How To Make 24 Custom Rubber Stamps

How do you make 24 custom rubber stamps? Easy, you hire CNCROi.com to make them for you!

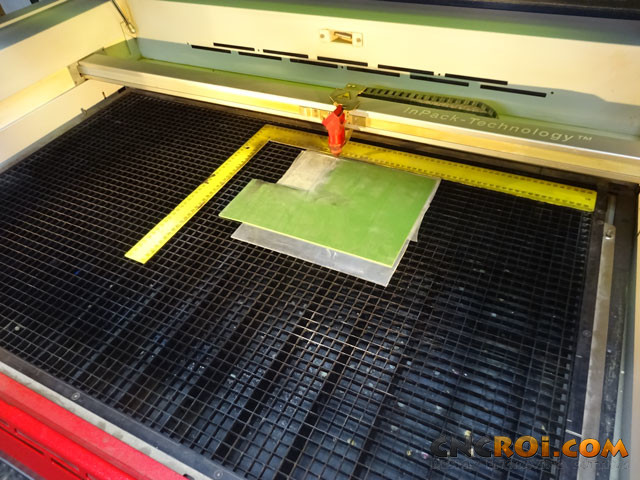

Like just about everything else in the shop, custom rubber stamps are made to spec, at your size, your shape, your material (wood through rubber) and at the volume you want for your particular application?

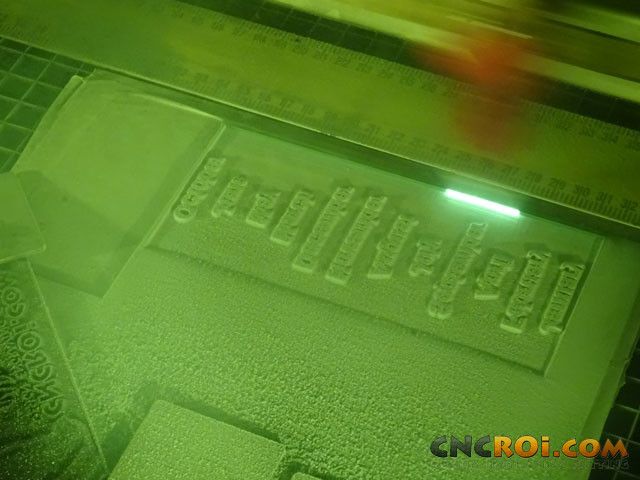

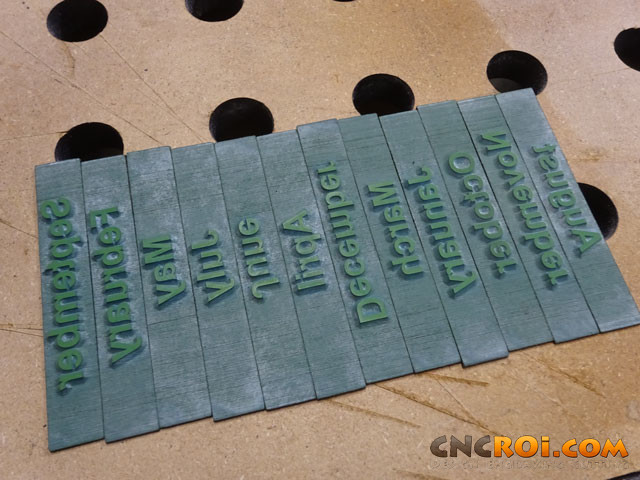

Up to this point, in all the videos I’ve made here on CNCROi.com relating to custom rubber stamps, they’ve always been orange or grey rubber so today we’ll go a little crazy with a more premium color… GREEN!

Green and grey are both from Trodat Austria, so the quality and consistency is there, the only difference is that the green is a bit more premium and for this demonstration, I wanted to show something slightly different from the traditional offerings.

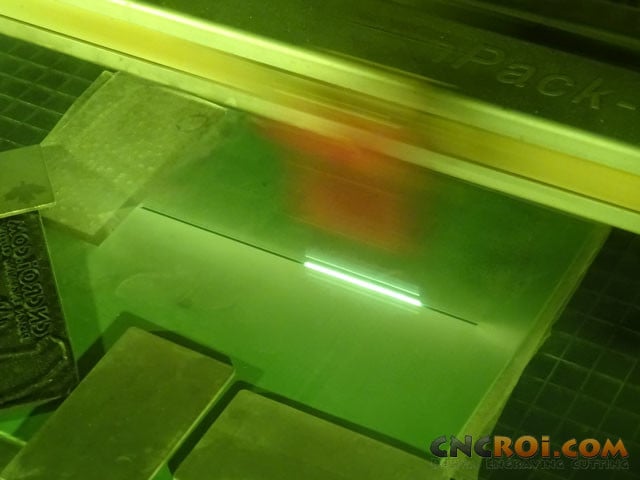

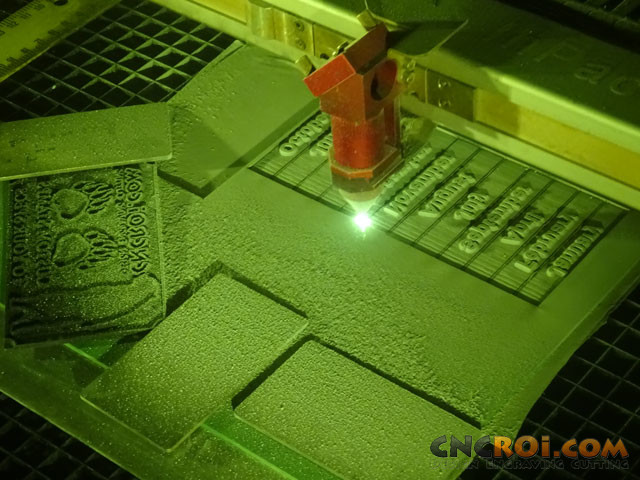

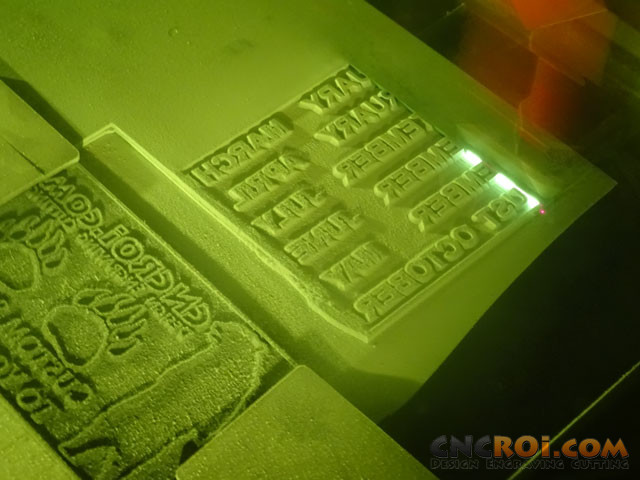

Regardless of the color, size or shape of the custom rubber stamps we make here in the shop, it’s always a messy process vaporizing rubber using our Trotec Laser, developed by the same manufacturer of our rubber and self-inking stamp assemblies.

The nice thing about this rubber vs the general grey rubber we used before and the orange before that is that this is easier to clean before shipping to our customers.

Still need soap and water, but the results become more apparent quicker than otherwise, take a look at this video to see the difference.

Personally, I find both type of rubber completely interchangeable, they both produce awesome results when making custom rubber stamps so whether you have green or grey, you are getting premium results regardless from CNCROi.com.

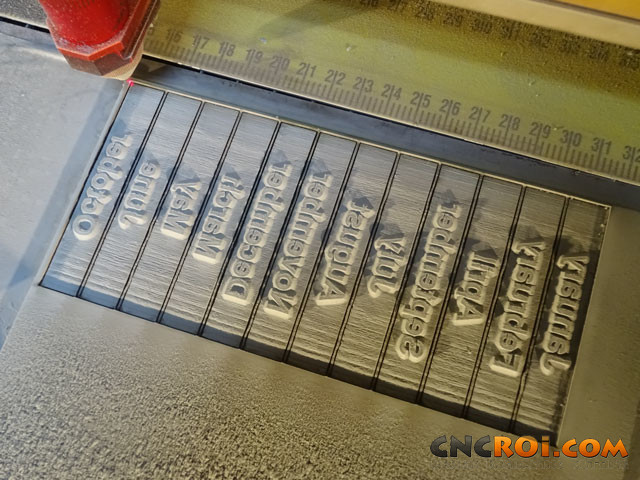

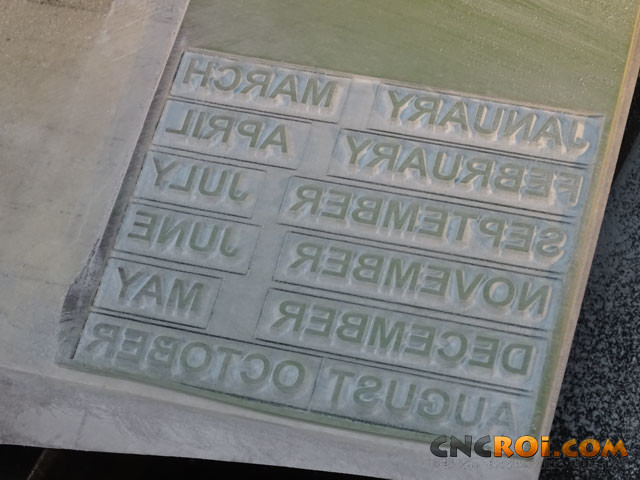

This project was done twice, just to illustrate the differences in what we can do when it comes to making custom rubber stamps, the first, is using capital and small letters where all the days of the month are on the same sized rubber stamp.

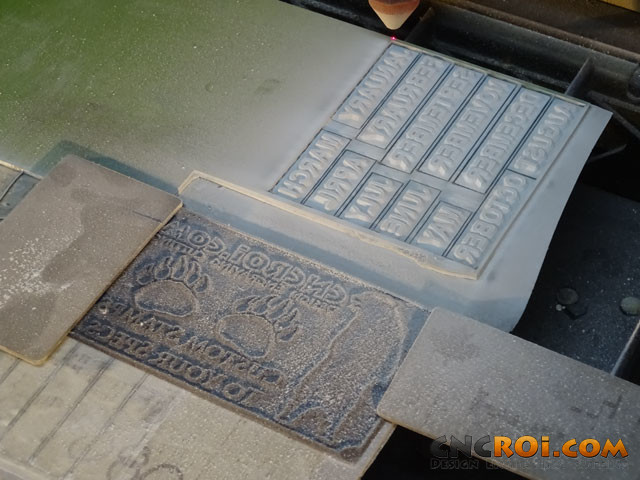

The second, which you’ll see a little further down in this blog or the second part of this video at the top of the screen, is where we’ve optimally placed the rubber to use a smaller surface area.

Both approaches are equally usable, just one more optimally uses material and laser resources than the other.

When it comes to custom rubber stamps, CNCROi.com has a partnership with Trodat, the word’s largest stamp manufacturer which means we get all our inks, rubbers, self-inking stamp assemblies and other supplies including our Austrian wide-format industrial laser from them.

This approach means that not only are our supplies optimized for stamp production from a world leader in the industry, but our hardware though software is just as highly set-up to produce the absolute best results when it comes to custom rubber stamp production.

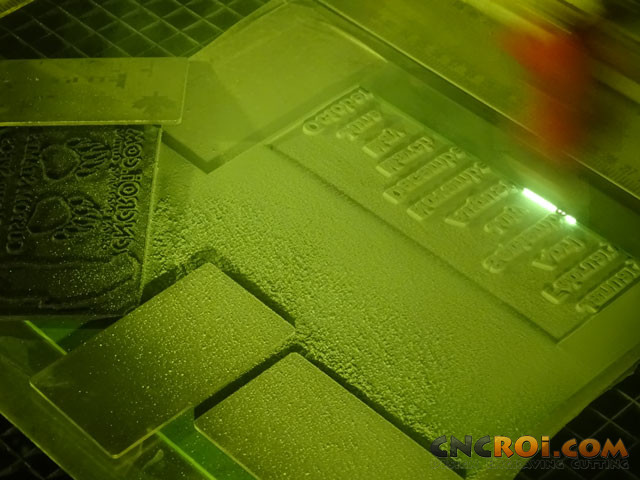

I stuck the rubber stamp we made earlier (in the above video) of the bear from the Trodat Professional 5212 self-inking stamp in the images to showcase to you yet another visual cue as to where all that rubber goes after it has been vaporized.

It also serves as a sizing reference, whether you want HUGE stamps or little ones, CNCROi.com has the experience, equipment and passion to produce the absolute best results for your custom rubber stamps.

These little stamps are pretty small, we’ve done some custom rubber stamps that were literally the size of our bed, 39 inches x 24 inches (1 meter x 60 cm) and small ones as “small” as 1 cm or half-inch squared.

When we make custom rubber stamps for the Trodat self-inking stamps, I generally like to test it before it leaves the shop, just to make sure that everything is in working order but more importantly, that the stamp performs up to spec.

Being a shop where essentially, all we do is custom, it’s always good to double-check things before they leave the door and are shipped to our customers! You may notice that with time, the rubber tends to “absorb” the ink from these stamps across the entire surface, it’s fine as it will still only imprint the top that isn’t vaporized by the way.

The most fun part of making custom rubber stamps after getting feedback from our customers is actually when they are done being made.

That’s when we can review them closer to see how they came 0ut and after a quick cleaning, test them out!

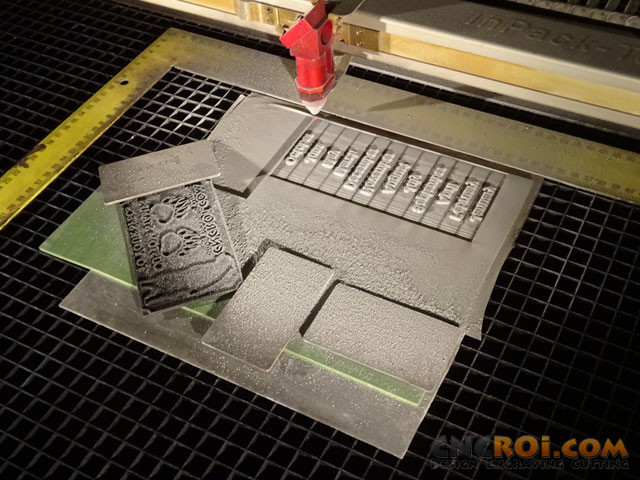

Don’t worry, the “green” rubber is still there, it’s just covered by a layer of soot from the vaporization of the custom rubber stamps we made.

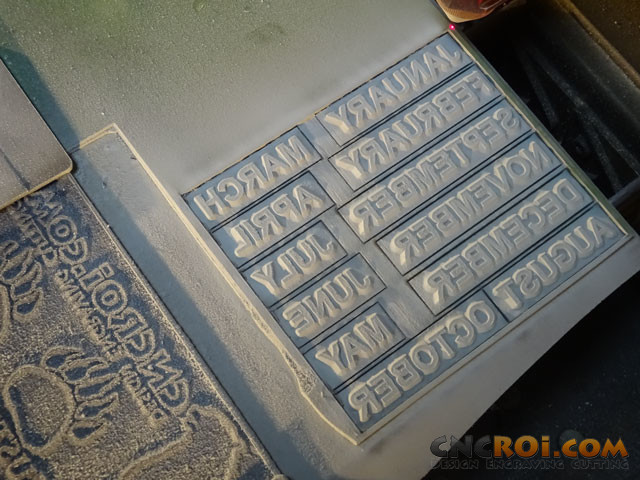

All the months came out sharp and clear, that’s Austrian precision for you! We generally produce them at a thousand DPI as well, for ultimate clarity.

The very fine powder gets everywhere, it’s not sticky or smelly, it’s just like an extremely fine dust that’s quickly and easily removed with a little bit of elbow grease.

Hard to believe that all this fine powder comes right off to reveal an incredibly details and high precision custom rubber stamps!

Although not necessary, I tend to leave a little rubber between the cut outs, just incase anything moves or gets blown away, nothing else is affected.

We have some serious air moving around inside our machine both onto the custom rubber stamps and away, nothing has moved on us yet but it’s just an extra precaution I like to take.

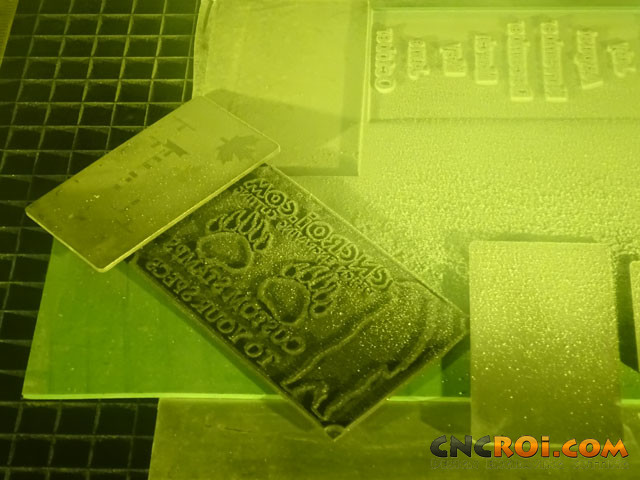

The custom rubber stamps peel right off, you can see that there is lots of soot on them, again, they are all green but look grey and out of focus, that’s why we clean them up!

And there you go, awesome beautiful custom rubber stamps! They are still a little wet but you can see all the edges (shoulders) of the rubber imprint are clear and sharp.

There are no issues with lifting, bubbling or other production problems. Why? Because we know what we are doing and have done enough stamps to know what works and what doesn’t in our production environment.

After they have dried-up, you can see how amazing these custom rubber stamps are. In this case, they will be affixed to a wood rectangle for manual stamping, so these are ready to be used as-is where-is.

Before we run-off to make the next batch of months custom rubber stamps, watch this video for a quick “what to watch out for” when designing something to be transformed into a custom rubber stamp.

Just to emphasize, durometer is generally outlined by the color of the rubber, the more “brown” the rubber is, the higher the durometer, or hardness of the rubber.

The lighter the orange, the lower, or softer, the rubber is.

If you want to see what a custom rubber stamp looks like out of the “orangy” rubber, that’s basically the same durometer as this Trodat rubber, check this video out.

Why would we use one rubber of the other you may ask? Well, some of our customers have applications where they need to use something very hard with an aluminium backing (light to dark brown durometer) as the process involves hot foil stamping or embossing on plastics.

As I mentioned, there are a ton of different applications and processes across a huge number of industries that require high quality, durable, and repeatable custom rubber stamps and CNCROi.com can make most of them in-house!

Other custom rubber stamps have applications where we have to make rolls of stamps with a seam to be put around a drum for industrial stamping.

There are a ton of different applications where manufacturers require and have, different expectations and in those cases, we use the rubber they supply or more precisely to their specs.

There is no perfect rubber that fits all the wide array of requirements our customers have, whether it’s making “simple” custom rubber stamps for a Trodat self-inking stamp…

Or something far larger where we have to account for material expansion and cooling during production, CNCROi.com is here to help with all your custom stamping needs, and no, they don’t have to be solely based on rubber!

How do we go about getting you a quote to make custom rubber stamps? The easiest way is to send us your EPS or PDF black and white image, from that, it gives us an idea of how much rubber the project will need and hence, production time. Let us know your budget and how many you need!

If it isn’t your traditional custom rubber stamps you want made, knowing the application is important because we may be able to offer alternatives, for instance, for some requirements, like imprinting cement or other types of media, rubber isn’t always your best choice.

We’ve even had some customers who didn’t know what they wanted but their application called for something very different, like a mold made out of acrylic or even solid wood. Again, there is no bet way to go about imprinting, there are many factors involved!

Time sure flies when you’re making custom rubber stamps! This second round of stamps are done, they have been fully engraved and now cut-out of their rubber bindings by CNCROi.com‘s industrial laser!

The difference other than surface area is that they are all capital letters, as we make custom rubber stamps on-demand, we offer you the ultimate flexibility when it comes to design, it doesn’t need to be text, it doesn’t need to be symbols, it can be anything you want!

Before lifting these custom rubber stamps, I decided to use our brush to just take some of the vaporized rubber off of them. Just like the last batch, these rubber stamps are all extremely clear, precise and consistent. There are now flaws at all present!

Just to show you the diversity of CNCROi.com‘s custom stamp and mold making processes, here’s another material we like to make custom stamps out of, wood!

After a quick wash, you can see how well they came out, they are so straight they can be used as a ruler! It’s incredible what the perfect mix of top end equipment and materials can produce!

Need some custom rubber stamps? Contact CNCROi.com right now! We love making all our customer’s stamp production dreams come true regardless of material or application requirements!