316SS Machine Tags: Plasma Cutting

Let’s make another round of machine tags using 316 stainless steel, in this blog post, I’ll just show the cutting through other processes are performed from drilling holes to fiber etching the surface with the customer’s machine information.

https://www.youtube.com/watch?v=cErB0qkKwnc/

For these 316SS machine tags, the thickness is 12 ga and although the surface still has some mill scale on it, I used an orbital to clean them up after the plasma cutting after the drilling operations and grinding was performed.

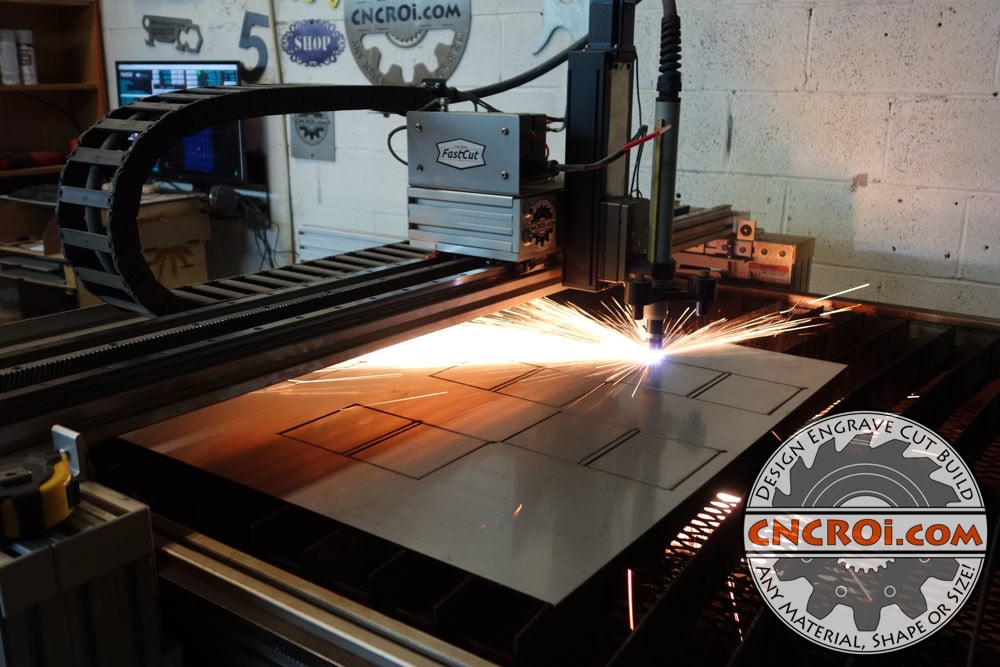

Plasma cutting stainless steel does produce a lot more sparks but the amperage and heat generated are the same as mild steel, for CNCROi.com, we cut dramatically more stainless steel than aluminum or mild steel at the shop as this material is fantastic for signage with a great corrosion resistance profile.

As these 316SS machine tags are going into a mine shaft after CNCROi.com does the additional work to them, 316SS was the best choice as it can be welded to the equipment that these will be applied upon, anodized aluminum was close second.

Custom real metal signage looks great in any environment.

https://www.youtube.com/watch?v=kD10k1Es-VA/

The sparks you see during the cutting process are a lot more extreme with stainless steel than mild steel, I’m not sure why, but it creates quite a light show that I enjoy watching as I review the cutting process right next to the machine during the entire cutting process.

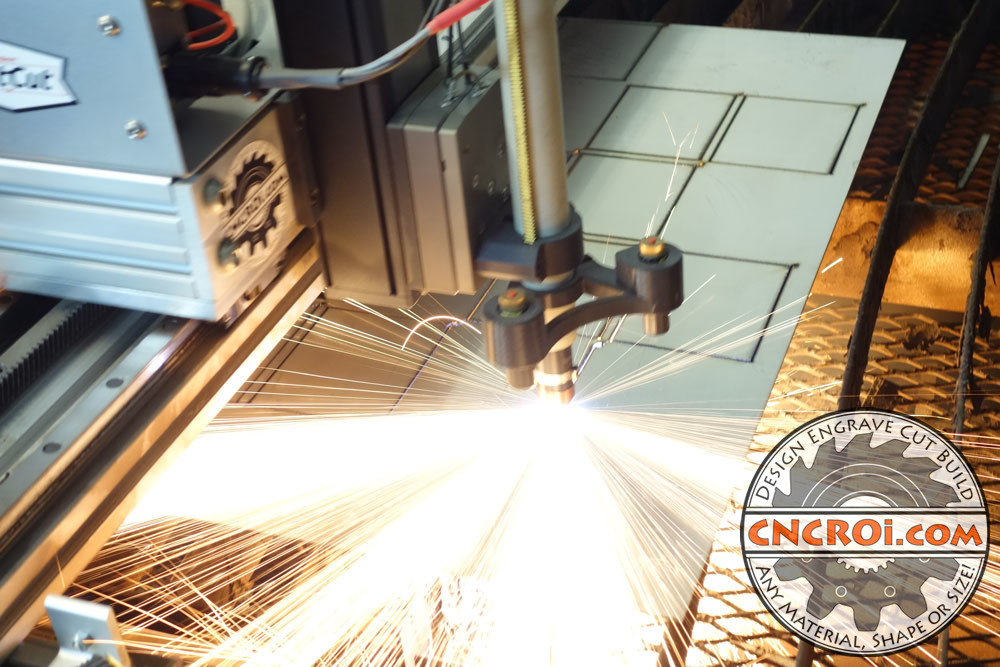

What happens to most of the steel that’s cut with the plasma? Most of it is vaporized with a little of it not hitting the melting point just becoming molten which quickly solidifies and forms a slight lip underneath the plate, under each of the 316SS machine tags.

We are able to do amazing work that’s incredibly beautiful and durable using nothing but stainless steel and lasers.

https://www.youtube.com/watch?v=B0463p1ovBw/

You’ll actually see puffs of smoke coming-up from where the plasma at CNCROi.com is cutting the metal, there is a lot more underneath but it’s extracted as it’s being produced by our vacuum system.

There isn’t any rhyme or reason in the cutting order of these 316SS machine tags other than doing them at least 12 inches apart, meaning one will be cut out and then there won’t be another cut right next to it, this reduces the chances of the metal getting too hot and starting to warp on me during production.

You may see some sparks on the top of the stainless steel sheet but underneath there is a raging fire shooting straight down, it’s pretty impressive how a fire can be generated using metal and a plasma arc, you can see hints of it by the light coming underneath of the sheet.

Another common activity at CNCROi.com is etching steel for our customers.

https://www.youtube.com/watch?v=rWeM9-VUOII/

Plasma cutting is a very efficient process for processing metal of all types, and it is only limited to metals due the grounding requirement for the arc to go through the metal with.

The only consumable other than what’s on the torch is electricity, in this case, the plasma cutter at CNROi.com runs off 3-phase so there is more than enough power going through the system to easily cut this 1/8″ thick stainless steel, in fact, we can cut up to two inches with our set-up!

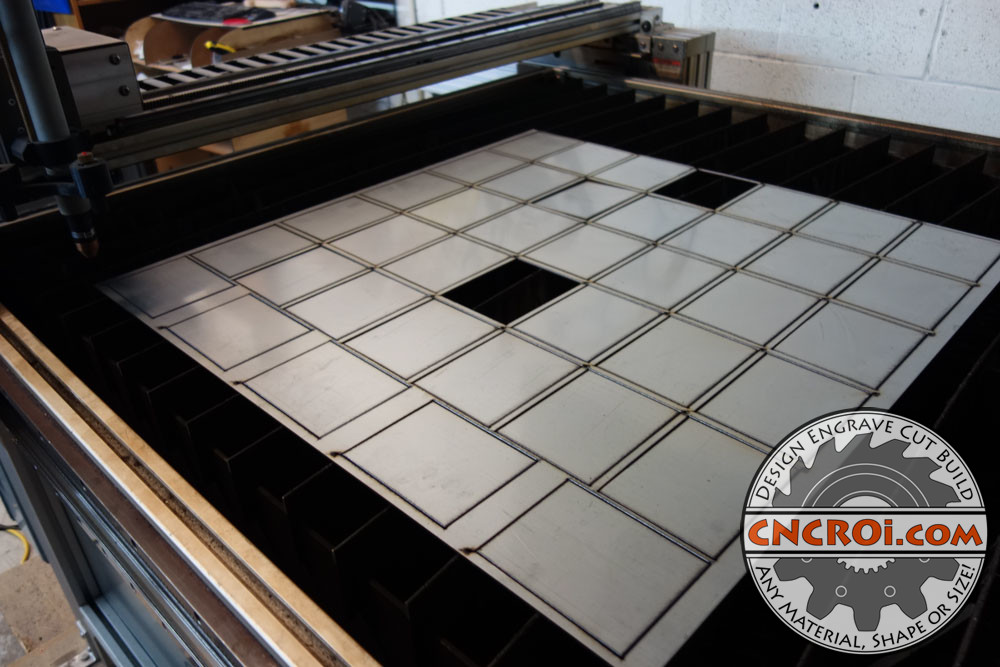

As these 316SS machine tags come to a conclusion, you can see that each of them is identical, there are no weird shapes or things that are off-spec, our machine is incredibly precise and does an amazing job cutting metals of all types at CNCROi.com.

Of course, we aren’t just a metal processing company, we do lots of custom woodworking jobs as well as plastic work too!

https://www.youtube.com/watch?v=VAasMmiPvy8/

Plasma cutting is a loud process, it’s a dusty process and most importantly, the cutting of these 316SS machine tags is a fun process, it’s amazing how such a powerful machine easily glides back and forth to cut a material that’s a real pain to cut manually, which I’ve done tons of in the past at CNCROi.com.

There are no real limits as to what design we can cut using our plasma, circles are round, squares are just that and anything else you can imagine is done perfectly, of course, if the spec or tolerances are too tight, then we flip the job over to the waterjet or fiber laser cutter but 9 times out of 10, plasma is the most efficient tool for the job.

One thing I have to always be aware of during the processing of these small 316SS machine tags is that sometimes they fall in such a way that they stick-up, this can cause a torch collision, so that’s why I’m next to the machine each and every time I’m cutting with this amazing tool.

We also make a good amount of custom BBQ pit grates at CNCROi.com, generally using stainless steel.

https://www.youtube.com/watch?v=Ln9EXslzc04/

Plasma cutting stainless steel, or any other metal, requires a bit of clean-up after the process is complete, but it’s nothing compared to what would be required if I was manually sawing these tags out.

In these two photos, you can really get a feel for the amount of power that’s shooting out of the plasma torch, you see the small sparks on top but look at the incredible brightness coming from under the sheet, there is some real fire being produced at CNCROi.com!

CNCROi.com also has two CNC routers but we don’t use them for processing metal generally because its too hard for the spindle, I do want to get a milling machine in the near future so we can not only cut metal but also form it but that’s down the line a bit.

Regardless of the metal being cut, our plasma cutter does an amazing job, accurately and fast!

https://www.youtube.com/watch?v=PI0PIukb5ME/

You can see overall, the edge quality is looking great and the surface of the stainless steel, even after it’s cut, is looking very pristine considering how much heat and sparks they have been subject to as I was cutting out these 316SS machine tags.

The reason two 316SS machine tags are missing in the above picture are because the fell-out, the grid table is great for holding material to the surface but sometimes, there is just enough to have them flip onto the lower table of the plasma cutter, no worries though, they are still safe and sound and will join their friends in a mine shaft soon enough.

Now that this small production run of 316SS machine tags is finished, you can see how tight the nesting was and how they all come out fantastically at CNCROi.com, they are now onto the next step of drilling the corner holes, angle grinding and then fiber etching.

Have some custom metal work? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=VtkLvlrHuZU/