CNC Laser Engraving Rock

CNC laser engraving rocks is something that’s only possible with a powerful industrial Austrian laser, like what CNCROi.com has!

We do a lot of hard substances here at CNCROi.com beyond just stones and rocks. From incredibly tough tiles and granite to concrete and cement. Some of these are paint filled and other applications, just left as/is such as this laser engraved rock.

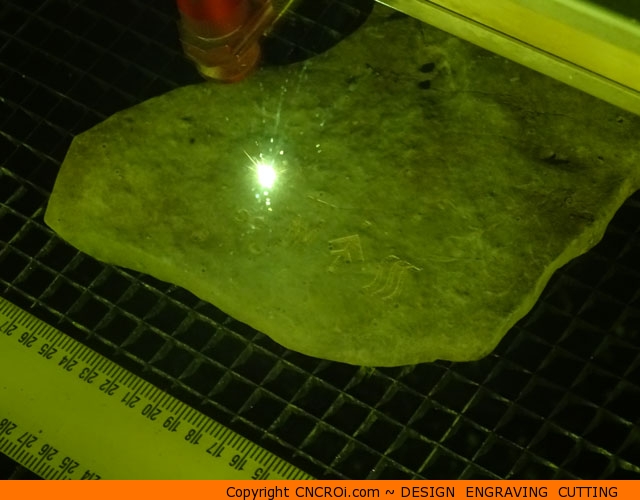

Laser engraving rock is a slow and powerful process. It’s slow because a lot of power needs to be pushed into a spot less than the width of a hair and max powerful is required to vaporize the upper layer of this very well-worn and naturally sanded surface.

In this case, the surface of this rock was cleaned in order to get the effect that is required on this rock, it’s suppose to be bare and to look as old as possible.

This is quite a contrast from the natural field stone above, where, once water was added, came to life. This is not what we want to have happen for this project, hence stripping the surface of any debris.

The point of light on this engraved rock is where the high power of our wide format industrial laser is vaporizing the surface. This point of heat is incredibly HOT, the entire rock gets so hot during production that it actually has to be allowed to cool down.

The heat build-up isn’t just isolated to large rocks that we laser engraved, for instance, here’s a video of CNCROi.com laser engraving small beach pebble stones and they also get hot to the touch regardless of the aggregate.

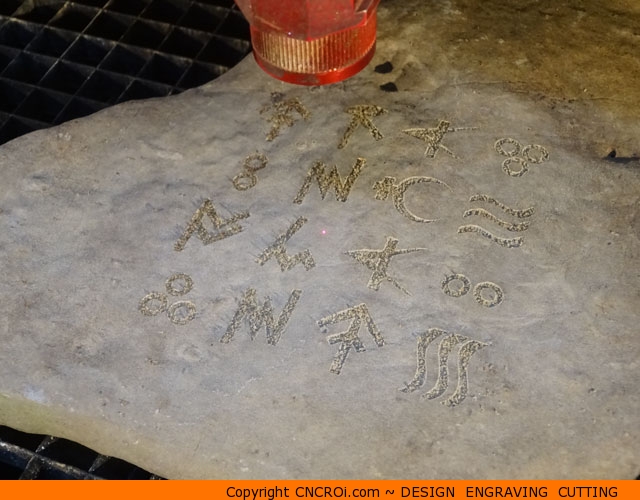

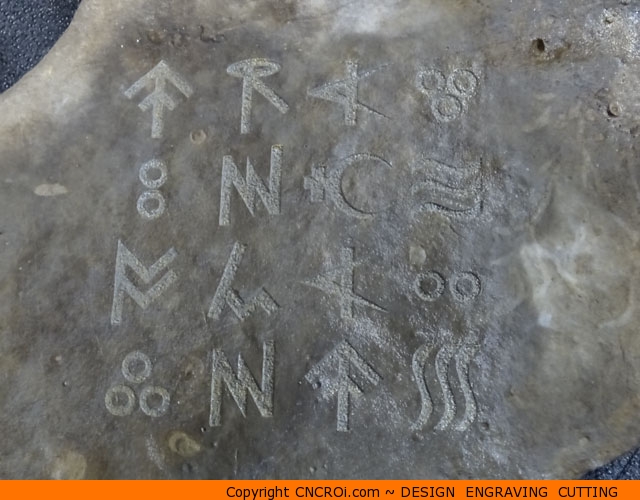

The resolution we achieve with our industrial CNC laser on stone isn’t limited really by the density, rocks in generally pretty solid and dense so even fine details come out pretty good, even if the surface is uneven.

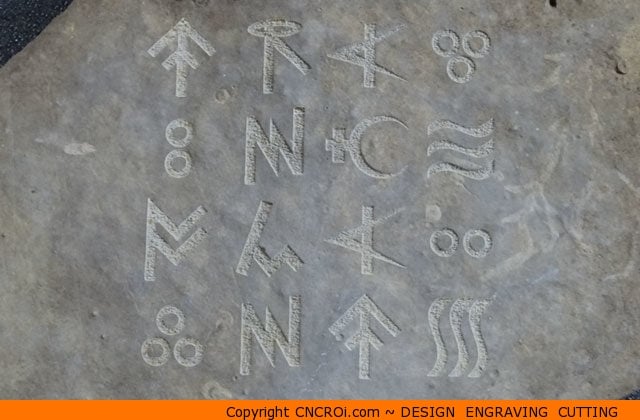

The design we engraved on this rock has lots of round and sharp edges to it, all have come out great. The advantage with CNC laser engraving wood is that there is plenty of tolerance built-into the material. Ironically, the properties that make wood such a wonderful substrate to work with are also shared with rocks and field stones.

The depth we achieve laser engraving rock is limited, going over the same area more than once doesn’t produce additional depth generally. For instance, this field stone was passed over 5 times and very little additional surface aggregate was taken off on subsequent passes.

The reason being, this rock is INCREDIBLY HARD. On software rocks like sandstone, we do get additional depth but again, it’s more a function of density and aggregate distribution than laser power when it comes to multiple passes generating more depth.

We get the same situation with concrete and cement, and to a certain extent, after the first laser pass, the rock is heated and becomes harder which makes subsequent passes less advantageous.

If you wanted to have, for instance, a signature or a portrait on stone, CNCROi.com is not only able to do the engraving at high-resolution using our industrial laser but also source the rock or stone to do the project. The engraving will outlast the last human on earth, that’s how permanent our process is!

There are some limits though when it comes to professional rock engraving, first, the image needs to be black and white as grayscale just doesn’t come out very well. It muddies the results achieved by laser engraving as the depth variances are so little.

As for stone type, it doesn’t really matter, it’s more a function of a consistent density and a relatively flat surface when it comes to predicting the results we can achieve on stone.

Once the laser engraving of the rock is finished, it’s time to give it a thorough cleaning to remove all the vaporized debris both on the surface and within the cracks and dimples found on the top.

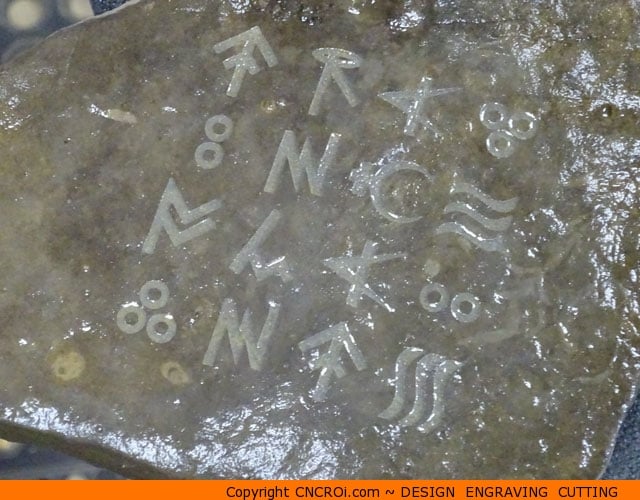

A quick dry clean is what you see below from the above initially out of the machine but we need to clean it further with water to really give the results optimally photographed.

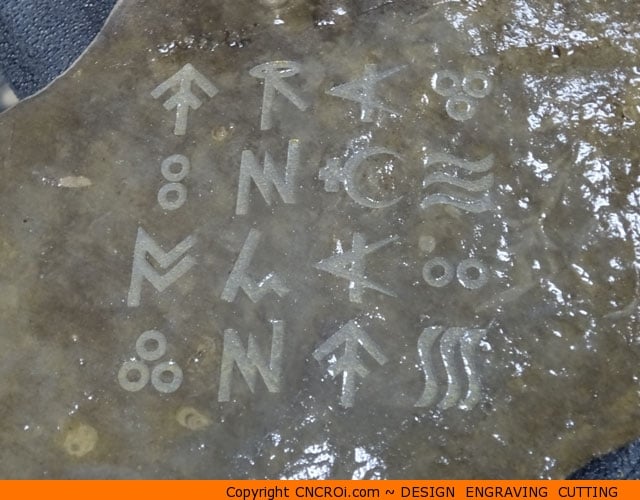

Looks fantastic now! The contrast comes mostly from the carefully sanded surface over eons which is then broken-up in selected areas by the laser creating both depth and a rough surface. The above image is just natural contrast, another stone can produce other shades such as Dwayne Johnson’s motivational rock engraving.

The light hits these two areas differently, hence built-in contrast.

Making the stone wet, only exaggerates the results further, as the shine is mostly found on the surface with little of it where laser rock engraving happened.

Taking a look at this from another angle, as photographing is very difficult with a surface that’s so uneven, things always look better by the human eye than any photograph can hope to achieve.

After the water is removed a bit from the surface, you can see the contrast is still very much present. Rock engraving is quite fascinating especially when the work is highly detailed or intricate.

We can engrave and paint fill a huge variety of tough materials, from acrylic to tile, cement through granite and many other surfaces that you wouldn’t traditionally think of being laser ready for engraving.

Looking for fantastic CNC laser engraving and marking of hard substances, contact CNCROi.com to turn your ideas and concepts into reality. We are here to help!