Working at a loss… why?

About a week ago, CNCROi.com was presented with an opportunity to bid on a pretty big project, I declined once I saw the numbers and here’s why.

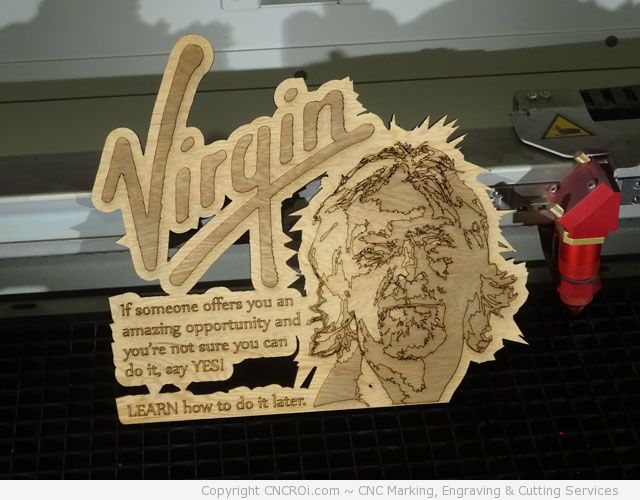

Although the words of Sir Richard Branson do ring true, they don’t when you are paying to do a project. Don’t get me wrong, CNCROi.com does to lots of samples and other marketing materials at a “loss” but they are in order to gain a project and attention which does lead to a profit more often than not – otherwise we wouldn’t be in business!

What I refuse to do, and have done so from the start of this company, is take on projects where we actually have to pay for a project. I won’t work for nothing or pay to work anymore than an employee at a company would be asked to work overtime for nothing or be docked pay randomly because there was some budget cutting.

Loss Leaders

There is always somebody or a company that can do more for less, ask most entrepreneurs this and they’ll be the first to admit that the guy “down the street” or “across the ocean” is undercutting them dramatically in order to get a project.

The problem with taking on these loss leader projects is that you are then trapped at those loss leader prices. Sure, you may be able to get other projects and get some fat from those but generally, you have a client BECAUSE you undercut everybody else, not because you are good, invested in quality machines or materials. At the end of the day, if you are taking on a project just to cover the expense of doing the project in order to keep yourself or your staff busy, you’ve lost already.

Very big companies can get away with this as they are diversified, they can make a loss here in order to make more gains there and overall, they are profitable even if not everything they take on is. That’s a very different ball game than what we are at now.

Laser cut and engraved wedding coaster.

Produce value, not junk

The one area where value still has some profit margins is in custom work, I’m not talking about adding a name to an already existing t-shirt where the prices are cut throat, I’m talking about completely custom work where the project in question has never been created or successfully designed. That’s the domain that CNCROi.com inhabits because we have the unique expertise from concept to capital equipment to make it happen.

There are more margins in value because the arena appreciates the investments required in software and hardware to make things happen. There is no cutting corners when they all need to be sharp and precisely milled!

Laser engraved cork.

Why companies work for nothing

The reasons for taking on a project for nothing can go back to a saying that a machine that isn’t moving is already a loss, throw in an employee sitting there waiting for something to do, overhead lights etc… and I think payroll and overhead pressures more than anything lead to companies taking on projects at a loss. At least then, the loss isn’t absolute or as bad as otherwise possible.

The other reason why companies work for nothing is they are trying to get “in” a company, although this strategy does work, the corners that need to be cut and extra margins required after the “in” to make-up for the initial loss, it’s a vicious cycle as you never know when you’ll be out of starvation mode.

Laser engraved copper backed mirror.

Quality always costs more

As I told one of my clients the other day, my goal with CNCROi.com isn’t to be the cheapest but to be the BEST. This costs more but what you get in return is company that will stay in business with strong investments in top of the line machinery and expertise. We could have easily cut a lot of corners setting-up our capital equipment to cheaper materials that won’t last but the short-term gain from doing so would come at the cost of future returns that our clients get from our work. This is a tradeoff I won’t do.

Annealed 304 stainless steel metal business card.