3D Printed Paddle Boat: Prototyping Design Challenges

CNCROi.com tackled a fresh round of prototyping design challenges with the evolving paddle boat project—now on its fourth version. Jon set out to build a simple elastic-powered paddle boat for his son, but as with all things involving custom fabrication, it quickly escalated into a layered journey of design refinement, problem solving, and hands-on iteration.

Starting from version one, which was more experimental sculpture than watercraft, each successive prototype addressed new performance shortcomings and added structural improvements.

Version one had fundamental flaws, the kind that only reveal themselves once a boat is put in the hands of an excited child. It lacked the weight and balance needed to stay upright under tension. With just one elastic for propulsion, it spun around, sure—but added power made it want to flip like a pancake. Not ideal for an object meant to float.

So Jon reworked it into version two, beefing up the hull slightly but finding that the balance issue remained. Too much energy in, not enough stability out. The boat was enthusiastic but unpredictable, like a caffeinated duck.

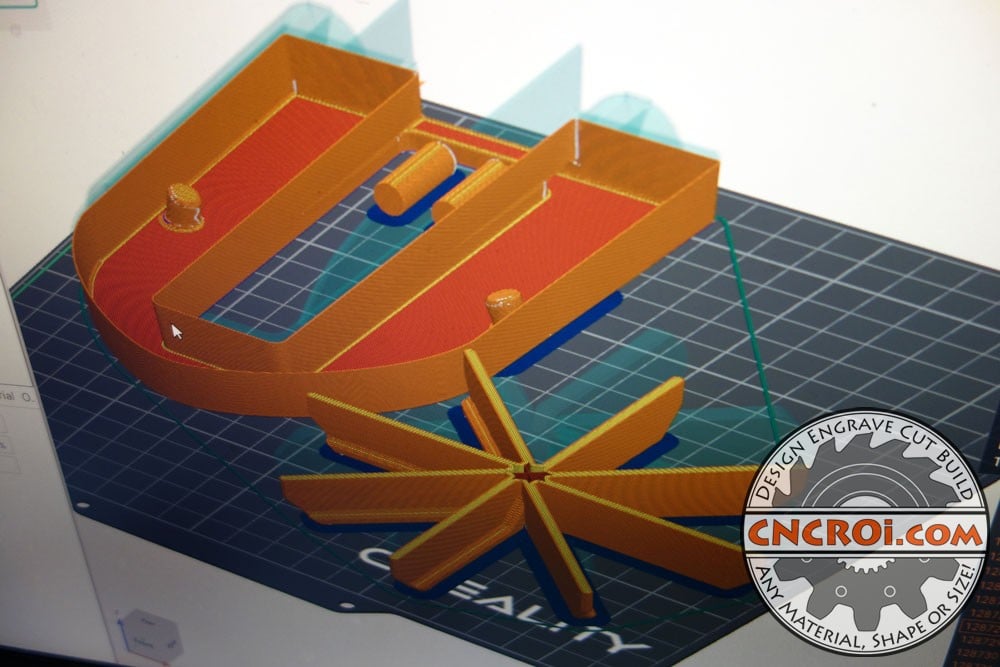

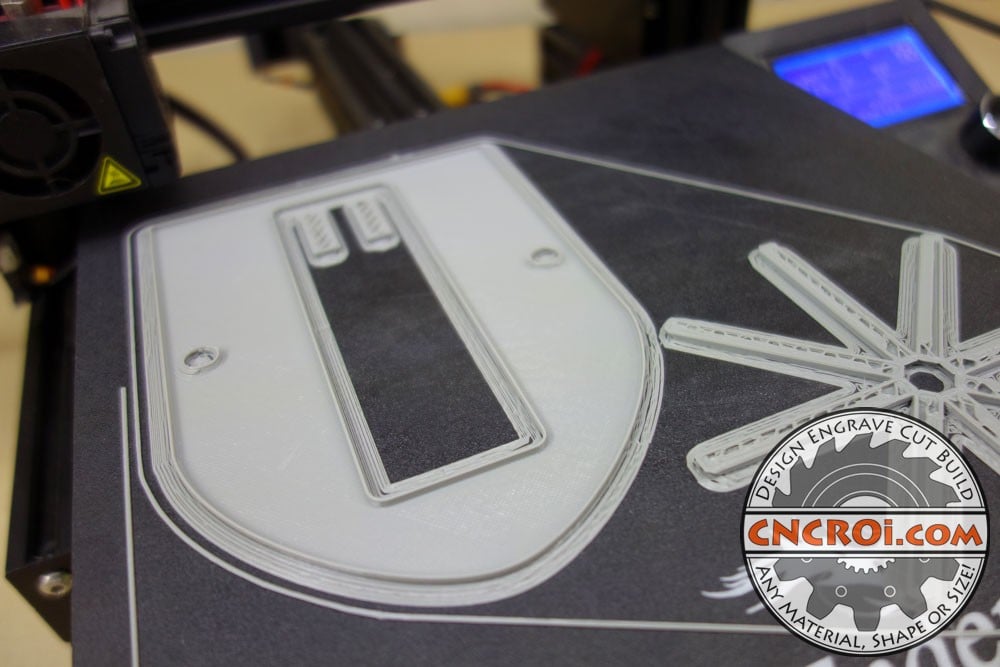

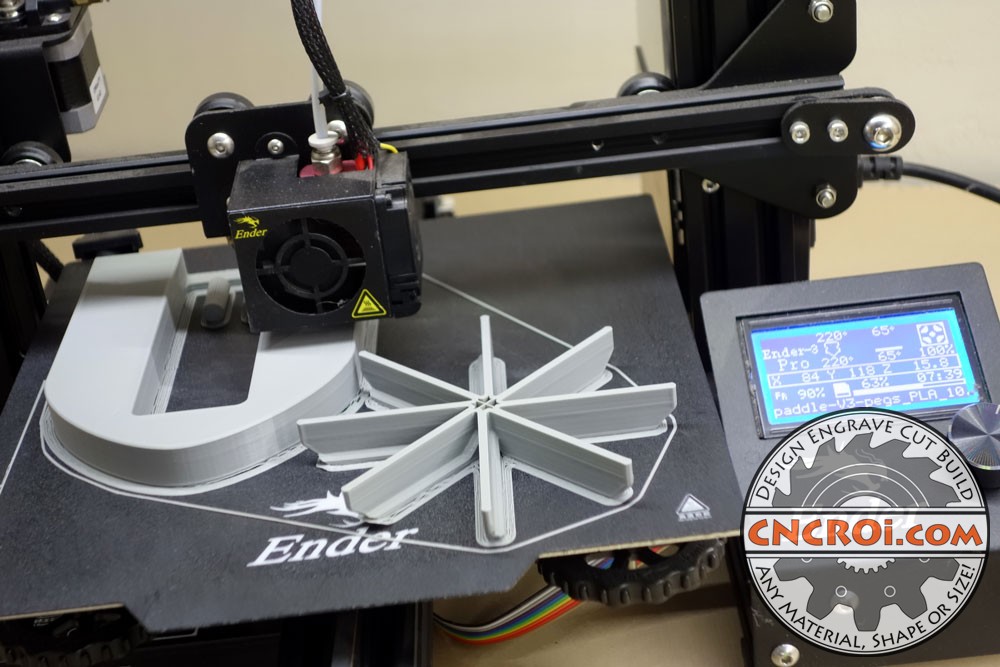

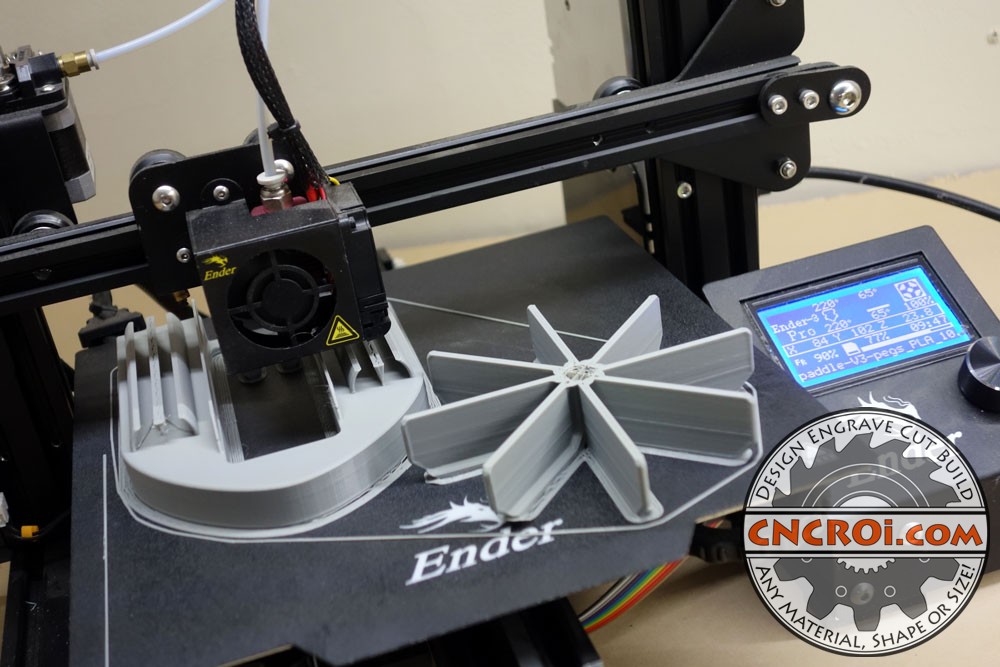

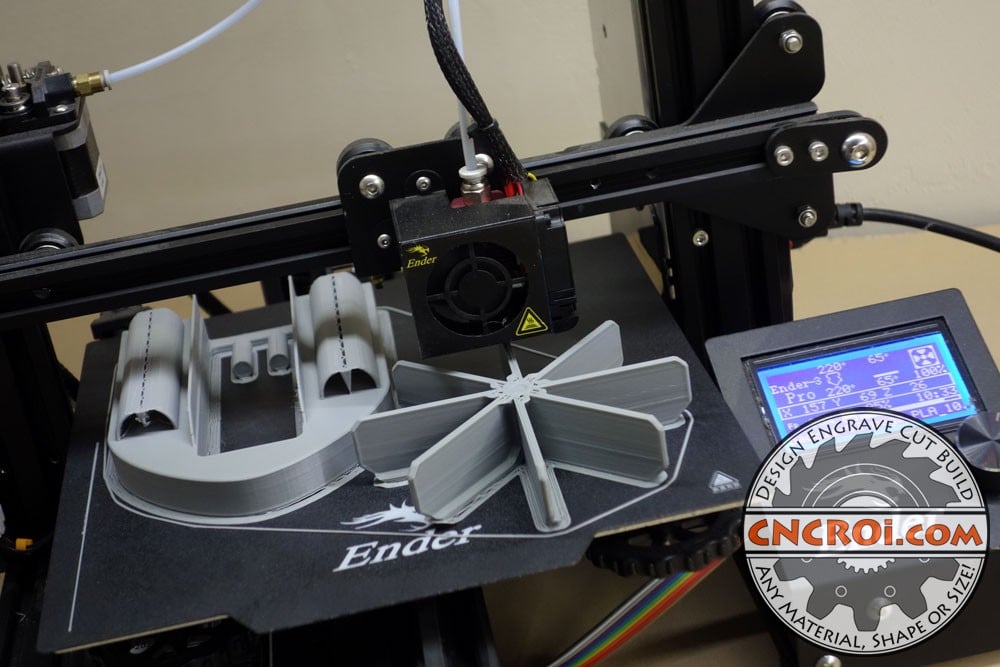

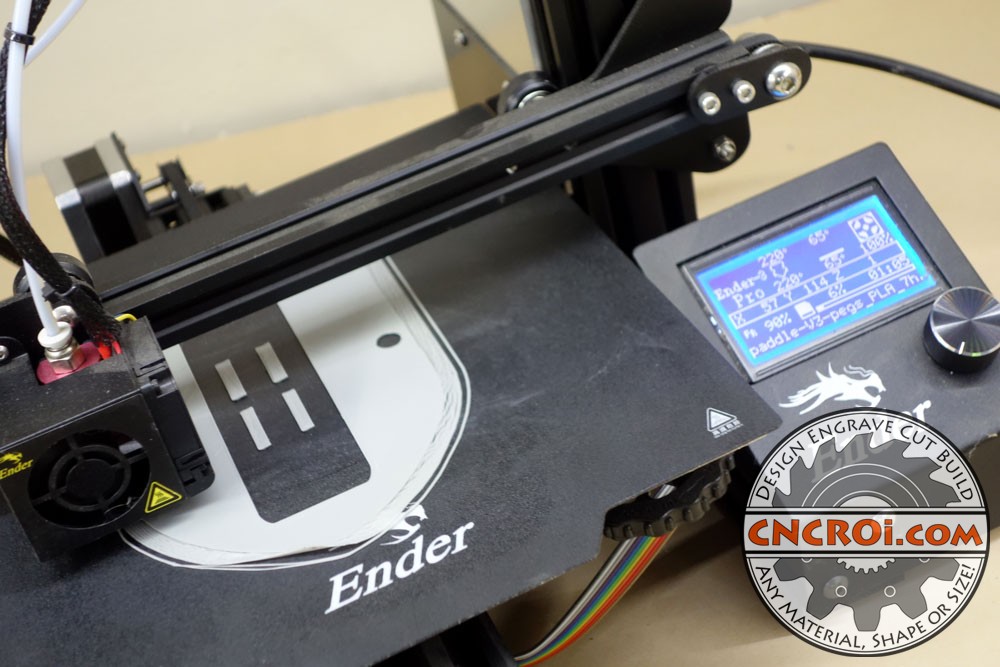

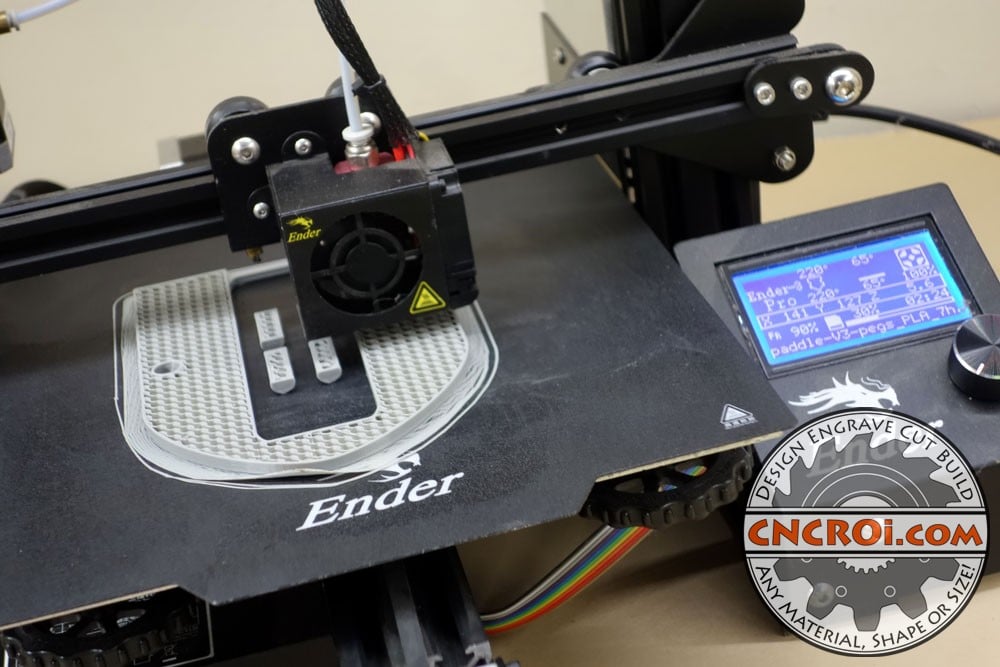

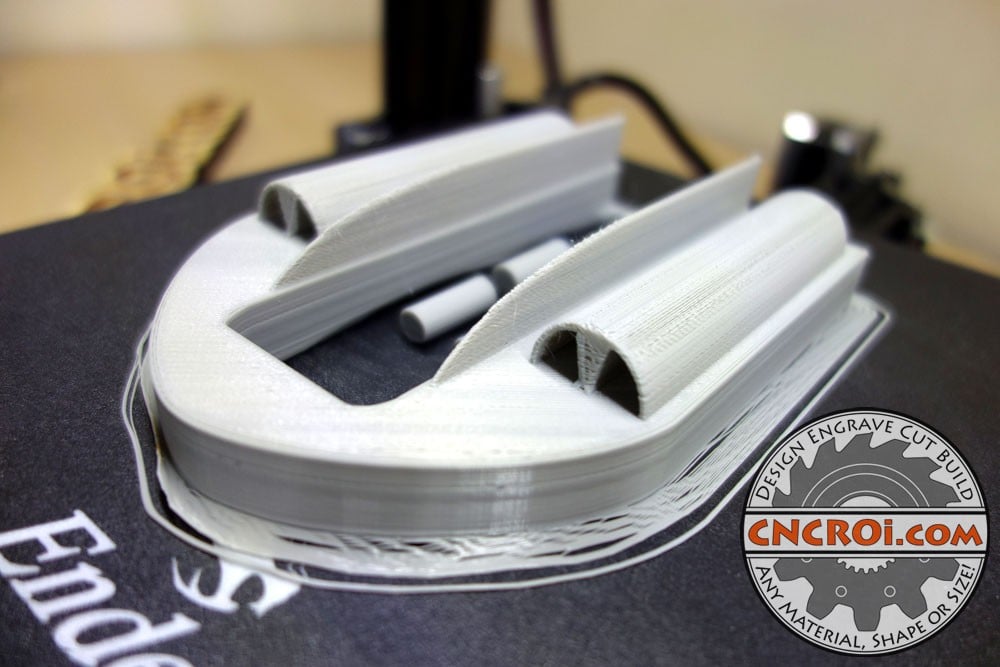

By the time version three hit the Ender 3-Pro 3D printer, Jon had gathered enough insights to make meaningful changes. First, he added mass directly to the paddle assembly by making it thicker, giving the boat more inertia. Then came the pontoons—two hollow floats designed not to resist water but to embrace it.

By letting water fill them during use, Jon added natural ballast. This clever bit of inverse buoyancy meant that once spinning began, the whole craft was less likely to flip over from the reaction force.

The pin system anchoring the paddle was also reimagined. Earlier versions had vertical pins, which bore the load in a single direction and created stress points. Version three introduced angled pins to distribute forces more efficiently. This shift in geometry allowed the assembly to handle elastic recoil without torquing itself into a pretzel.

These kinds of small but significant adjustments show how solving prototyping design challenges is often a matter of finding where the forces want to go—and helping them get there in peace.

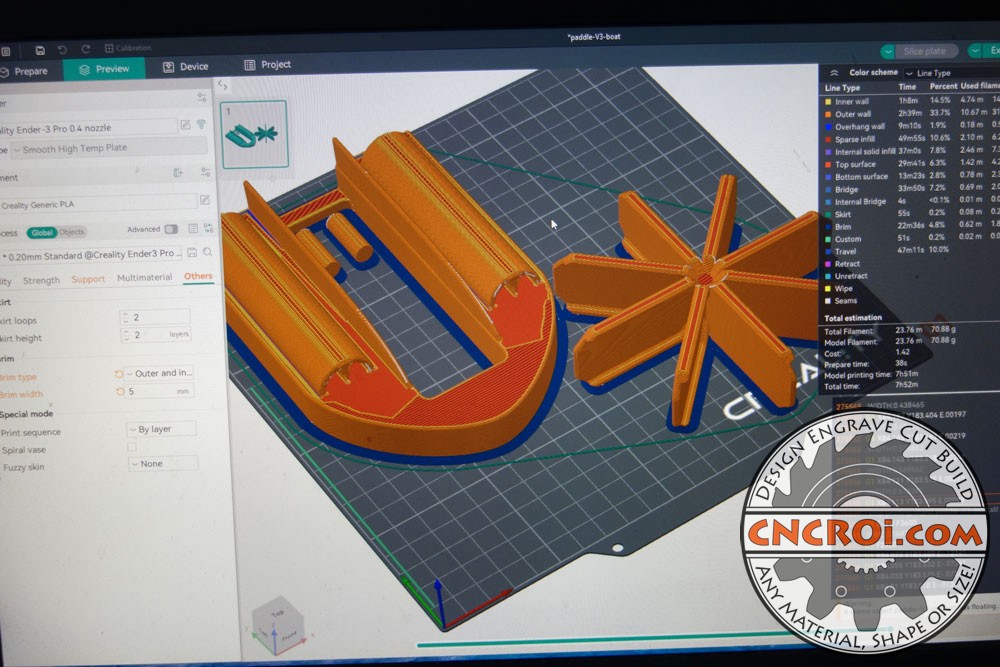

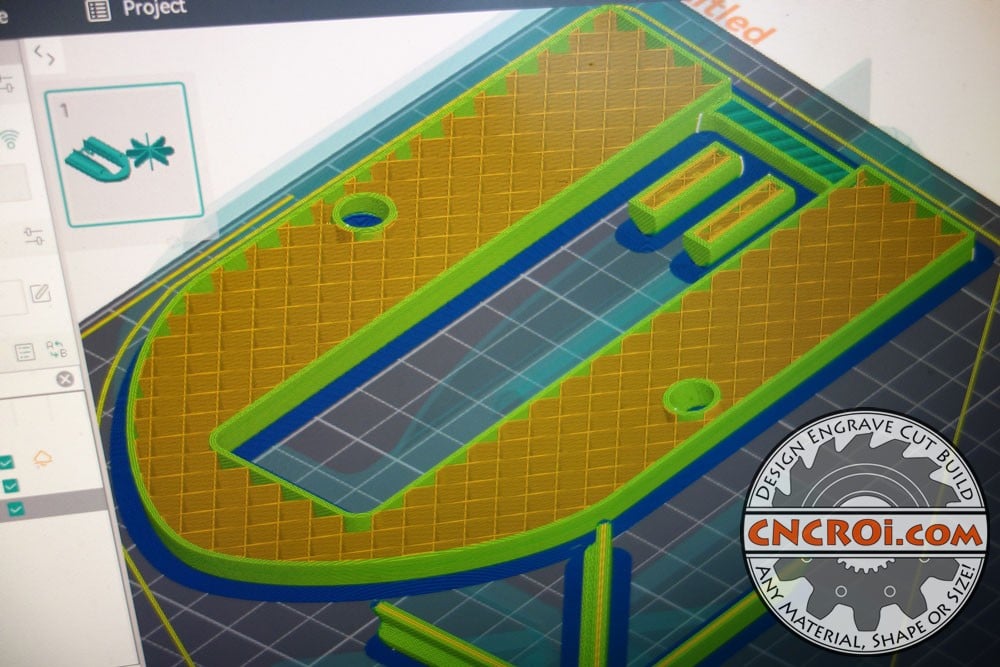

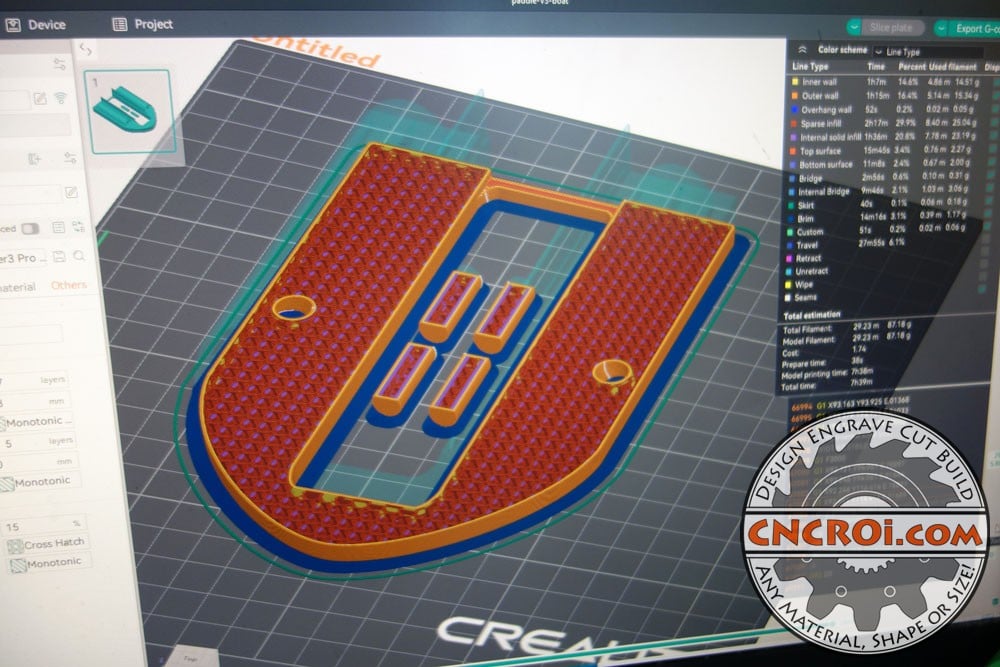

Designing for a 3D printer like the Ender 3-Pro brings unique headaches. Unlike CNC routers or lasers that operate on two axes (X and Y), 3D printing involves the third dimension—Z, or height. More dimensions, more room for things to go wrong.

During a print, if any axis is misaligned or misconfigured, it doesn’t just mess up the surface; it can cause a full-blown structural failure. In one version, the slicing software failed to generate proper infill, so the model printed hollow where it should have been dense. Without internal support, the top layers simply fell in on themselves like an overcooked soufflé.

This problem was traced back to a missed simulation step. CNCROi.com normally reviews print simulations to catch errors like this, but because the design had been printed before, Jon skipped that check. Classic trap.

The lesson was loud and clear: slicing previews are not optional, no matter how many times you’ve run the file. Especially when solving prototyping design challenges, the details always matter.

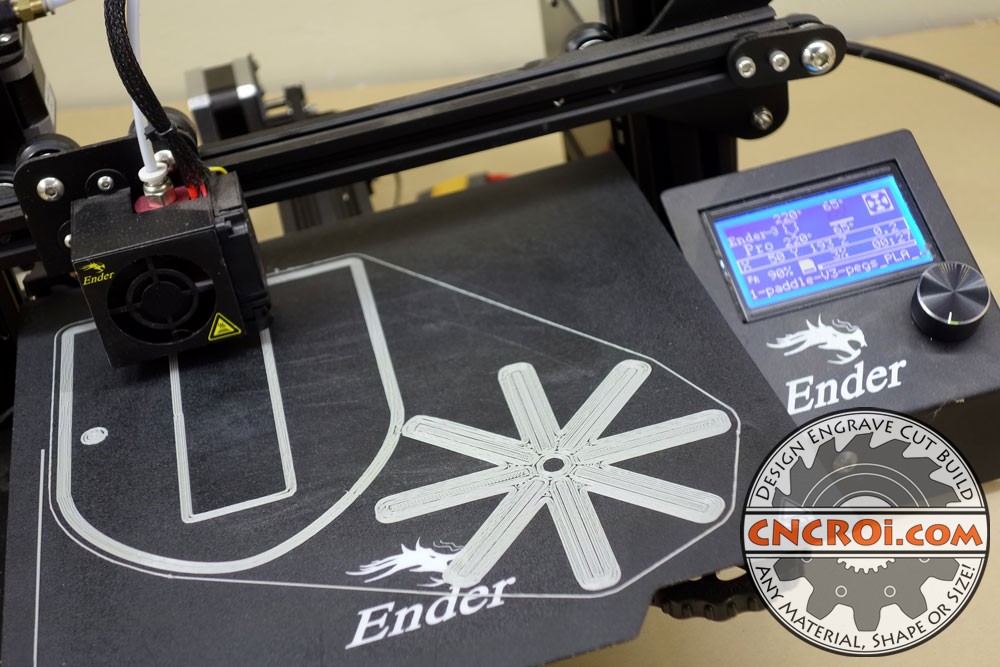

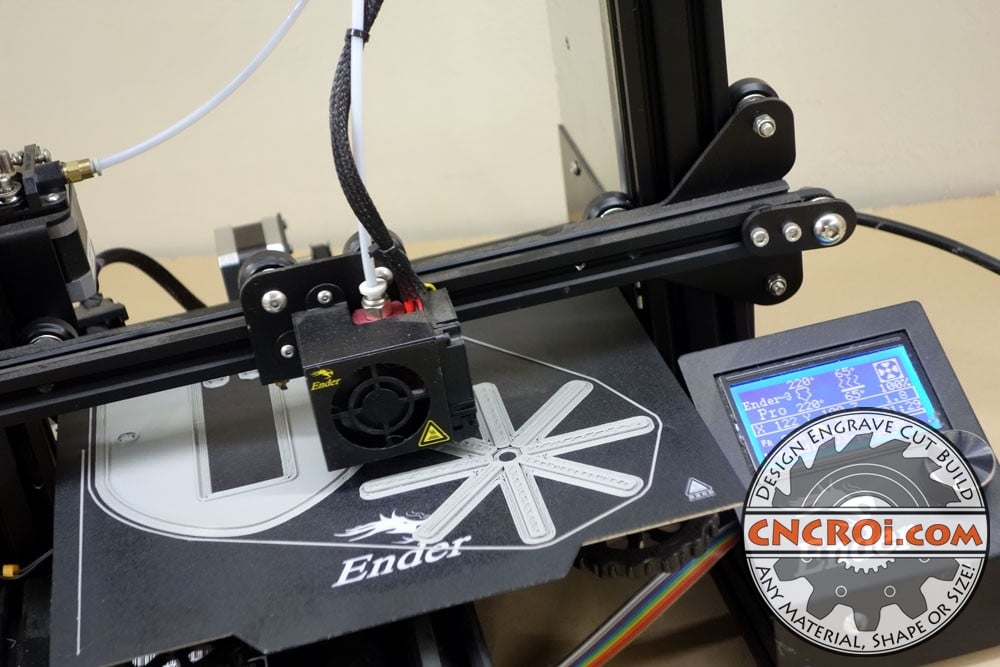

Despite using an older Ender 3-Pro, the results were consistently strong. While newer printers boast faster speeds and fancy features, speed isn’t everything when you’re focused on quality. Most prints run overnight, monitored remotely via camera.

Whether it takes ten hours or twenty, it doesn’t slow down workflow. That makes an older but reliable printer like the Ender 3-Pro perfectly capable for in-house design testing.

Of course, CNCROi.com is keeping an eye on modern printers—especially enclosed-chamber models, which open the door to advanced materials like carbon-fiber infused filaments. Stronger, heat-resistant, and ideal for demanding customer applications, these materials require a more controlled printing environment.

But until a clear winner emerges from the rapid-fire innovation happening in the 3D printer market, patience is the smarter investment strategy.

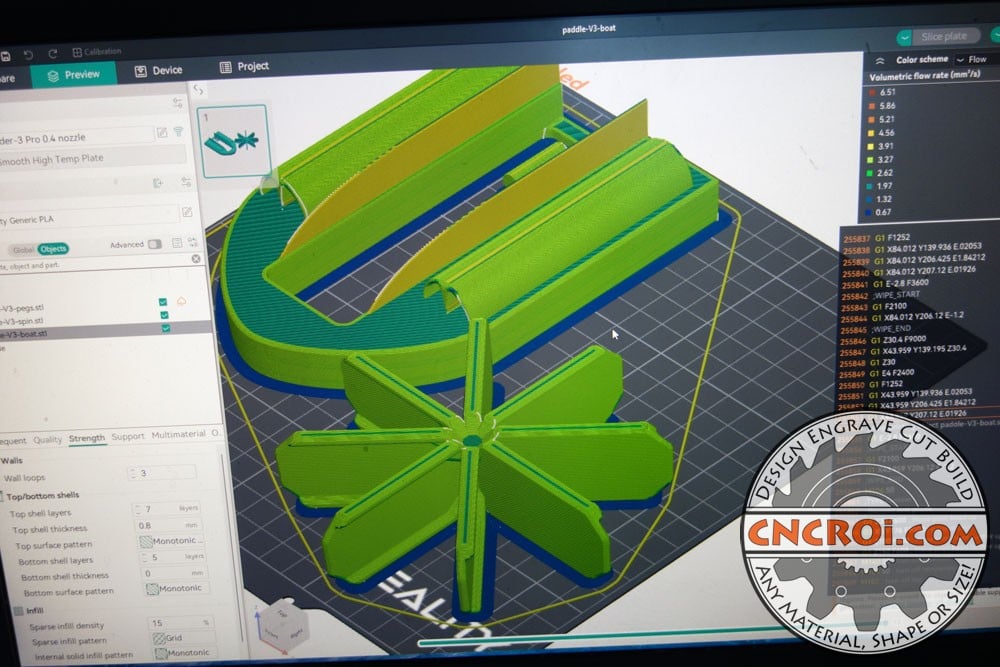

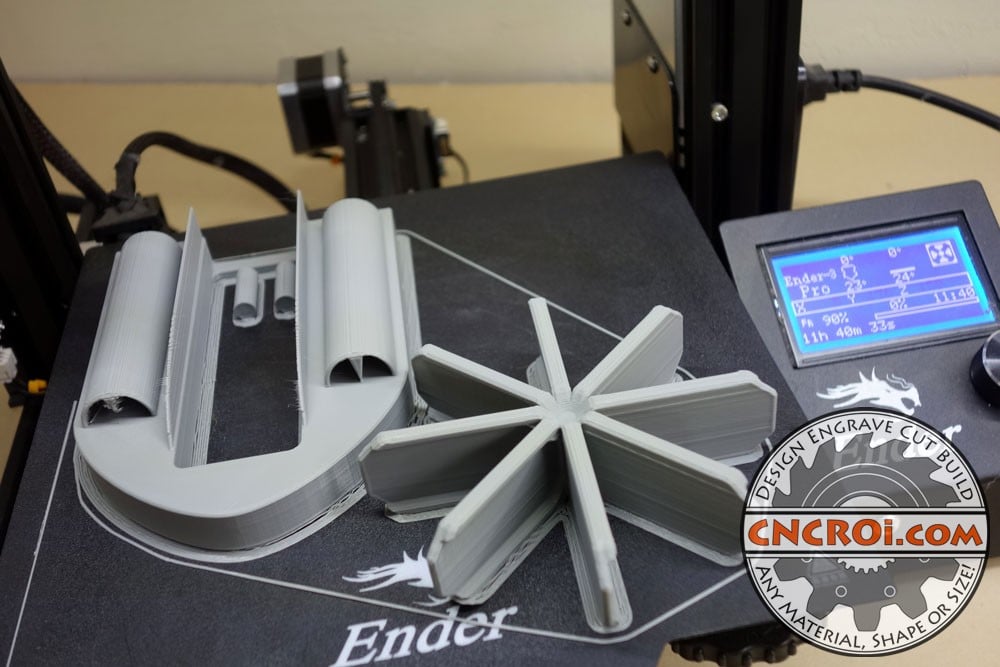

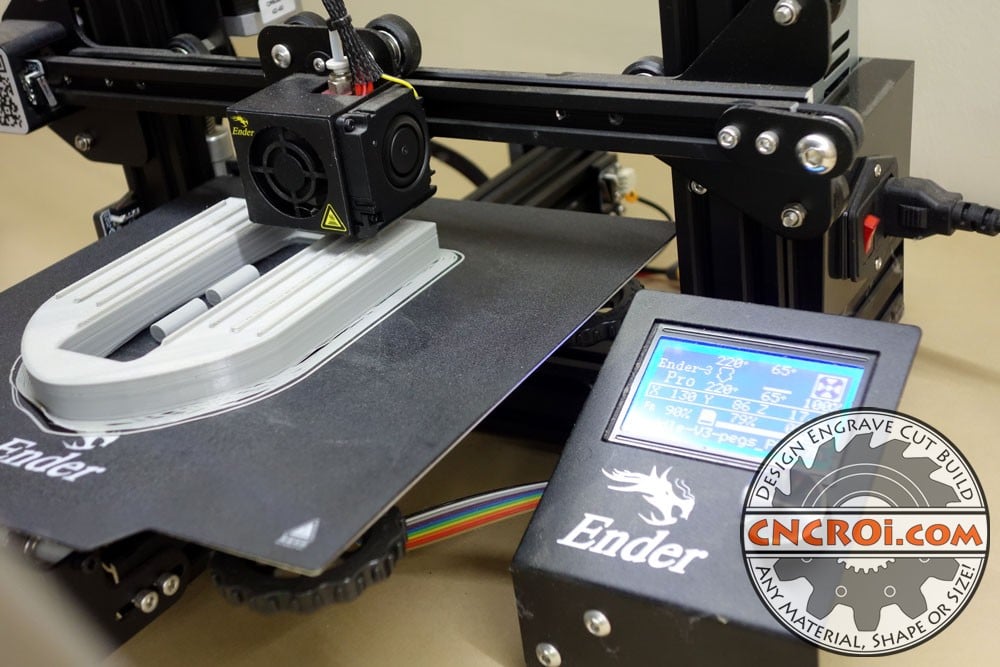

As version three wrapped up, another hiccup appeared—this time, scale. Comparing the new model to the previous one, it became clear that something had gone a little wonky. The latest print stood taller, likely the result of an unnoticed 5% scaling change before printing.

It still fit together, barely, but any pressure on the winding mechanism caused rubbing and jamming. That’s the sneaky thing about 3D modeling software; it’s easy to accidentally bump a scale value and not notice until you’re sanding edges or hearing plastic grind against plastic.

Still, that’s the magic of rapid prototyping. If something’s off, you just print it again. With a print time of 11 hours for the full boat and 7 to 8 hours for individual parts, it’s a manageable cycle. Iteration becomes part of the design process, not an interruption.

Jon reflected on how 3D printing differs from CNC work. Subtractive methods—like plasma cutting or routing—remove material from a block. Additive manufacturing builds it up layer by layer. But the modeling process behind both is often similar.

Good design principles, like managing tolerances or accounting for torque loads, carry across machines. The difference is in execution. CNC cuts. 3D printers construct.

What makes additive especially powerful is how it consolidates steps. A single 3D print can achieve what might require routing, gluing, and fastening across three machines. Add a logo, a gear, and a fixture point into the model, and the printer builds it all at once.

For prototyping design challenges, that’s a serious advantage—less time, fewer variables, and more integrated functionality.

CNCROi.com is also eyeing advanced filaments to push designs further. PLA is great for most uses, but tougher applications call for tougher stuff. With the right printer, materials like PETG, nylon, and carbon fiber blends unlock new possibilities.

That includes everything from customer jigs and fixtures to product enclosures meant for outdoor use or mechanical stress. The more materials available, the more problems CNCROi.com can solve creatively.

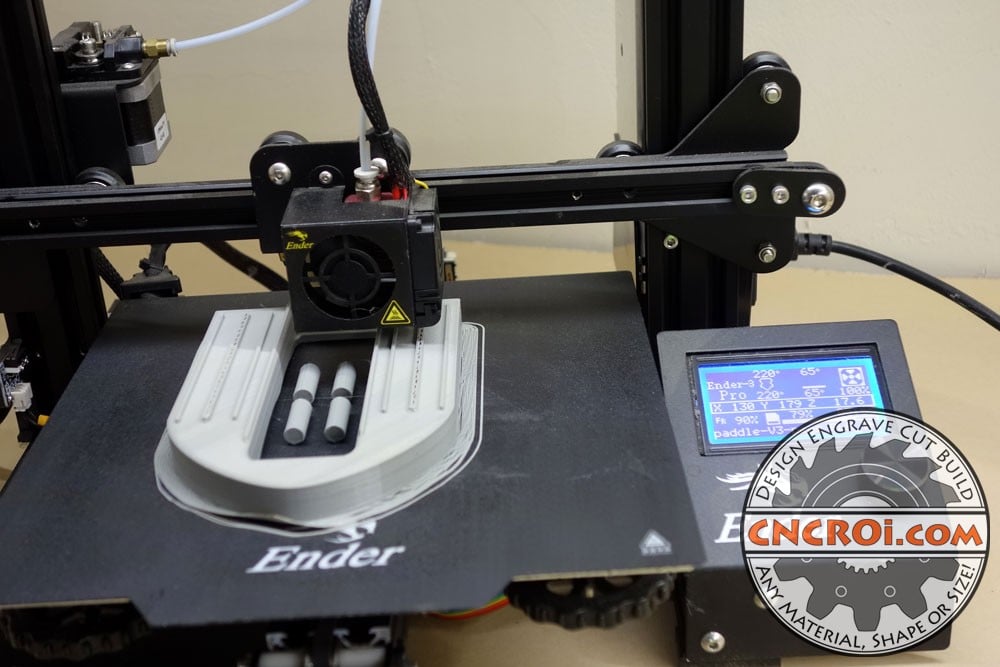

When version four rolled off the Ender 3-Pro, it looked nearly complete. The most obvious improvement was thickness—especially in the paddle arm, which had previously been a thin 0.302 mm strip that offered all the rigidity of a spaghetti noodle. This time it was bulked up properly. Fitment was cleaner too, thanks to a corrected approach to modeling gaps.

In earlier versions, shell and solidify modifiers were applied in 3D Studio Max to beef up the geometry. But those modifiers also bloated the mesh slightly, throwing off tight tolerances. In version four, Jon modeled those thicknesses directly, no modifiers, and the result was a clean snap-fit.

Still, a few thin areas remained—places where wall thickness looked strong on screen but felt fragile in hand. Those will be addressed in version five, where the solution is simple: double the wall thickness and get on with it.

Not everything needs to be elegant. Sometimes you just need more plastic between you and the water.

This paddle boat journey has been more than a kid’s toy—it’s a rolling case study in how iterative design meets practical constraints. From design software quirks to slicing bugs to physical assembly snags, every stage introduced new variables to solve.

And that’s exactly the kind of environment CNCROi.com thrives in—where complexity meets creativity and nothing is truly finished until it works, prints cleanly, and ships reliably.

If your next project needs prototyping, custom 3D modeling, or hands-on fabrication with real-world use in mind, CNCROi.com has you covered. From paddle boats to parts for your production line, we handle the unexpected so you don’t have to. Let us help you bring your vision to life—start to finish, layer by layer.

Continuing with the fourth version, one additional design refinement CNCROi.com implemented was balancing the force distribution between components. The elastic-powered paddle assembly exerted significant rotational energy, which, if not counteracted properly, caused structural twisting.

By adjusting both the mass and angular alignment of key parts, CNCROi.com ensured the boat not only remained upright but also maintained directional stability. The result was a smoother propulsion cycle, reducing vibration and unexpected lurching that had previously caused capsizing or directional veering.

The choice of the Ender 3-Pro 3D printer played a key role in refining this process. While it’s not the newest on the market, it offered more than enough precision and reliability to consistently produce functional prototypes.

With careful calibration, proper bed leveling, and a reliable filament feed, each print was clean, dimensionally accurate, and ready for functional testing within hours. CNCROi.com demonstrated that for many prototyping design challenges, you don’t need the flashiest tools—just tools that do their job, print after print.

Another takeaway from version four was the importance of tolerances in fitment. CNCROi.com learned that even a fraction of a millimeter off in the shaft diameter or a slot depth could make the difference between a part snapping together perfectly or refusing to assemble at all.

That’s why careful measurement in CAD software and real-world adjustment post-print are essential steps. Layer height, extrusion width, and even nozzle temperature can all impact the final outcome. These details may seem minor, but when repeated across multiple components, they can add up to a lot of unwanted friction—literally.

During testing, the team at CNCROi.com noted how changes in material thickness had a direct impact on the paddle’s durability. While earlier versions cracked or flexed too much under tension, the reinforced fourth version held up much better under repeated use.

This kind of stress testing, while simple in execution (just give it to a kid and see what breaks), provides invaluable data. Iterative physical feedback is a key tool in solving prototyping design challenges, especially when real-world users are involved.

In addition to the paddle and pontoons, the hull geometry was slightly revised in this iteration to provide better water displacement. While the pontoons added weight and lateral balance, the hull’s curvature controlled forward momentum and prevented drag-induced tipping.

CNCROi.com took these fluid dynamic principles into account, shaping the hull to guide water away from the paddle mechanism. As a result, each rotation translated into more efficient propulsion instead of just splashing.

By using a multi-part print approach, CNCROi.com also ensured each component could be reprinted independently if needed. This modular philosophy is useful not just for cost-saving during iteration but also for long-term maintenance.

If a customer breaks a piece or wants a design upgrade, CNCROi.com can send just that part, no need to redo the entire assembly. This type of foresight is key when tackling larger-scale prototyping design challenges, especially for products meant to be used over time or in different environments.

Beyond physical improvements, each design version gave CNCROi.com insight into process optimization. From better model export workflows to naming conventions and print queue organization, each step offered an opportunity to reduce overhead.

So whether you’re developing a part for industrial machinery or something more whimsical like a paddle boat for your kids, CNCROi.com has the experience and facilities to make it happen. Through every version, test, reprint, and redesign, the team is dedicated to building better results with fewer surprises. Reach out to CNCROi.com for your next custom project and see what’s possible, one layer at a time.