304SS Heavy-Duty Machine Tags

Let’s make some 304SS heavy-duty machine tags at CNCROi.com using custom 12 ga sheets, plasma cut and fiber laser etched.

CNCROi.com recently took on a project that involved making custom metal tags, and it was anything but ordinary. The job featured a wild assortment of tag sizes and a mountain of different information to be engraved onto each one. Managing a job like this can quickly turn into a logistical circus when trying to track five of these, two of those, seven of another, and so on.

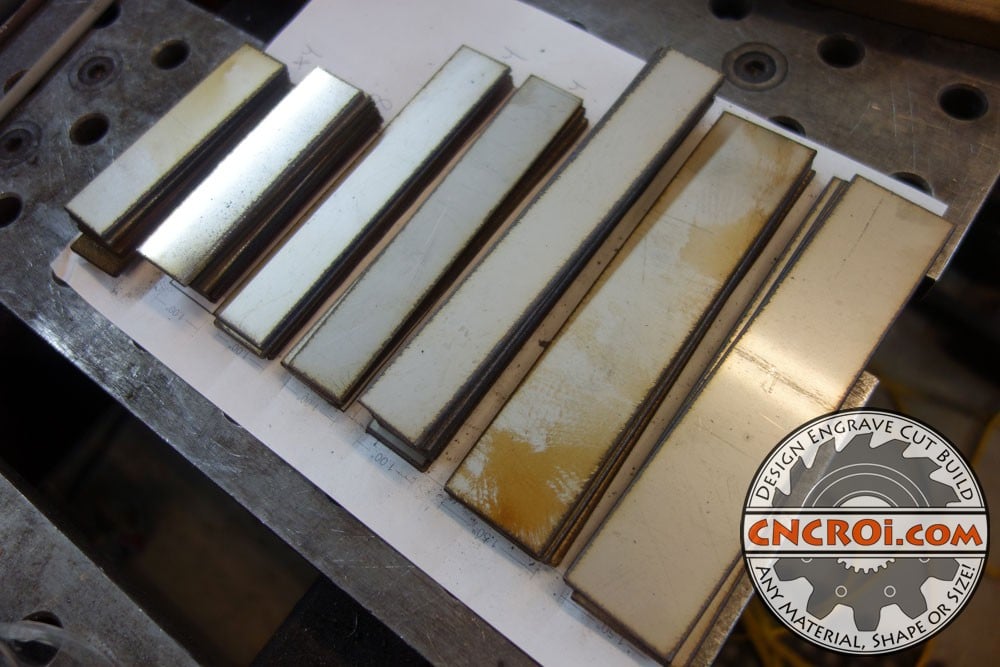

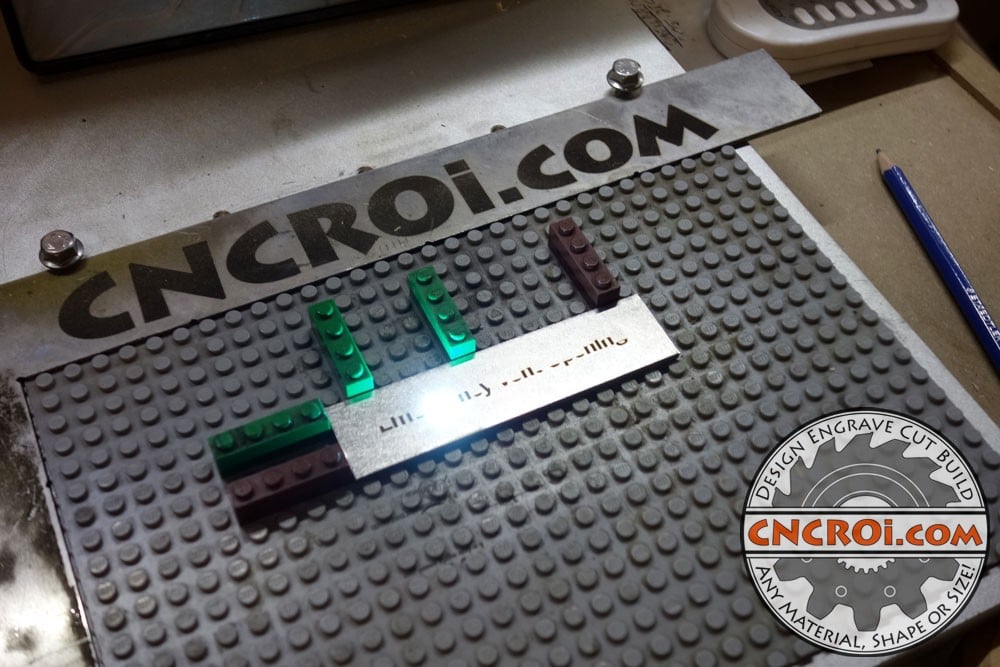

To maintain order through the chaos, CNCROi.com printed out the tag specifications and used a simple but effective overlay system. No fancy tricks here—just printed sheets and scraps of material from around the shop. Some of these pieces were deemed scrap due to small dents or imperfections, but they served their purpose beautifully. Each completed tag was placed on the overlay, counted, and accounted for before moving to the next batch.

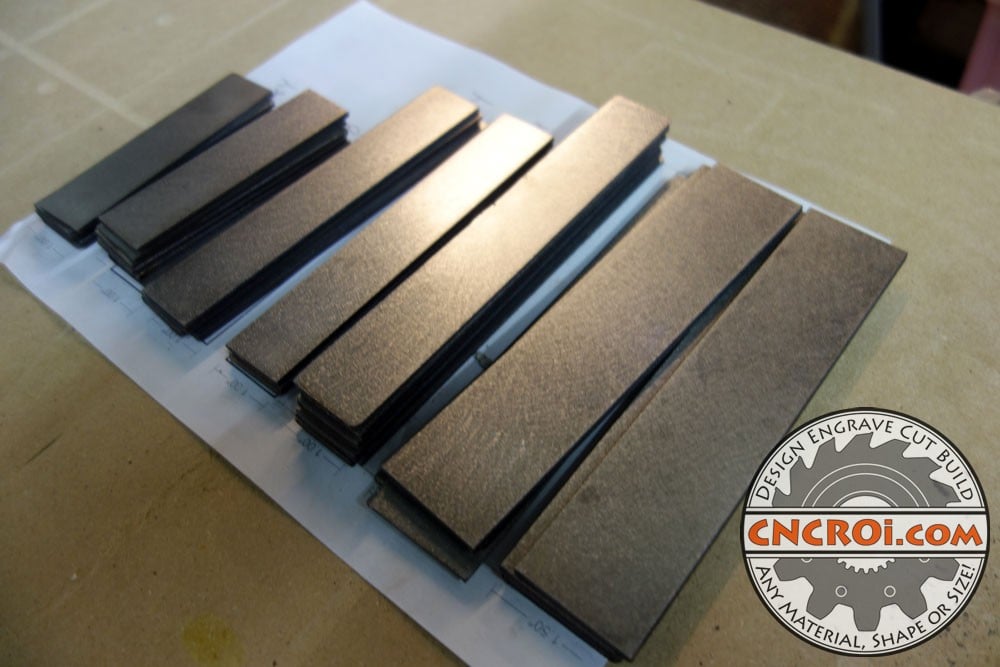

For this project, CNCROi.com plasma cut the tags out of leftover pieces of 12 gauge 304 stainless steel. These sheets had a 2B finish, meaning they were smooth but not brushed, making them ideal candidates for plasma cutting. The plasma cutter in the shop is capable of slicing through material up to 2 inches (51 mm) thick, although most projects are kept to 1/4 inch (6.35 mm) or thinner to avoid the need for forklifts and hernias.

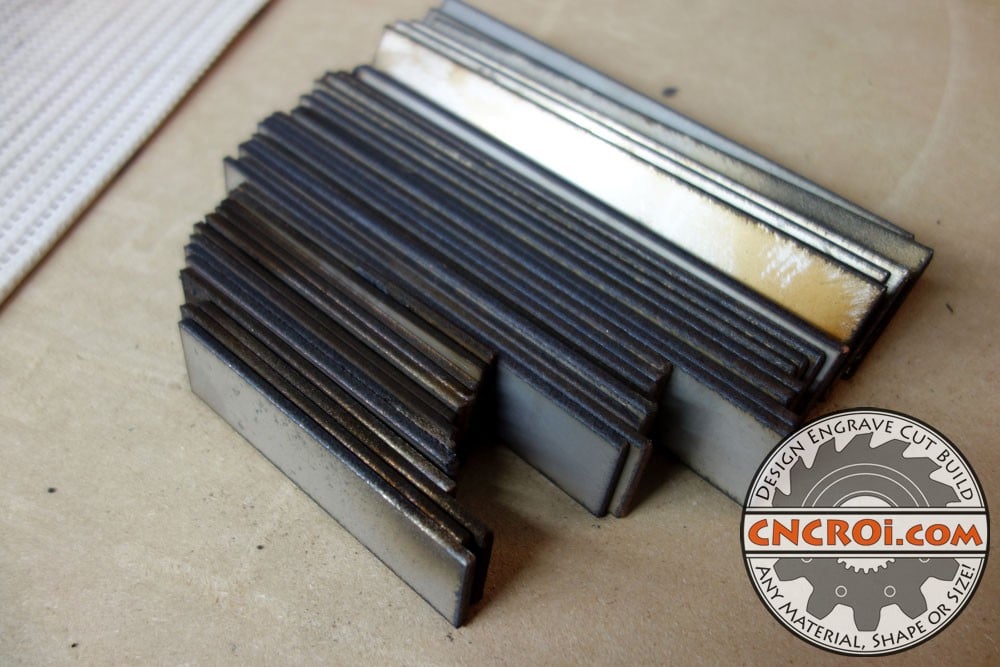

Rather than diving straight into a pristine full sheet, CNCROi.com prefers to put leftover scraps to good use. Plasma cutting small tags from shop leftovers isn’t just environmentally conscious; it’s also a smart way to keep costs down and maximize material use. After all, selling scrap to the recycler yields mere pennies on the dollar.

While working with smaller bits can create even more scraps, CNCROi.com doesn’t lose sleep over it. Most of these leftovers would have ended up in the recycling bin anyway. Plasma cutting is so efficient that producing scrap from scrap feels more like a clever strategy than a wasteful one.

If the job had required hundreds or thousands of tags, CNCROi.com would have transitioned to full sheet production for efficiency. However, for a batch of around 30 custom tags, investing a few extra hours into nesting and cutting from odds and ends made perfect sense. It’s one of the little details that sets CNCROi.com apart.

Precision was the name of the game for this project. If a tag needed to be exactly 2 inches (50.8 mm) wide, it came out 2 inches—no guesswork, no rounding errors. When working with metals, especially stainless steel, getting the dimensions spot-on is critical for ensuring everything fits and functions as expected.

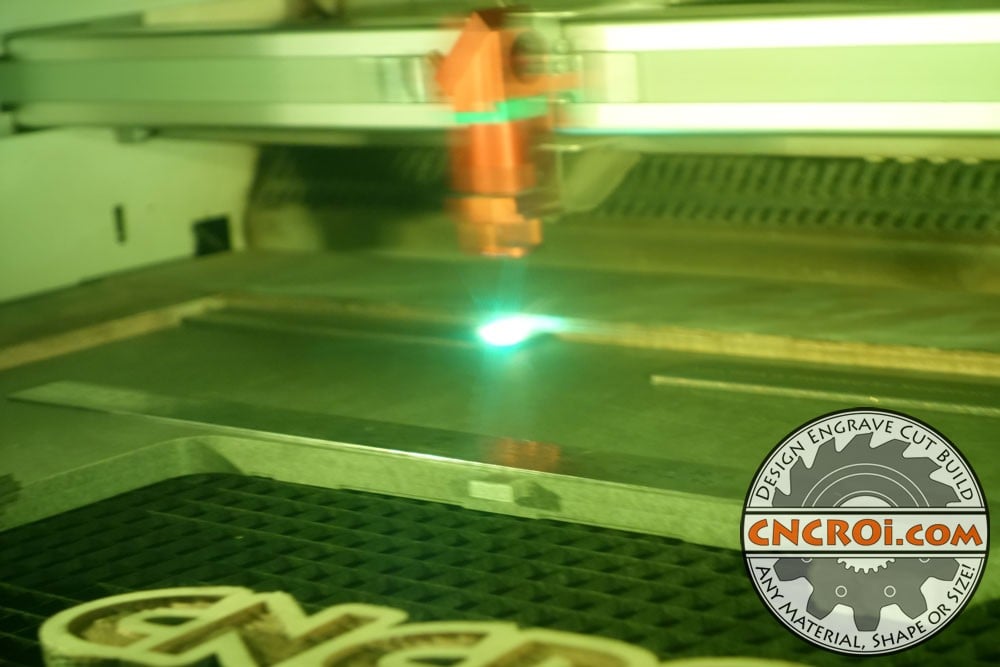

Adding the necessary information onto the tags was accomplished with CNCROi.com’s fiber laser etching capabilities. Virtually any design, text, or serial number can be etched onto almost any material, making CNCROi.com a one-stop shop for customized solutions.

Several CNC technologies could have been used for this project, but plasma cutting emerged as the most logical option. Water jet cutting and CO2 laser cutting are fantastic alternatives for different types of projects, and CNCROi.com has all of them ready to deploy depending on the unique needs of each customer.

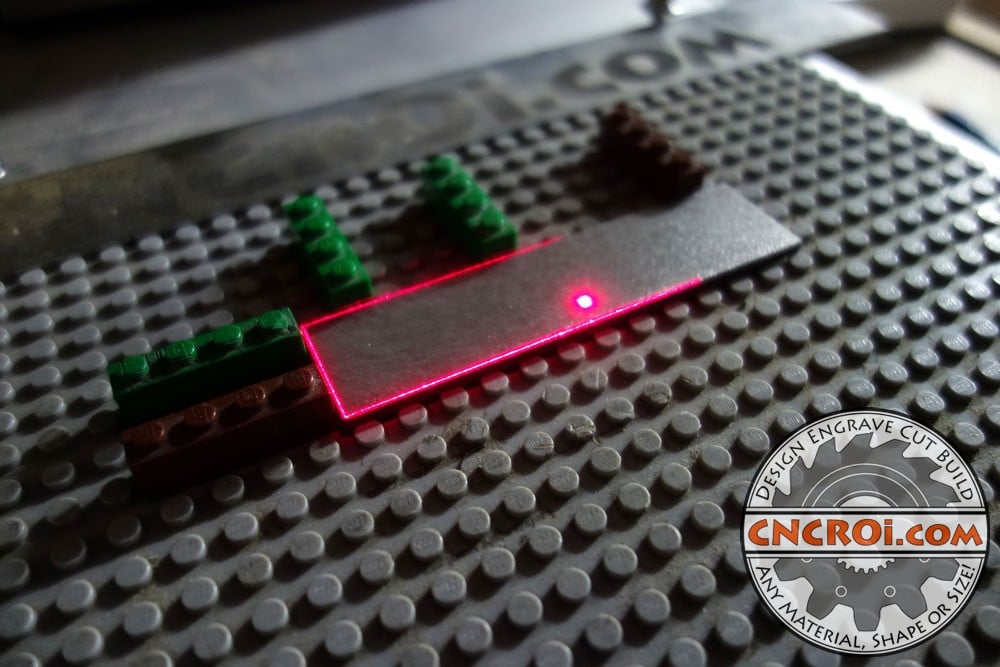

To add flexibility to the etching stage, CNCROi.com utilized both gantry and galvo fiber laser systems. Gantry fiber lasers shine when working on larger tags, while galvo lasers dominate anything under 4 inches (101.6 mm) across. It’s all about using the right tool for the right part.

Whether the etching was done by gantry or galvo, the fiber lasers delivered consistent, high-quality results. A 30-watt fiber laser is 30 watts no matter what hardware moves the beam, so the real magic happens in workflow efficiency.

Galvo lasers are CNCROi.com’s go-to for rapid-fire, small item production. Open systems allow operators to swap out pieces quickly, keeping the project humming along. For repetitive, identical tags, galvo systems are unbeatable for speed and convenience.

For unique, one-off designs like those required for this custom tag project, the gantry fiber laser provided the flexibility needed. Its superior software made setting up different layouts a breeze, and helped CNCROi.com meet the customer’s exact specifications without unnecessary delays.

Software can make or break a project. CNCROi.com’s gantry fiber laser, powered by a Trotec Laser system, boasts outstanding software that’s intuitive and powerful. In contrast, galvo systems can sometimes feel a little like operating a spaceship with sticky buttons, but they still get the job done when speed is the top priority.

No matter which fiber laser was used, one thing was consistent: heat. Fiber laser etching heats up the tags to the point where they are warm to the touch but not scorching. Whether a tag came off the gantry or galvo setup, the warmth was the same because the energy input was identical.

Unlike fiber lasers or plasma cutters, water jet cutting is a cold process. There’s no heat-affected zone, which can be critical for delicate materials. However, when it comes to stainless steel tags that are just a few inches across, heat-affected zones are not something CNCROi.com loses sleep over.

Using a water jet for tiny scrap pieces isn’t practical. Aligning origins for X and Y on such small bits would be a nightmare. Plasma and laser systems are far better suited for these smaller, custom tag projects, making the process at CNCROi.com smoother and faster.

Full-sheet production is best left for high-volume projects, which CNCROi.com also specializes in. However, when dealing with low-volume, high-mix jobs, plasma and fiber laser systems shine by delivering flexibility without sacrificing quality.

Each CNC machine has its strengths, and CNCROi.com knows how to match the right machine to each project. Material choice, job volume, and precision requirements are all factors considered before even the first cut is made.

For custom tags in any size, any material, and virtually any shape, CNCROi.com is the team to call. Offering complete start-to-finish service, CNCROi.com ensures that your tags arrive exactly as ordered, ready to use.

Whether a customer needs serialized ID tags for an industrial fleet or elegant engraved plates for a boutique brand launch, CNCROi.com delivers. No order is too small or too strange to be handled with care and professionalism.

Materials available for custom tag production include stainless steel, aluminum, brass, copper, acrylic, and even wood. Got something exotic or experimental in mind? CNCROi.com is ready to rise to the challenge.

By maximizing the use of shop scrap wherever possible, CNCROi.com helps keep material costs low for customers while reducing waste. It’s a win-win for everyone—except maybe the metal recycling guy.

Attempting to move full sheets of thick stainless steel without heavy equipment isn’t just impractical; it’s a recipe for comedy at best and a pulled muscle at worst. CNCROi.com wisely focuses on smarter production methods.

The combination of plasma cutting and fiber laser etching provides unmatched durability, precision, and customization. CNCROi.com’s tags are built to withstand harsh environments without sacrificing readability or appearance.

With multiple CNC systems in-house—including plasma, fiber laser, CO2 laser, and water jet—CNCROi.com offers unparalleled flexibility and fast turnarounds. There’s no middleman, no waiting, and no excuses.

This integrated approach means that every project gets full attention, tight quality control, and the ability to pivot quickly if adjustments are needed. CNCROi.com prides itself on delivering consistent excellence no matter how complex the job.

Working with CNCROi.com also means a little humor along the way. Manufacturing might be a serious business, but keeping things light makes for a smoother experience for both the team and the customer.

Every custom tag project is unique, and CNCROi.com treats it that way. No cookie-cutter solutions here—just thoughtful, personalized service designed to make your project a success from the first cut to the final shipment.

When it’s time to create custom tags for any application—whether industrial, commercial, artistic, or just because—there’s only one name you need to remember: CNCROi.com.

CNCROi.com operates both gantry and galvo fiber laser systems, each running at 30 watts, offering maximum flexibility depending on project needs. Even though both systems deliver the same power output, the way they move and focus the laser beam is completely different, which has a big impact on workflow and efficiency. Understanding when to use a gantry system versus a galvo system is key to maximizing precision, speed, and overall project success.

The gantry fiber laser at CNCROi.com works much like a CNC router or a traditional plotter, where the laser head physically moves along the X and Y axes to trace the design. This method is slower compared to a galvo but allows for a much larger engraving area and incredibly precise control over longer lines and larger parts. Gantry lasers excel at handling oversized tags, panels, and sheets that would be impossible to fit into a compact galvo system without magic or wishful thinking.

In contrast, CNCROi.com’s galvo fiber laser uses fast-moving mirrors to steer the laser beam across the material. Instead of physically moving the head, the mirrors change the direction of the beam, allowing for extremely rapid etching within a smaller working envelope, typically around 4 inches (101.6 mm) square. Galvos are fantastic for small tags, serialized parts, and high-volume production runs where speed is king, and every second saved adds up to major efficiency gains.

While both systems at CNCROi.com boast the same 30-watt laser source, they serve very different roles in production. Gantry fiber lasers are the go-to for custom jobs with larger dimensions or intricate one-offs requiring broader engraving fields. Galvo fiber lasers, on the other hand, are perfect for stamping out repeatable designs quickly and accurately, especially when working with smaller parts in large batches.

By having both systems in-house, CNCROi.com offers customers the best of both worlds. Whether it’s a massive custom stainless steel nameplate or a run of hundreds of tiny serialized tags, CNCROi.com can handle it with the optimal fiber laser setup. This flexibility ensures better lead times, consistent quality, and project pricing that fits real-world manufacturing needs without cutting corners.

Ready to get started? Contact CNCROi.com today and let the team turn your ideas into reality, one plasma cut, one laser etch, and one carefully counted stainless steel tag at a time.