Custom Acrylic Mold Production: CNC Laser Engraving & Cutting 1/4″ (6 mm)

Custom acrylic mold production can be useful across a large range of industries, today CNCROi.com will focus on acrylic but this mold could have been just as easily produced using rubber, wood, delrin or lots of other materials.

The reason we are making this specific sample mold in acrylic is that this is for an application where there will be pressure involved, repeated use on an abrasive material (sand in this case) and needed to be welded to a “dowel”.

Acrylic is the best choice for this client but I made an extra to demonstrate what we can do for custom casting applications.

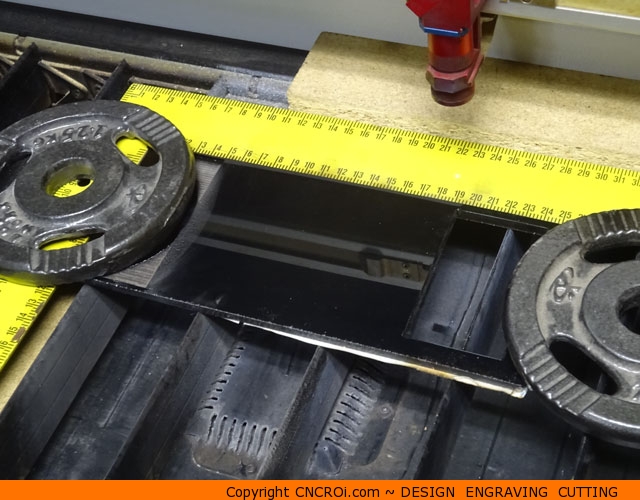

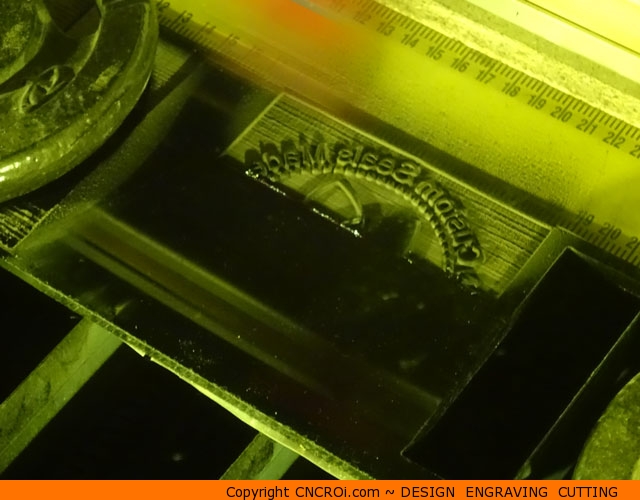

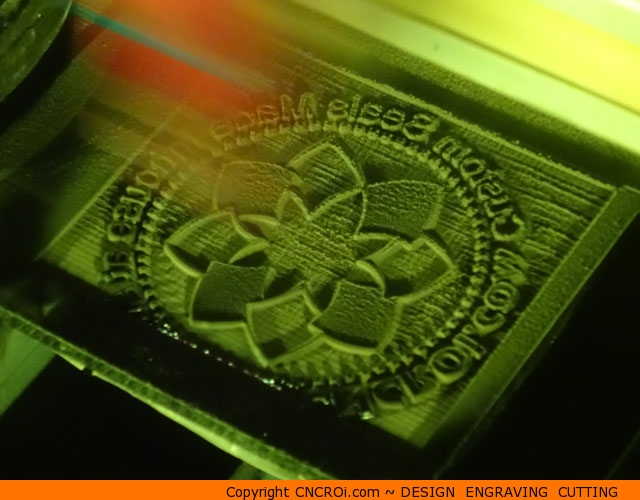

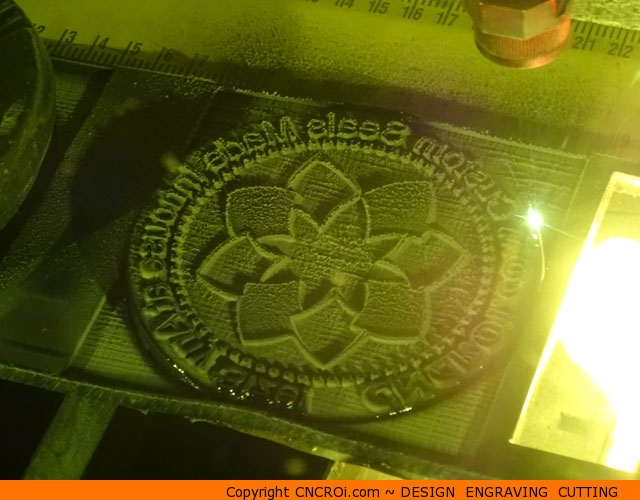

The reason for the weights on both sides of this acrylic is to hold it down, this is a piece of scrap 1/4 inch or 6 mm thick acrylic and the mold process introduces lots of heat during the custom mold engraving process.

This makes the acrylic at both ends bend upwards and the weights are there to prevent this from happening.

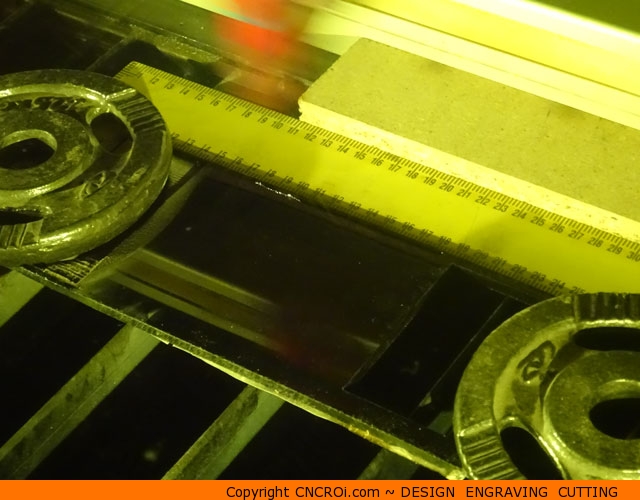

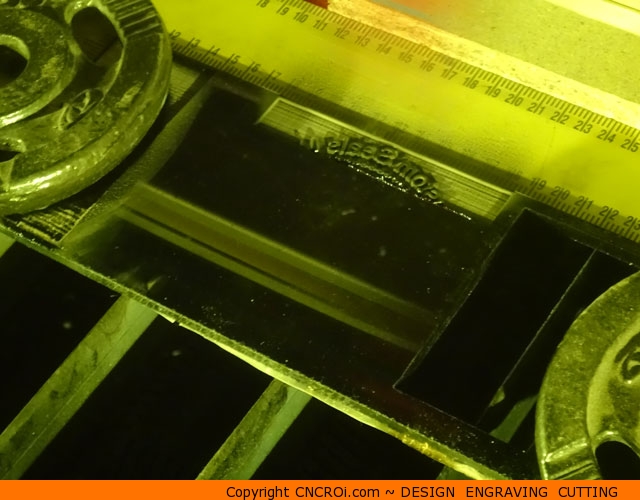

The white you see developing on the mold is just the dust that builds-up during the mold engraving process, it causes no issues and for this application, a little roughness is actually a good thing.

We can polish the top down slightly but as this is to be used for sand casting and cement castings, the finish on the surface doesn’t matter.

For this specific application, we are more about depth quality, consistency and strength of the finished design than the finish on the surface. That being said, it’s still pretty smooth after being cleaned-up at the CNCROi.com shop.

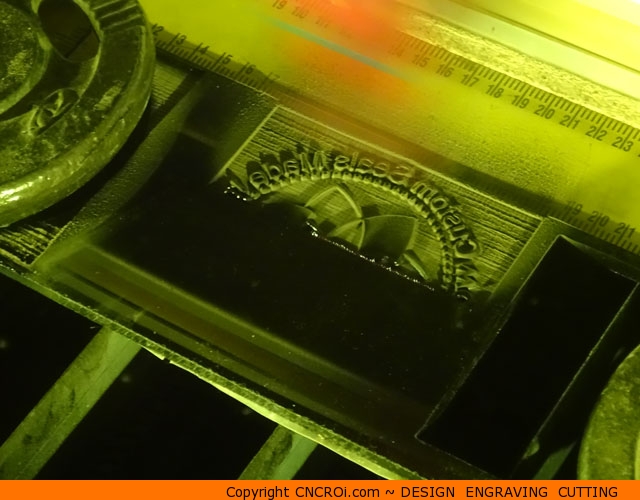

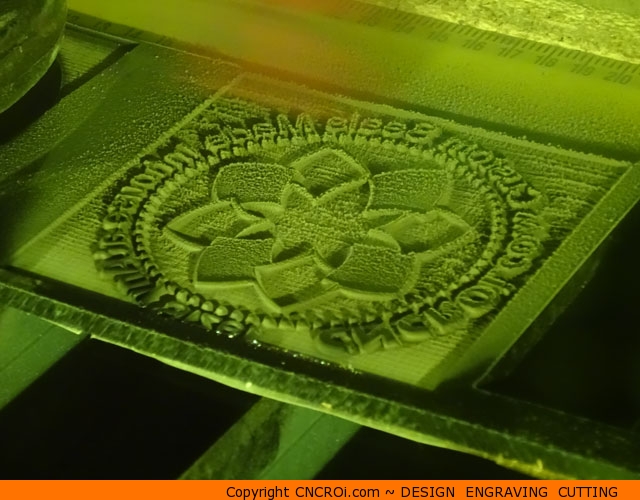

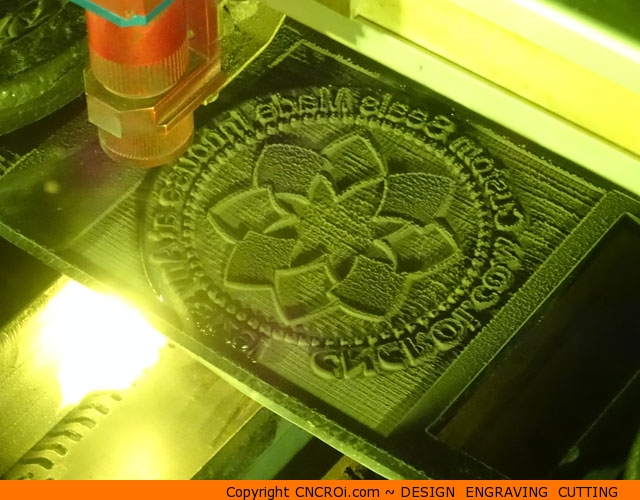

Essentially, what you are seeing in the video and photos in this blog posts is highly controlled and precisely focused melting of plastic, the shoulder is also flat for this mold, meaning the edge is straight down, or more specifically, as straight down as possible when melting into acrylic.

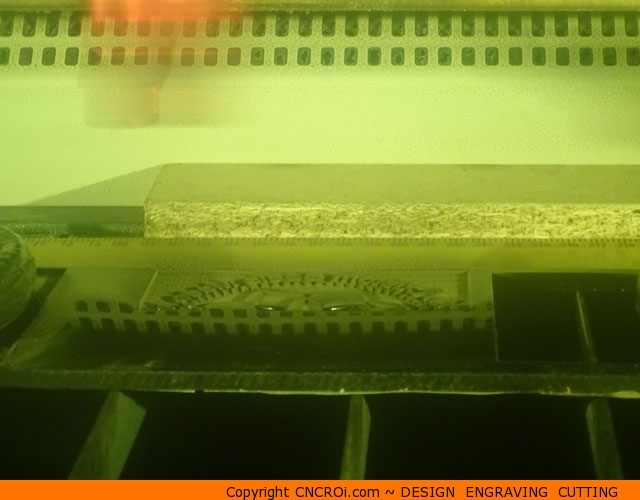

There is plenty of head room between the material and the head of our Austrian CNC laser, as a result, even molds that are a few inches deep can be custom engraved by us here in the CNCROi.com shop.

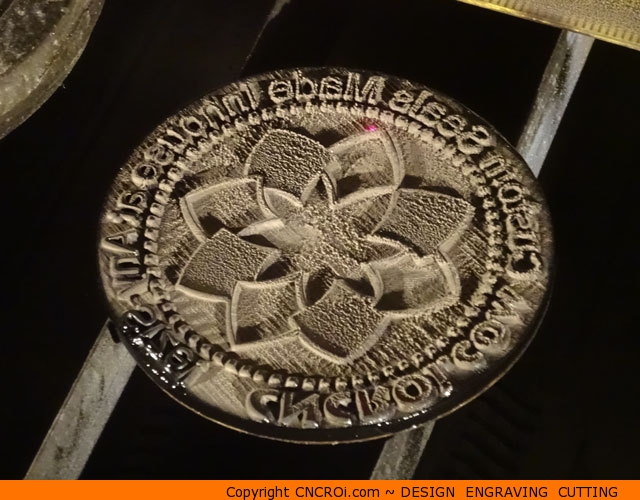

You can see the vertical lines going across the acrylic mold surface after it’s been engraved, this is NOT because of laser power fluctuations but material inconsistencies, in other words, we are finding minute density changes in the quarter-inch or 6 mm acrylic which follow through from the upper surface down to the bottom.

They are exaggerated due to the fine powder left over and also represent differential cooling as well, we have strongly compressed air shooting down so the airflow of that also helps to create valleys and peaks of cooling onto the base acrylic. The same thing is present on rubber and a host of other materials.

Keep in mind that we are also using an extremely hot beam of energy to do this mold engraving, as such, there is very minute temperature differences between what was engraved and what wasn’t during the cooling process, causing stress in the acrylic itself, again, leading to the fine lines you see.

Finally another reason you see those lines is there is very minor overlap between the beam source and what’s being vaporized, so all these factors cause this to happen.

Again, they seem far more extreme than they really are in this very close-up photography with dust filling the valleys far more than the peaks.

We’ve also made molds using our industrial American router, a Shopbot, but this extremely fine lineage in this material wouldn’t be possible in the manner shown, that’s used more for aluminium and woods rather than plastics.

This could have also been made in Corian, yep, a solid Corian mold is also possible!

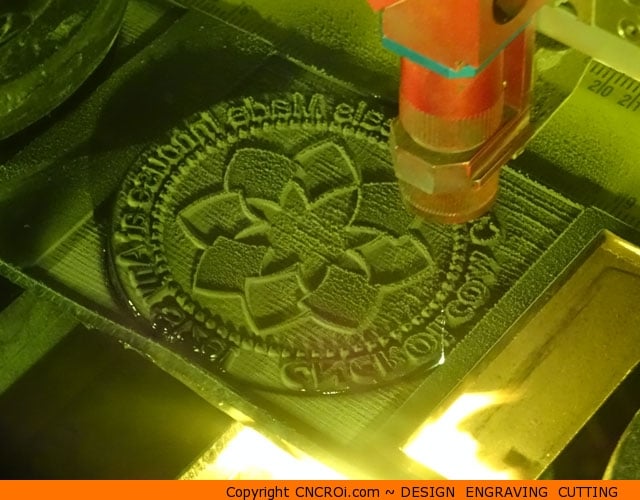

Now that our custom acrylic mold is complete, it’s time to cut it out as this isn’t a square mold but a round one! This is, by the way, the exact same design as I made a while back on delrin. Here’s the video!

This shows you the endless flexibility we can offer you, regardless of the material, we can make you a custom seal or mold though you have to account the costs and benefits of each material.

For instance, we could have made this out of wood but it would be far stronger out of oak rather than basswood.

There are generally prototyping of design optimization required if you are on the bleeding edge tolerance wise but we can do that for you.

The reason why we don’t CNC laser cut out the disk first and then do the engraving is due to the fact that it would move around and the resultant custom mold wouldn’t be accurate.

Making custom molds is an exercise in precision, as it will be used repeatedly for making whatever our clients needs this for application wise. So, any faults in the mold won’t just affect one part but can lead to a rejection of thousands of units!

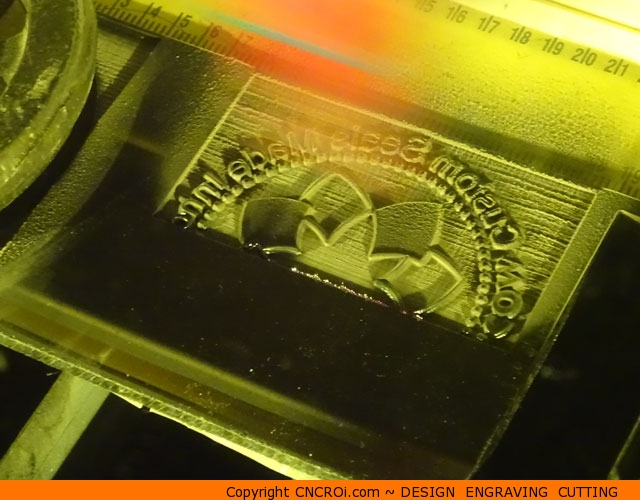

The custom mold is now finished, the shiny part on the bottom is just melted plastic heated from the laser due to the cutting round. As cutting is a different process than engraving, there is a lot more heat involved which vaporizes more material so you don’t end-up with the same deposition of “plastic ash” as was created during the engraving passes.

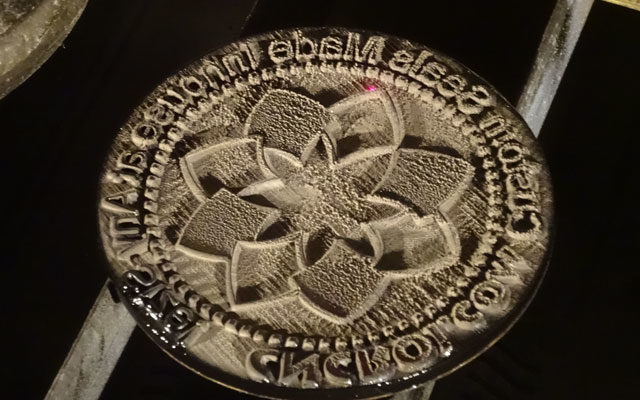

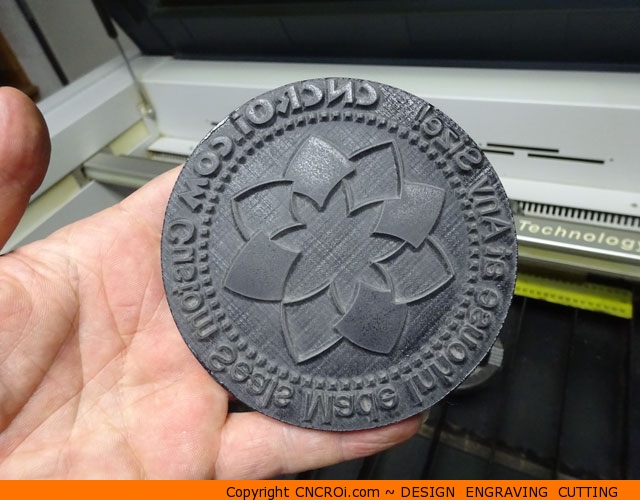

After cleaning-up the mold, you can see the picture below of what the finished custom acrylic mold looks like.

A straight-on view, you can see the incredible quality of the custom acrylic mold, this is also a very SOLID mold, it’s very strong and made incredibly precisely thanks to the accuracy of our Austrian CNC laser.

Need a custom mold out of just about any material? Contact CNCROi.com right now!