications.

When it comes to cutting wood, we also have many tools at our disposal. From a custom downdraft table to industrial CNC router through to many other top of the line solutions for our customers far and wide.

Using top of the line equipment helps us greatly as well, you need good quality tools to do a top shelf project.

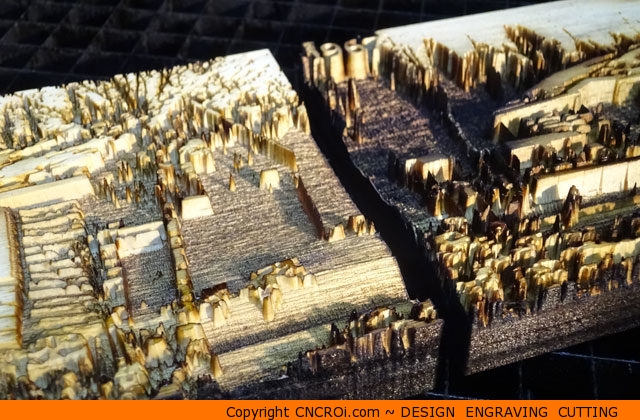

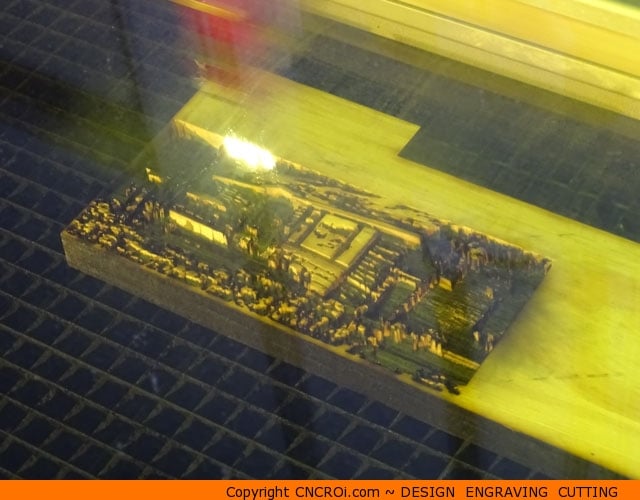

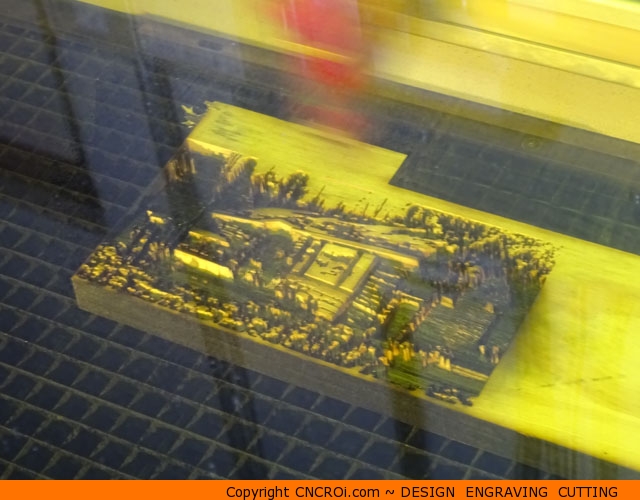

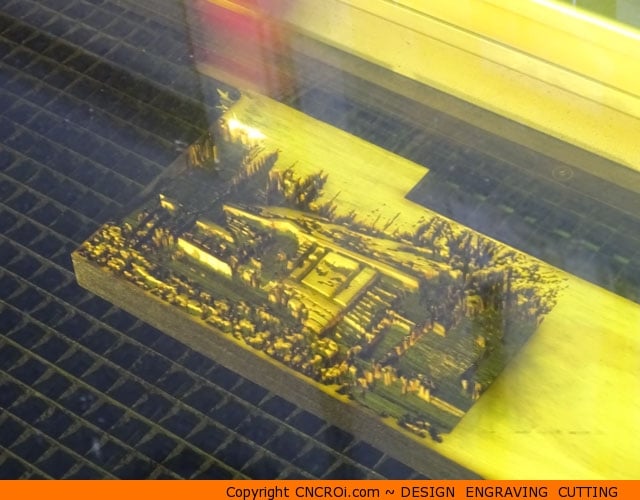

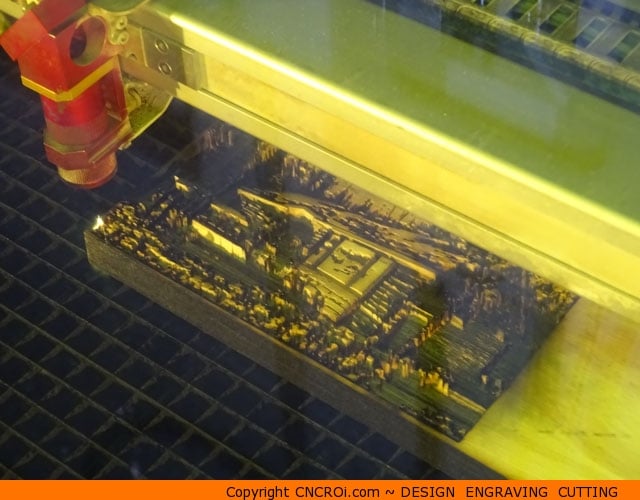

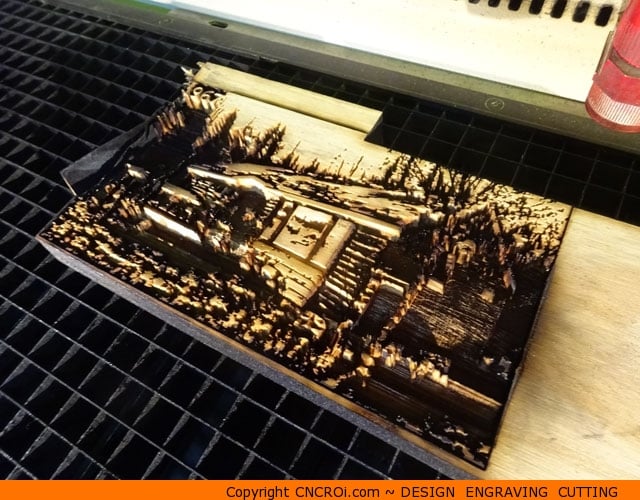

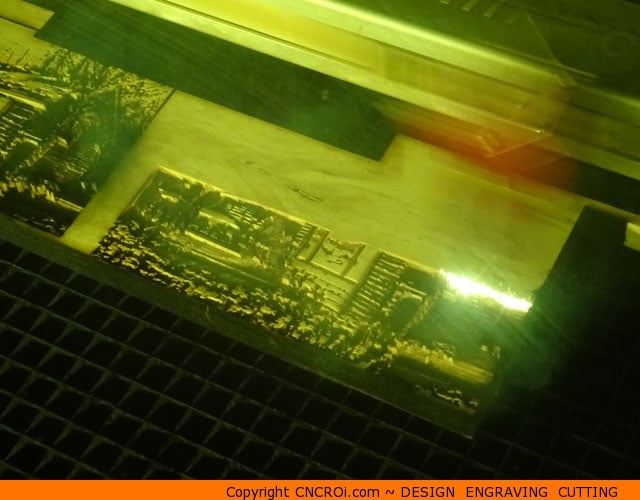

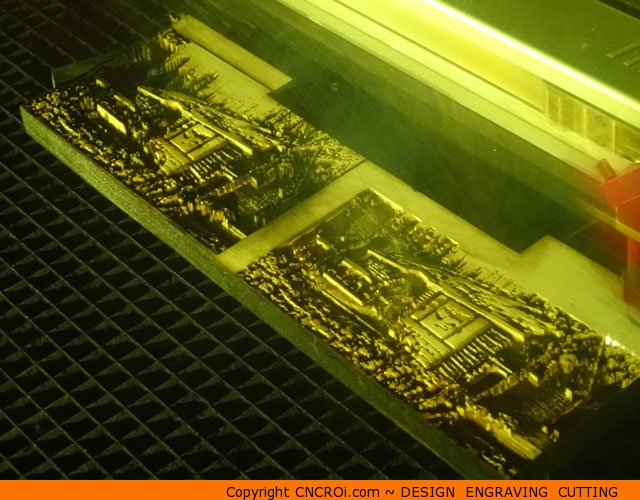

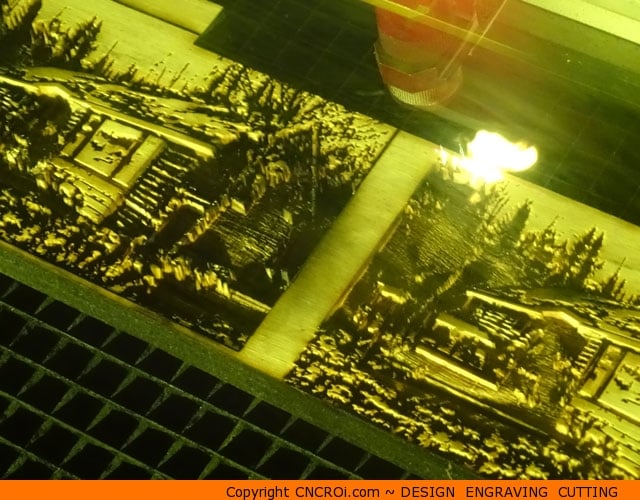

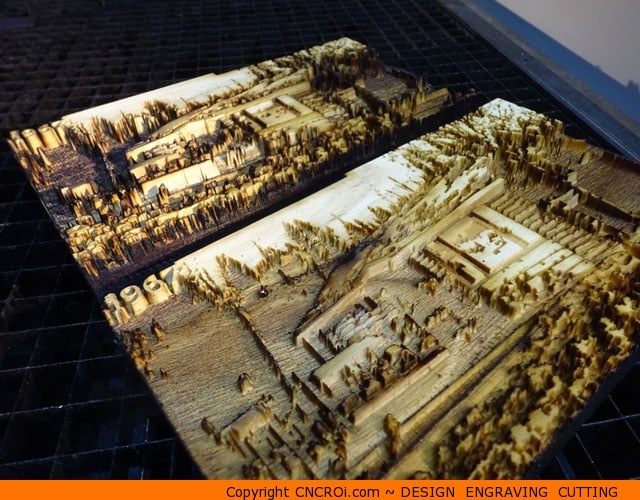

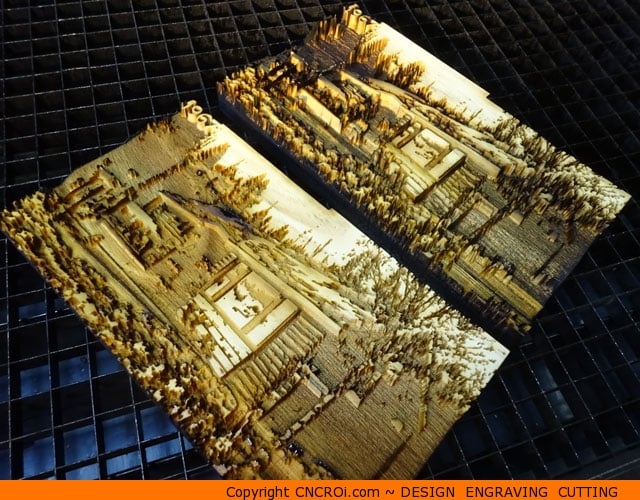

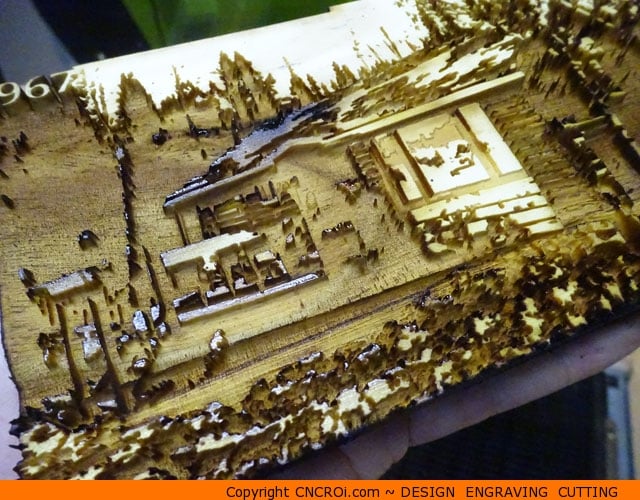

Taking a look at the two boards in the pictures below,one was engraved at twice the speed of the other, using the same settings. You do not have twice the depth but you can see a gentle slope caused by wood density variations instead.

The one that’s “darker” is engraved deeper as it projects more shadows, these were both laser engraved and cut from 3/4 inch or 18 mm pine.

Darkness in engraving is also somewhat controlled by being out of focus, as such, the deeper engraved board is darker as a result as it was able to vaporize more out of focus than the other board.

Something that wasn’t lost through is the clarity, both look great, are almost the same equally.

This video above showed you where the design is from and the results using a lot less power to achieve a more consistent depth control over the wood.

The darker soot you see on the surface is made-up of resin and smoke stains, this is why sanding is a good idea after something like this is done and the deeper you go, the more of this is released in one shot.

Looking for a custom CNC company to make laser engraving wood come-out the way you wish? These are two extreme examples to illustrate a point but regardless of application, but CNCROi.com‘s experience to work for you!

Contact us right now!