12 Years of 3D Printing Progress: Creality Ender 3 Pro vs 3D Systems Cube

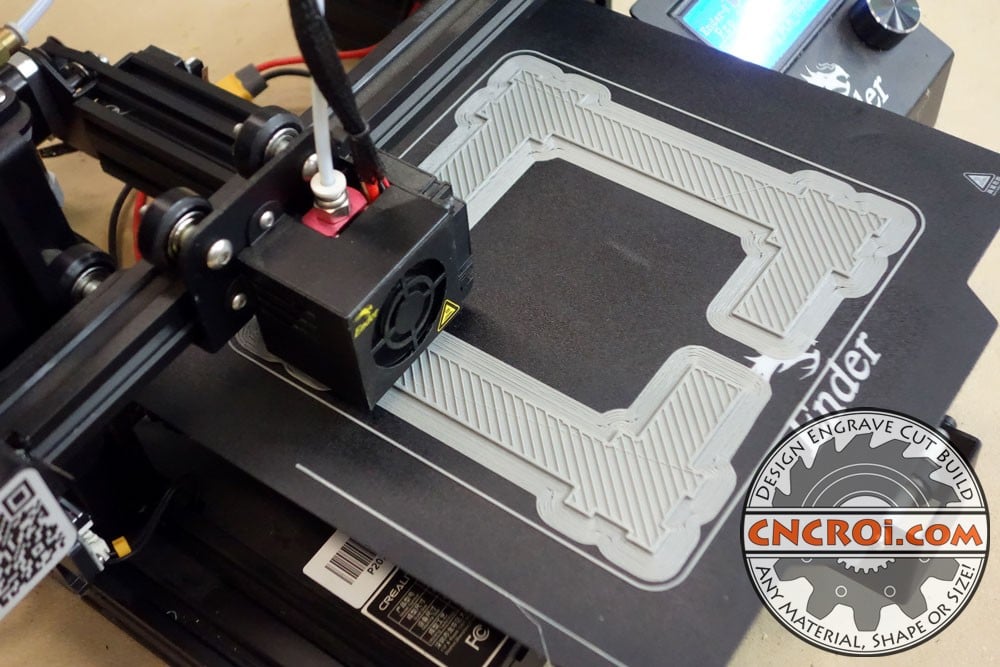

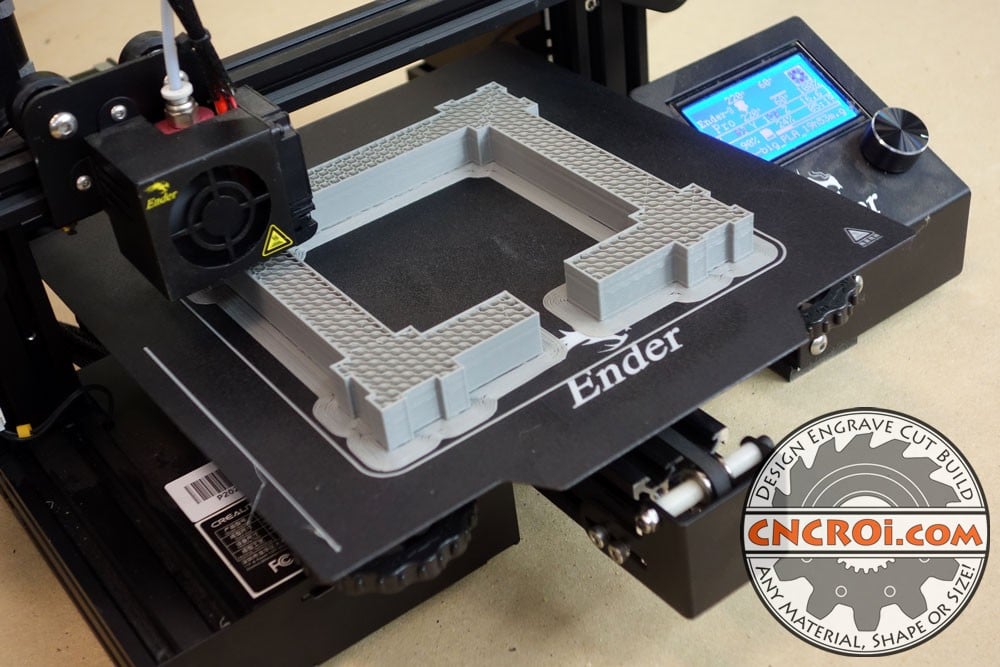

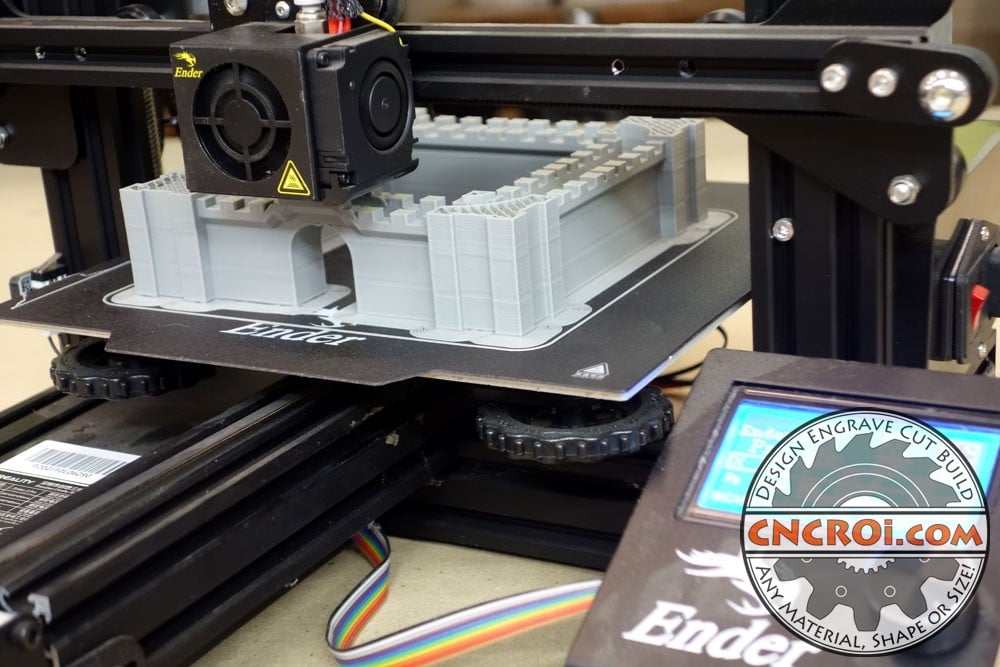

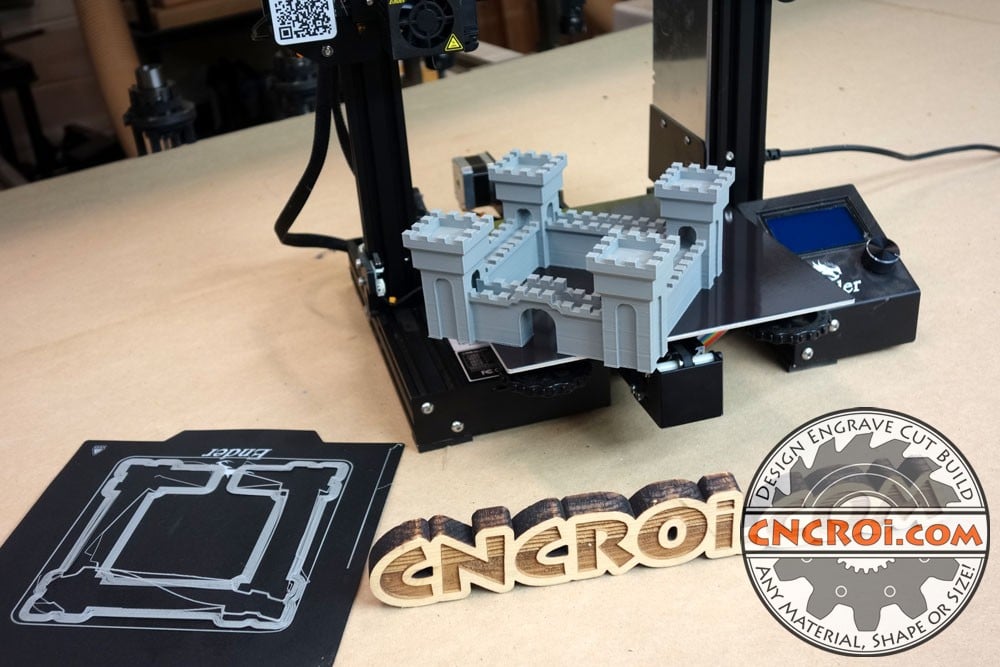

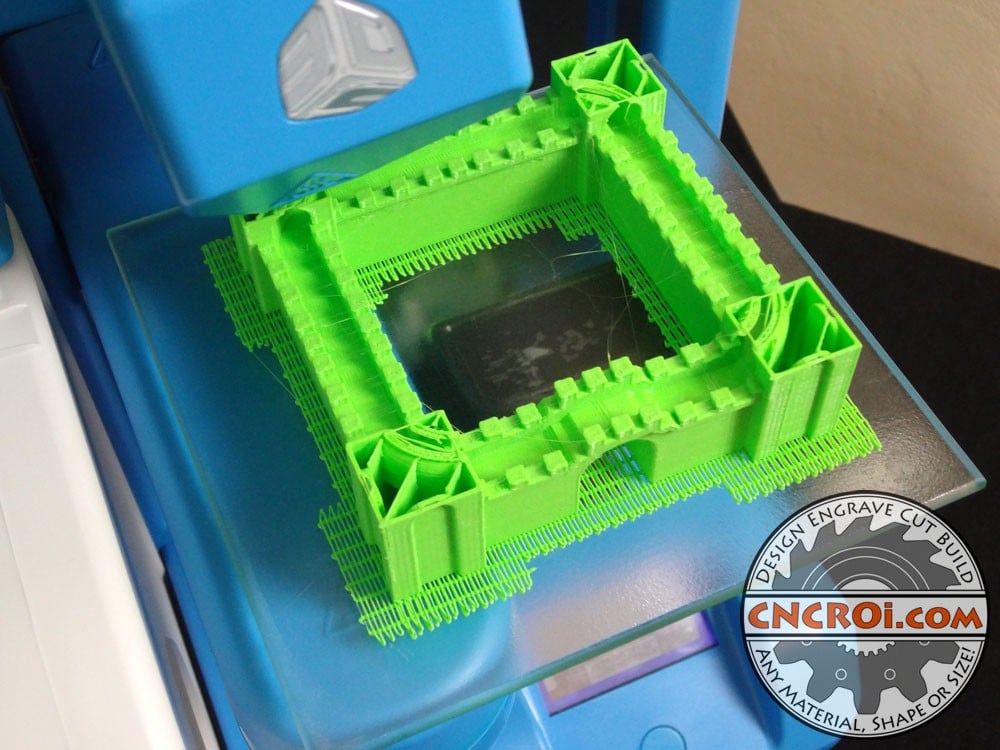

CNCROi.com recently revisited a project that marked the company’s early experimentation with 3D printing: a medieval castle wall segment, first brought to life over 12 years ago using a now-vintage 3D Systems Cube (video below).

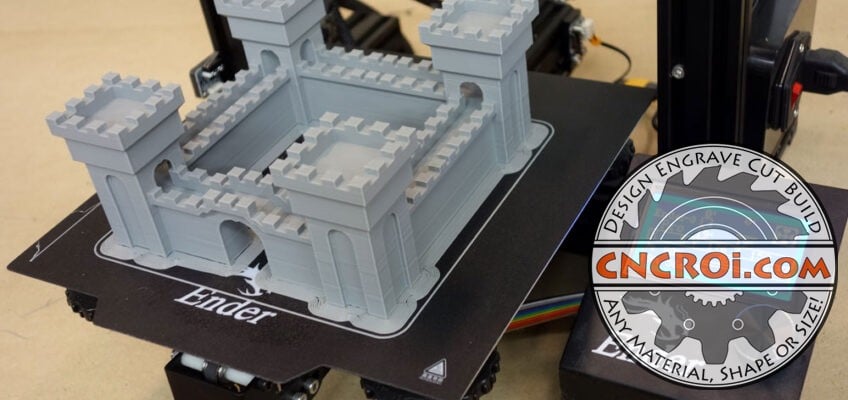

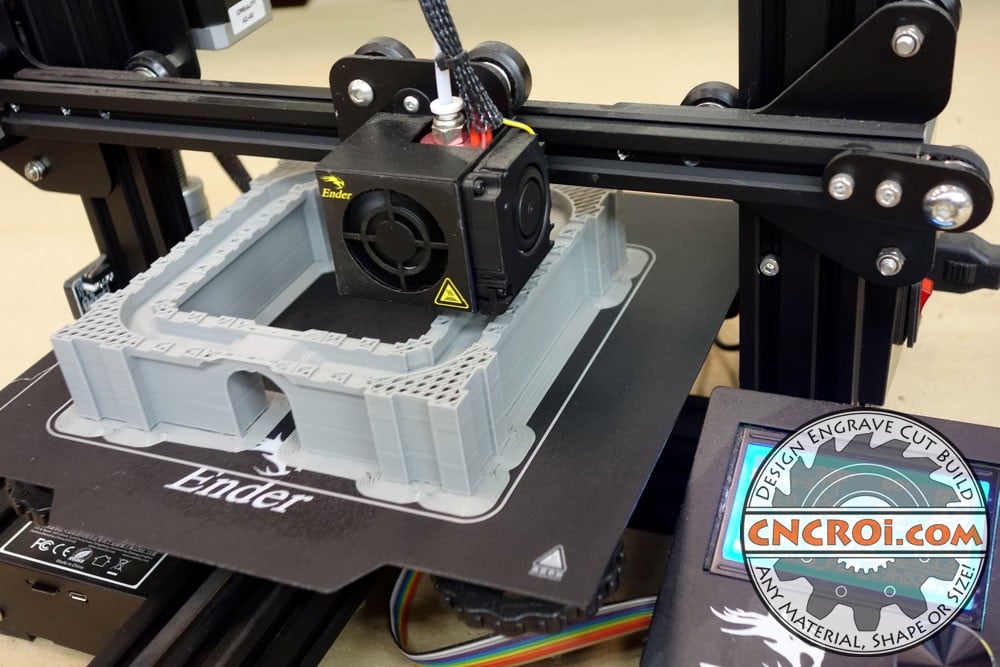

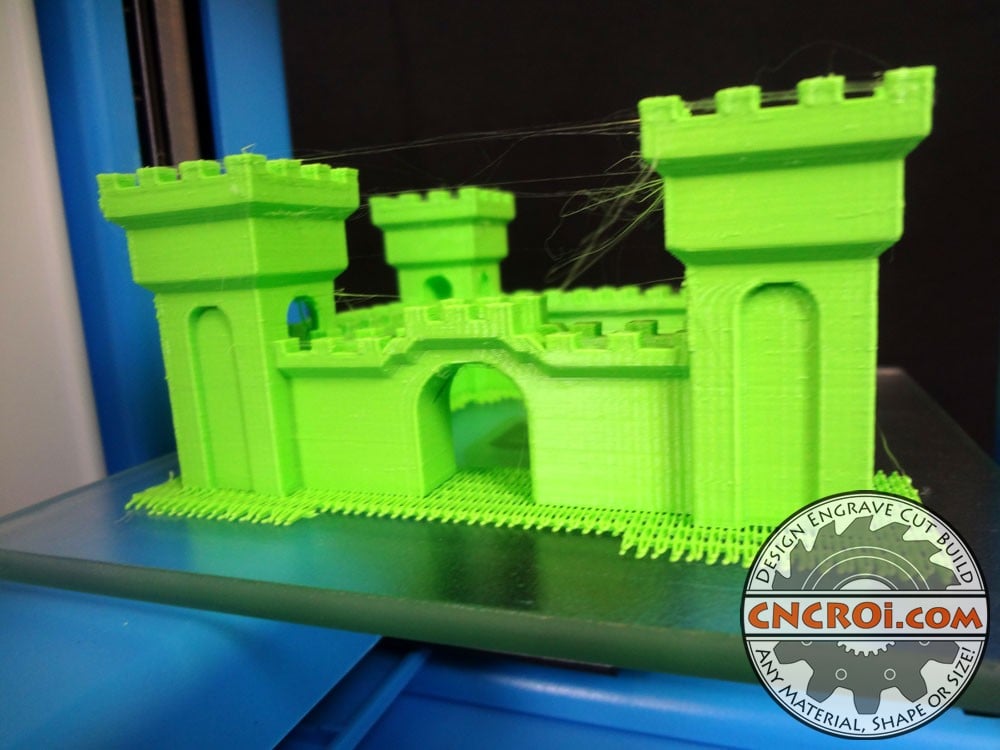

Fast forward to today, and the same model—reprinted at a larger scale using the Creality Ender 3 Pro—illustrates just how far the world of 3D printing has evolved. It’s not just about print quality or bed size anymore; it’s about reliability, affordability, and realizing visions that once felt just out of reach.

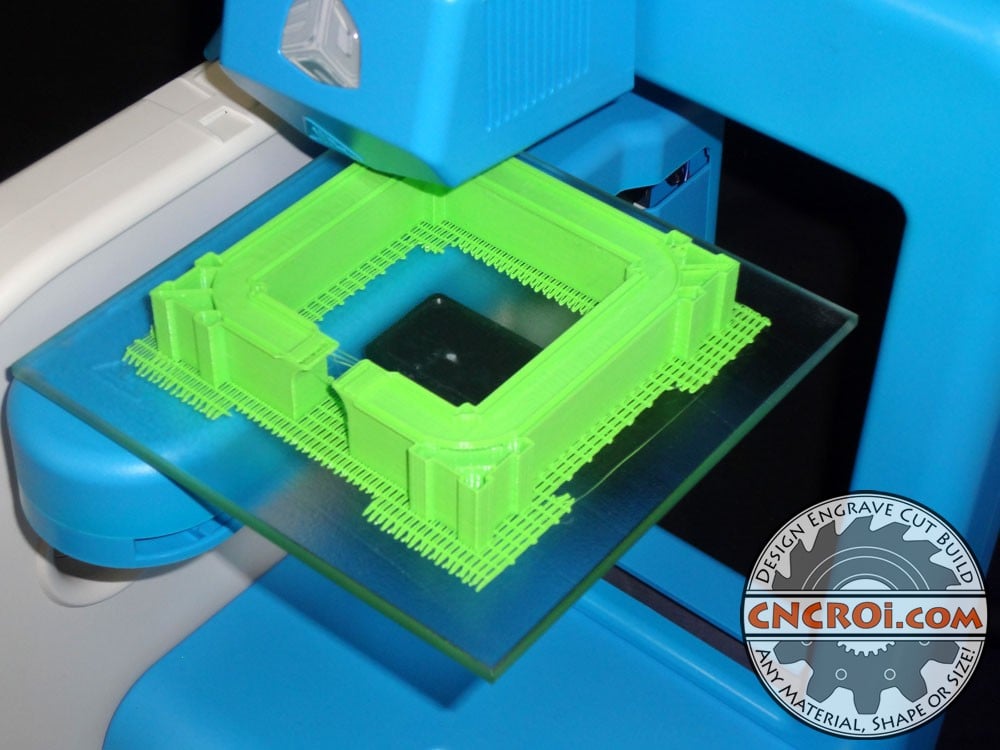

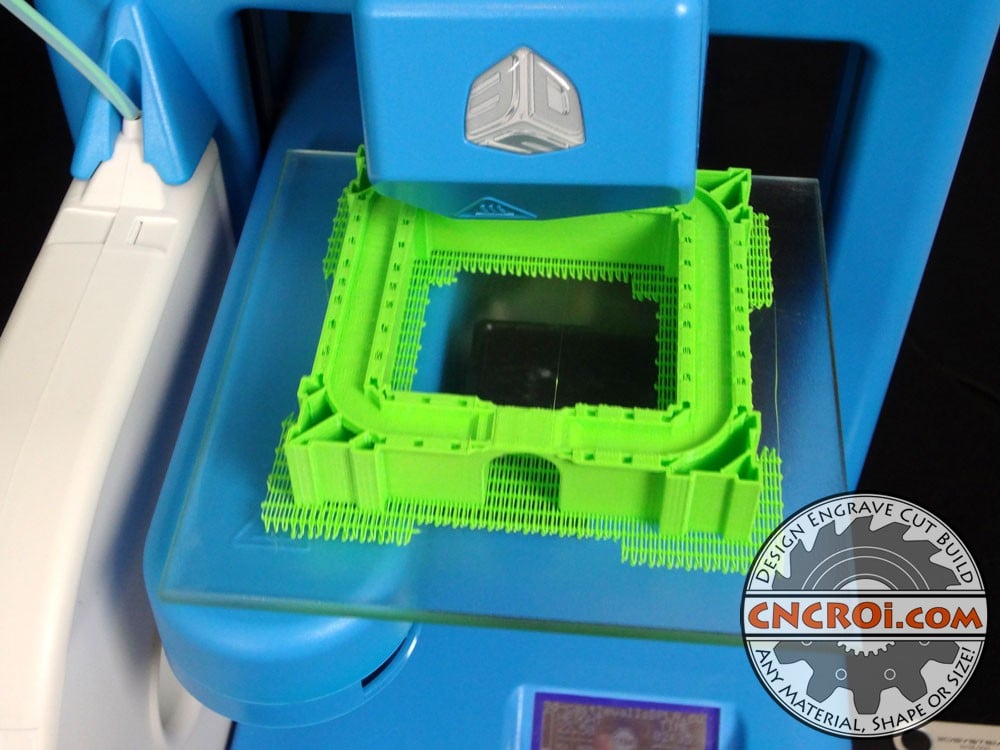

Back in the day, the original cube printer was considered cutting-edge. It had its quirks, like needing a glue stick to help prints adhere to the glass bed—timed just right or you’d get spaghetti.

It had no heated bed, and layer adhesion was more hopeful than guaranteed. Despite all that, Jon, founder of CNCROi.com, created an entire lineup of medieval castle-themed STL files that pushed the Cube to its medieval limits.

The concept? Bring to life castle designs inspired by Jon’s passion for medieval architecture, translating digital dreams into physical reality.

The Cube did its best, producing small-scale models with impressive detail for the time. But limitations in platform size, slow speeds, and frustratingly high failure rates made 3D printing a time-consuming and patience-testing endeavor.

Jon originally envisioned using 3D printing to complement his CNC-based toy company, customizing wooden toys with fully printed alternatives in color and shape. Unfortunately, a multicolor-capable 3D printer was priced like a small car. So, the idea was shelved—temporarily.

The models and even the Cube printer itself eventually vanished during a shop clean-up, buried under the weight of disappointment and glue sticks.

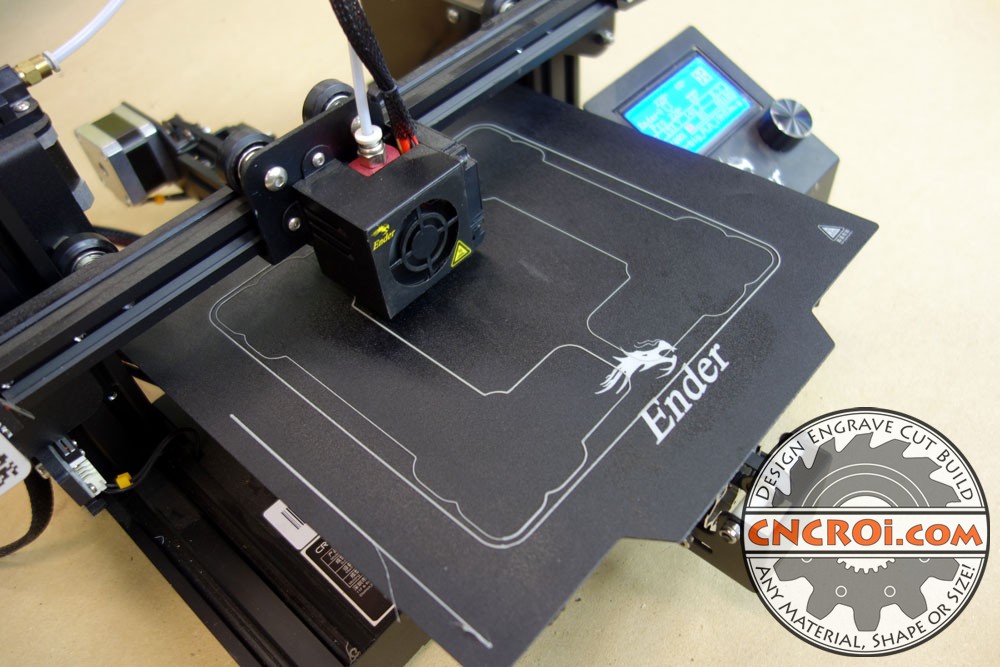

Twelve years later, things changed. Affordable machines like the Ender 3 Pro opened the door once more to revisit those long-lost designs.

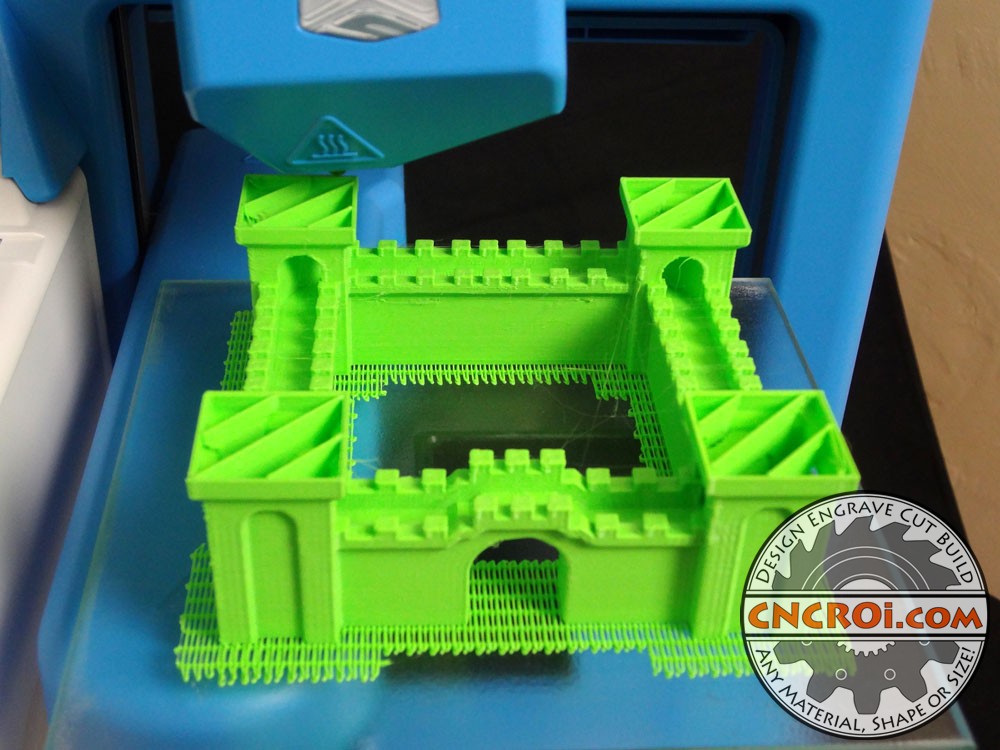

Reprinting the Medieval Castle Walls B model on a larger bed, with better adhesion and improved layer precision, proved to be a rewarding resurrection. This new machine, priced in the low hundreds instead of tens of thousands, reignited the creative flame.

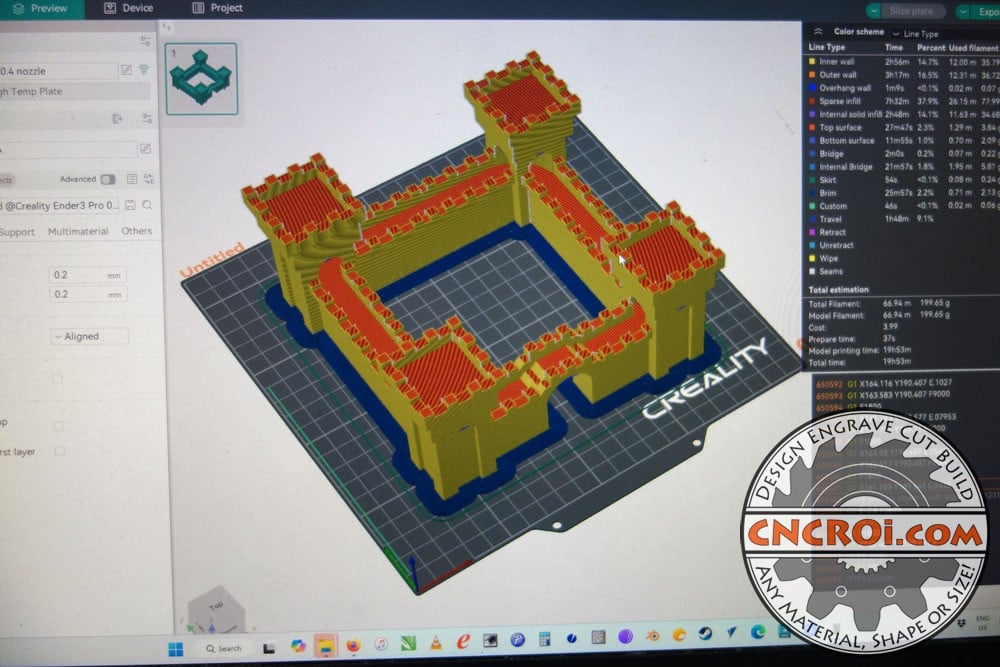

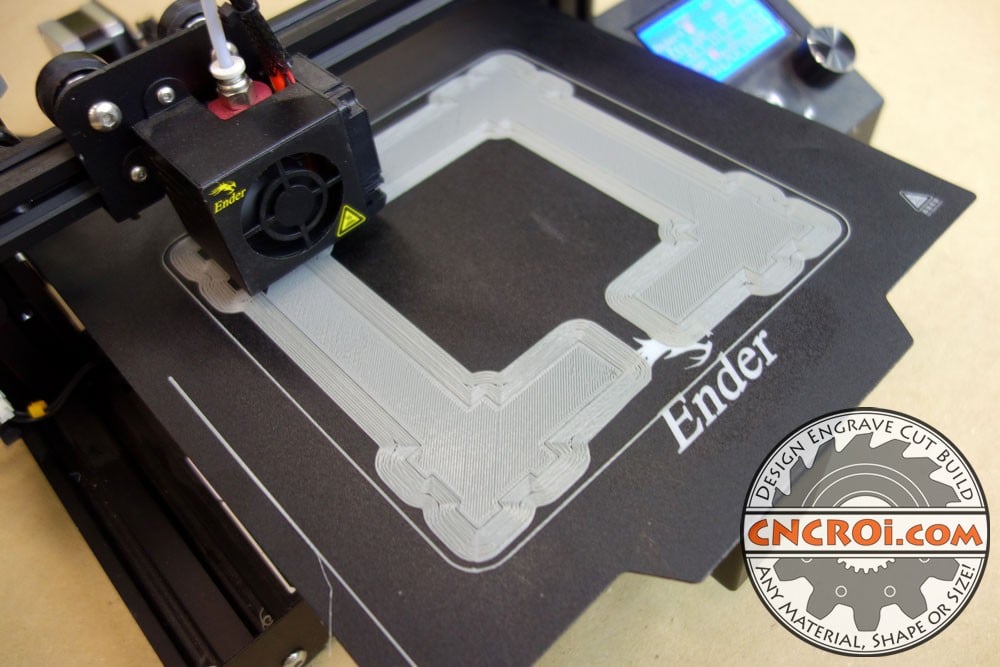

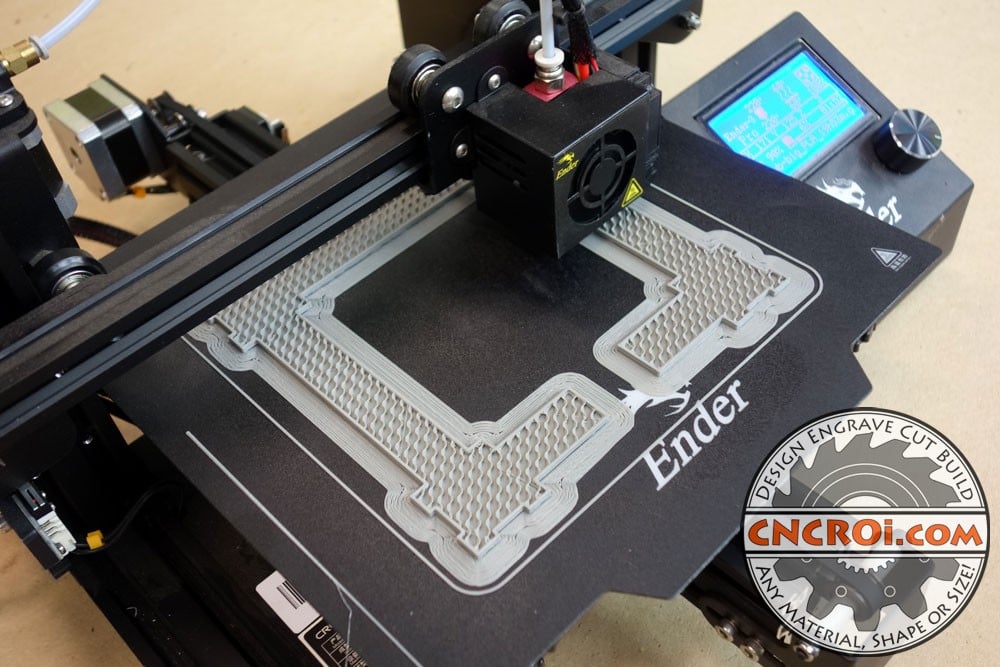

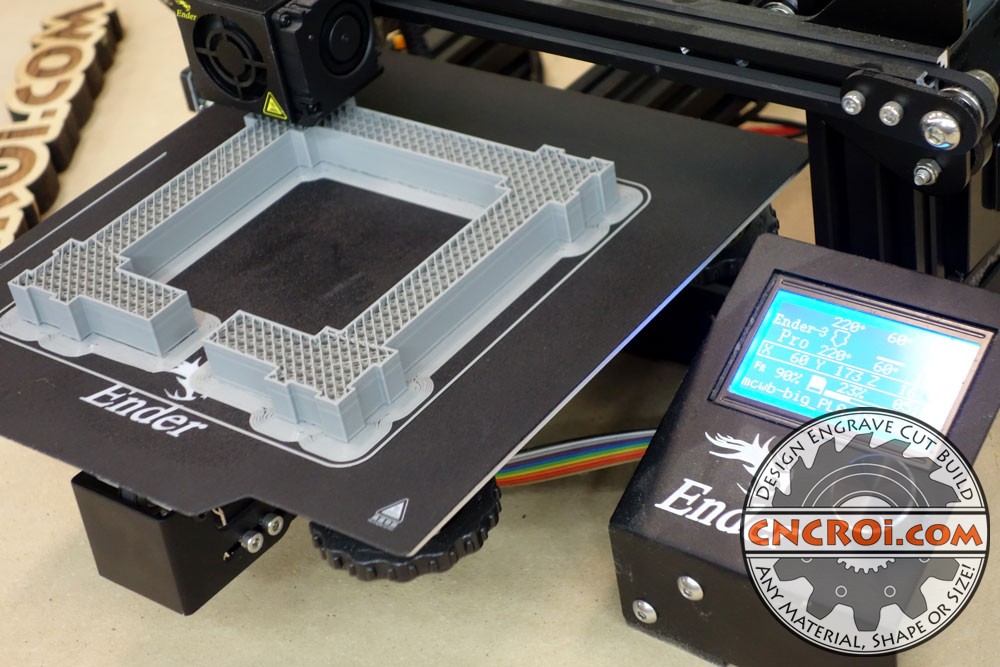

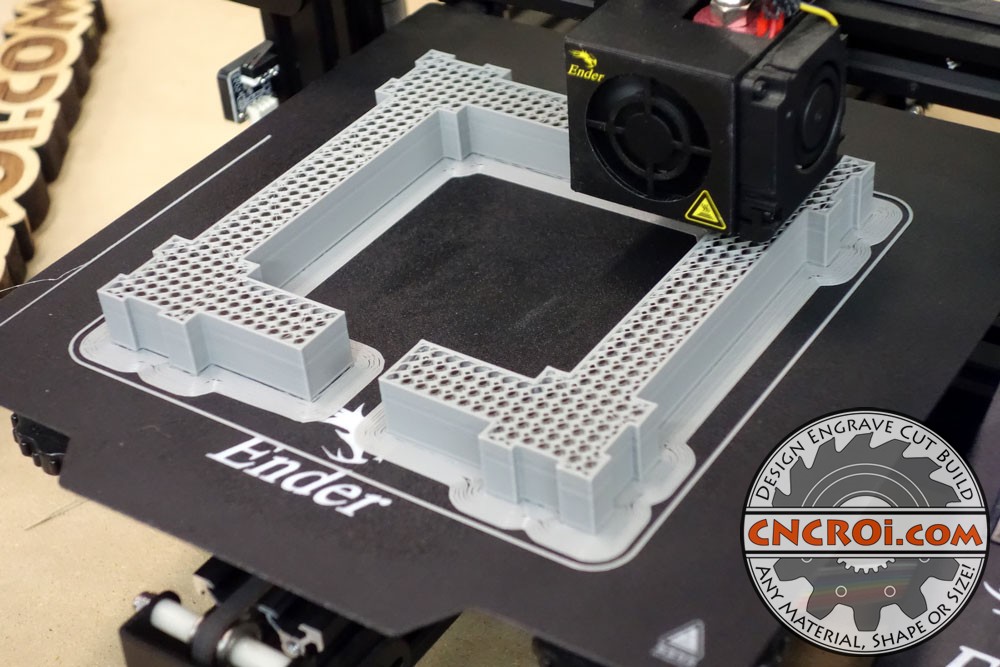

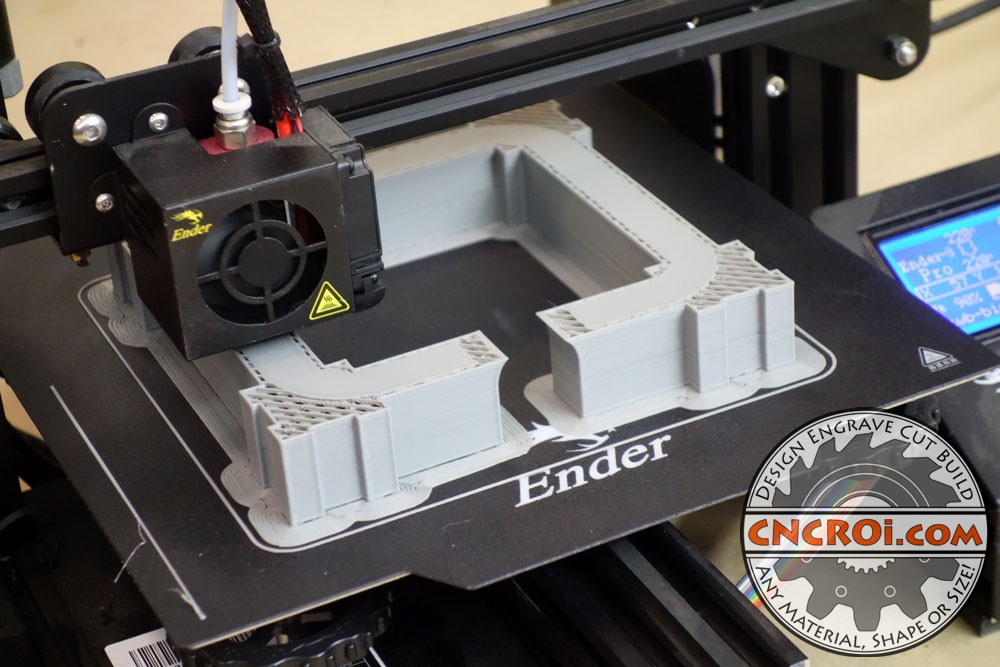

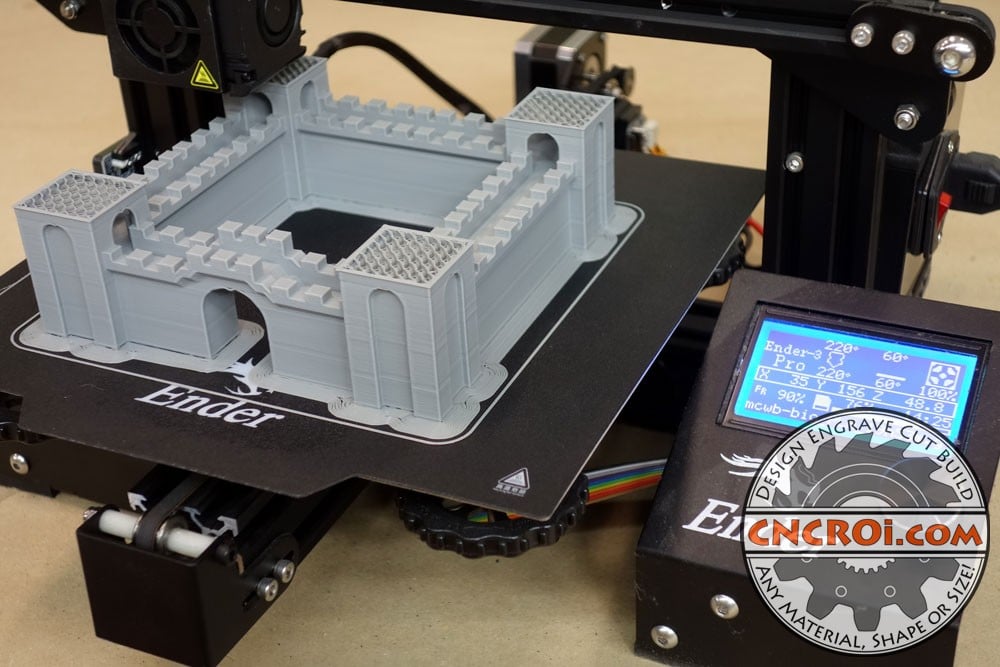

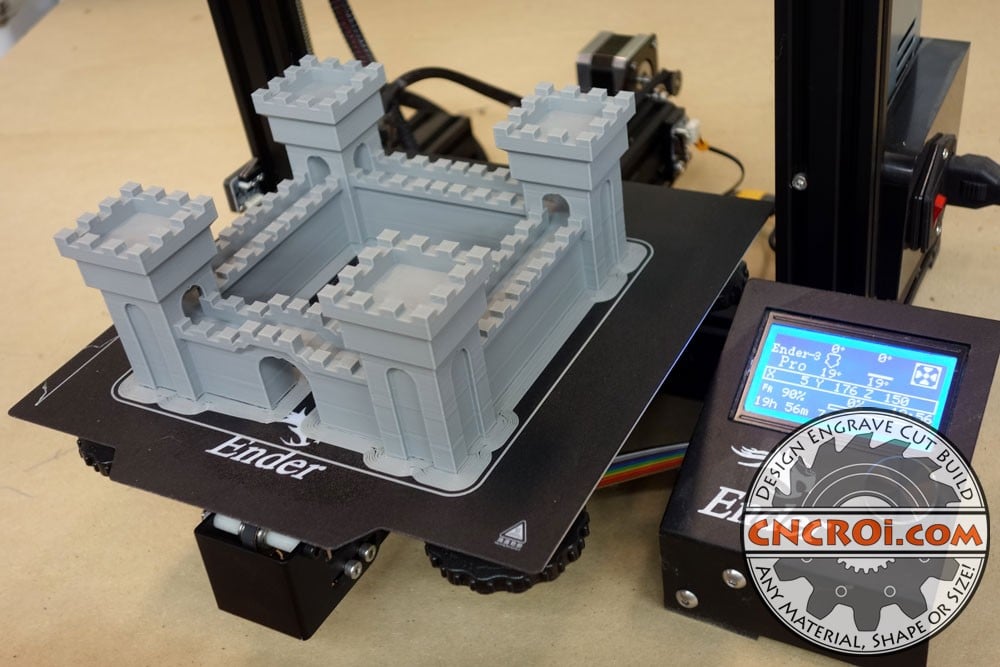

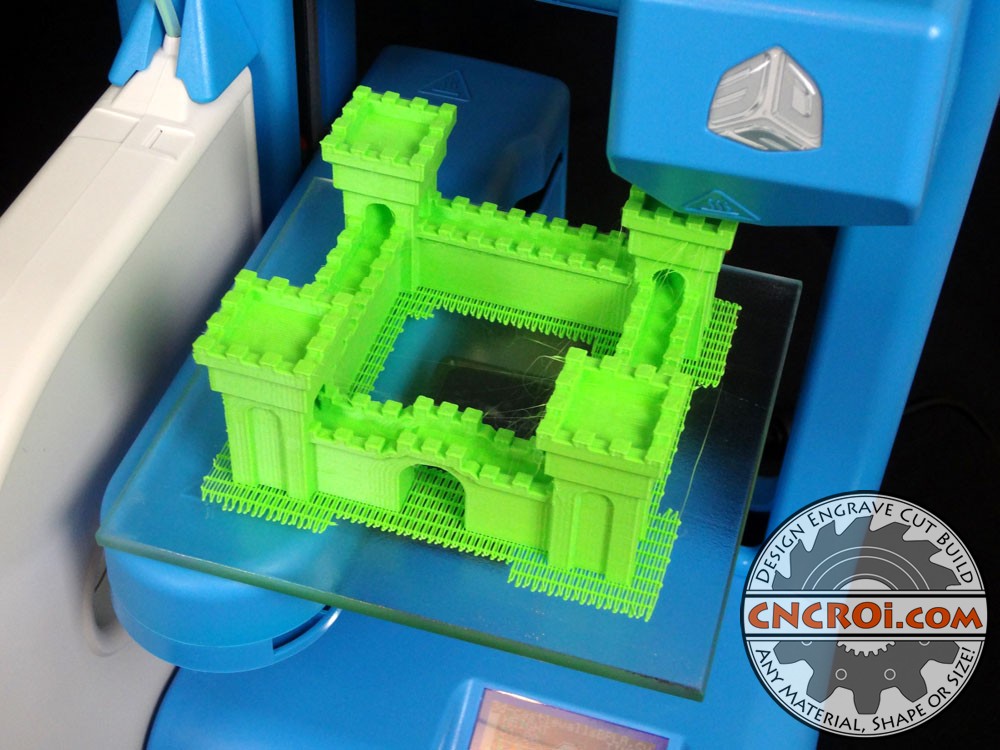

With the Ender 3 Pro, the model printed seamlessly over 19 hours thanks to the heated bed and modern firmware. Unlike its predecessor, the print didn’t lift or shift mid-job. It held fast to the bed, emerging intact—no spaghetti, no rework. And better yet, the PLA output was shockingly crisp.

For a model originally created in 3D Studio Max and exported with the same STL file from over a decade ago, the improvements in detail and structure were obvious.

CNCROi.com didn’t change the design; the model was tested as-is. That consistency made it the perfect benchmark for measuring progress in 3D printing.

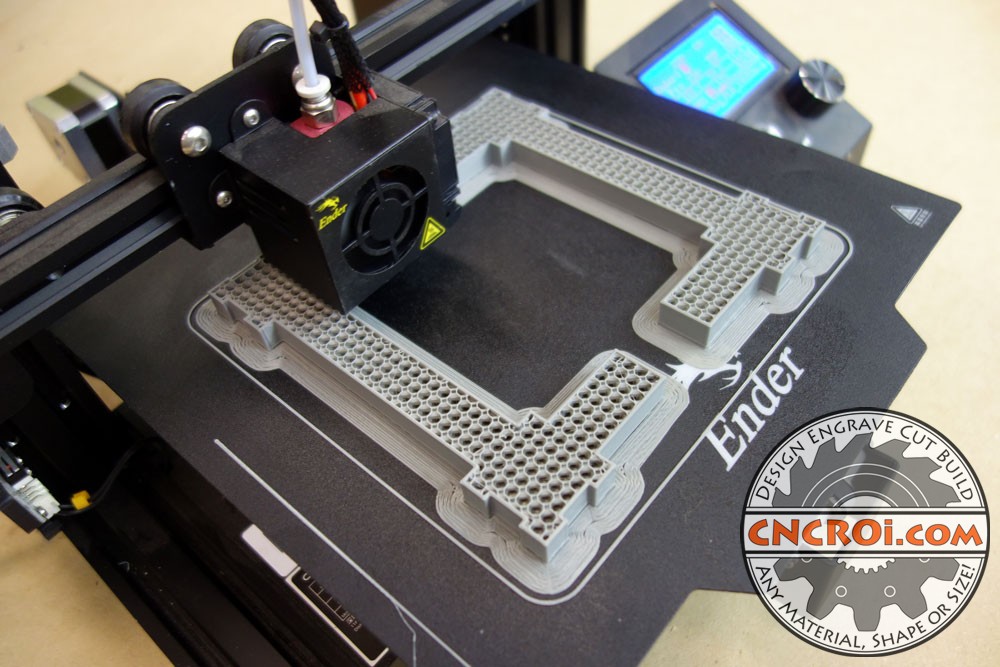

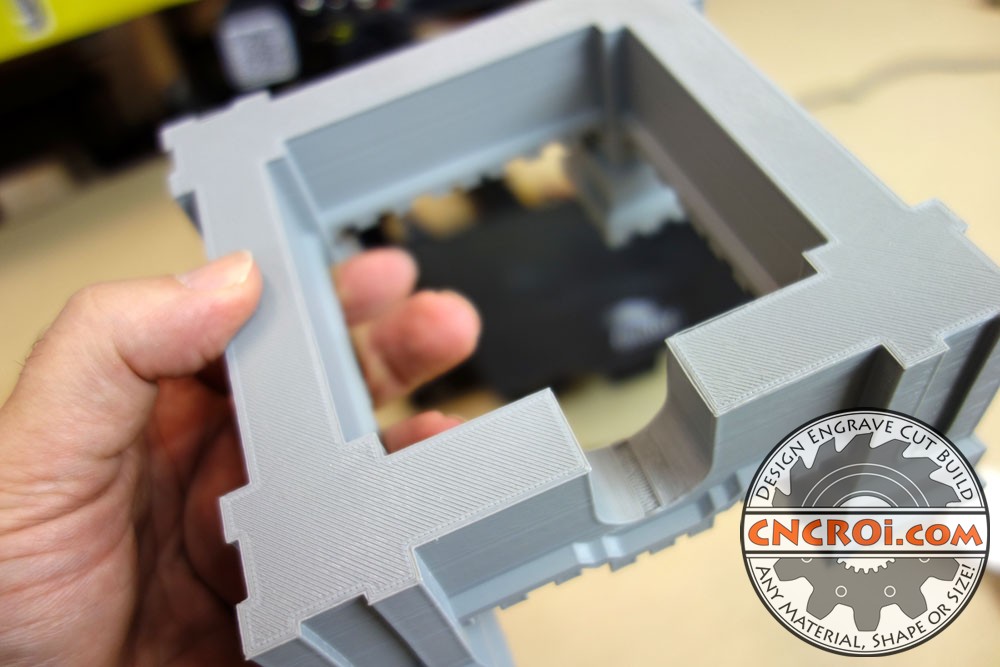

The results speak for themselves: stronger walls, finer arches, better bridging—even if a few quirks remain. Compared side by side, the 3D Systems Cube produced chunkier, more rigid archways, likely due to thicker filament that resisted sagging better than today’s finer PLA strands.

Despite that, the overall output from the Ender was dramatically better. Support material peeled off easily, the bottom layers showed flawless adherence, and the clean-up was minimal.

Even the print soundscape changed—gone were the loud, robotic screeches of yesteryear, replaced by smoother, quieter operations. It felt like stepping from a medieval siege engine into a modern-day manufacturing line.

CNCROi.com took this as an opportunity not just to print—but to dream again. As memories returned, so did design ambitions. Jon began planning Version C of the castle wall series, aiming for even more complexity: walkways, battlements, ramps, internal structures, and more.

With 3D printing, complexity is “free,” as Jon once heard during a visit to 3D Systems’ headquarters in Rock Hill. That quote stayed with him, especially now that printer costs no longer gatekeep innovation.

Back then, a $30,000–$40,000 printer could barely do what a sub-$2,000 machine does today. And it still required a binder jet, powder cleaner, and post-processing just to make something passable.

Today’s PLA filament and open-source slicers make hobby and commercial prints faster, better, and more creative than ever before.

CNCROi.com’s revival of this castle project is more than nostalgia—it’s a case study in perseverance and how far additive manufacturing has come.

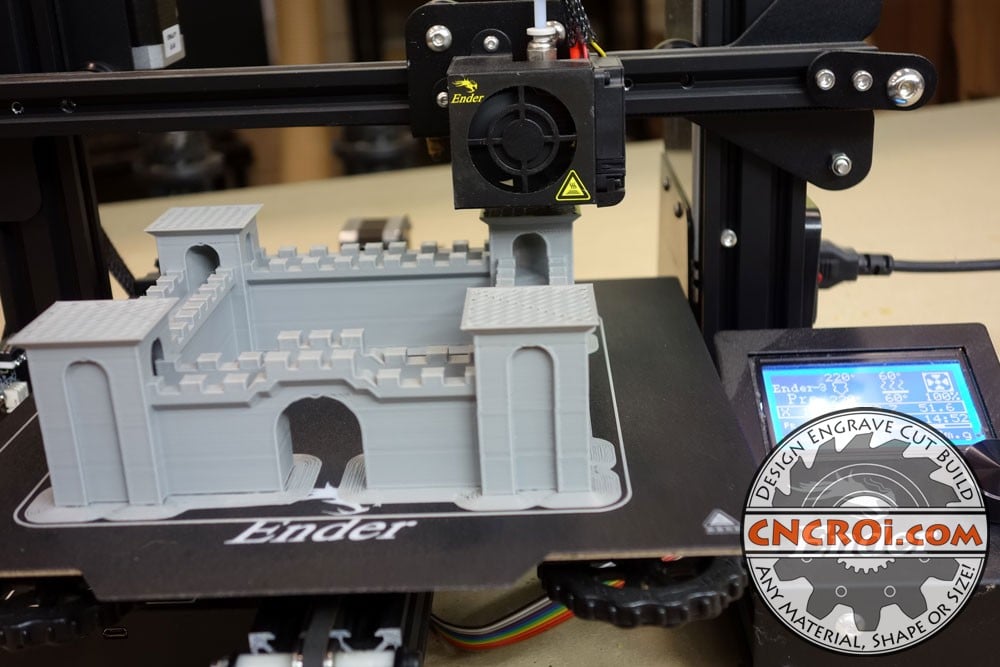

From a 75% success rate on the Cube—usually plagued by sudden failures in the final hours—to a fully realized 19-hour print that didn’t blink once, the difference is astonishing.

Each turret and wall segment in the new model printed cleaner, supported better bridging, and showed fewer layering artifacts. Though some arches sagged a little—owing to the thinner material strength—future tweaks to model thickness and support placement are already planned for the next iteration.

Unlike routing or laser cutting, which rely heavily on support jigs and fixturing, 3D printing allows for far more geometric experimentation.

That experimentation is a big part of what fuels CNCROi.com’s ongoing work. Whether it’s laser cutting a faux stone wall from plywood or routing out gothic windows in thick oak, medieval architecture remains a recurring theme.

There’s a creative thrill in designing castles, drawbridges, and turrets—and a professional one in delivering museum-quality results with modern tech.

Even with modern advancements, the journey isn’t always perfect. During one of the turret prints, a minor mesh error almost caused failure, but slicing software automatically compensated and corrected it—something unheard of during the Cube era. Back then, a mesh error was game over.

Today, smart slicers and auto-repair features save hours of frustration.

Looking at the latest model, it’s evident that fine detailing—from arrow slits to decorative corbels—is more feasible than ever.

With each version, CNCROi.com pushes the boundaries of what’s physically and visually possible using desktop-grade machines. And with a little medieval flair and some modern filament, the results feel like a bridge across centuries.

The new prints don’t just work better—they feel more durable, easier to clean, and more adaptable. PLA still isn’t perfect for everything, but it opens doors for prototyping parts that might later be cast, CNC-milled, or laser engraved into wood, acrylic, or even aluminum.

Every 3D print begins a conversation that can lead to a finished product made across multiple machines.

This kind of creative pipeline—3D modeling to 3D printing to CNC routing or laser cutting—is exactly what CNCROi.com excels at. The ability to jump between formats allows for projects to evolve organically.

A printed prototype becomes a routed hardwood gate. A laser-cut window insert becomes a printed mold. No tool is isolated, and no design is locked to one path.

Jon’s love for medieval design isn’t just a hobby—it’s shaped CNCROi.com’s product line.

Clients looking for themed signage, props, architectural accents, or educational models have found his designs both functional and fun. And with better printers now at hand, scaling up has never been easier.

Though Jon tossed the old Cube and its early models during a workshop purge, the lessons learned from 3D printing’s early days remain.

Failures taught the importance of proper adhesion, optimized support paths, and mesh cleanliness. Today, those same insights make each new print faster, better, and more consistent.

From archways and battlements to gates and wall sections, each model adds another layer of realism and modular potential.

Jon is currently planning features like internal staircases, exterior walkways, and miniature defense mechanisms. Because why settle for a basic wall when you can build a fortress?

As the models evolve, so do the print strategies. With better understanding of material flow, layer cooling, and bridging mechanics, Jon can push the envelope further.

Each version becomes not only a visual upgrade but a mechanical one—adapting form for function without sacrificing historical style.

The transition from the 3D Systems Cube to the Ender 3 Pro also highlights a shift in philosophy. Where once every print was a gamble, now it’s a production method.

Where once glue sticks and wishful thinking kept things together, now heated beds, smarter slicers, and auto-leveling beds ensure reliable outcomes.

This stability opens new possibilities for CNCROi.com’s clients. Whether you’re an educator needing a historical replica, a film set designer sourcing prop architecture, or a game developer prototyping terrain, CNCROi.com has the tools—and the passion—to bring your project to life.

With each castle wall print, Jon gets a little closer to building an entire fortress. Modular systems make scaling easy. Corner turrets, wall extensions, raised platforms, and decorative gates—all interlocking, all printable, all routed or laser-etched upon request.

The future of 3D printing at CNCROi.com is more than models; it’s merging the past and present with technology.

The company continues to explore how classic architecture and digital manufacturing can coexist—and thrive—in a shop filled with machines ready to turn any dream into reality.

So whether you’re inspired by medieval walls, need custom architectural models, or just want something uniquely creative for your next big idea, CNCROi.com is ready.

They’ve resurrected 12-year-old STL files and transformed them using today’s tools. That’s not just a callback—it’s a leap forward.

The journey from 3D Systems Cube to Creality Ender 3 Pro isn’t just about hardware. It’s about revisiting ideas, embracing new capabilities, and building something better from lessons learned. CNCROi.com now stands at a point where anything Jon can imagine, the shop can create—faster, cleaner, and more reliably than ever before.

If you’ve got a concept—even if it’s still on a napkin—CNCROi.com can model it, print it, engrave it, and ship it.

With a CNC laser, router, and now a reborn 3D printing pipeline, every creative detail becomes a possibility. And if it has a turret, even better.

So reach out to CNCROi.com today. Whether it’s a full castle, a small archway, or a dragon-emblazoned gate, they’re ready to help you build it—layer by layer, pass by pass, turret by glorious turret.

What makes this journey even more rewarding is how accessible it has become for CNCROi.com to take a customer’s rough idea—something as vague as “I want a castle wall with dragons”—and turn it into a tangible, high-resolution model using tools that were once out of reach for all but enterprise-level firms.

Now, with affordable, capable machines like the Ender 3 Pro and CNC-grade software suites, even the most intricate concepts can be modeled, printed, and modified on the fly. This accessibility means faster prototyping, quicker client approvals, and more impressive final products.

The fusion of medieval aesthetics with cutting-edge digital fabrication also aligns perfectly with growing demand in the gaming, education, and event industries.

Whether it’s a tabletop roleplaying game terrain piece, an architectural study model, or part of a trade show booth with castle flair, CNCROi.com’s blend of 3D printing, CNC routing, and laser engraving delivers authenticity with durability.

There’s no need to compromise between historical design and modern engineering when both can be done in-house, all under one creative roof.

Beyond visual appeal, CNCROi.com also designs for functionality. Internal walkways, modular connectors, and part integration allow for these 3D-printed walls to become part of larger interactive builds. Some clients request models that can snap together like toy blocks, while others want them to scale into full set designs.

The versatility of the design process—from idea to finished part—means CNCROi.com can tailor each build to its environment, whether it’s a display case or a castle-themed boardroom.

As 3D printing continues to mature, CNCROi.com is keeping pace by experimenting with new materials and hybrid workflows. PLA is a start, but PETG, ABS, and even composite filaments are being explored for strength and durability in more demanding applications.

Combined with CNC milling of hardwood or laser engraving into stone-textured laminates, the result is a multidimensional approach that gives every project—yes, even a tower—structural integrity and visual depth.

Twelve years ago, Jon set out to merge artistry with technology. What began as a frustrated walk away from early 3D printing has turned into a triumphant return, powered by machines that finally live up to their promise. CNCROi.com has bridged that decade-long gap by honoring the original vision, applying modern capability, and continuing to expand what’s possible. T

he Middle Ages might have been dark, but the future of medieval modeling has never looked brighter.