Custom Stencils 101

Making custom stencils is a lot of fun for our customers, CNCROi.com has made them in a variety of materials, polycarbonate to cardboard so today we’ll just review a few aspects of custom stencils 101.

Please be sure to read an earlier somewhat related post here: http://cncroi.com/get-perfect-stencils-8-custom-production-tips/ where I went more in-depth regarding specific issues we (you) need to be aware of when it comes to custom stencil production.

Custom Stencils 101: One or Multi Use?

Before CNCROi.com goes about making a custom stencil for you, we need to know how many times you plan on using it.

The reason is quite simple, if you just plan on using a stencil ONCE, then it’s far more cost-effective to make it out of cardboard than it is to use material that costs a lot more money like mylar or solid wood.

If you have a logo and want to spray it onto concrete multiple times, then a stronger material is best than something like paper or cardboard just so it lasts a bit longer.

Custom Stencils 101: Storage

For small stencils, like the business card sized, storage isn’t much of an issue, they are easily stored in a small box but for larger ones that are a few feet or meters long, this is something else you need to consider.

Again, this is where material selection is important, it’s far easier to “roll up” polycarbonate than cardboard and it won’t crease or bend awkwardly for storage.

Custom Stencils 101: Esthetics

Some CNCROi.com are all about how things “look” while others couldn’t care less as long as it does the job, to each their own, but do let us know ahead of time if this is a consideration.

For instance, polycarbonate has an ugly yellowing around the edges when the mask is left on, if that doesn’t bother you, we’ll leave it on your stencil and after using it a few times, you can peel it off and basically save yourself a lot of cleaning if it’s for a multi-day or yearly use.

Custom Stencils 101: Images and Text

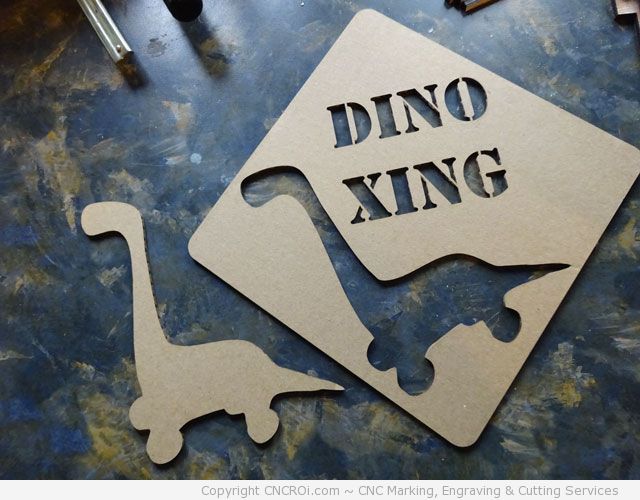

Do keep in mind that as stencils are by definition, a solid material full of holes that you use to “imprint” the images and text found on the stencil do become more fragile the more holes you put into it.

Cardboard stencil.

As such, you want to keep some healthy margins and space around the stencil and between different elements, it really makes a big difference when it comes to having a stencil that will be passed onto future generations or one that only lasts until the end of the day.

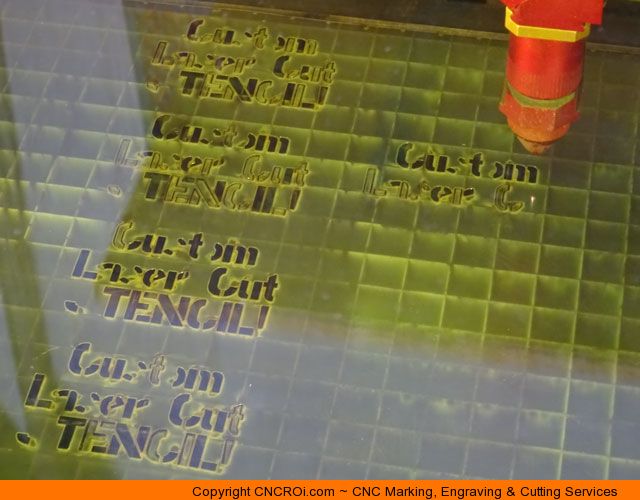

Custom Stencils 101: Polycarbonate

Without exception, by far the most popular material that CNCROi.com uses to make its stencils for customers far and wide is polycarbonate, sure, we’ve made some out of paper, cardboard, wood, PETG, lamacoids… you name it, but polycarbonate is really hard to beat for most applications.

Custom Stencils 101: Polycarbonate TRANSPARENT

Yeah, that’s a HUGE factor, the fact that polycarbonate is transparent allows for EASY placement over just about any surface, it’s so transparent that we use it to make optically accurate and precise medical “instruments” for some of our clients.

Of course, we also use this fact to make some really crazy durable products for weddings and funerals too, CNCROi.com uses whatever material for your application that your budget can support BECAUSE we work from raw sheets and materials to begin with.

Custom Stencils 101: Polycarbonate STRONG

How strong is polycarbonate? Well, you may already know this material by its other name, bullet proof glass!

The thickness CNCROi.com uses for polycarbonate stencils isn’t thick enough to STOP a bullet but even at 0.02″, it’s incredibly difficult to rip apart, it’s really a crazy strong material and unlike PETG which we have made stencils for upon special request, it isn’t brittle after the heat of the laser has hit it.

Custom Stencils 101: Lots of thickness options

Rarely has CNCROi.com had to cut though polycarbonate that’s thicker than 0.06″ thick, at that thickness, it’s pretty much indestructible as it is, but if your application calls for something thicker for lets say a safety glass for an industrial machine, we can of course make it for you too.

When it comes to stencils, big and small, complex or simple, durable or throw-away after use, contact CNCROi.com and we’ll make it just for you!