304SS Deep Etched Machine Tag: Etching through Finishing

A deep etched machine tag, generally out of 304 stainless steel, is yet another option CNCROi.com offers our industrial customers and even some company owners use them as their business cards, due to their bullet proof nature and incredible clarity.

We offer almost endless possibilities, from shape and size to grade and gauge, you want custom tags out of any material, CNCROi.com can make it for you to your specs!

Before we jump into our deep etched machine tag options, watch this other video I did showing you the incredible durability of this process verses “regular” fiber laser annealing and shallow etching.

Alright, now that you are a pro at the various process, let’s dive deeper into the specifics how we went about producing this custom ultimate deep etched machine tag!

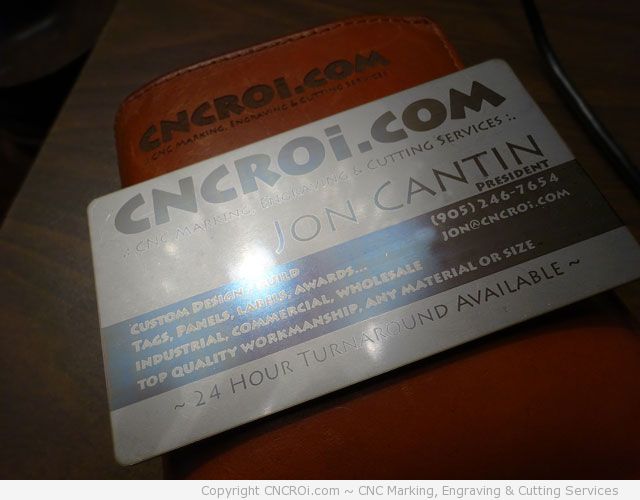

For this test, like the previous ones, I just used our typical business sized 304 stainless steel plate, we use these as samples for our customers to test internally and for us to try other things that customers ask us if we can do.

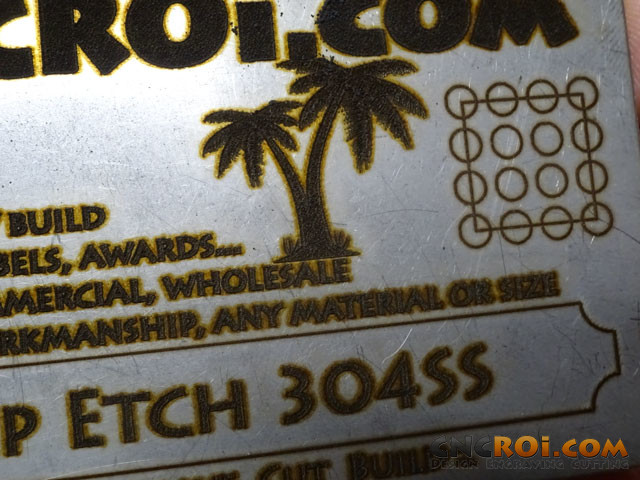

Annealed 304 Stainless Steel business card.

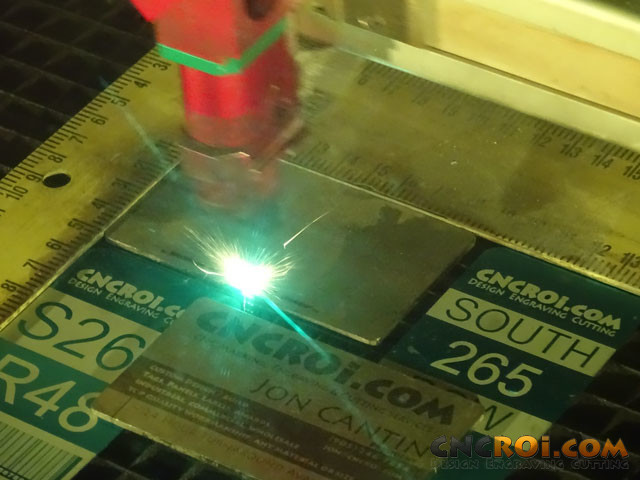

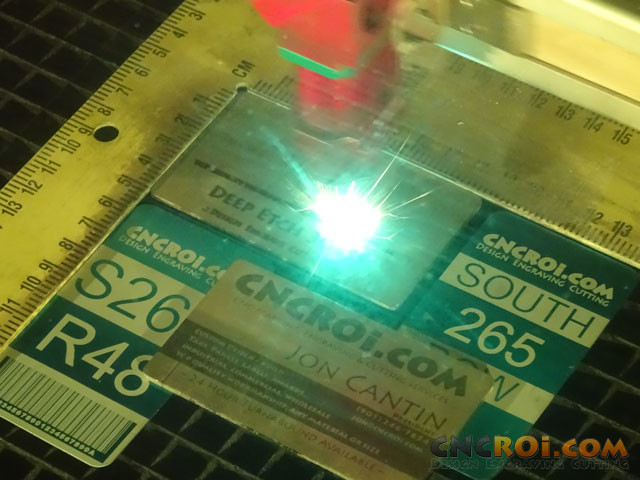

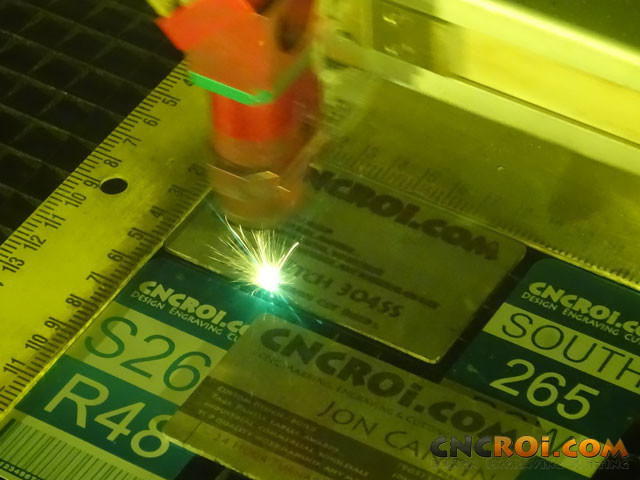

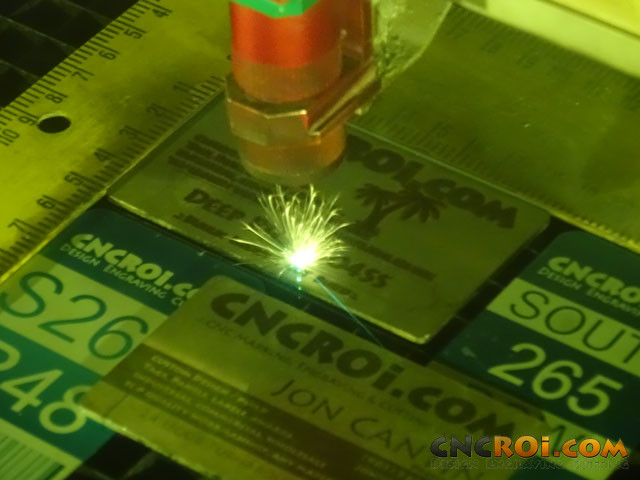

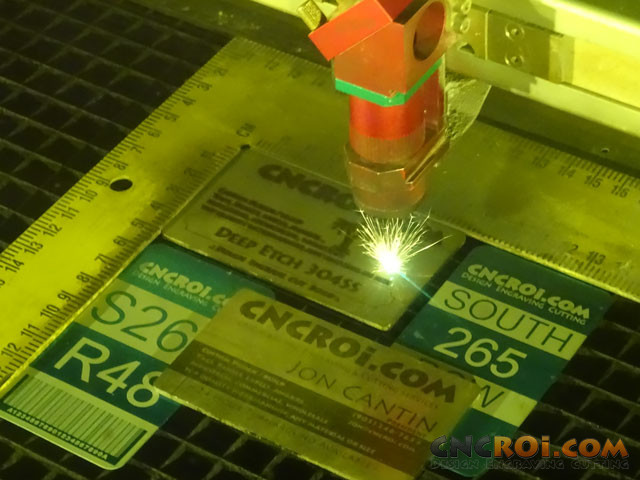

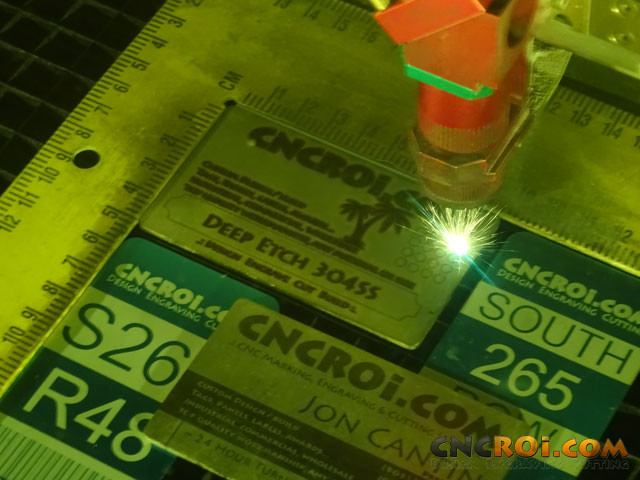

There is a bit of dust on it, just from some earlier work we did and the purpose of the other cards is to try to FINALLY get a clear video of the etching process, with all the sparks produced, videotaping the process always goes out of focus unless I have lots of references for the camera to focus on other than the work being filmed.

There are several ways to go about producing a deep etched machine tag, we have both a CO2 and a fiber laser source on our Austrian CNC laser, this gives us options for some metal types and coatings, one laser source produces a faster and more efficient result than another.

CNCROi.com can also work off your scrap that’s rusting away in the back lot, a quick trip into our industrial sand blaster or touch of angle grinding turns rough into beautiful relatively quickly in our custom CNC shop!

As both of our tubes in our wide format industrial laser are plenty powerful, deep etched machine tag production can also be done using a “cutting” and “engraving” pass, at various depths and levels of resolution.

This allows us to produce beautifully detailed and highly intricate designs as well as big and bulky images and text, which comes in handy when we make a deep etched machine tag that’s used for electrical or block plans.

Not only can we etch at various depths, we can also anneal!

Annealing is the process of heating the metal and oxygenating the surface, producing a dark brown to black permanent result that requires a sand blaster or heavy grid sand paper or angle grinder to remove.

So, you have three options when it comes to custom machine tag manufacturing by CNCROi.com, each with a cost benefit curve that suits your needs, budget and timelines.

By far the most cost-effective is annealing or shallow etching, followed by deep etching. If those are outside of your budget range, we also offer engraving onto custom anodized aluminium tags too!

What’s really fun about etching into metal are all the sparks we produce in the process, it’s like the 4th of July in our machine!

Unlike annealing which produces a black or dark brown result on metal, etching produces a mix of both as you’ll see further down in this blog post about deep etched machine tag fabrication.

In order to produce the optimal “base” of etching, we generally go about making the deep etched machine tag at various passes to make sure we are in the optimal focus zone for the most efficient production (depth to speed to power ratio).

CNCROi.com makes a lot of custom machine tags across a host of materials, these optimal settings come about from experience and feedback from our customers.

The light and sparks are both incredibly bright during the process of deep etched machine tag production, the results may look messy but that’s why we have an industrial sand blaster on the ready to quickly clean-up the tag rather than having to resort to chemicals and sprays.

The challenge with deep etched machine tag isn’t in making them, it’s in producing the absolute best result for our customers for their given application! That’s why we are always testing new things to improve!

It’s touch to photograph but going over a previously etched area produces more etching but also a more messy result, it looks like CNCROi.com is producing wonderfully expensive scrap but in reality, all this dark metal soot and powder producing during the deep etched machine tag fabrication comes off quite easily with the right equipment.

It’s fun comparing the production of this deep etched machine tag with what we do for our welding tag customers as it couldn’t be any more different yet, it’s done with the same machine!

Something to keep in mind though is that we do lose a little resolution the deeper we do the etching into the metal, this is because of two factors, the first, the heat of the laser source is vaporizing not only exactly where we want the metal removed but also a little beside it and the sand blaster also “sands” the edges slightly too.

The resolution “drop” in deep etched machine tag is hardly noticeable though, that’s why annealing produces a sharper result but for about 95% of the applications where deep etching is done, it’s hard to see the difference unless you know what to look for.

There is also a tremendous amount of heat produced on deep etched machine tag itself, so it has to be left to cool down a little before grabbing it of the bed of our industrial CNC laser.

If you are curious as to the origins of the blue anodized aluminium tags also found in this picture and video for the camera to have something to focus on, watch this video!

Just about everything mentioned in this video by the way is just as applicable towards deep etched machine tag fabrication, except the contrast isn’t as great.

As you saw in the durability video, what you lose in contrast you gain in incredible durability but it’s all relative, any of these processes are wicked overkill compared to lamacoid or UV printed alternatives.

In addition to the deep etched 304SS tag CNCROi.com is making right now in these photographs, I also stuck an annealed 304SS tag done a long time ago for both contrast and to show you how “dirty” the process is of etching by comparison.

You can safely run your fingers across the surface of an annealed custom metal tag as it’s smooth to the touch but the etched tag, don’t bother until it’s been sand blasted ans you’ll get some deep etched machine tag shards stuck that will be painful to remove!

Just for fun, I also decided to do a few passes using a finely cut path as well, the focus isn’t to cut through the deep etched machine tag but to just add a reference point for sanding.

95% if the time, we are solid engraving (etching) into the metal, and not using cut paths as they are too thin for most custom applications our customers send our way to make on their behalf.

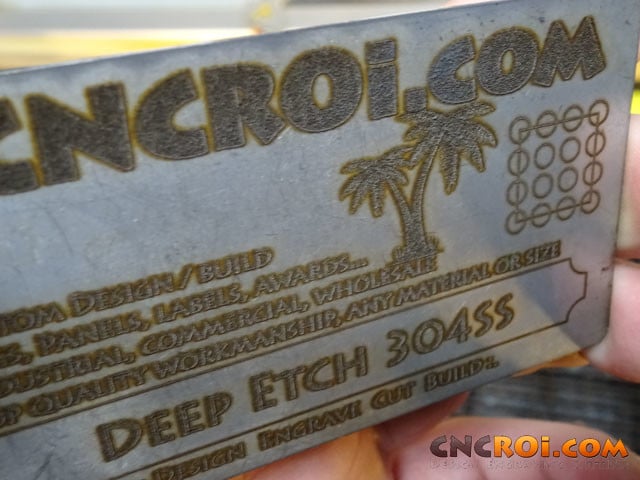

After the deep etched machine tag is given a bit of time to cool down, you can see how rough and dirty the deep etch 304SS really is, the surface is much to be desired but under all this is a diamond from the rough!

Looking at the deep etched machine tag a bit closer, you can see the difference between the deep etching and the lighter “cut” lines, again, added just for reference.

Anybody can make a rough etched tag, not many can make it deep enough to withstand both an industrial sand blaster pelting the surface (to clean it) then a sanding to remove the resultant matte finish.

At another angle, you can see the difference in surface qualities across the deep etched machine tag.

Alright, one final look before we stick this deep etched machine tag into our sand blaster!

Although the vast majority of our customers never care about the “back” of the deep etched machine tag, we do, hence putting a plastic grid table above our sand blaster’s metal one so there aren’t scratches!

CNCROi.com cares both about the details you see and those you don’t!

If you are wondering what it looks like if we annealed ONTO a sand blasted metal tag, here’s the video for comparison.

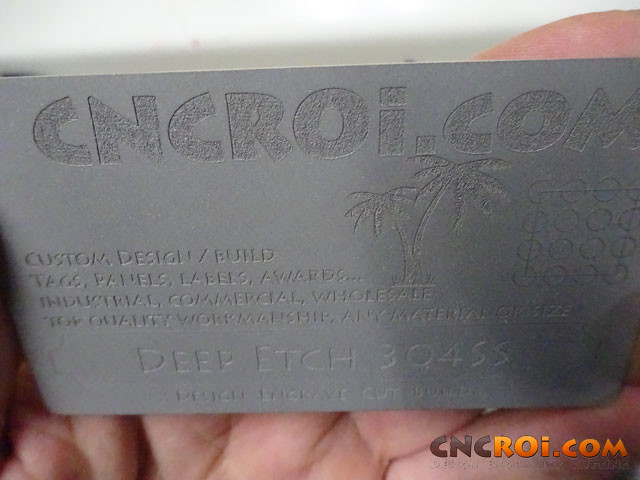

The sand blaster does an amazing clean-up job on this 304SS deep etched machine tag, some customers like this, some don’t which is why we’ll go through yet another process of sanding the surface to a nice brushed metal surface to add some shine to the top while keeping the darker grey etchings.

The nice grey color is quite a contrast to what we do with anodized aluminium isn’t it? So whether you want a custom tag out of solid steel or colorful aluminium that’s been anodized, CNCROi.com has you covered!

At least with CNCROi.com, you have OPTIONS though I have to admit, lots of customers really like blue for some reason for their custom equipment identification tags!

The tough choices we give to engineers and marketing departments never end!

As another area of contrast, take a look at this stainless steel with #4 brushed finish to the sand blasted look of this annealed tag.

I really love sharing these samples with customers who are blown away at CNCROi.com‘s capabilities!

Your application and branding needs will dictate which material is best and what options, etching through annealing, best fit your needs.

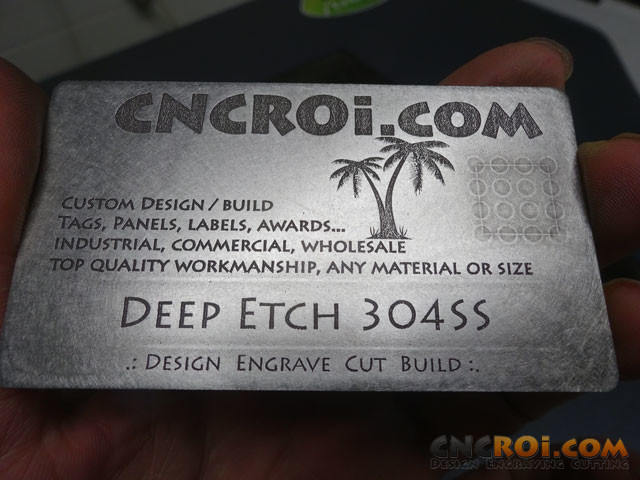

And here’s the deep etched machine tag after it has been sanded, you can see where the lighter etched area was almost entirely removed, just a little longer and it would be gone!

If you are wondering how this compares, to say custom annealed polycarbonate machine tags we also make, check this video out.

And if you are a long time customer and reader of this CNCROi.com blog, you will recognize some elements of our design which comes from our sample swatch test.

Some of the finer details were omitted on purposes, just because generally when it comes to deep etched machine tag production, the focus is on more clearly legible details that are “fatter” than the microfiche type details we add to say, an annealed or anodized aluminium tag.

I tried my best during the video to keep moving the deep etched machine tag so you can see how the contrast is affected by the light, when you run your fingers over this, you can very much feel something was engraved, while with annealing, you can only feel a very light raising of content.

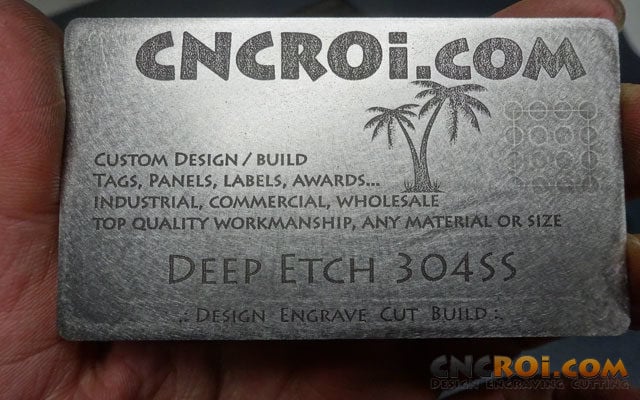

I want you to focus on the absolute clarity and sharpness of the text and image on this deep etched machine tag .

You can clearly make-out the ends of the palm leaves, the DEEP ETCH 304SS also stands out wonderfully as the logo and the smaller text.

This is high quality etching at its best! While doing this I also decided to update the branding of CNCROi.com as well, to DESIGN ENGRAVE CUT BUILD!

Need a custom deep etched machine tag for your equipment, mine shaft or military application? Contact CNCROi.com right now!