10 Years of flexx…

When I decided to jump back into business founding CNCROi.com, the first machine I had on my list to acquire was an Austrian Trotec Speedy 400 flexx… patented technology that’s been in development for already a decade!

Sure, our shop has many toys across the woodworking and metal production field including an awesome ShopBot Desktop which can make surprisingly big projects fast, efficiently and precisely…

… but the real workhorse at CNCROi.com is our Austrian Speedy 400 flexx, it’s so vital to my business that I consider any other equipment we have as feeders to it. Even when we get our full sheet ShopBot later in the year, the 400 flexx will greatly complement what we can accomplish with this and other industrial CNC equipment we have at our disposal.

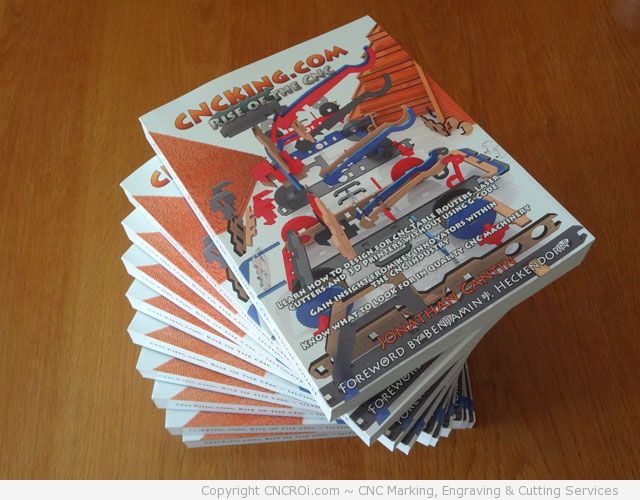

I remember back when I was in Australia, looking at the 400 flexx that’s also in my last book volume and saying to myself, I got to get me one of these somehow! It was truly love at first sight when I realized the potential of this CNC technology and how much of a game changer the flexx option really was. It’s easily one of the most versatile pieces of CNC equipment out there and I’ve had the honor and privilege of being able to use it to wow our growing client base across millworking, manufacturing and even aerospace!

How do you backup a 400 flexx?

With another 400 flexx! Having both a CO2 and fiber laser tube in ONE machine is a massive game changer, it allows CNCROi.com to use the same machine to both anneal stainless steel or fiber mark anodized aluminium or cut acrylic and wood (yes, we’ve even cut pallets with it… more on that in a future blog post!)

How does our flexx benefit your business?

CNCROi.com was the first company in Canada to acquire a 400 flexx, these machines aren’t cheap but the investment we made has helped our clients tremendously, from our massive 1 meter x 60 cm working bed with pass through capabilities that allow us to take-on projects even bigger than our working bed size to the precise Austrian engineering that allows us to perfectly reproduce units day in and out with absolute precision.

We also got it equipped with a gas kit which means we can cut through acrylic and other plastics with little risk of fire – something that’s vital if you want to keep your machine in tip-top shape… throw-in our 2 HP extractor in the back sucking fumes out before they have time to settle on our work, a fire detection system to let us know if we are getting in trouble before trouble starts and the ability to easily flip between CO2 and fiber laser sources and it become apparent how vital this machine has been to our business.

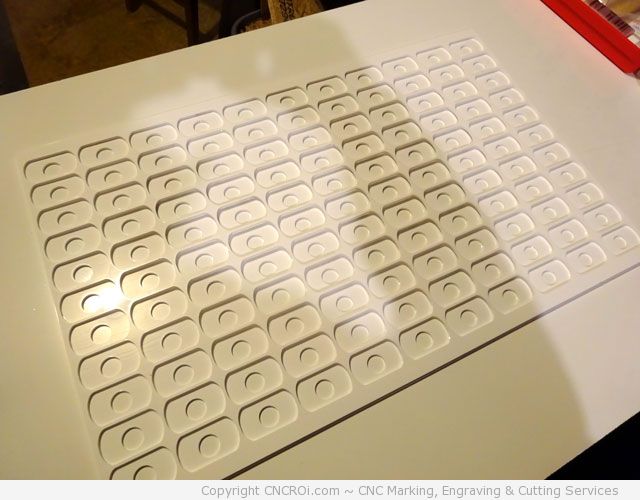

We’ve done everything from annealing stainless steel name badges with our fiber laser tube to cutting paper and cardboard with our CO2, including making countless acrylic jigs for both ourselves internally and customers far and wide.

We’ve color changed polycarbonate and…

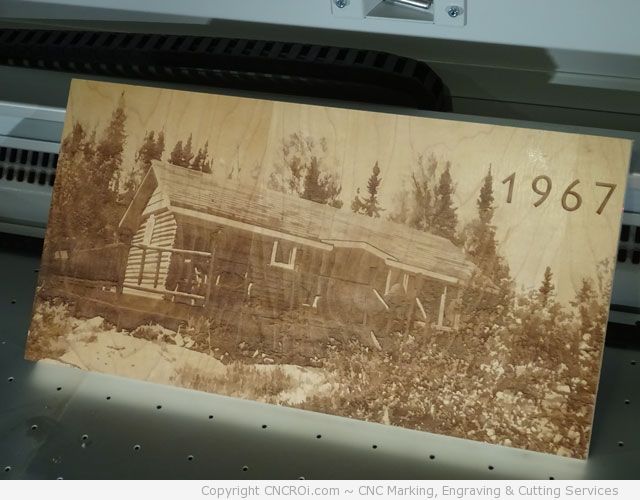

… engraved lots of wood… one of my favorite materials!

We’ve even engraved into stones and bricks with our Austrian Trotec Speedy 400 flexx!

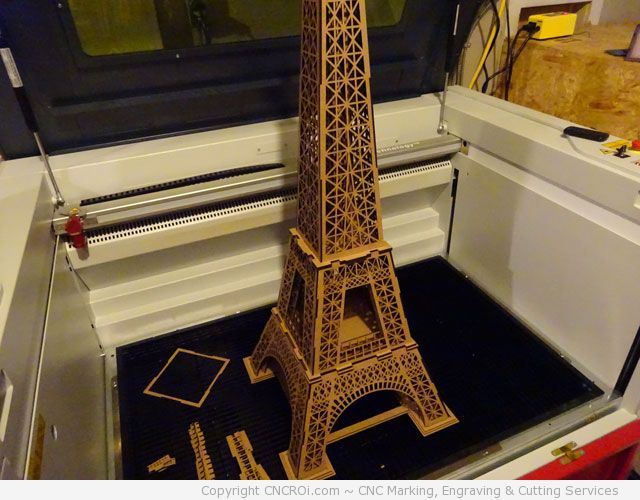

Out machine is so awesome, it even cut one of my Eiffel Tower designs that still works perfectly using friction fit to this very day!

This Austrian machine also helps us in the kitchen… cutting another model of mine holding dangerous knives at bay!

Oh yeah, we’ve also cut through 3/4 inch laminate…

… and 9 mm of solid clear acrylic like it was butter!

Although I can keep on going, we’ve also successfully completed a number of projects in the aerospace industry, an area where crazy tight tolerances are the norm and anything less than PERFECT is simply not good enough.

A big congrats to Trotec Laser for 10 awesome years of innovations in the CNC laser industry… I’m not just an enthusiast but also a very proud Trotec Laser client!