How to get PERFECT Stencils: 8 Custom Production Tips

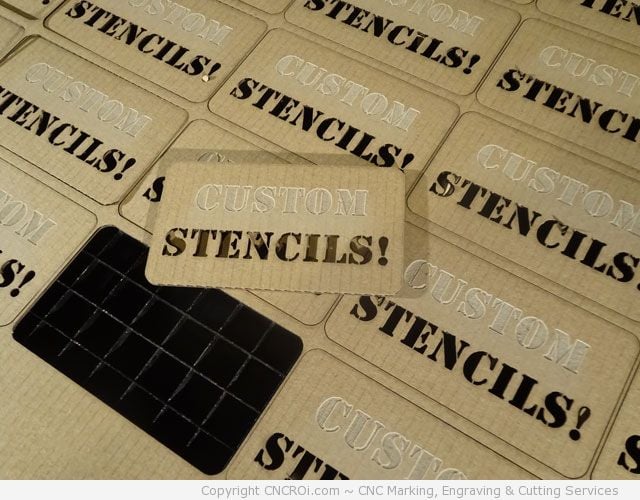

CNCROi.com has made LOTS of PERFECT stencils, here are 8 custom production tips based on our experience making custom stencils for a wide variety of application. Anybody can make a stencil using a knife, not everybody can make a PERFECT STENCIL using a CNC machine.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 1: Optimal Material for Application

The first tip towards the custom creation of perfect stencils is to use the right medium for the stenciling job. There is a huge variety of materials that CNCROi.com can make your stencil from, we’ve made custom stencils with MDF and plywood down to PETG and polycarbonate, even some out of fabric like leather! Each material has a + and – and it’s knowing which works best to fit your budget and timeline and material qualities that will dictate what direction to take.

For instance, if you want us to make you a custom stencil that you will be applying onto concrete for identification purposes (we can make a mold too), I’d suggest having us make it out of plywood which is sealed rather than polycarbonate or mylar. The biggest reason being, you want something that’s easy to grab, easy to push into material (good luck doing that with thin plastic) and can be raised right off.

This is why when it comes to producing a perfect stencil for your application, you need to consider how it will be used both “in the field” and where you are putting it after the stenciling is finished. This will affect durability and the ultimate resolution you will wish to achieve from your design.

Alternatively, if you want a perfect custom stencil to spray paint an uneven surface, polycarbonate and mylar are tough to beat. There are advantages to mylar over polycarbonate and vise versa, it will depend on your application which is best, for ultimate durability, polycarbonate is best but for affordability, even if both are the same thickness, mylar is tough to beat.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 2: Don’t sweat the details

Keep in mind that when we are making you a custom stencil that it is a CUSTOM STENCIL, this means that depending on your spray, you want something big and clear that you are stenciling, all those little details will generally get plugged-up the moment you use the stencil more than once, especially in the same settings.

Very small details do two things, they quickly become useless as they fill-up with “stuff” and can add a lot to production costs and your timeline. What you want to do is look over your custom stencil design and decide what details are IMPORTANT and which you can live without. Also keep in mind that leaving a gab that’s too big is just as bad as having too many little ones, a careful balance, based on intended use, is something you want for your perfect stencil. It’s a fine line that we are more than happy to help you with achieving optimal results for.

For instance, if you want to make a stencil to spray paint across a physical bus that will fit an area 10 ft x 8 ft, details that are a fraction of an inch won’t be noticeable, I’d even argue any fine details less than one inch really are overkill. Why? Because the distance people are going to be seeing the resultant stencil will be pretty far away, especially on a moving object.

Go over your custom stencil design with a fine tooth comb, and decide which areas are worth being ‘stenciled’ and which are not, and just take them out. It will also save you a lot of time with clean-up as only large parts will end-up being clear and those small insignificant details will most likely be inconsistent and hit and miss at best.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 3: Inner Piece Supports!

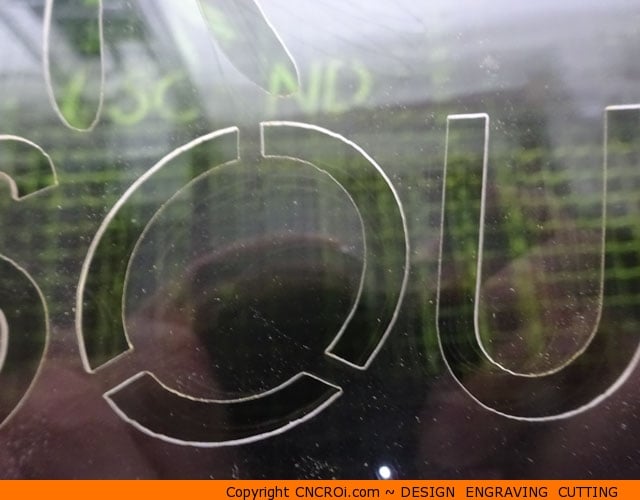

This might sound obvious but all those inner parts, if they don’t have a support bridge inside of them supporting them to the outer parts of your stencil, WILL FALL OUT. That inside of an “b”, “p” and the dreaded “0” will just end-up looking weird. This of course, by extension, also affects your graphic design options as well, many people and companies send us designs and forget this very important aspect of their stencil!

A stencil, by its very nature, will be fleeting, so you want to make those inner support bridges strong enough to last but no so strong, in thickness, that they become a distraction. Ideally, you have a custom stencil design without any inner parts but so far, we have yet to have a customer with such an optimal design. A harder design will also generally require less bridge numbers and the thickness of each. For instance, some large gaps may require several bridges to prevent warping during use while if you used just one big bridge, there is enough support material to keep everything together.

The end application will also have a direct bearing as to how many and how wide those support bridges have to be, as does the material we are cutting it out of for your custom stencil application. For instance, if it’s something you are holding up against a wall, I’d suggest going with polycarbonate as it’s relatively strong and keeps its shape, while if it’s something to go on the ground, mylar or even cardboard or acrylic may do the job.

As mentioned previously, if you were putting this on fresh cement, go with thick quarter-inch plywood but as it will get “wet”, you probably want those support bridges a bit thicker than normal just for better durability. The design options are almost endless when it comes to custom stencil production, at least with CNCROi.com, you have OPTIONS!

Here is a brief listing of what our stencils have been used for in the past.

- graffiti (industrial and street)

- marketing purposes

- promoting events and at events themselves

- adding details to a coffee for a coffee shop both on the walls and on the drinks themselves

- wall art and artistic installations

- industrial marking on containers, shipping crates and equipment

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 4: Size Matters

Ultimately, the size of your stencil will be dictated by your application but you also have to keep in mind the material it’s made-up of. For instance, the really nice thing about thin polycarbonate is that it can be rolled-up and is incredibly durable while a custom stencil made out of quarter-inch acrylic will not bend.

Some materials are easier to tile than others, if it’s for an especially large installation or with repeated use, we’ve made great plywood stencils that interlock, sort of like a puzzle, to keep them together yet strong enough to walk and work over. We’ve also made reference engraving marks on the custom stencils for thinner materials, again, each material and application we use for your stencil will dictate what direction to go with it.

The bigger the stencil, generally, the more reference points we need to add to make things easy. We can add as many or as few details as you wish to make your stencil job as straight forward and dummy proof as possible. Volunteers really want something that requires no thinking when it comes to stencils, we’ve made tons for universities and students where they were numbered for easy reference.

We can be as involved with your design as you wish, from helping you getting the initial concept off the floor to custom production of your stencil across a huge array of applications.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 5: Margins Matter

The size of what you are stenciling also needs to be kept in mind, as you will most likely have overspray, some of our custom stencil customers want overspray as part of their design, it adds a neat effect, while others don’t. You need to decide, based on what material you are spraying or filling with, how much you want.

If you want no overspray at all, there are two ways around, either make your stencil smaller with a wide margin or make it right-up to the edge and use another material as a backing. Generally, I suggest to our customers to make the custom stencil as big as possible with their inner stencil as small as possible (if they don’t want overspray) and it seems to work well.

Other thing to keep in mind is that not all stencils are the same, remember those reference points? Well, how are you going to see them if you have a massive cardboard margin? Better to go with something completely transparent like polycarbonate, PETG or mylar rather than something that you can’t see through.

Margins can also pull double-duty as references themselves, with holes and cross hatches which we can make in our shop for you, for the ultimate placement repeatability. Your application will dictate how much of this to keep in mind for your custom stencil production.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 6: One time or multi-use?

How many times do you plan on using your custom-made CNCROi.com stencil? If it’s one-day-one-time then there is no point in having it made out of ultra-durable material now is there? Something like paper (yes paper!) might be totally fine, it cuts fast, after use is recyclable and won’t get in the way as it rolls right up and weighs nothing.

We’ve had other customers who use their stencil with chalk and literally run it along the inner stencil parts, over and over again, day in and out… paper would be a complete disaster for their custom stencil application! Best to go with 0.06″ or almost 2 mm thick polycarbonate with thick and wide bridges for inner piece support!

An important consideration is always how much pressure you plan on applying on the custom stencil, both in USE and CLEAN-UP. People often forget that after a stencil has been used, that they’d like to clean it up and during this process, they can damage the stencil, depending on the material selected. As a result, consider how many times you plan on using your custom produced stencil and if needed, we can also make totally dead-accurate copies for you as well if it’s for extended use so as one wears out, you have another in the wings ready to take its place.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 7 Vectors Matter

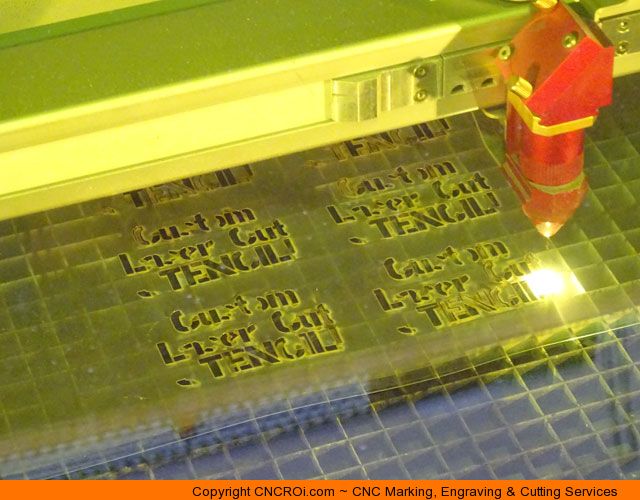

You want to make sure that when you are ready for a custom stencil to be made that you send us the right paths for our laser or router to follow. Sending us a bitmap that’s in full color is rather useless for this application, send us a vector, PDF is “ok” but EPS is best!

The reason why we require “paths” instead of “imagery” is because our laser is following the contours of your design and images, as a result, you want nice smooth lines and curves for it to go along. That bitmap that you blew-up from 25 pixels to 5 000 will just not work with us, the line information will be all gone, the amount of detail you thought you had will be gone. Why?

Vectors are resolution independent, whether it’s smaller than a business card or bigger than a tank, a vector will be clear and precise while an image, blown-up to those proportions, will just be a jagged mess. Want the best results for your perfect custom stencil? Send us your curves, not your color.

One more thing, be sure to tell us what you want cut vs color changed or engraved. Generally, make the inner parts of your custom stencil blue and outer margins green, hairline thickness. Don’t worry if you don’t know what this means, we have internal design capabilities to get the ball rolling.

How to get PERFECT Stencils: 8 Custom Production Tips ~ Tip 8: Experience matters!

There is a reason why we can offer custom stencil production across a huge variety of materials, that’s because we make a lot of them! We have an Austrian industrial wide-format laser that is fantastic for accurate custom stencil production and design stills that are second to none when it comes to optimizing your design to produce the best perfect stencil results.

At the end of the day, you want to get your stencil made professionally, on time and within budget using the best material to suit your application. This is what CNCROi.com is offering you when it comes to stencil production, whether you need one or a thousand, we are here to help with years of stencil work under our belt.

Whether you need a custom stencil for a medical application or something for your dorm or to mark parking lots, contact CNCROi.com right now for your ultimate perfect stencil, custom-made just for you!