Etching 316SS Plate: Special Protective Industrial Coating

CNCROi.com does a lot of etching 316SS plate, most of the applications are super heavy-duty where 304 stainless steel isn’t enough nor is annealing, the customer needs etching into the plate in addition to a protective industrial coat.

When CNCROi.com first started, mostly all our plates were made of corrosion resistant custom 304 stainless steel but as our client demands increased, about a month ago, I decided that by default, all our custom plate will be made out of 316 stainless steel.

Is this wicked overkill? Yes and no.

If a 304 stainless steel plate is going into a corrosive environment like marine or even an enclosed pool with chlorine, it will start to corrode, that’s why 316 is better in on itself, it will resist this far better than 304SS, so in that case, 316SS is better than 304SS.

Think of mines, hot sandy deserts and a host of environments that are tough on life, much less plates, that’s what CNCROi.com makes for some of our customers but annealing just wasn’t enough, so we moved onto etching 316SS.

Watch this video to show you the difference.

Recently, we had customers where just etching 316SS still wasn’t enough, they wanted a protective industrial barrier between the plate surface and the environment, so with a lot of testing, we’ve figured-out how to do it to the great benefit of ALL OUR CUSTOMERS.

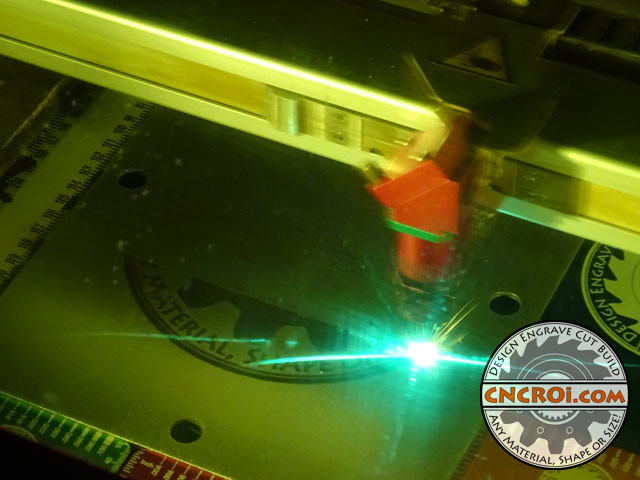

You see, fiber etching stainless steel is a slow and heavy power process for our laser, it lasts longer than annealing because CNCROi.com is actually going into the plate rather than just on the surface with annealing.

An extreme example of this is this video.

Now, I’ve been at this game for a very long time, testing and playing around with different methods and coatings to get better and more efficient, here’s a video showcasing the difference between industrial fiber etching, annealing as compared to just regular anodized aluminium using CNCROi.com‘s industrial sand blaster.

Let’s say you are a mining outfit in the outback where the heat is intense, the sand and wind is tough on just about anything, it’s an abrasive agent that’s nowhere near as powerful as my sand blaster test above but it’s still there, year after year after year.

The best solution in that case is to etch 316SS so that the marking is in the plate, and then coat it with an incredibly durable coating.

I actually have grounded down these plates from an etching test (it was for a customer so I can’t show it here but I’ll make a video of one later).

It literally took me ONE HOUR to remove the etching, using an angle grinder, sand blaster and sand belt!

Regardless of the size, whether it’s a stainless steel business card or huge metal plate, CNCROi.com can apply this technology to your application.

That’s crazy durability, and you know why it took so long? Because the etching is into the plate which means the entire surface of the plate must be ground down in order to remove the etching, not just the area with the etching.

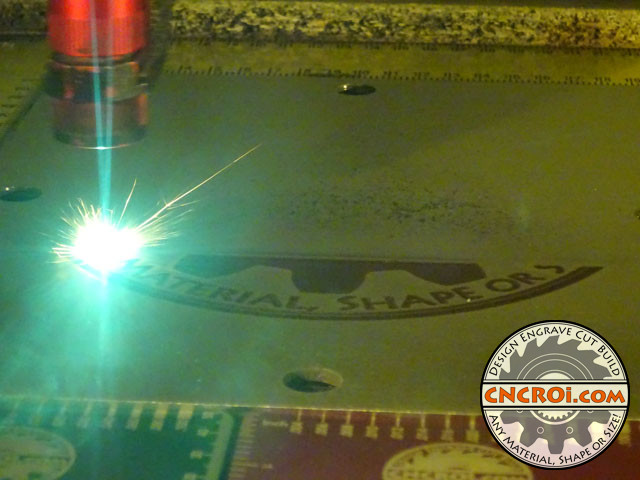

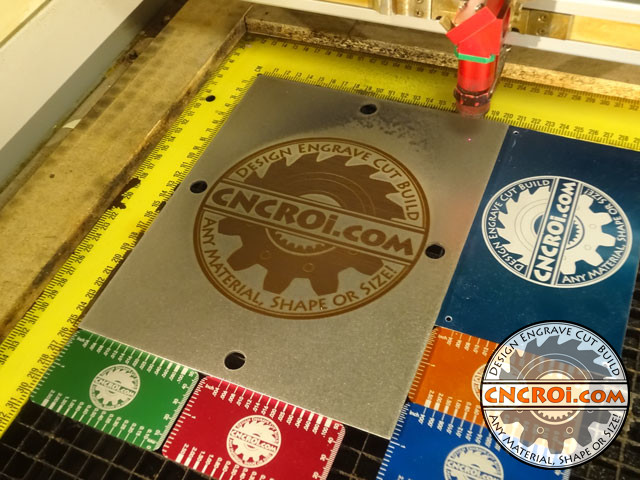

The issues with etching 316SS (and 304 or any other grade for that matter) is that visually, annealing looks better than etching, the contrast is really that much better.

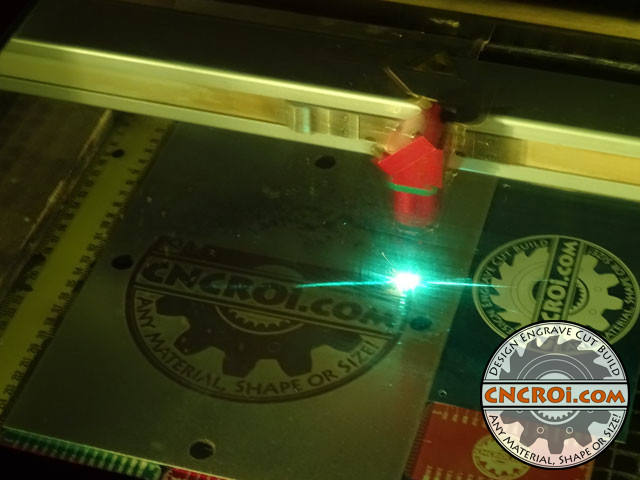

Well, using our industrial coating on the plate as you see in this blog post, we’ve achieved something really cool that all our CNCROi.com clients will appreciate, the “look” of annealing with the super extreme durability of etching.

You really get the best of both worlds, esthetics with performance!

CNCROi.com is etching 316SS in all these photos and videos, the surface is rough but like wood, once the protective coating is added across multiple layers, it takes about 48 hours to cure properly, the grain in the steel really pops and the contrast is exponentially increased as well.

The benefit of this for all our customers is that CNCROi.com can offer this protective coating on all our custom metal projects, but do keep in mind, if you plan on welding these plates to your equipment (not rivet) then the coating will be damaged (not the metal) which is why we need to sort out the details ahead of time.

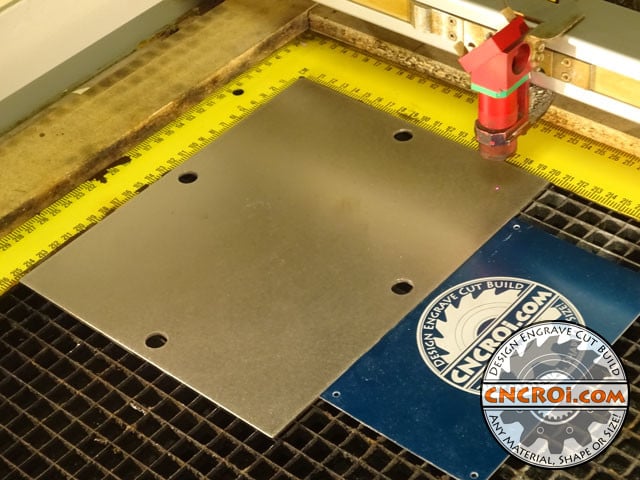

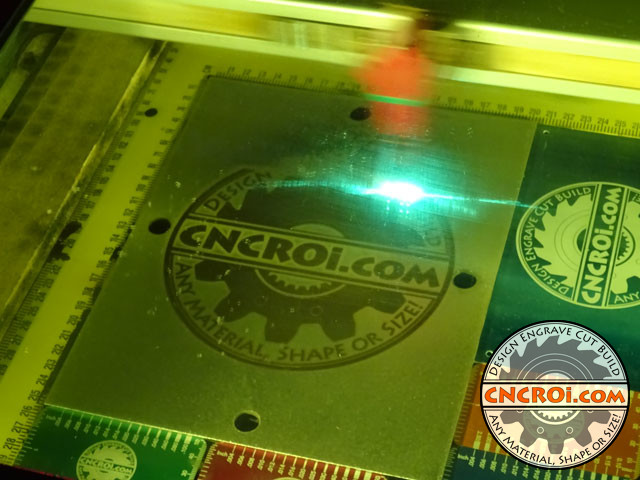

Etching 316SS looks brownish, and you can see the metal powder in the top of the logo still hanging out on the plate, that’s what was removed during the fiber laser etching process, there is a lot more of course, all over the plate.

What I really like on metal (and wood) is that when a protective coating is added, the material at hand looks “wet”, whether it’s stone, wood or steel, this really gives is a really like feel and superior esthetics.

If you are wondering how those anodized aluminium cards we use for filming focus were made, here’s another video for your viewing pleasure.

And yes, we can also apply this protective coating on anodized aluminium plates as well, to give them extra durability where a lightweight material is required rather than comparitively “heavy” steel.

The picture below is before the initial cleaning process, you can see the metal powder that develops during the etching 316SS process all over the design, a few mm around which makes it pop.

And here is what the etched 316SS plate looks like after it was washed, looks fantastic, but again, this is when it’s still “wet”, when it dries, it goes back to the brownish look.

After several coatings of our industrial coating though, the etched 316SS plate looks “wet” permanently, greatly increasing the contrast while providing an industrial level protection of the entire plate from the environment.

If you notice, the gain of the stainless steel is also enhanced, basically, you turn a rock into a diamond and when you run your fingers over the surface, you also won’t be cutting it, as the coating is OVER the sharp metal etching that our fiber laser produces.

If you need custom stainless steel plate that’s durable and esthetically beautiful, put CNCROi.com‘s experience in your corner, whatever the size, shape, gauge (thickness) or design you want, we’ll make it custom to your specs!

Contact us right now… and yes, that includes custom welding tags that you can rivet or weld to your product…

In addition to amazing stainless steel party favors.