3D Printed Paddle Boat for Kids: Design Fail to Bathtub Success!

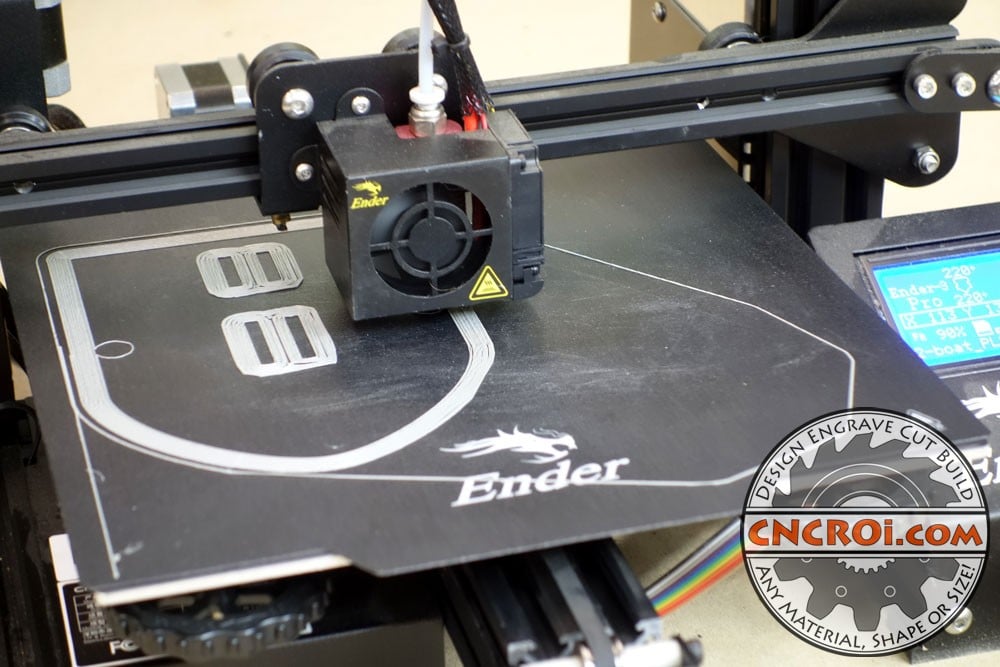

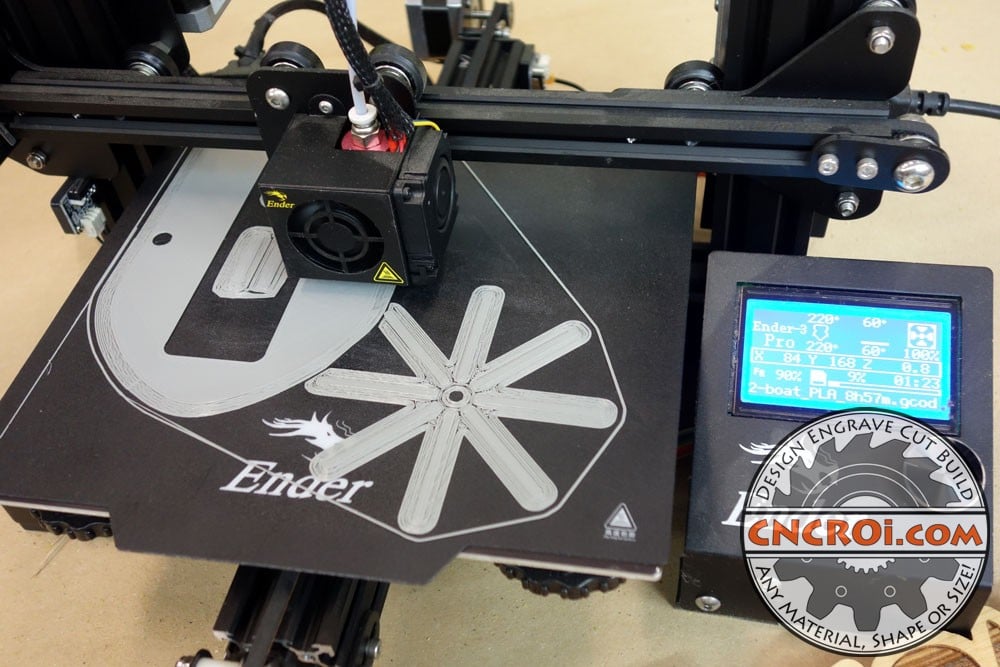

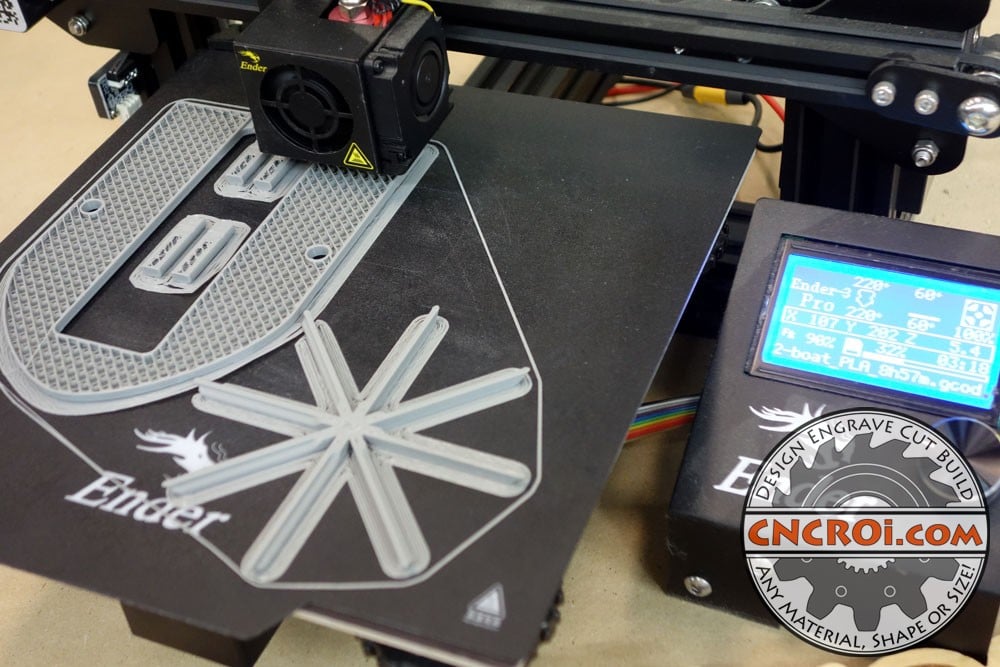

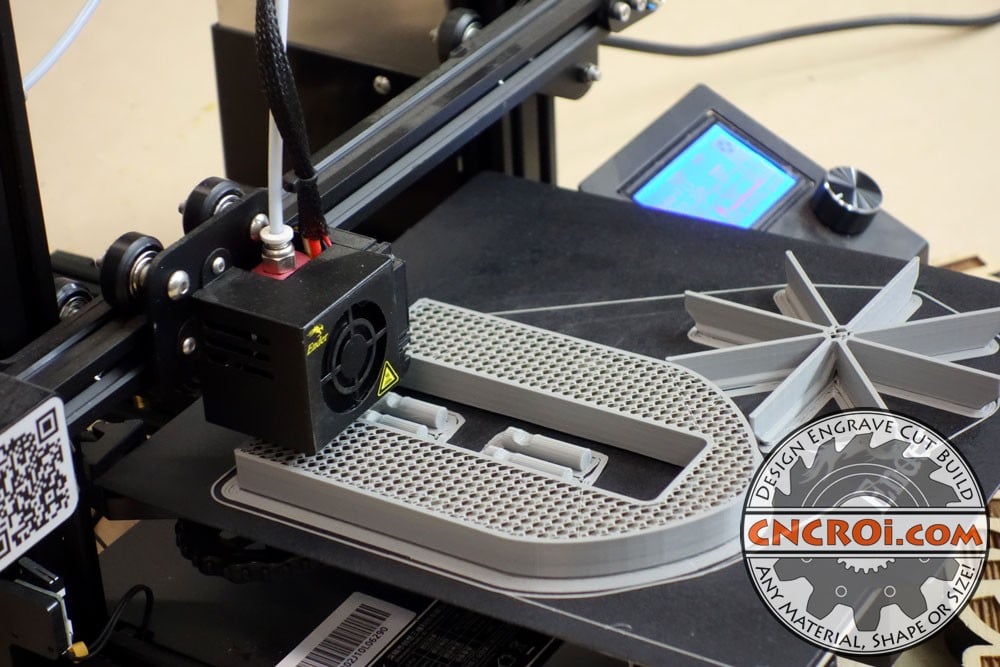

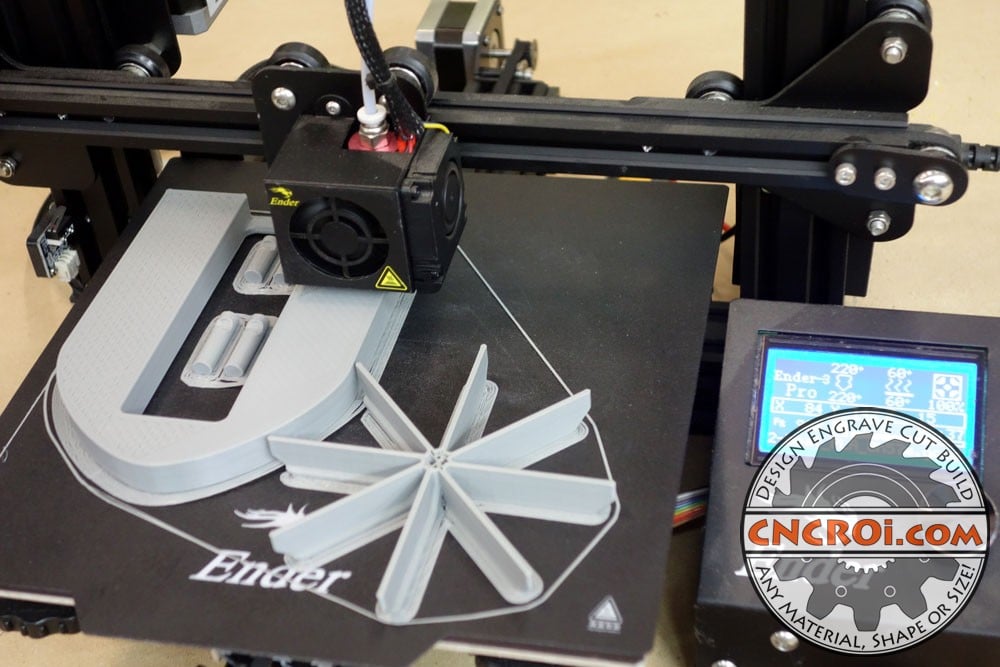

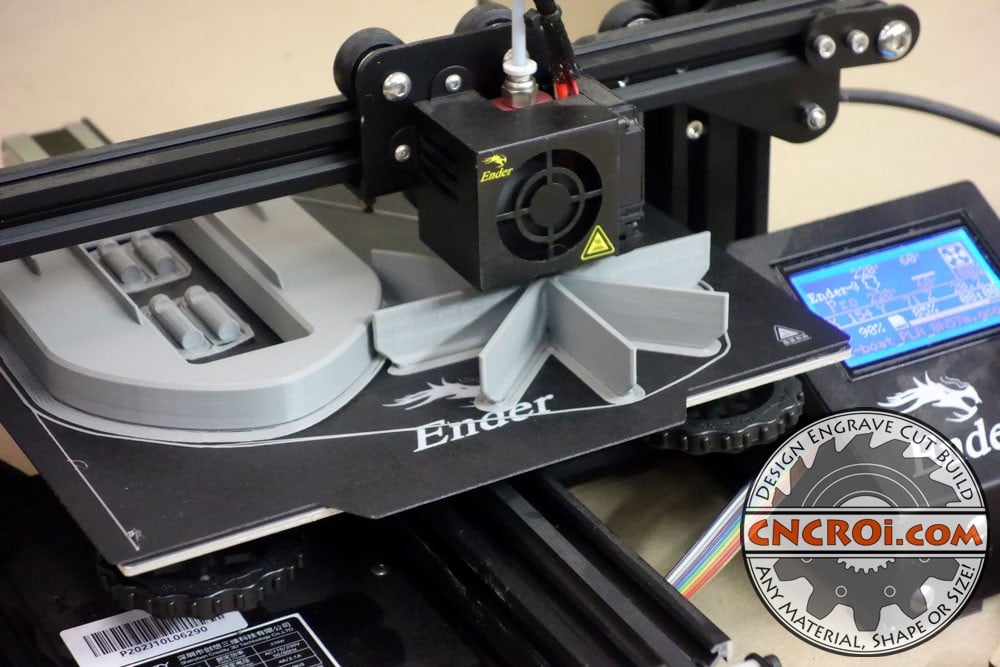

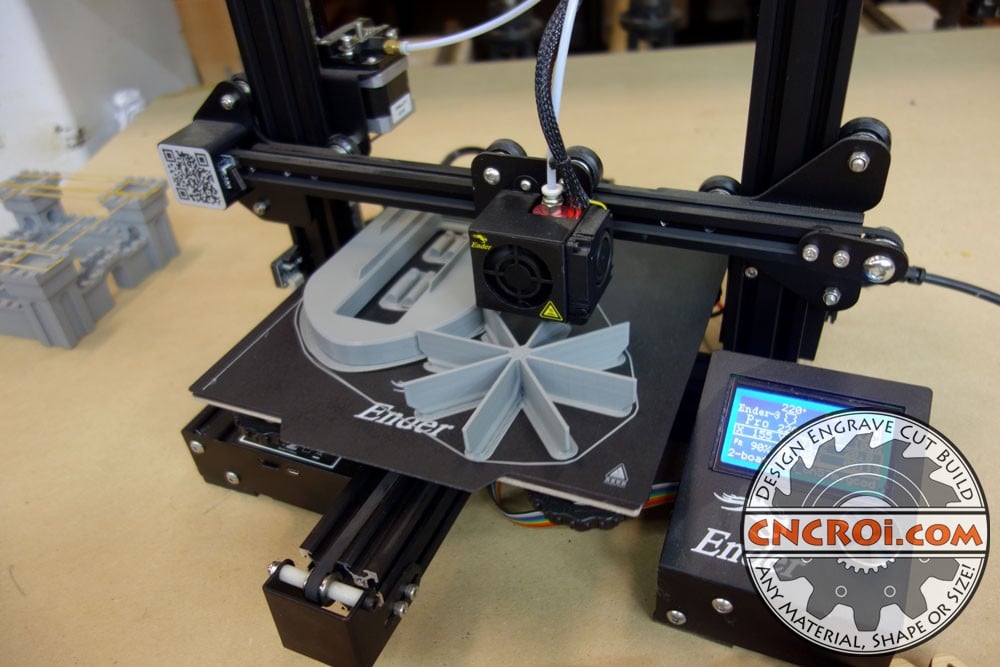

CNCROi.com recently revisited a playful and practical project: designing and 3D printing a functional 3D paddle boat for kids’ bathtub fun using PLA and our FDM Ender 3 Pro printer.

While the idea might sound simple at first, the journey from a Thingiverse download to a fully custom, robust, and bath-tested 3D printed paddle boat turned into a deep dive into design flaws, mechanical tweaks, and why learning how to 3D model is the ultimate game changer.

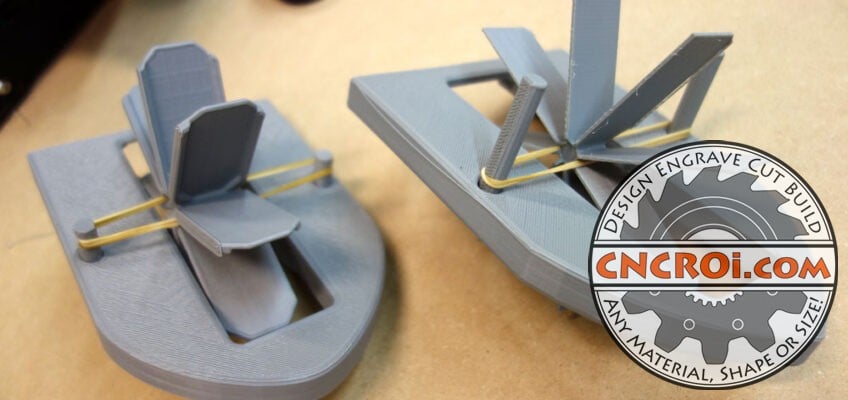

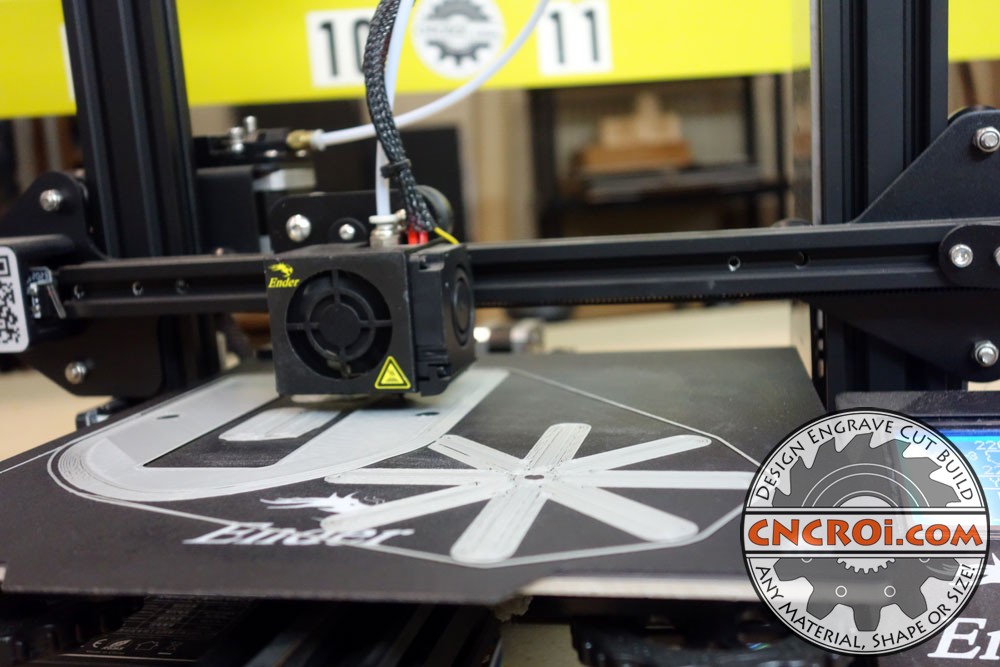

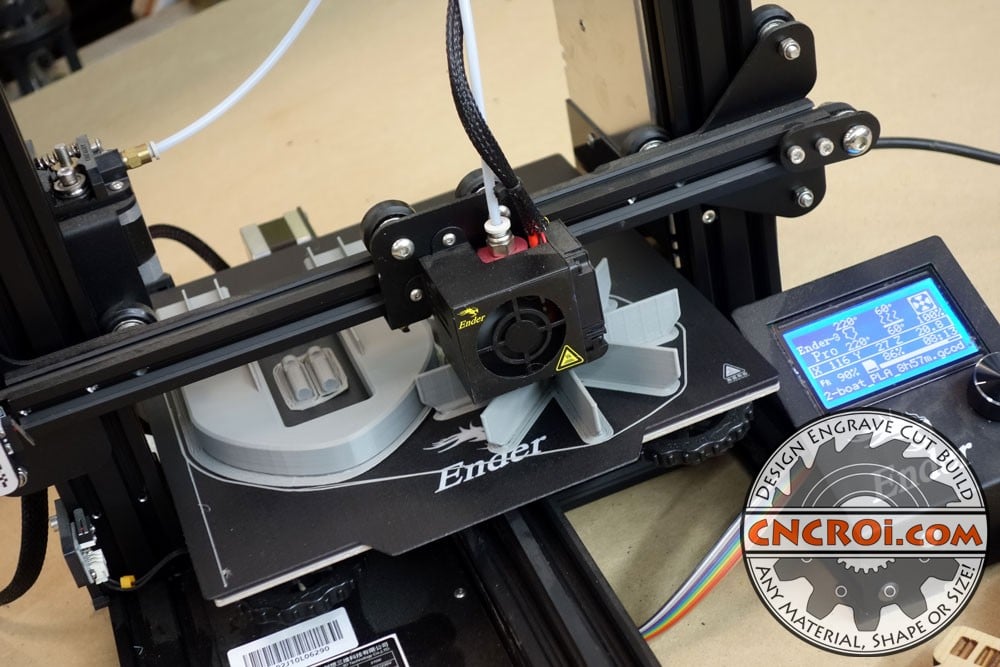

The first version was a downloaded STL file that looked promising but quickly revealed shortcomings. Thin paddles, weak structure, and a lack of proper watertight integrity made it more of a display piece than a bath toy.

Printed on an Ender 3 Pro, the original model struggled with adhesion, particularly at narrow points. When the bed moves and your print is flimsy, delamination and failure are inevitable. That pop you hear when removing a successful print from the bed? That’s the sweet sound of not making scrap.

Jon at CNCROi.com wasn’t about to let that be the end of the project. The original boat had elastic-powered propulsion, but the paddle design and build orientation created instability and inefficiency.

The spinning mechanism was underwhelming, the pegs holding the elastic were overly long, and the entire build felt more like a prototype than a usable toy. And that’s exactly what it was—a prototype for version two.

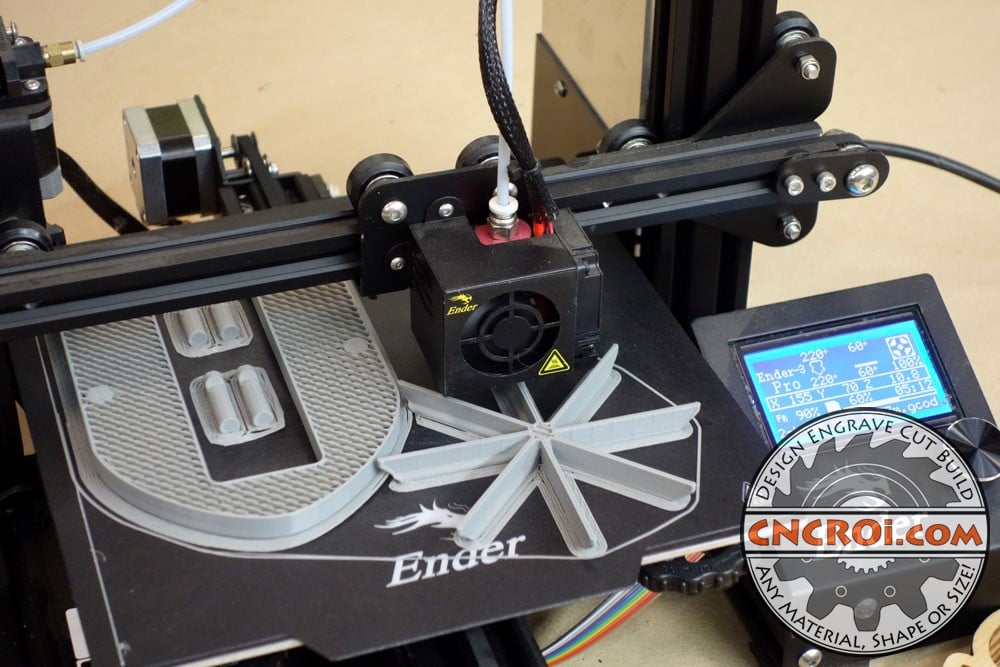

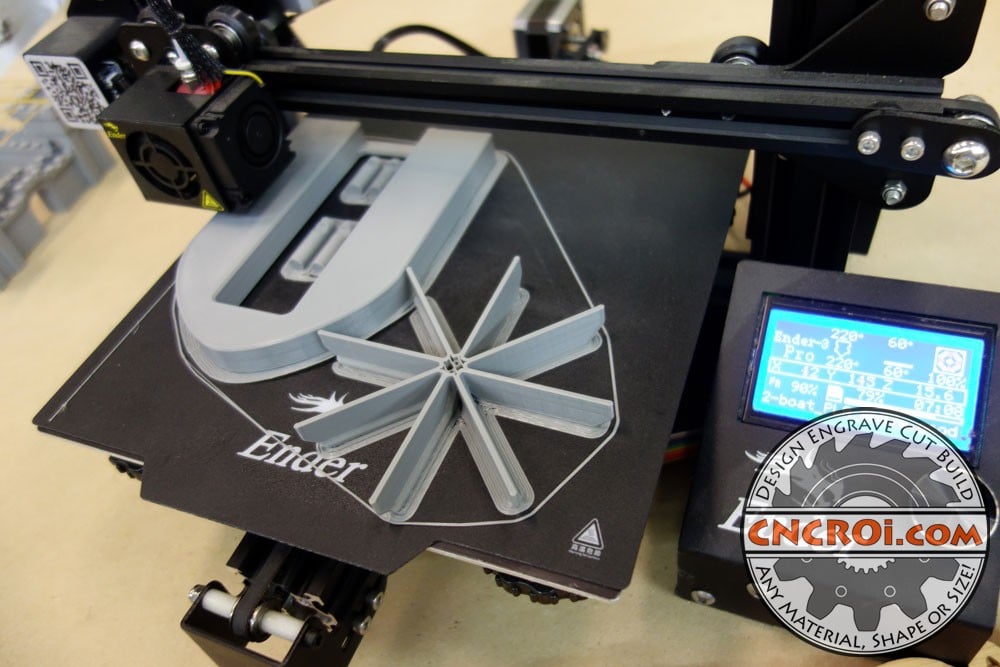

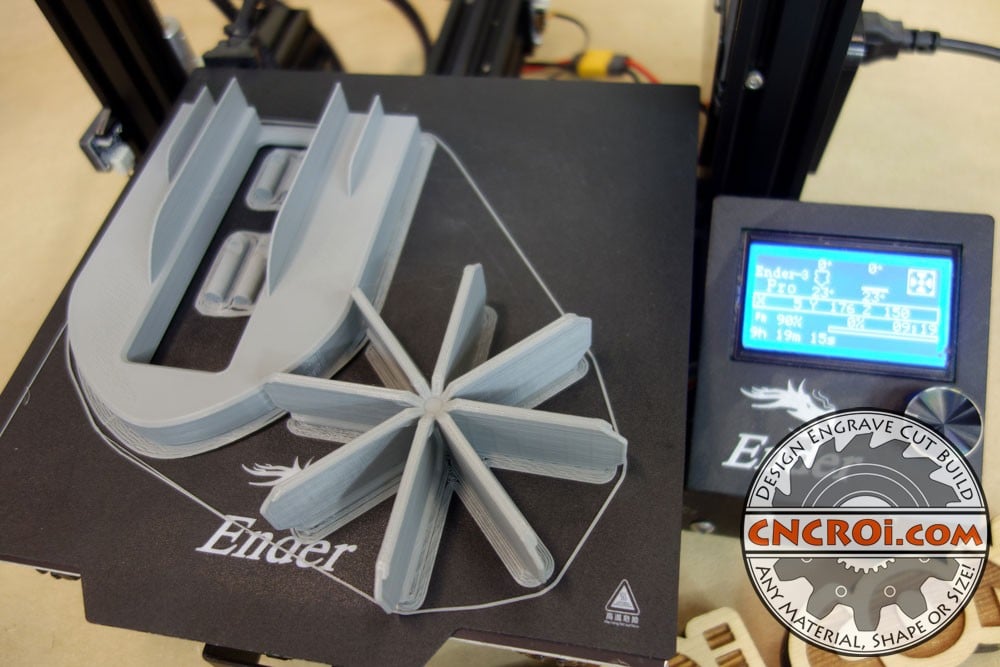

The redesigned 3D printed paddle boat was completely overhauled. Jon beefed up the paddles and flattened the bottom so it could displace water more efficiently.

More pronounced paddle edges gave the 3D paddle boat added propulsion power, a critical improvement when your boat’s main goal is to paddle its way across a bathtub without flopping sideways like a confused goldfish.

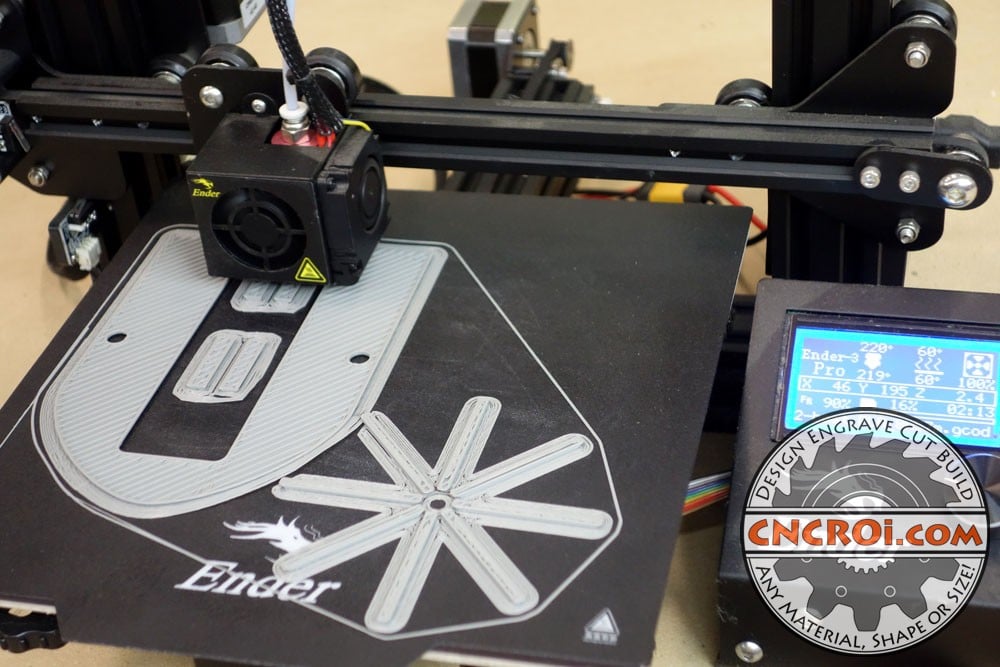

Version two wasn’t just a tweak—it was a full design reboot. The pegs were shortened to reduce unnecessary filament usage and actually hold the elastic in place better.

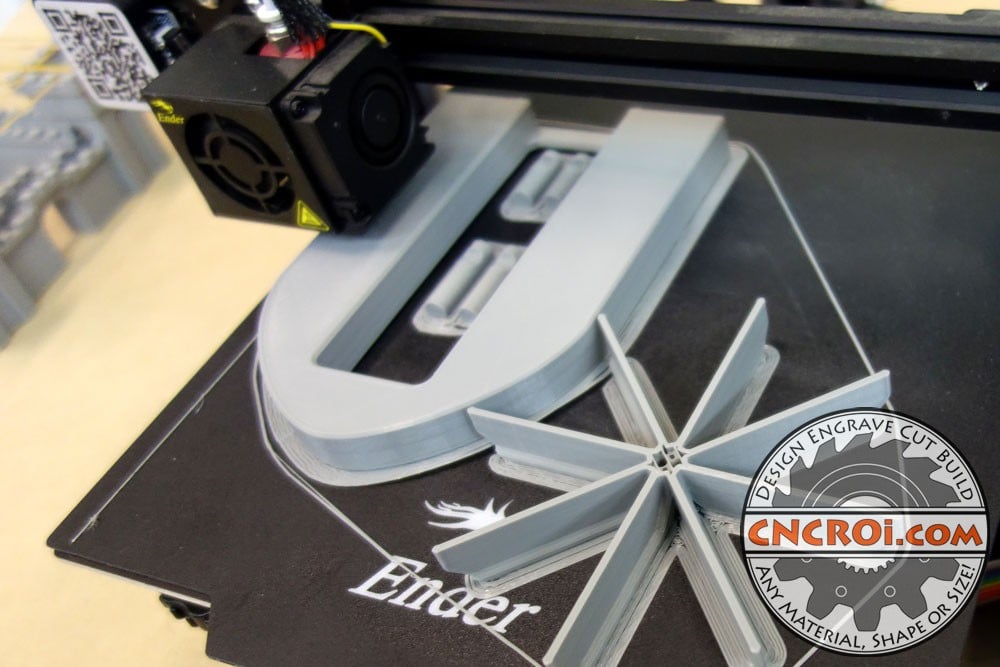

Fins were thickened and multiplied to keep the boat moving straight instead of drifting. Structural integrity was doubled across the board by increasing overall thickness, making it feel like a durable toy rather than something cobbled together.

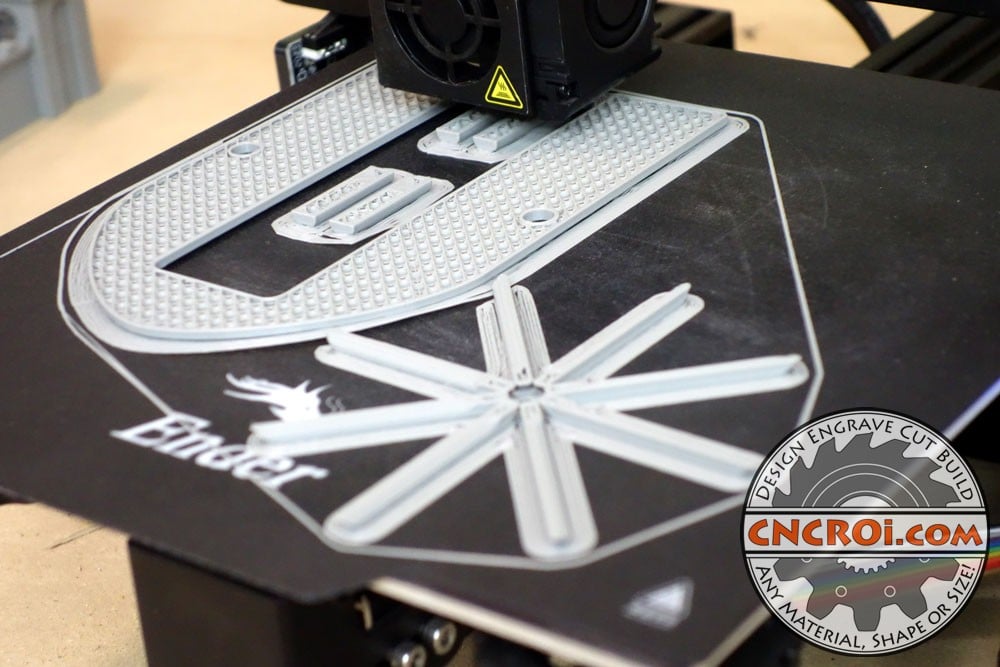

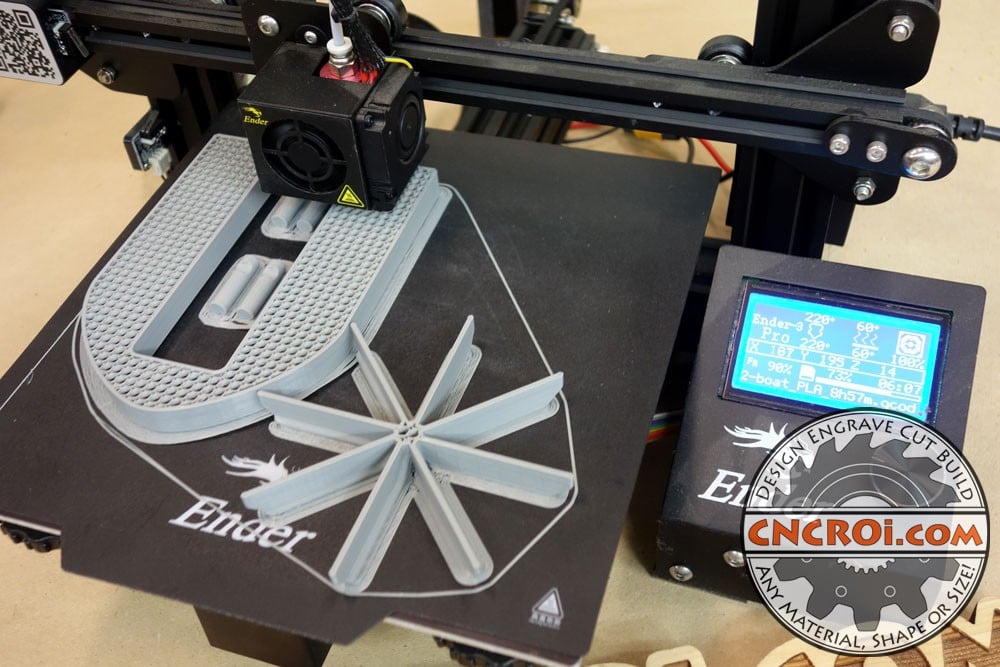

One of the most satisfying surprises was the watertight hull of the 3D paddle boat. Without explicitly designing it to be waterproof, the revised version floated without taking on water.

Sometimes, happy accidents do happen in 3D printing—especially when you learn to model and understand the limits and strengths of your equipment and materials.

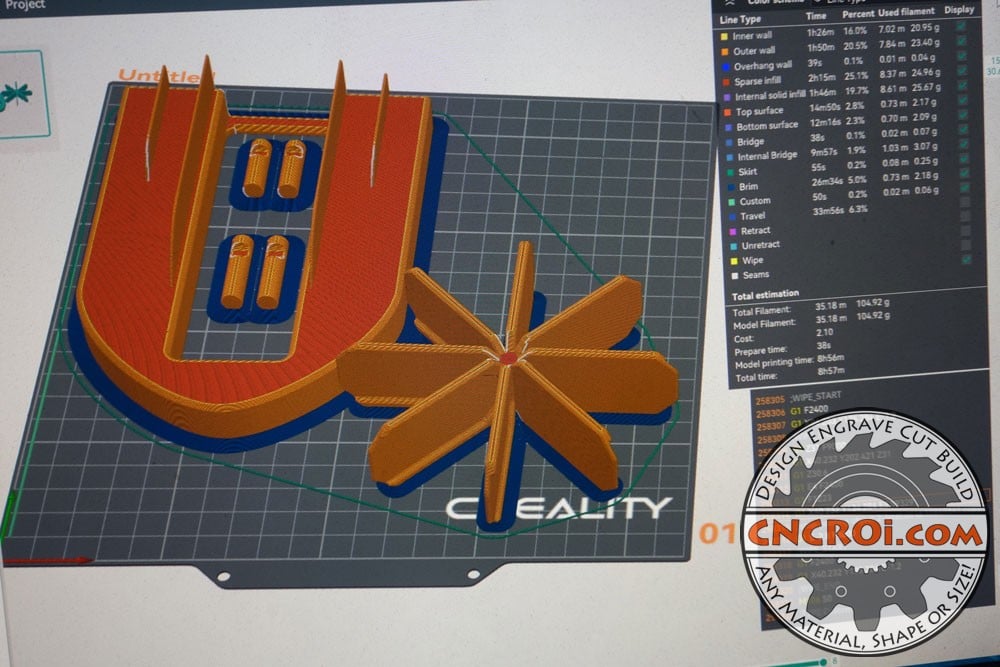

Jon’s philosophy at CNCROi.com is that 3D printing is the final step in a much bigger process. The real magic happens in 3D modeling. Whether you use paid tools like 3D Studio Max or free ones like Blender, the ability to modify, repair, and redesign STL files is essential.

Rather than relying solely on downloaded models, CNCROi.com encourages analyzing and rethinking them—because there’s always room for improvement, especially when the goal is creating toys that can survive bathtime.

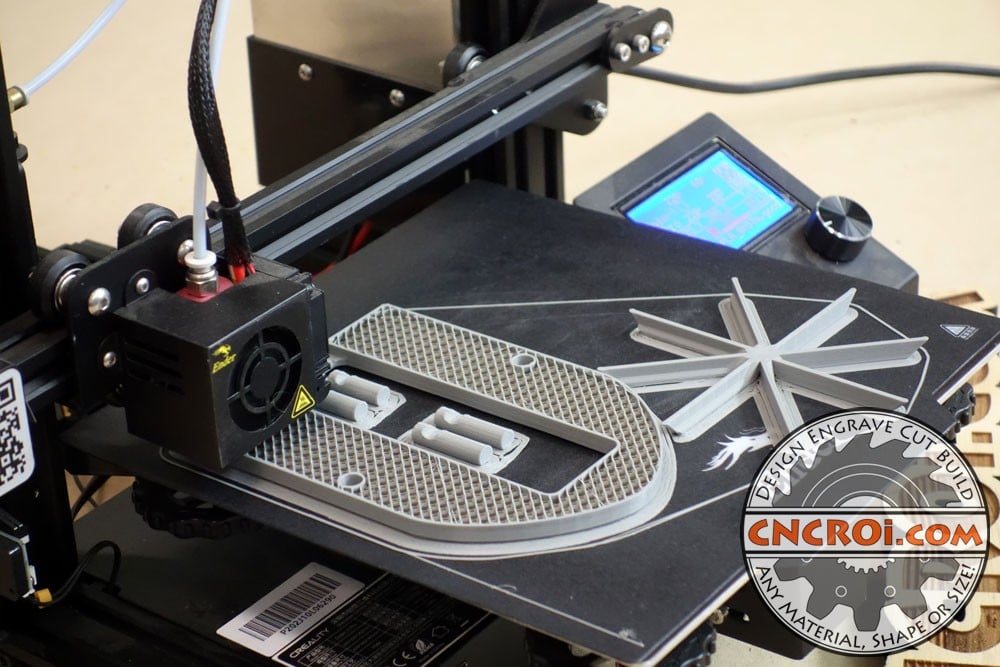

Designing the second version of the 3D printed paddle boat also included rethinking the orientation during printing. On the first try, the boat was printed with the fins perpendicular to the bed movement, introducing unnecessary stress during layer deposition.

In version two, the entire model was reoriented to align with the bed’s motion. That simple shift significantly improved adhesion, structural consistency, and ultimately, print success.

This kind of attention to detail is what sets custom work at CNCROi.com apart. Everything is designed with intent.

When you feel the second version of the boat in hand, there’s an immediate sense of weight and quality that the first model lacked. Despite the toy’s small size, the added mass gives it a better tactile experience, something often overlooked in lightweight 3D prints. It’s not just about form and function—it’s about feel.

Even the paddle fit was rethought. In version one, there was considerable space between the paddle and the housing, creating inefficiencies.

Version two used the precision of 3D printing to get nearly zero clearance between moving parts. That level of fit and finish is hard to replicate with other CNC tools and gives 3D printing its own design advantages, particularly for mechanical toys and small assemblies.

These lessons aren’t just for kids’ paddle boats. Every iteration of a project builds on previous mistakes and ideas. CNCROi.com believes in leveraging that process to improve not only the end product but also the production workflow.

Even seemingly minor tweaks to the 3D paddle boat—like chamfering edges or adding fillets—can dramatically affect durability and user experience.

Jon has been 3D modeling since his teens, back when tools like Strata Studio Pro and Bryce were the industry standards. Over two decades of experience have given him a strong design intuition and a drive to improve every object, no matter how basic.

Now, tools like Blender are accessible for everyone, though he’ll tell you the user interface leaves something to be desired compared to legacy systems.

Still, the core point stands: learning how to model in 3D opens up endless possibilities, not just in 3D printing but across the custom CNC landscape.

CNCROi.com specializes in taking these ideas and bringing them to life—whether it’s a bath toy, signage, corporate award, or a fully custom industrial part. Owning the ability to design from scratch gives full control over strength, performance, and aesthetics.

Jon’s latest version of the paddle boat is almost twice the weight of the first, which might seem counterintuitive for a floating toy. But that weight distribution adds stability and durability, giving it a quality feel and better real-world performance.

It’s a great reminder that heavier sometimes means better—especially when it comes to custom 3D printed toys.

This project also reinforces the idea that design isn’t about simply scaling things up or down. It’s about understanding how form affects function.

Just taking a model off Thingiverse and stretching it 200% might give you a bigger version, but not necessarily a better one. When every design detail—from elastic pegs to paddle thickness—is reconsidered and rebuilt, you end up with something worth printing and playing with.

For bathtub adventures, a 3D printed paddle boat has to strike a balance between fun, function, and finish. The final design by CNCROi.com ticks all three boxes. With reinforced walls, better water displacement, smarter fin orientation, and a tight paddle mechanism, it’s a solid upgrade from version one’s splashy but fragile approach.

This playful project turned into a design case study. From adhesion issues to structural weaknesses and unnecessary material waste, everything was addressed and resolved through modeling. It’s the type of iterative thinking CNCROi.com applies to all custom manufacturing projects, whether they’re made for a child’s bathtub or a company’s trade show booth.

You’ll also notice that surface finishing wasn’t a primary concern in this 3D printed paddle boat, because the focus was entirely on functional performance. That said, CNCROi.com has extensive experience with surface treatments, from sanding to painting, and can easily apply those lessons if aesthetics become a priority.

Jon made sure that the toy not only floats but performs. With shorter elastic holders and strong structural design, this toy can handle repeat play without falling apart.

The thicker paddles and better fit make it more responsive in water, while still being safe and fun for kids. It’s the kind of design challenge that brings together technical knowledge, practical engineering, and a touch of whimsy.

Version two of the 3D printed paddle boat is a success story not just in fixing a flawed design but in showcasing what’s possible when you combine 3D printing with real-world problem solving. CNCROi.com’s approach always puts the end user—whether it’s a kid in a bathtub or a client in a boardroom—at the center of every design decision.

As Jon put it, 3D printing is just the last step. Pressing “start” on the printer is easy. Getting to a design worth printing? That’s the real work. CNCROi.com encourages everyone to think, model, iterate, and then print. That’s how you turn a random download into something that actually works.

So if you’re looking to create custom 3D printed projects—whether for play, prototyping, or professional use—contact CNCROi.com.

We can handle the modeling, prototyping, and production, shipping it right to your door. And yes, if it needs to float in a bathtub, we’ve got that covered too.

CNCROi.com understands that not all prints need to be complex to be effective, especially when it comes to toys designed for children’s bathtub fun. Sometimes, the simplest designs are the most rewarding, provided they’re well thought out. This paddle boat project exemplifies that belief.

While version one was cute and had potential, it lacked durability and thoughtfulness in execution. Version two, however, is something that could be proudly gifted or used repeatedly without the fear of snapping paddles or losing parts down the drain.

The value of 3D printing in projects like 3D printed paddle boat isn’t just speed or affordability—it’s personalization. CNCROi.com could just as easily produce a dozen variations of this toy paddle boat to match themes, names, or even shapes of actual tugboats, pirate ships, or racing catamarans.

Because each version starts as a 3D model, it’s infinitely adaptable. Whether you’re a parent looking to make bath time more exciting or a company wanting to brand a fun giveaway item, the possibilities open up the moment modeling begins.

Another benefit Jon embedded into this design is reduced post-processing. The first version required considerable cleanup because of poor supports and weak geometry. With version two, support areas were optimized, minimizing the need for sanding, trimming, or reprinting broken pieces.

Less waste means lower material costs and faster turnaround times—something CNCROi.com always factors into every design, no matter how small the project may seem.

Let’s not forget the importance of usability. The redesigned 3D printed paddle boat not only holds together better in water but is also easier for little hands to use. Shorter pegs mean easier assembly and safer interaction. Elastic bands stay where they should, and the boat tracks in a relatively straight line, which makes bath time more fun and less frustrating. When a child can wind it up and let it go without fiddling endlessly, it becomes a toy they’ll keep coming back to.

There’s also something to be said about teachable moments. A parent or teacher using this 3D printed paddle boat can also use it to explain propulsion, buoyancy, and mechanics in a fun and engaging way.

The transparency of 3D printed components—when done in clear filament or bright colors—helps spark curiosity. And when a kid asks, “How does it work?” the answer doesn’t just involve science, it becomes a story of design, testing, and improvement—a perfect learning opportunity powered by play.

If someone were to mass-produce these using injection molding, the design would have to be stripped down and simplified to meet mold constraints. But with 3D printing and CNCROi.com’s in-house capabilities, each boat can remain uniquely detailed and functional. There’s no compromise needed to hit volume targets or tool limitations. This is small-batch manufacturing at its finest, tailored for a bathtub but backed by industrial thinking.

Beyond the 3D printed paddle boat, the same design logic carries over to client work. Whether CNCROi.com is designing interactive exhibits, functional prototypes, or decorative installations, the balance of form, function, and durability remains consistent.

Each job benefits from the lessons learned in hands-on projects like the 3D printed paddle boat—where tight tolerances, material properties, and part interaction are tested in a real-world environment, even if that world is a bathtub full of bubbles.

At the end of the day, CNCROi.com treats every project with the same mindset: make it better than what came before. Whether that’s by improving adhesion with better part orientation, strengthening components, or redesigning assemblies from scratch, the goal is simple—deliver something useful, fun, and built to last. And if that something happens to make a kid laugh during bath time, all the better.

Contact CNCROi.com today to bring your custom CNC or 3D printed idea to life.