2-Sided Business Card UV Printing Jig: 3/4″ MDF

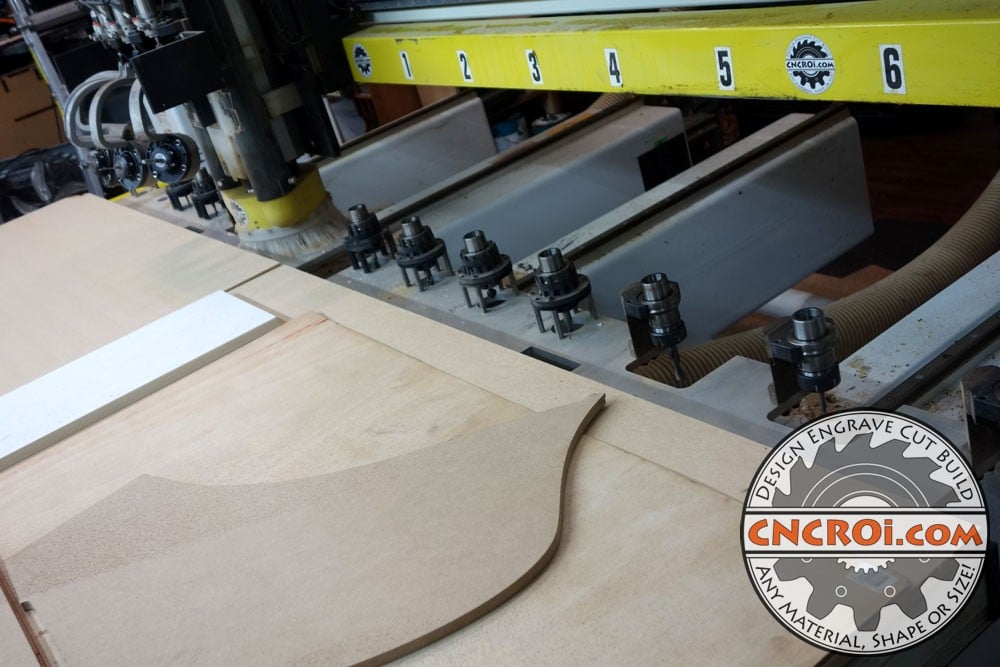

This 2-sided business card UV printing jig is made using 3/4″ MDF, carefully carved out using our Thermwood CNC router.

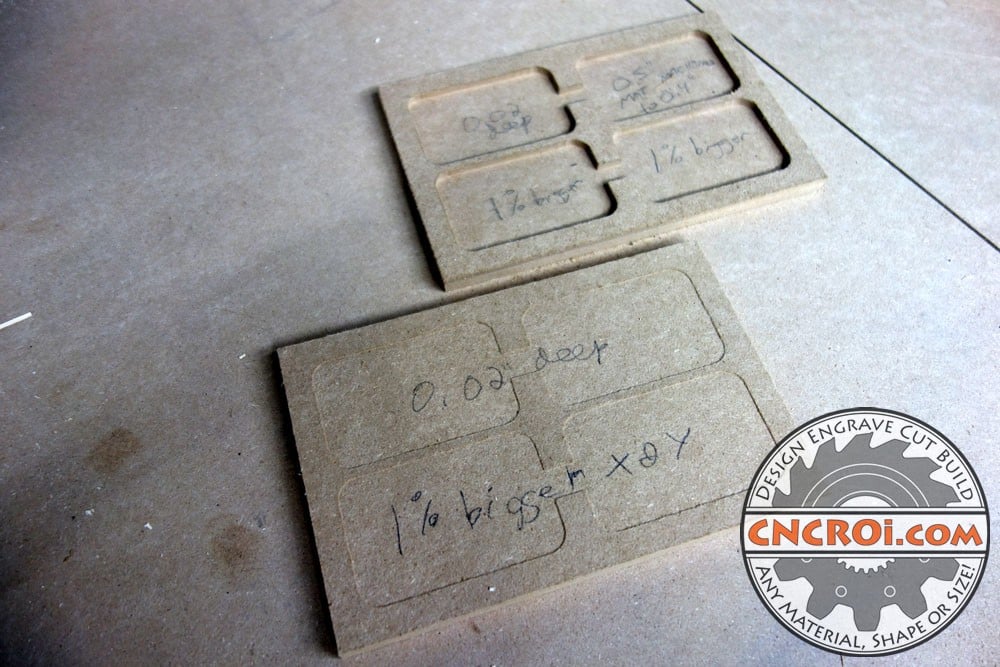

When it comes to making a highly precise jig for one of our customers, when ever it’s a new item, we first make a prototype for evaluation by the customer.

Literally any piece of MDF can be used to test out a prototype, so that’s why you see this piece looking like a piece of scrap, that’s because it is.

CNCROi.com’s been known to also make custom jigs using our laser too.

I don’t like wasting material, so any piece of material that could possibly be used for something else, will at CNCROi.com.

After two sets of custom prototypes are made, they are shipped to the customer for evaluation so that we can then make an absolutely perfect 2-sided business card UV printing jig at CNCROi.com.

Skip over by a week and since then, we’ve done at lot of custom production at CNCROi.com using our router, you can see how messy that sacrifical table is in the above photo, so before going ahead and making a 2-sided business card UV printing jig, we need to clean it up!

HDPE and Delrin are options as well, when it comes to making jigs, of course, aluminium is possible as well.

After cleaning-up the spoilboard, making it perfeclty level, parallel and square, it’s time at CNCROoi.com to go ahead and make the 2-sided business card UV printing jig.

Of course, this jig is 2-sided, meaning CNCROi.com is carving out both sides of it, on one side, are the vacuum channels that match-up with their UV printer table.

These channels do two things, first, they help to suck down the overall jig and secondly, match-up the holes in their vacuum table to further act as a suction for their actual cards that fit onto the other side.

That hole that goes THROUGH the jig, from one side to the other of this 2-sided business card UV printing jig, are drilled from the opposite side.

For larger jigs, we can make puzzle pieces that allow you to be able expand your jig to just about any size yet still have manageable sizes to work with.

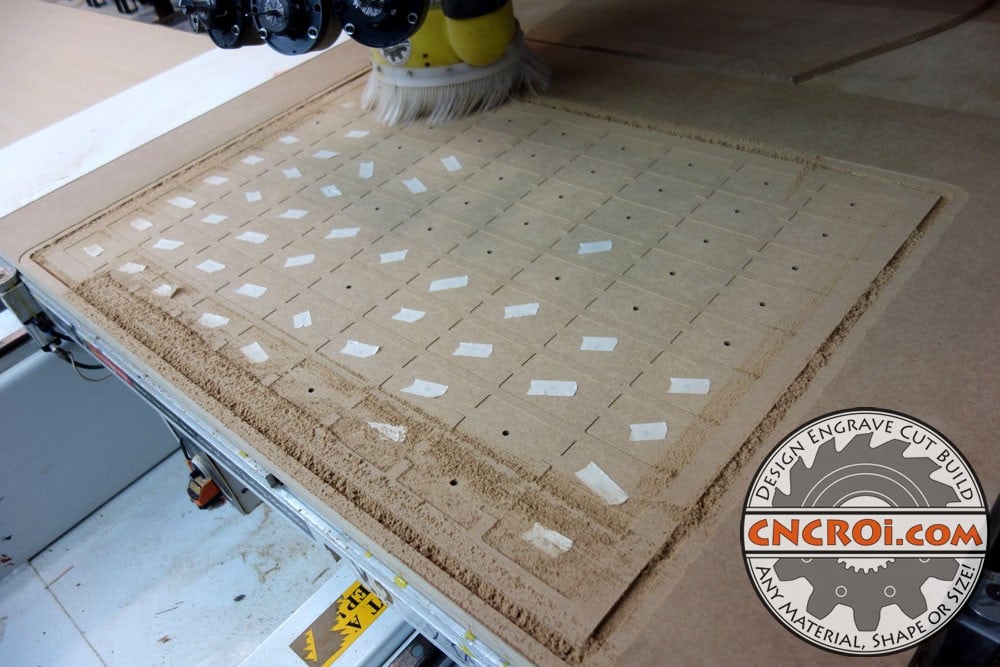

Before going ahead carving out the card location and sizing onto this 2-sided business card UV printing jig, I must flatten it to make sure the MDF is totally flat and parallel.

I didn’t need to do this on the other side as it makes no difference, this is made parallel by default by carving out one side, doing this twice for this 2-sided business card UV printing jig is redundant.

You’ll notice I also carve out channels on the “front” of the jig as well at CNCROi.com, unlike the backside where they are used to build-up and maintain an equal vacuum, on this side, it makes it easy to remove the cards with your fingernail.

The depth of these cards and the channels on the front of this 2-sided business card UV printing jig are 0.02″, it’s almost nothing, and on the backside, they are slightly deeper.

Our jigs can be made to just about any spec requirements you require to fit perfectly within the production platform(s) you use.

MDF is a great material for this 2-sided business card UV printing jig because it’s consistent in density as it’s basically glued-together saw dust.

During production I’m testing out the jig and double-checking depths and other areas of this 2-sided business card UV printing jig to make sure if there are any issues, I get them early when I can still fix them… of course, this jig has no problems.

Now that all the pockets are carved out of the MDF, it’s time to drill out a hole in the middle of each one at CNCROi.com, this will provide additional suction for the cards to make sure they don’t move during production.

Although my industrial vacuum system has no problem sucking-down this UV jig even with lots of holes, I still, out of an abundance of caution, capped the holes with some tape during production to make sure nothing moves during the cutting-out process.

Of course, we can make HUGE jigs as well, CNCROi.com offers total flexibility when it comes to making the jigs you need.

The nice thing about CNCROi.com’s process is that each and every jig we produce for our customers is exactly to their specifications, and if you ever need a new one or an extra one in order to make production more efficient, that’s great!

Cutting out the jig out means that now this 2-sided business card UV printing jig is finished.

After everything is cleaned-up from the saw dust made during production, this belongs in a museum not a UV printer bed, everything is dead-on and precise to spec.

Need a 2-sided business card UV printing jig? Contact CNCROi.com right now!