Laser + Wood: What REALLY happens?

Wood, both solid and engineered, is among the easiest materials to work with when it comes to CNC laser and router applications but the process behind what is actually happening isn’t as it seems. Let’s dive in deeper!

3 mm hardboard with masking so no resin and adhesives have a chance to stick to our materials, this is removed after the CNC laser cutting process.

Our large format industrial Austrian CNC Trotec Laser is similar to a magnifying glass, it focuses the energy coming from our CO2 laser tube onto a very small point on the wood but that’s about all it really has in common. You’ll notice that with a magnifying glass, it’s easy to generate a fire, that’s why in a survival situation, a magnifying glass is far more practical than matches as long as it doesn’t break as you’ll never run out of Sun.

Like our laser, a magnifying glass can be used almost endlessly to generate a high energy beam but the laser light is actually infrared heat radiation which is why most CNC lasers are enclosed (like ours) to keep everybody safe from its harmful effects. When the highly focused CNC laser beam hits the material, it isn’t actually putting it on fire but vaporizing the organic material shavings and dust with oxidation. It’s similar to what happens when you use a blowtorch to burn a piece of toilet paper, the power is so overwhelming that it just turns it into gas on contact.

A CNC laser beam is also very thing, measuring less than a mm but the reason why you typically see a spacing of 1 mm is the cutting process also vaporizes material next to the focal point, hence making it wider, this is also why it’s best, unlike a CNC router, to try to cut through wood in one pass verses several because what’s left over is essentially charcoal which is great at lessening the effectiveness of a laser beam, something that just doesn’t happen with routers unless you are doing things very wrong.

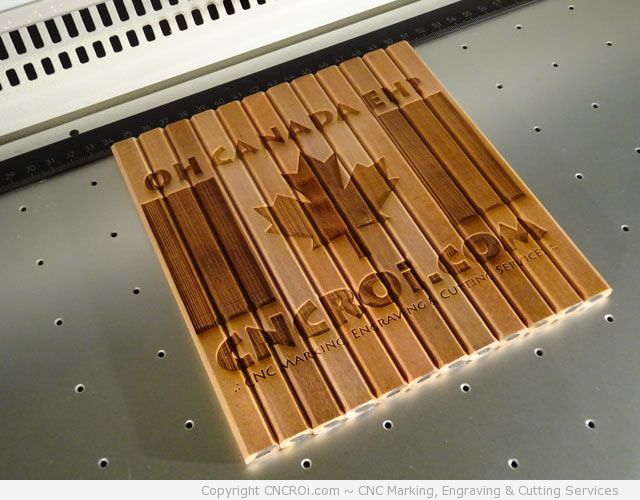

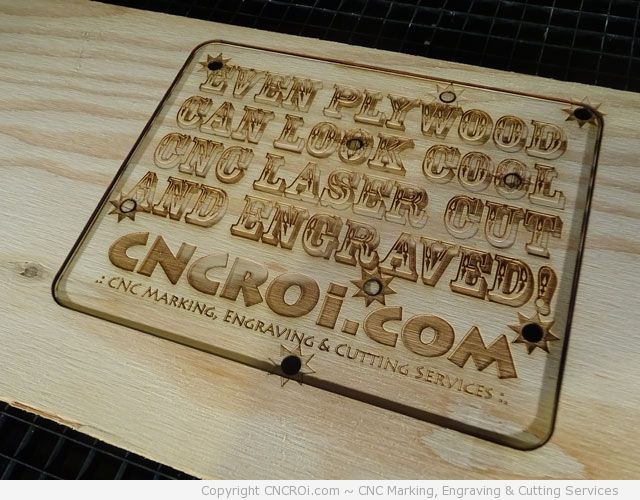

6 mm thick plywood CNC laser engraved and cut, it has a lot less adhesives than the hardboard so masking isn’t generally necessary.

Not all woods are the same though, being a natural material, even within the same board, we may have variances in material density, moisture, oils, adhesives, texture and resin which may affect both cutting speed and power output needed to produce a cut or engraving. For instance, the density of cardboard is dramatically less than Oak which means we can cut and engrave cardboard faster than cardboard using our 100W CO2 laser source. This is also why more homogeneous woods like MDF produce more consistent results than a chunk of wood full of knots and growth rings where sometimes, we are heating them up to actually be harder instead of vaporizing them.

The resins found in wood are very sticky which is why generally, we mask our wood projects because removing resin after it has set on a piece of wood is like trying to remove gum from a shoe. As such, sometimes there is combustion of the resin, which is why it’s very important to have a gas kit and extraction going on all the time to quickly get rid of it. There is also sublimation happening (solid to gas without any transition) as mentioned earlier which can build-up in a machine. This is why we also have a hazardous kit on our CNC laser to protect electronics and the few parts in a CNC laser that do move.

Cork is full of resin, producing a stick black or dark brown surface when engraved or cut. Masking is a must for this material.

Going back to the engineered woods we work with, which includes MDF, plywood and laminates, depending on how the wood is put together, it may release toxic substances which is why a material data sheet comes in handy as more and more manufacturers state whether the wood is good or bad for laser engraving and cutting processes.

It’s the fillers and the glues especially which are a main concern but regardless, these materials tend to produce a lot of smoke and gunk up a machine and the lens pretty quickly. The more fillers and tougher the glues, the longer it takes to cut some of these materials as well so just because you bought MDF doesn’t mean it will have the same cutting times across the board as variances can also happen within production batches.

CNC cut and engraved “love” coasters… designed and cut inhouse at LoveTatoo.com!

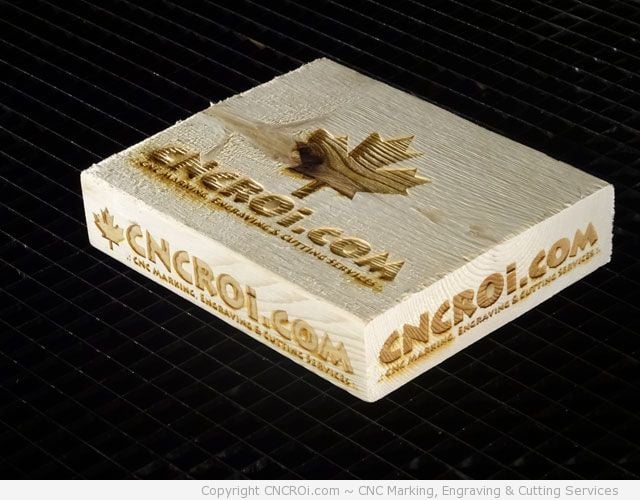

Why brown edges?

Want a quick way to figure-out if something is CNC laser or router cut? Look at the edges, if it’s cut with a CNC laser, wood will generally have a darker edge than the surface (or flame polished for acrylics) while with a CNC router, the edges should have no color change and some slight chipping (scratched edges for acrylics). This happens due to the oxidation when I mentioned above and generally, cannot be avoided unless you have something extremely thin like paper. The higher the moisture content in the wood, the darker things get which is why Balsa produces an extremely light edge while Pine a far darker one. Using compressed air also makes a big difference (we use that as well) in the edge quality and consistency.

Custom display at the Nürnberg International Toy Fair.

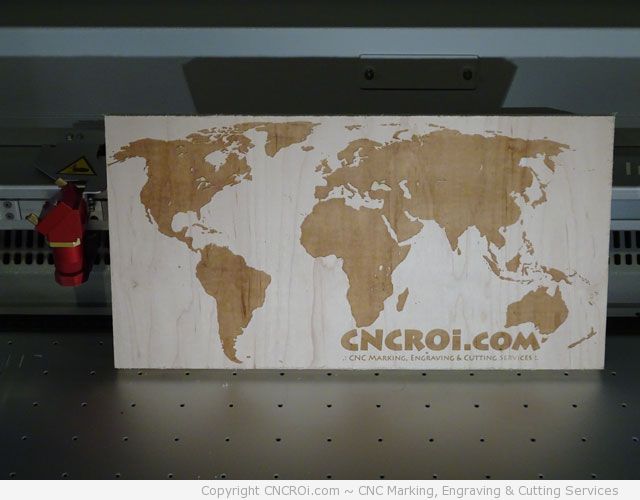

Oxidation for Engraving

When CNCROi.com wants to cut through wood, we generally use full power and a slow speed while for engraving, we generally employ the opposite settings. If 100% power and 1% speed cut through 6 mm plywood, then engraving is accomplished using 100% – 20% power with 100% speed. The more power, the deeper we get but also the more smoke is produced which may or may not be wanted.

CNC laser engraved wood, with masking still on – notice the resin under the 1967, that would be a lot of trouble to remove but with masking, it’s easy as the resin is stuck to it and not the wood.

If you want more contrast, use more power but this depends on the wood’s properties and results from material testing as sometimes, we produce too much contrast at 50% and need to dial it down or use more compressed air. Regardless, there is no flame or ignition during this process and as it’s a contactless process (unlike CNC routers where the bit touches the material), no chips produced.

Why do lasers have such wide price points?

Now the million dollar question, why do some lasers with the same wattage have such massive price differences between manufacturers? The simple answer is machine quality and GAS… the more stable and properly mixed the gas is in our CO2 laser tube, the more consistent results we’ll get cutting and engraving. Truth be told, when you purchase a CNC laser, you are actually buying a CO2 and/or fiber tube that happens to come with a machine around it.

Sure, CNCROi.com could have jumped into business with a cheaper and higher powered foreign CNC laser but that would come at the cost of speed, quality and headaches during production. Our focus is on custom and high quality and if you don’t want to invest in top of the line capital equipment, you should be in another line of work.