Custom Project Development: Virtual Model to Physical Prototype

Having an internal custom design capabilities, sketch through finished product, allows CNCROi.com an incredible capability for our customers.

As I explained in the above video, most of what we do here in the shop is the first time it was made and short of a few kinks during the prototyping process, everything works perfectly as designed.

The reason for this is two-fold. First, we have the equipment and software to create virtual models that can be tested before any saw dust is created. Basically, we are experts at editing pixels to the point that when we transform those ideas into real products, they “just work”.

Secondly, I’ve been designing complex 3D models for well over a decade, both wood, 3D printing etc… so designing something that “just works” is intuitive at this point. I’ve published books showing this to other people as well, I’ve taught myself how to design and been practicing every since!

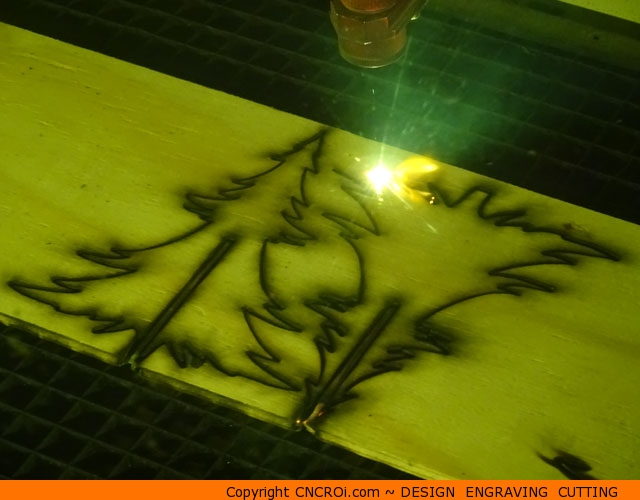

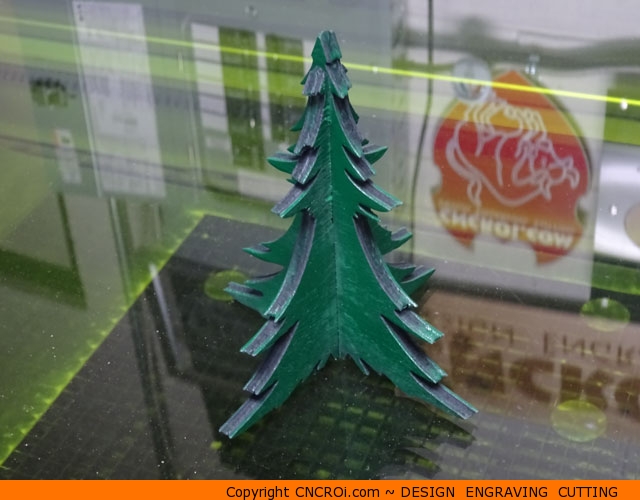

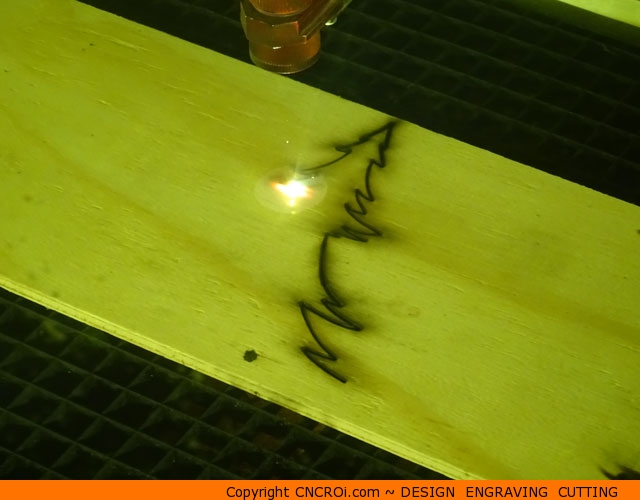

In this case, we are laser cutting a simple stand-up Christmas Tree which is just the same shape with a different hole placement. Dead easy, just to showcase how easy it is to make 3D objects out of 2D ones.

The nice thing about having the in-house design capabilities is that we can handle custom projects across the spectrum from initial concept all the way through completed model for our custom work. Whether you are at the prototype phase or ready for full-on production, CNCROi.com can help!

This Christmas Tree was cut out of quarter inch or 6 mm plywood, it was the perfect shape and very easily painted for this application to showcase how 2D becomes 3D.

The 3D animation you saw in the video above of my custom designed sanding downdraft table was built using our laser and here’s how that came together.

This small Christmas tree could just as easily scaled-up or down depending on the application, scaling-up allows additional opportunities for custom design though, as there is more surface area to engrave, cut or anneal, if this was to be made out of metal or stainless steel.

In the image below, you can see the simple design method of holding the two identical Christmas tree shapes together, this could just as easily be extended for more sides as well.