How to Save Money with CNC Laser Services: Top 10 Tips!

Save money with CNC laser services! With years of experience behind (and ahead) of me with lots of different CNC machines, design through production of a finished model, something that keeps coming up is how can customers save money on our professional CNC laser services? These are my top 10 tips to do just that!

How to Save Money with CNC Laser Services: Tip #10 to Save Money ~ Top of the Line Equipment

Surprisingly, the most important factor towards saving money on a production cycle is to buy the best damn equipment you can get.

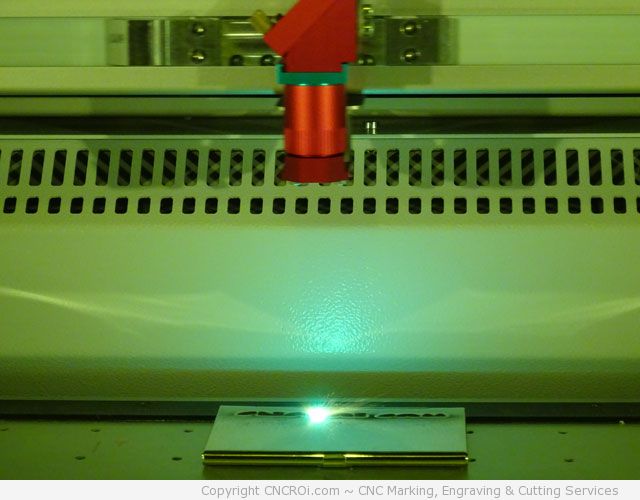

When I started CNCROi.com, my focus was to buy the best machine for the projects I thought my customers would have for me. That meant going with a top of the line Austrian CNC laser engraver that was meant for industrial production.

Not only that, I knew I’d have lots of metal work as well as other materials, that meant I needed to invest even more resources in a machine with both a fiber laser tube and a CO2 one in it.

Why is this important? It means that regardless of the application my customer had, 9.9 times out of 10, I could do it for them! Out machine is the same as the one in the video but better!

Another factor for going top of the line Austrian with an industry leading industrial wide-format laser was accuracy. Sure, I could have saved a ton of money buying a rebranded Chinese import but I needed something that was accurate within 5 nanometers.

Not because I wanted totally accurate Christmas ornaments, but because the clients that I was going to have to go after upon starting my business had to know that I could handle even the most fragile and precise work they had on hand.

Not only that, buying a premium industrial CNC laser also gave me the fastest machine on the market, that didn’t break down, was fully supported and put all this together and guess what, when my customers have a tight deadline, they can COUNT ON ME TO GET IT DONE!

That’s worth every dollar of this awesome Trotec Laser Speedy 400 flexx! Yes, these videos are just a small showcase as to what our machine has and can do, technological wise, it’s bleeding edge stuff!

How to Save Money with CNC Laser Services: Tip #9 to Save Money ~ Have design reviewed by an industry expert

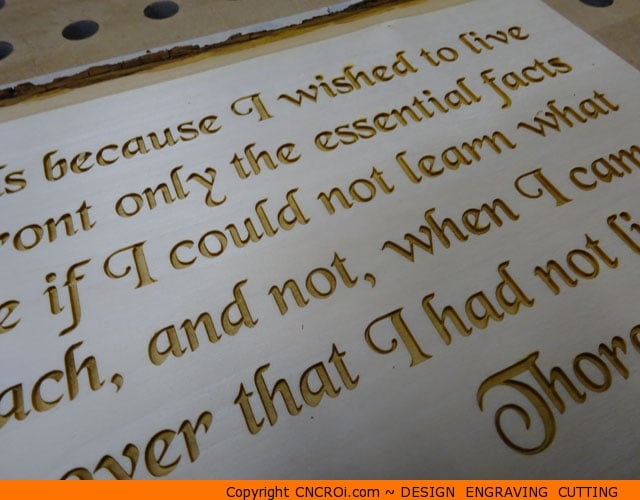

There is a huge difference between getting a file from a customer and cutting away and having a design from a customer reviewed by somebody who has spent well over a decade designing for CNC machines.

I published 5 books about how to design for these machines, CNC lasers through routers and by extension, plasma and waterjet. When I look at a design, I can quickly optimize it for production.

For instance, something that comes-up often are annealing jobs, they are incredibly slow yet precise heat treatment of (generally) stainless steel and optimizing a file correctly can save up to 75% depending on the design file.

I’ve literally had jobs that went from 10 hours for a single plate down to half an hour because I KNOW WHAT I’M DOING and as a result, can produce things at a fraction of the time and pass those savings onto you.

It goes beyond that though, for projects that are far larger and more extensive, time spent optimizing files can allow incredibly complex and time intensive production jobs to be done rather easily and straight forward.

A few months ago we had a huge job CNC routering hundreds of custom Corian (used for countertops) with our ShopBot CNC router and then, CNC laser engraving them using our Austrian laser THEN paint filling each one THEN sanding them to a nice finish.

Having experience with CNC routers from design through finishing, using optimal router bits and having an industrial laser able to handle large production runs accurately while having designs optimized to the hilt allowed us to get this done accurately in record time.

Having an industrial sand blaster also helped tremendously for this project as well. Essentially, we have the tools that don’t break down so that even big production runs can be done and with regular production updates to our customers, they’ve come to really enjoy doing business with us as a result.

TThey can count on the equipment, as we can, to make their products accurately and time efficiently across a huge swath of materials within budget at the volumes they need.

The reason I wrote books about this stuff is because I’m passionate about CNC machine work, that passion follows a product start to finish, with attention to detail to produce amazing results for our customers!

How to Save Money with CNC Laser Services: Tip #8 to Save Money ~ Get extras made

Whether you need 10 or 1 000 of something, always get a few extra made. Time and again, customers start a project with us and then at the last-minute or a week later upon delivery, realize that they actually needed “just a few more”.

I’ve lost count of how often this happens, to the point where I actually make extras even if the customer doesn’t ask for them, if they ask for them, great, if not, it’s a bonus.

It’s tough to dictate as to how many extras you may need, we’ve done production runs here at CNCROi.com where we did 30 units of custom luggage tags and then the customer asks for another 5 as well as some custom wood coasters in the hundreds to just get another order for a few hundred more upon delivery.

Both are fine, but again, I generally advise customers to get an extra 10% of what they think they need for us to make for them, worse comes to worse, these extras become a gift to hand out at trade shows or stocking stuffer.

The advantage, at our end, to do extras when we are in a production cycle is that there are generally some things that just don’t work out, either because we screw up, or the material had a defect or a host of other problems arose.

It’s just part of running a custom CNC shop that sometimes, for whatever reason, what we are making just won’t work for a certain percentage of the custom production cycle. This is the same for any industry, that’s why, by default, we make extras.

We recently did a job making custom widgets out of pallet wood, was a fun project, but there are always defects in pallet wood, from nails being where they shouldn’t to cracks, splits and a bunch of other issues.

What’s interesting is that some of these defects aren’t apparent until AFTER you are essentially finishing the project. Our shop configures itself to a specific production run, so moving the router and the laser and other equipment into a “production line” makes thing efficient but after a project is done, we put everything back to where it’s suppose to go.

If we get an order for “one more” after we put the entire production line back into order in the shop, then it’s just an incredibly time inefficient, much less machine and generally equipment inefficient to make that “one more”.

This is why extras are an important factor you must consider, regardless of what you get CNCROi.com to make for you.

How to Save Money with CNC Laser Services: Tip #7 to Save Money ~ Pick the right material

We recently had a slew of projects custom CNC laser engraving and cutting leather patches which I wrote about earlier on this CNCROi.com blog. Many of those projects we didn’t get as the price point the customer wanted wasn’t realistic given the material and spec work they wanted. REAL leather is expensive, and when it’s to be cut using our industrial laser which uses heat to accomplish this task, it needs to be the thick stuff. Generally, we use something called bridle leather, it’s the ultra-premium stuff that’s thick and incredibly strong, and NOT CHEAP.

What many of these quote requests had in common is they assumed the cheap man-made leather would work for their application, which can generally be had for about a quarter the price of the real leather. Nope.

There are several problems with man-made leather that most people don’t realize. The first is that IT’S JUNK, it will not last, it easily cracks and wears out rather quickly. The second is that for most applications, it shrinks dramatically under heat and “melts” more than engraves.

For instance, take a look at my REAL leather brief case which I laser engraved two years ago, the engraving is still strong, clearly legible and considering how much abuse this leather case takes, it still looks fantastic!

If this was made out of the man-made leather junk, it would have ripped a very long time ago and I’d probably be on my fifth leather suit case by now!

Using the proper material for the job is vital, sure, using the wrong stuff may save you some money but you end up, just like just about anything else in life, buying it over and over again instead of once and forget it.

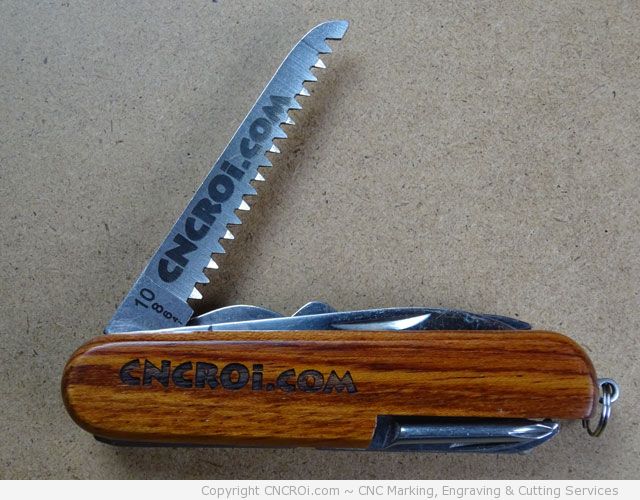

We have the same issue with our custom welding tags, yes, they are more expensive than the lamacoid or UV printed ones but these will not fade, crack or peel and best of all, you can actually weld our tags to your project!

The same goes with our REAL wood business cards, live edge work and so many projects we do with our customers. My goal with CNCROi.com wasn’t to be the cheapest, it was to be the best and give our customers something they are truly proud to have on their equipment or hand out to their customers alike.

This is why we don’t make junk or cut corners and picking the right material for the job is vitally important.

How to Save Money with CNC Laser Services: Tip #6 to Save Money ~ Contact us before you quote customers

Every once in a while, like the leather patches I discussed about before, a customer will put themselves in a corner by assuming a price and quoting that to their customer only to find out they are way off and can’t do the job properly without cutting corners.

Material prices vary wildly and can change at any time, volume also plays an important role as does timeline. Generally, if you want something yesterday in a material that takes us a week to acquire, you will end-up paying through the nose for it.

Not because we are trying to rip you off, but because our supplier has to run around with their head chopped off getting it ready, the shipping company has to “next day” deliver it and then we have to work 24 hours straight to get the production done and shipped “next day” to you.

All of this adds tremendous costs that can be easily avoided by contacting us earlier within the production cycle.

A great example is our live edge work, if you are picky about the wood species, dimensions and other fine details, it just might not be available at all until a few months from now from our raw material suppliers.

The trees might still be growing, the kiln needs another week or that wood species is so expensive that moving onto something else should be a serious consideration.

We can’t make trees go faster, you can’t dry wood faster in a kiln without causing material issues (warping) and that exotic species of wood you want, like Ash, just is dying all over and you are a decade too late for wanting that nice Ash live edge executive desk.

The earlier you contact us, the better material selection you’ll have, the better pricing we can get from our supplier (as we have lead time for a bulk order adding your materials to that of other customers) and the shipping can be no rush.

It really helps everybody to not be in a rush for the last-minute production cycle. Our machines can easily handle 24/7/365 production but our bodies can’t for any extended period of time.

Save yourself the stress, contact us early if you can.

How to Save Money with CNC Laser Services: Tip #5 to Save Money ~ Jigs are useful… for you and us

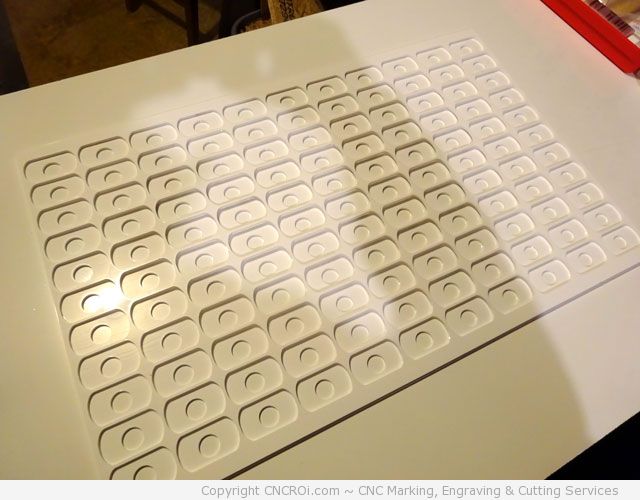

Generally, CNCROi.com is a cog in a wheel, customer gets A, sends it to us, we do B and then it goes onto another supplier or customer to do C. As such, jigs come in handy not only for our production, if we are engraving, for instance, a thousand brass valve tags but also to the next guy down the line to test their processes.

We recently did a job where “our customer” was going to insert what we did into something another supplier was manufacturing for them. Right off the bat, we made a jib for us to be accurate but more importantly, talked to the next guy down the line to make a jig for them and their process.

Custom jigs have a lot of advantages, they speed-up production as it’s a mindless task to stick part A into part B and due to the repetition involved, this mindlessness quickly becomes a massive source for errors.

Humans aren’t meant to be robots, doing the same thing minute after minutes, hour after hour and day after day. The mind tunes out and as a result, mistakes start to creep up and get worse as the production cycle continues. Jigs lessen errors on mindless tasks!

Jigs are also important because they allow more to be done in one shot, for instance, if we have a thousand stainless steel dog tags that need to be annealed, doing one at a time in insane but doing almost a hundred in one shot isn’t!

This factors back into machine accuracy, if your machine isn’t accurate, you will have problems doing a production run like this as any variation in precision gets worse the more away from the “source beginning” gets. CNCROi.com doesn’t have that problem because we have top of the line equipment!

Jigs are great, we generally make them internally for an endless variety of repetitive tasks, this saves our customers money as there is fewer mistakes and more efficient use of our CNC machines and it saves us from going insane due to the repetition.

One more thing it does is allowed for larger production runs in a given amount of time, something that’s vital considering the huge diversity of projects that we do here at CNCROi.com.

How to Save Money with CNC Laser Services: Tip #4 to Save Money ~ Give us time to material test

Some of the projects we do here in the shop are using materials we know very well and dear, we’ve done X a million times on Y material and as a result, material testing isn’t required. But sometimes, we get projects where the application or material at hand is very unique.

Sometimes, our customers don’t even give us anything to test with before going right into production!

Material testing saves you money and by extension, us time. Why? Because it allows us to hone our equipment for the material at hand and most importantly, allows us time produce the best result for that given application on that material.

We had one project about a year ago for a military contractor, they knew what they wanted but had no extras and wanted us to go straight into production.

The material was something pretty damn expensive, and the material testing had to be done on the fly during production, this is absolutely the worse way to do things but we had no choice, as a result, we went slower, with less power and kept changing our settings to produce “better results”.

The accuracy they required was also extremely narrow, CNCROi.com did a great job and the customer was very happy, but I told them from the beginning to the end, that I wished they had something lying around with the same properties we can test with, it would save them money and us time.

Other times when this comes-up is somebody wants a watch or laptop engraved, this isn’t generally the business we strive to get but if it comes, we’ll take it on.

A while back, we annealed a really expensive Rolex watch in the back with a person’s signature, they paid a lot for it, simply because it was one of a kind and if we screwed it up, it was ours, but the results came out great.

Sometimes material testing requires a warehouse of experience to pull off, which is what I used for this very expensive watch, but it would have been nice if they had a scrap one we could have optimized things for!

Another application we had a few months back was a medical device made out of polycarbonate, no problem, our CNC laser also has a fiber tube to permanently color change it black. The shape was odd, required a specialized jig which we made in the shop and the specs had to be accurate within a fraction of a millimeter.

This isn’t the kind of stuff, due to the end application, we could afford to be off as it can affect the test results this was to be used for.

As a result, were given quite a few units that were rejects from their supplier to hone our skills, develop the jigs for and make sure we product the results on the polycarbonate that were within their specs.

This time, very important, allowed us to make a big production run of their medical products without any rejects being produced BECAUSE we had time to get things right well ahead of time.

How to Save Money with CNC Laser Services: Tip #3 to Save Money ~ Have volume and budgets sorted

It’s a given that the higher your volume, the lower the price per unit will be but something that’s not to be overlooked is sorting out your budgets per units you want the production to cost.

Having no idea as to the price point you wish to have your product produced at doesn’t give us the opportunity to suggest alternatives to what you may be considering that would work better as, for instance, a few tweaks here and there can change a job from within spec to outside rather quickly.

For instance, let’s say you want us to produce a thousand stencils for wholesale, your material choices are generally PETG, mylar or polycarbonate.

Each of these materials is available in about a dozen thicknesses and each of these materials have properties that are best suited to specific applications. For instance, mylar is cheaper than polycarbonate but it won’t last as long as it’s a weaker material.

If you can tell us ahead of time what your budget is per unit at your given volume, we know right away which material is best suited for that wholesale account you want us to fulfill for you. Also, just because you got things done one way before doesn’t mean we can change it up.

A change in not only base material for this stencil but also thickness and even the design tweaks, can increase or decrease unit price.

Saying “cheap as possible” doesn’t really help either, as we don’t know what is “cheap” for you. Going back to those custom medical devices, they had a set budget and we produced accordingly at their volume.

If they would have said “cheap as possible”, then we are basically firing blanks in the air as it doesn’t give us any platform spec wise to stand for and optimize towards.

Another prime example of this, yet again, is custom annealing jobs, there are variances depending on the grade of the stainless steel, brass, copper or whatever material you have at hand to allow us to play with.

Saying you have X units which need to be annealed for Y price for Z deadline will help speed things up tremendously.

A logo for instance can be done in many different ways, but we need some solid number and don’t worry, we’ll let you know if these numbers are realistic or not.

How to Save Money with CNC Laser Services: Tip #2 to Save Money ~ Be open to creative possibilities

At the end of the day, CNCROi.com is a company that’s creative at heart. We try to get your project done at the spec you need and how we go about achieving this is up to our creativity.

There is no set way to achieve the results you want, from equipment to expertise, there are many ways to get from A to B. Generally though, the more room you allow us creatively, the more money you will save.

Being open to material changes, spec size and shape optimization allows things to be less regimented and as a result, faster for us to make. A great example of this is the bank below, we could honestly make that out of any material.

If you wanted the exact same design to be made out of stainless steel and real glass, it would cost exponentially more money than using just white wood and acrylic.

If you wanted this custom Egyptian coin bank to be the size of a car, again, would cost a lot more than something you can put on a shelf. These might be extreme examples but the show you how material, size and volume play a critical role in your budget making process when it comes to creative flexibility.

Creative options also are something to keep in mind for larger items. For instance, IKEA focuses on making “what you see” to look great while what you don’t, be just enough to get the job done, as a result, their price points are competitive for something that looks like it should cost a lot more!

This is one of the keys to their fantastic success in retail.

Creative options also includes volume changes. Sometimes we get material in that if we made just X more, it would actually bring the price down of the overall production per unit as it would fit perfectly within a given raw material sheet.

Other projects, if you aren’t picky about grain direction in wood, allow us to optimize things dramatically which, yet again, brings the price down per unit. Other times, our suppliers will give us a better price if we get X instead of the Y spec you needed.

Our CNC laser can engrave wood and anneal steel in ONE PROCESS with ultimate precision.

The more creative flexibility you have for a given project, the more we have to play with to make your project done on time, within budget and even better than you could have ever imagined!

How to Save Money with CNC Laser Services: Tip #1 to Save Money ~ Lamacoids & acrylics are a great alternative

I know I don’t publish as much lamacoid or acrylic related project on CNCROi.com as I should, but that doesn’t mean we don’t make stuff using it! I have a whole shelf of lamacoids and an even bigger one of acrylics at different spec that we regularly go through for customer projects.

The advantage to lamacoids is their cost, for instance, making a thousand custom valve tags out of stainless steel will cost dramatically more than doing the same out of plastic!

There is a trade-off though, in durability but the price can be substantial, especially if they need to be custom sized and spec’ed out for a given application.

The same holds true with acrylics, making the sign below could have been made out of painted wood or even anodized aluminium, but making “one” within the time and budget constraints I put myself into, acrylic was the only and best option.

The nice thing about acrylics and lamacoids is the massive diversity of thicknesses, colors and textures they are available in.

We can get lamacoids that look like glass, lamacoids that are every color of the rainbow and even some that look like steel or other materials that have far higher price points. It’s actually really good materials where the spec can “get away with it”.

Would I use this for an outdoor sign? No way! But a door sign to indicate the broom closet, yeah, no problem!

Our equipment is incredibly powerful and precise, we can generally make “the same shape” out of a variety of different material, paper though steel.

If your application doesn’t call for something that will outlast the building it’s going into or it’s for a temporary trade show display that will be done only once, lamacoids are a great solution as are acrylics.

Lamacoids can also be combined with other materials to strengthen them, for instance, this custom wall plaque was made using a quarter-inch acrylic in the back (for strength) bonded to thin laminate (for color) to give it a very strong presence yet still making it affordable.

Sure, we could have made this with an endless variety of other materials but for this, it worked perfectly and looks fantastic! It has weight, presence and doesn’t cost an arm and a leg to produce!

How to Save Money with CNC Laser Services: BONUS to Save Money ~ Deal with a passionate company

A company that doesn’t care is one that just goes through the motion without thinking. It’s Saturday afternoon, where am I? I’m in the shop! Where will I be tomorrow, most likely, in the shop!

All the content above you see, and a whole lot more was totally optional, I could have been playing video games, getting drunk at the local bar but instead, I decide to write over 400 blog posts (thus far), make close to a thousand videos (thus far) and endless thousands of videos to show YOU how we make this stuff!

Passion counts for a lot, I get paid to make awesome stuff for our customers! How great of a “job” is that? Each and every one of my customers helps support what I enjoy doing, to me, I couldn’t think of anything else I’d like to do.

I’m on vacation every day, doing neat things, sharing my expertise and giving my customers something they are proud to weld, rivet or display in their showroom. If you want to get an idea of how we go about coming-up with what we do for our customers, watch this video.

If you have a custom application, regardless of volume, material or budget, contact CNCROi.com right now and we’ll make something awesome for you! Let me share my knowledge on your project so that you learn how to save money on CNC laser services!