Custom Branding Floorboards: Raw vs Finished

Custom branding floorboards can be done either in raw or finished form, though production wise, it’s more efficient depending on the finish to work from raw formed boards.

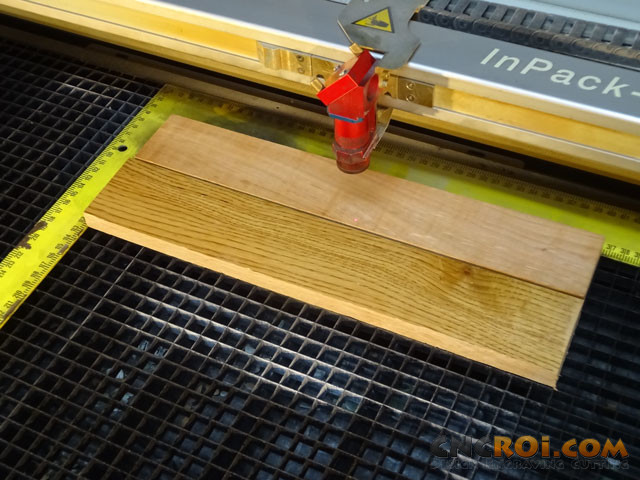

Custom branding floorboards today will be done on an unfinished Cherry and finished and coated oak board.

I didn’t apply masking on either board to show you the more extreme results that can be achieved with smoke and resin that lifts-up from the engraved floorboard.

Although both of these scrap wood floorboards from the CNCROi.com bin which we’ll brand shortly are from completely different sources, they both interlock perfectly using tongue and groove.

The Cherry floorboard is up top with the Oak below it, now it’s time to get some branding floorboards processed with our Austrian CNC laser!

Regarding the resolution we can achieve with our wide-format CNC laser, it can be up to a thousand DPI so your design options are really unlimited and we can have the same with our cutting process as well.

Here’s an example for you to see what’s possible design wise on wood, in that case, it was whitewood.

Custom branding floorboards is a pretty straight forward process, CNCROi.com loads the design files into our software and the laser goes ahead and vaporizes the material where it was assigned to do so.

When it comes to custom branding floorboards, there are a large variety of depth and darkening options.

For instance, if you wanted a darker hot iron branded look to the CNCROi.com logo being engraved om these wooden floorboards, it’s possible to achieve that to a certain extent but with the precision of our industrial CNC laser.

CNCROi.com can achieve a number of unique applications for custom branding floorboards, for instance, if you had a very rustic building like a log home, we can engrave whatever you want, images and text, in an endless variety of combinations onto live edge floorboards, walls and ceilings.

Alternatively, if you had your wood floorboards made-up of well-worn pallet wood, which looks and is readily available, we can custom brand those as well.

Custom branding floorboards can also be done onto uneven boards as well, something that’s exceedingly difficult if you wanted us to do this work with our CNC router but relatively easy using our CNC laser.

You can already see some of the smoke stains on the surface of the Cherry floorboard, each wood produces different amounts of smoke at varying levels of stickiness.

Generally though, whatever vaporized resin and resultant smoke that raw wood gives, it’s far “worse” when it comes to doing the same work after it’s finished as those compounds contain additional glues, paints and stains.

CNCROi.com has done lots of wood engraving and cutting, our custom branding solutions are unparalleled and we’ve found from experience that masking is rarely a perfect solution.

Masking projects before production helps lessen the amount of work required afterwards, but doesn’t entirely remove it.

The reason is quite simple, our compressed air shooting down on the laser head tends to move and lift masking, especially when there are lots of fine details being engraved into the project.

I don’t think this would have been an issue with custom branding floorboards but if we had a run of these to do onto raw wood, I’d probably prefer just sanding the floorboard after work as this generally needs to be done even if masking was applied.

Branding floorboards can also be done using photographs, we’ve found that black and white images produce the best results due to contrast than straight color.

The higher the contrasting details in a photograph, the better the results will look on solid wood, and this includes floorboards and wood plaques.

CNCROi.com can also paint fill wood and other materials, this works best with dense material as it produces a cleaner result.

Finishing after the paint filling and sanding process produces the most consistent and even results.

Again, working off raw wood, the results are easier to achieve and clean-up than something that has already been finished, finished wood can’t be sanded as it removes the finish, cleaning chemicals can also interact with the surface finish of the floorboard.

These are all issues that we don’t have to content with if we are working of raw planks to start.

The white lines and sparks you see during custom branding floorboards process is just the surface material being instantly vaporized, afterwards, a smoke is produced and that’s extracted out of our wide-format industrial CNC laser.

If you are wondering about the depth we can achieve CNC laser engraving into wood, branding floorboards makes no difference, check out this video.

This is an extreme example of what can be achieved, generally the deeper the results, the less esthetic the result as you can see.

That is an extreme example, generally branding floorboards is not done very deep at all, less than 1 mm or 1/16th inch in-depth as our customers like to finish the boards so you don’t feel the engraving at all.

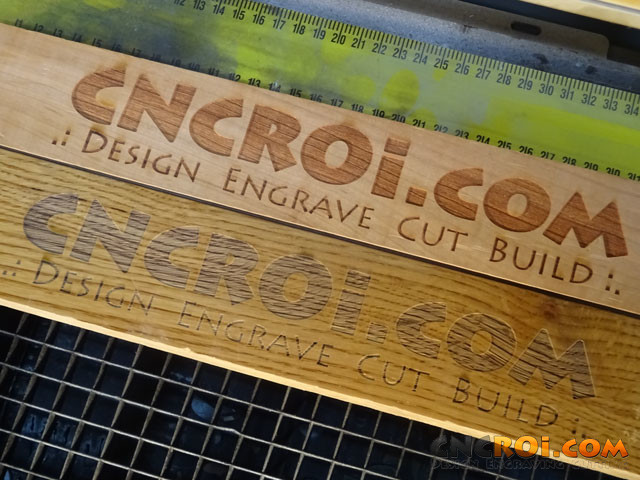

Now that the branding floorboards are finished, you can see the results from the same design across two different wood and finish types.

Notice that the smoke stains on the finished oak board are darker, we’ve found that generally, this is what happens as there are more chemical compounds in the finish than any raw wood we’ve worked with.

On this Cherry floorboard, you can see the smoke stains around the letters, again, not a problem at all and it’s a given.

Sanding this off is a very easy and straight forward process, if the amount of smoke was this extensive on a finished floorboard, it would take a lot of elbow grease to clean it up.

Here is the cleaned-up finished floorboard, the branding in nice and sharp, especially when you have light dancing around on the surface.

After a quick cleanup at CNCROi.com, the custom branding floorboard samples I made today looks clean and sharp, it takes more legwork to clean the finished oak floorboard than just quickly sanding the cherry floorboard.

If you are looking for a company that can offer a host of custom branding floorboard and other wood solutions, contact CNCROi.com right now!