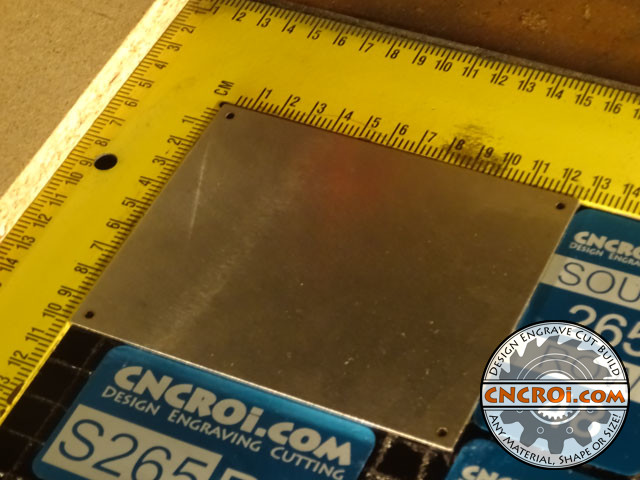

Fiber Annealing VS Etching Stainless Steel: 11Ga (1/8″ or 3 mm) 316 #4 Finish Plate

Fiber annealing vs etching stainless steel is something that CNCROi.com does a lot of in the shop for a wide variety of clients so today we’ll grab a fresh 11Ga (1/8″ or 3 mm) 316 #4 Finish Plate and contrast the two options we have available for you.

Thanks to our industrial wide-format Austrian laser, we can handle many different aspects of a metal project because we have both a CO2 and fiber laser source.

The work you’ll be seeing done here on the stainless steel is all PERMANENT fiber laser work.

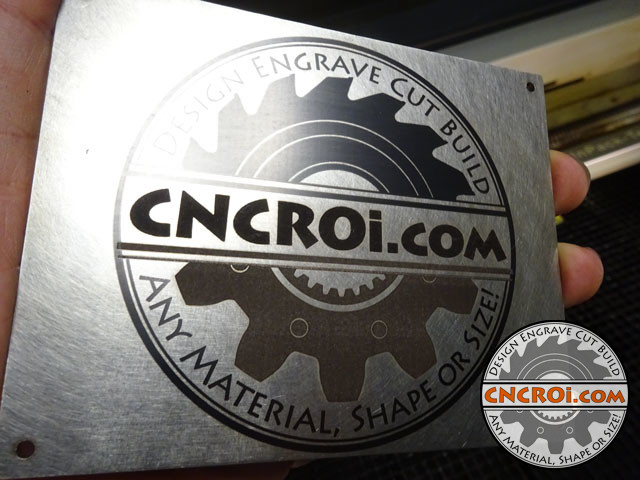

What we’ll do for this demonstration is etch one part of our logo onto this 316SS and anneal the rest on this #4 finished 1/8th inch or 3 mm thick plate.

The reason we need to go “so thick” is due to material warping from the incredible heat our CNC laser produces during both processes, thinner gauges would fold-up and cause the annealing to become etching and vice versa.

If you are wondering about the durability of these contrasting options, CNCROi.com did a video of just that, regardless, both of these processes are permanent, you need to use a sand belt to remove them (removing the metal in the process).

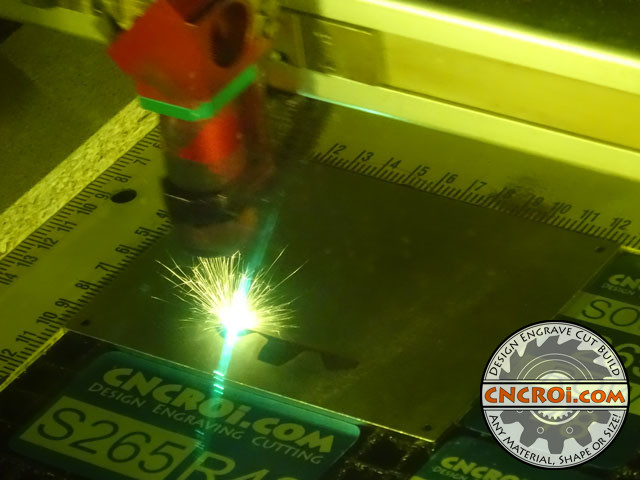

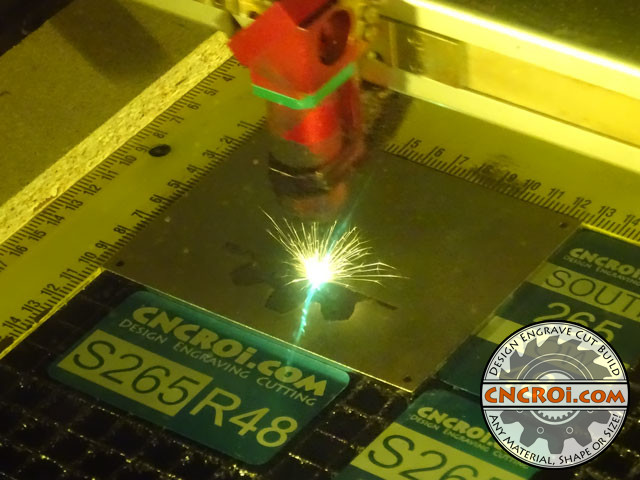

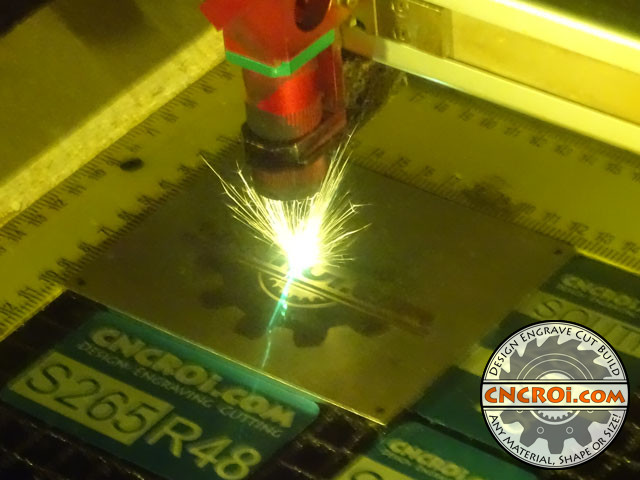

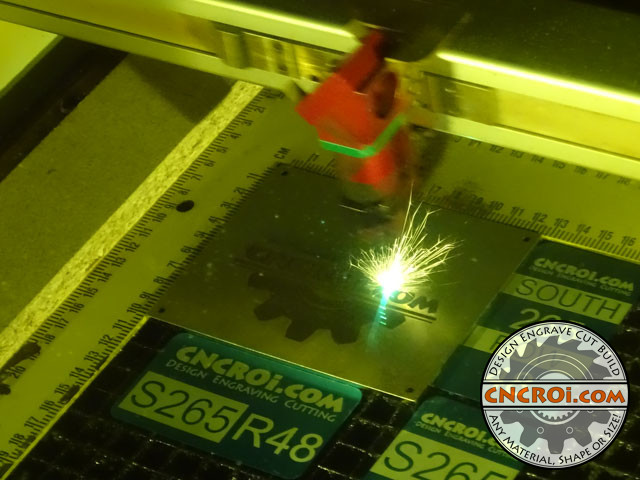

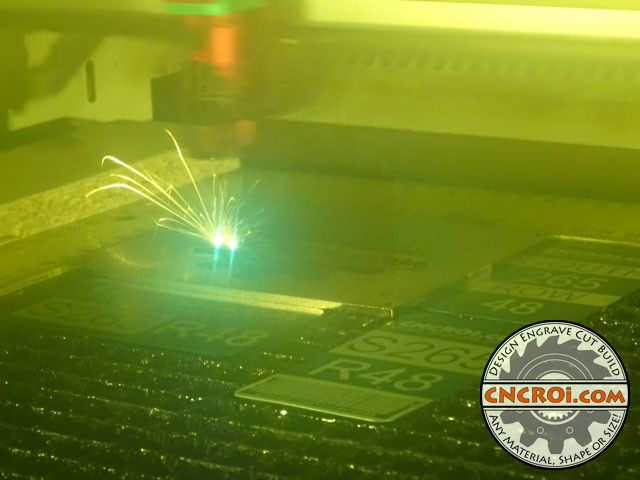

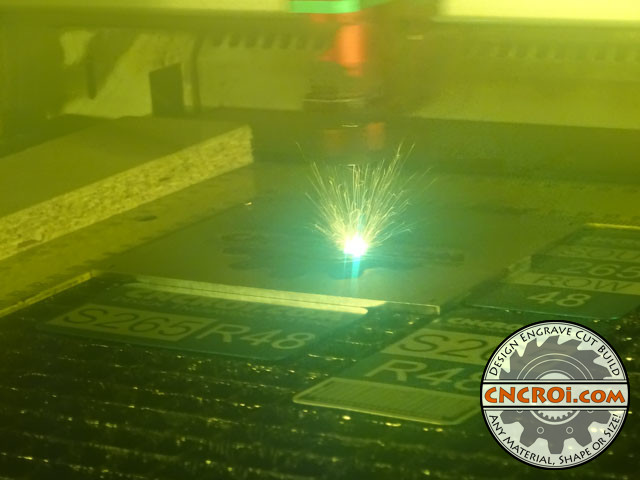

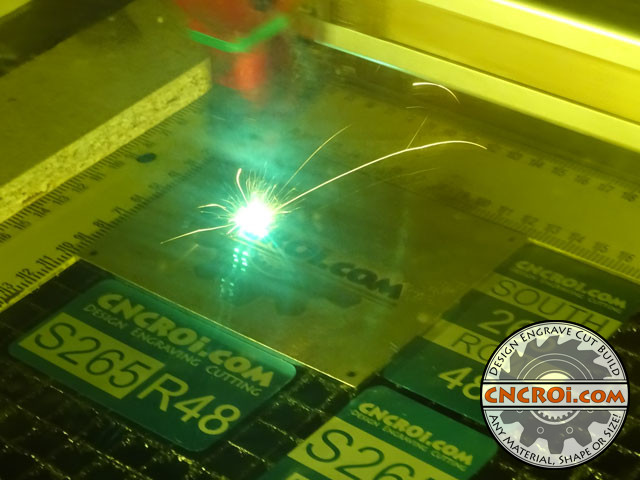

The sparks you see in these videos and photos are the result of the etching process, it’s quite a contrast to the annealing one where all you see is a bright light without any real reference of where it comes from.

I’ve done so much etching and annealing onto stainless steel that I can visually calibrate my Austrian CNC laser for optimal results using either permanent branding process.

Notice that nothing is added or removed during either the stainless steel annealing or etching, it’s all straight laser work producing these results on the 316 steel plate.

If you are wondering, we also have compressed air shooting down from the laser head onto the work and a vacuum system sucking the heat out but it makes no difference, these plates are HOT after production!

If you are wondering, we can do these processes on a huge variety of plate thicknesses, here are some coasters that are far thinner that were annealed and engraved (onto anodized aluminium) which is a popular second choice.

The advantage of anodized aluminium is weight and costs (production and raw material) but for ultimate longevity and strength as you saw during my test, nothing beats stainless steel.

I’m very sure that if I tried to do in this blog post using the thinner gauge in the video above, the results would be far less spectacular, it would bend upwards and sideways and pop even.

So the results we achieve given a particular plate thickness are highly dependent on the design and process we are applying onto the stainless steel.

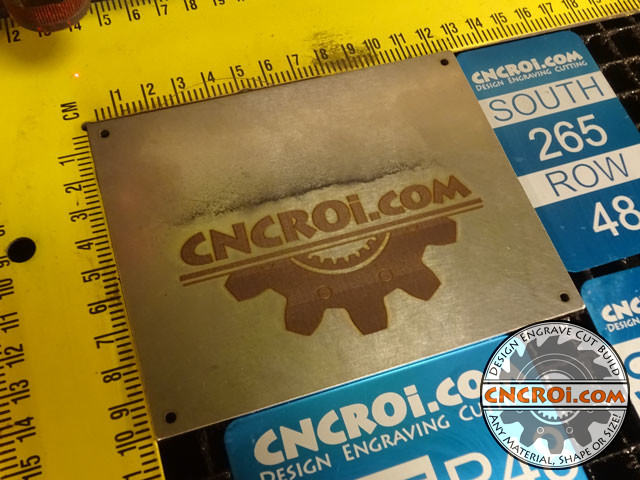

Etching, unlike annealing, produces far larger and more steel powder as you can see from the image below, this is easily wiped-off using cloths.

The color also improves once the layer of dust and debris is removed, although photography of this is very difficult, as is filming, due to all the sparks and bright lights happening inside our industrial laser.

Next-up was doing CNCROi.com using a few additional passes, just to show you if the higher cost is really worth it.

It does provide a little more contrast but each time you pass over an item, you are doubling production costs so most of our clients are more than happy with just one strong pass onto the stainless steel.

Other applications we make a lot of stainless steel products for are our very own custom welding tags.

We generally anneal the stainless steel as these tags are thin enough to take quite a bit of heat though they still bend slightly, for the demonstration today, I wanted something that DIDN’T MOVE AT ALL so you have the perfect masterpiece to compare results from.

As you can see, lots of sparks and smoke being made from the heating of the stainless steel plate in the CNCROi.com laser.

Regardless of how much pressure we have going down the head of the laser, the sparks don’t seem to be affected by what is being pushed onto them.

You can see the results of the etching of CNCROi.com are quite a bit darker, again, once this is cleaned-up, the contrast will be a lot less though the difference will still be noticeable.

If you want to get an idea of how deep we can go (technically, straight through the plate with enough passes), check out this video showing you the results, and this deep etched stainless steel tag was also sand blasted (we got one in the shop too) for the ultimate “clean”.

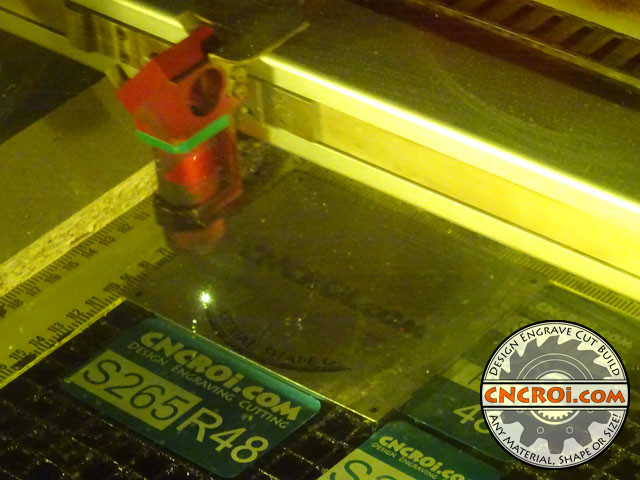

Now we are going to move onto annealing!

Annealing 316 pr 304 stainless steel produces the same results, you can’t visually see any differences between these two common plate grades, what does affect it, far higher than anything else, is the focus of the machine onto the surface of the plate.

Any type of warping or bending will almost instantly move the annealing into etching zone.

Annealing is a lot cleaner than etching, it’s an oxidation process rather than engraving one but there is still a little clean-up required.

The DPI we can achieve with annealing is astounding as well, far higher than etching because, again, we aren’t removing material.

The drill bits above have been used tons of times and the annealing looks just as good as the day it was done by our fiber laser source, they haven’t aged a day even with all the wood abrasion and heat.

Another type of project we use a lot of annealing for are industrial machine tags and plate, including memorials and even pet tags.

The longevity of these items is second to none, even if it’s 304, it will last a very long time even in rough outdoor conditions with huge swings in temperature and humidity.

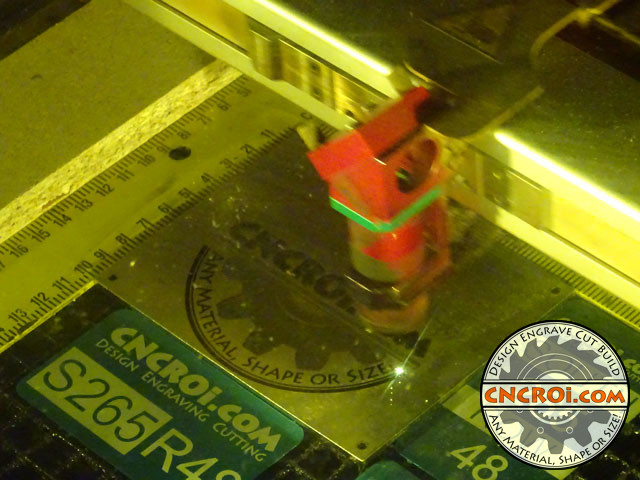

Annealing, unlike etching, is performed in this video at the same speed, as a result, you can see the effects of focus using the same power and speed settings when it comes to permanently branding the stainless steel.

Annealing is a darker black than the etching, so it really comes down to personal preference as to which process you want, annealing is sharper, but only on the very top surface of the metal plate while etching is scratching the surface.

CNCROi.com has extensive experience with both methods, which is why I generally ask what the application for these plates will be and the general environment they will be in.

Compare the light color and sparks in these annealing photos and the etching ones at the top of this blog post, quite a difference focus makes!

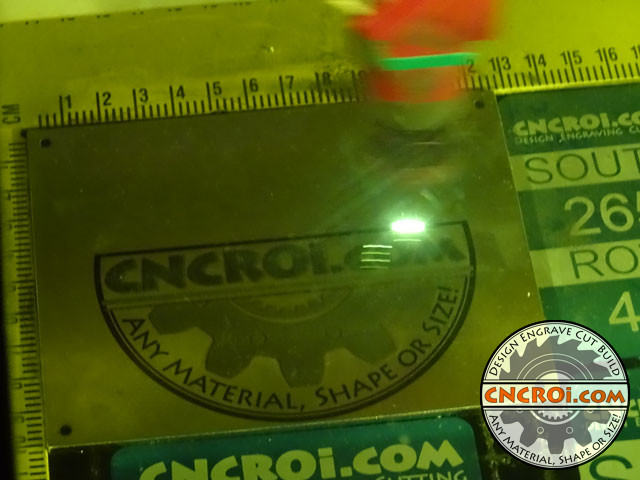

Now that the annealing of CNCROi.com‘s logo is complete, you can see the results without any cleaning and notice the big difference they had on this 316SS plate.

If you are curious, we can also anneal and etch brass and a host of other metals but the contrast isn’t as great as they are with stainless steel.

I ran my finger across the annealed part, right under the DESIGN in the top left of the logo, you can see the soot that was removed, annealing always looks great out of the machine, the results are just lessened a bit after clean-up though the results are also sharper.

This is what I really like about #4 finish on stainless steel, it’s nice and shiny but not too reflective and the grain looks great at just about all angles, it really transforms a good-looking plate into an amazing one.

It’s a similar effect to wood grain on wood, that little extra really makes a big difference, and CNCROi.com really focuses on the details such as these for our customers.

Metal cleans-up very nice, contrast the above with the below, you can also see the difference in texture and sharpness onto this 316 stainless steel plate.

Same tube, same laser, same power, same frequency and same speed produces dramatically different results with just a few mm difference in height.

Throughout the video, I kept moving the plate around to move the shine around, it’s really hard to convey that the above photo is the same plate as the one below, but what you can notice now, finally, is that the CNCROi.com really is darker than the etching below but not shiny like the annealing above it.

But from another angle of this 316 stainless steel plate, you can see the difference is a lot less, lighting plays a big factor in what things look like after we’ve annealed or etched it.

Regardless, the results are permanent!

And here’s the money shot, annealing on the left, triple etching in the middle and one pass etching on the right.

The CNCROi.com logo never looked so good!

If you need some custom metal plates, blank or full of etching and annealing, you know who to contact, CNCROi.com!