Aluminium Christmas Ornaments: Fiber Laser Cutting

Let’s make some custom aluminium Christmas ornaments… a bit of a delay in posting things but I’ve had a full plate of stuff to get to at CNCROi.com in the meantime.

The customer who wanted us to cut these aluminium Christmas ornaments will be TIG () welding them together, so we didn’t need anything thick, these are 16 ga, or roughly 1 mm or 1/16″ to give you a little perspective.

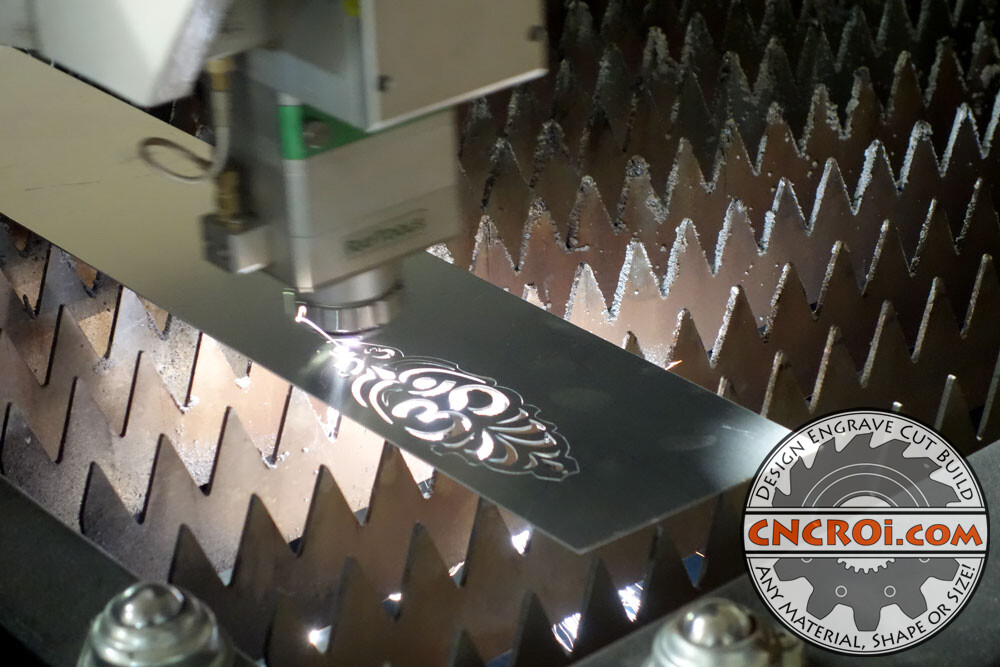

As they weren’t sure as to the sizing they’d eventually go with, we made these in several sizes from which they’ll do a larger production run based on their customer’s feedback and their own preferences when it comes to fabricating these.

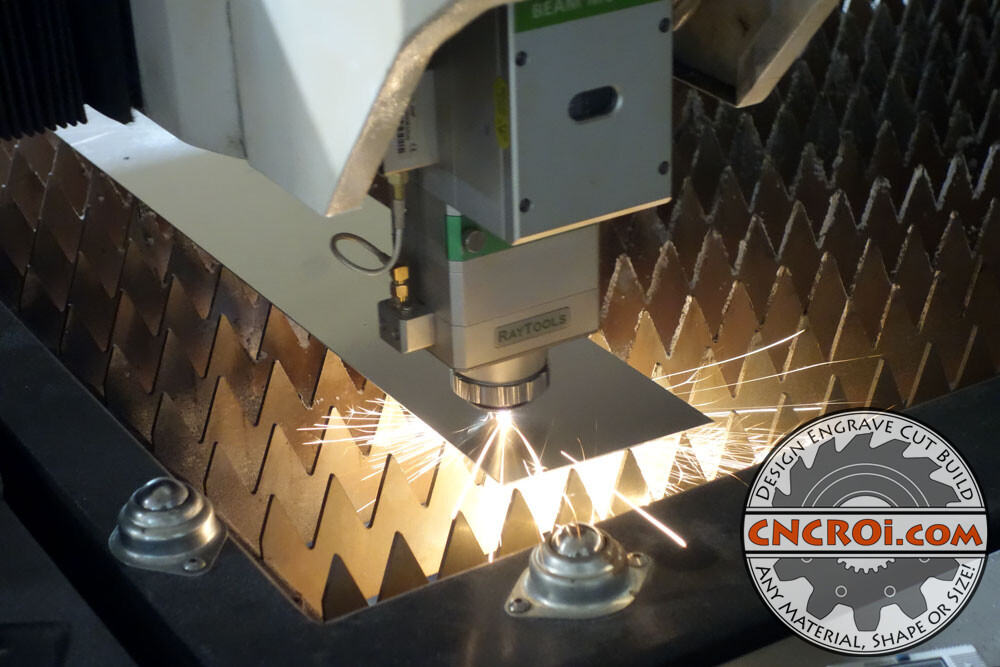

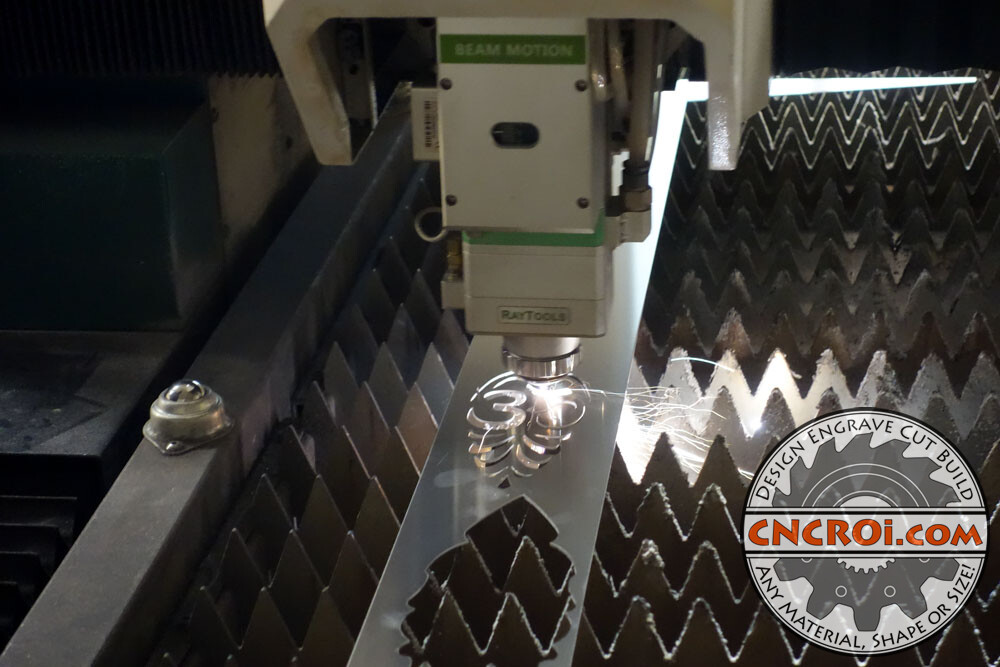

Due to how thin this is, and being aluminium, the best machine for the job was actually fiber laser cutting, which is what you see here at CNCROi.com.

Most of the aluminium we process at CNCROi.com is actually anodized ahead of time, using a fiber laser like this one but an engraving rather than cutting optimized machine, we vaporize and bleach the surface.

It’s tough to do such thin stuff using waterjets as it can start to vibrate and move around while with plasma cutting, it’s like using a sledge hammer to knock in a pin nail, too much power and too many small intricate parts that can cause issues.

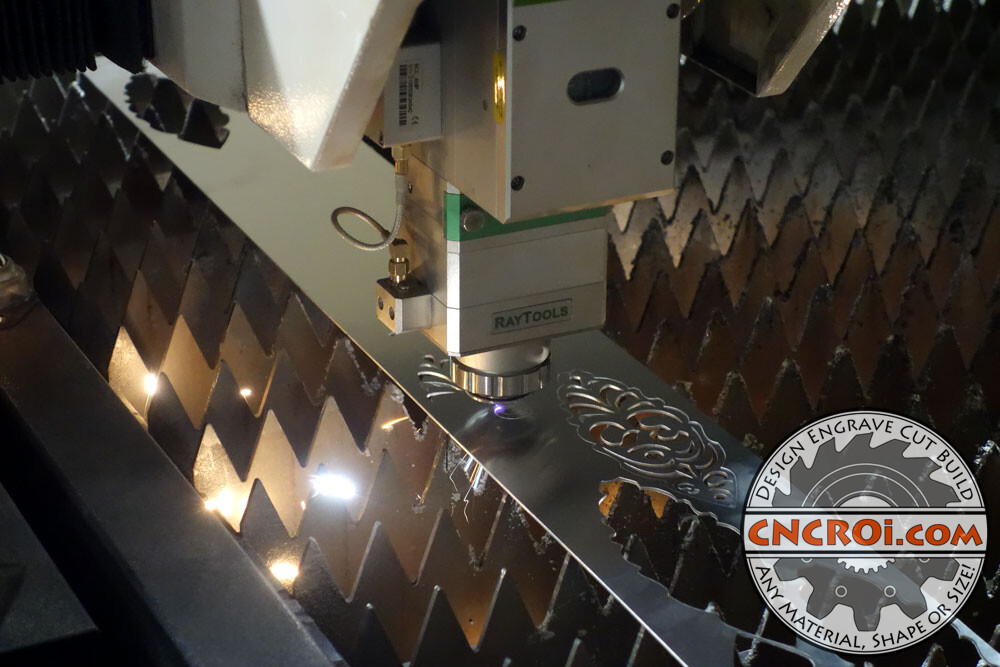

For this specific project, as CNCROi.com was cutting various sizing of the same thing but in very low quantities, it was decided that using scraps was the best way forward, it’s a pain to do production runs with lots of little bits but if you are making lots of little bits, then it works perfectly to not waste material.

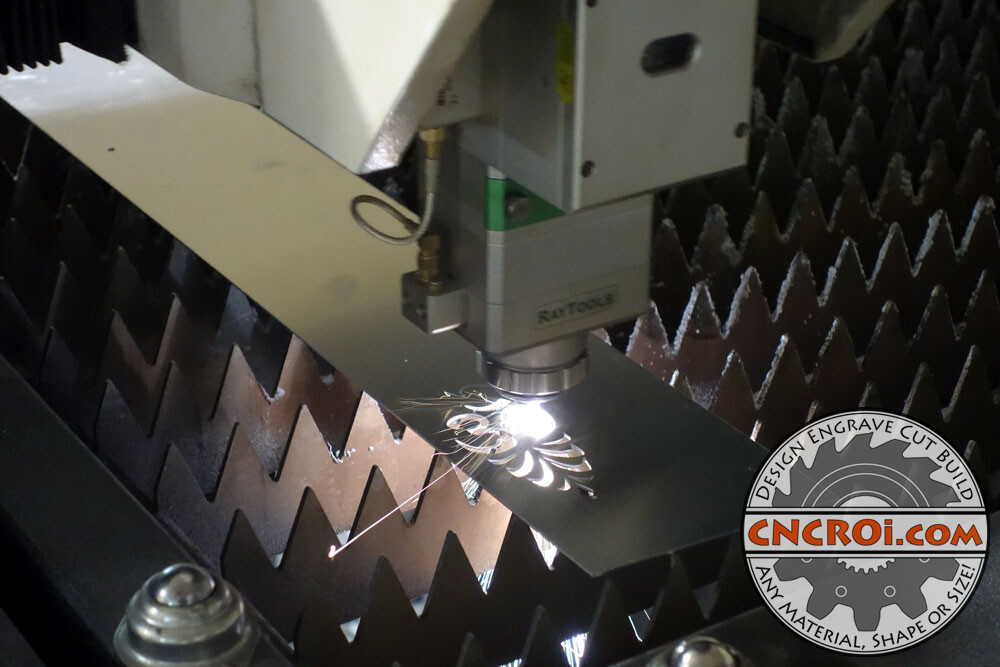

There are always issues with such a small and detailed part though as these custom aluminium Christmas ornaments are, because the little bits like to lift from the compressed air shooting down, they tend to leverage themselves up, as a result, they have to be manually picked after pausing the machine… that’s why you see fingers and hands removing them and I edited out exponentially more of that happening during the process as well.

What’s nice about anodized aluminium vs clear coated as this is, are the colors that are available, hence why we use a lot of it for name badges and company branding requirements.

These custom aluminium Christmas ornaments are made out of aluminium because it’s light weight, very easy to gas tungsten arc weld together and easily modified into a ball by the customer, this would have been a pain to do if it was stainless steel.

When it comes to laser cutting, or plasma cutting, or waterjet cutting or router cutting, they are all pretty much interchangeable, but they all have different optimal production envelopes and that’s what CNCROi.com offers it’s customers, the best machine for the job.

Regardless of the platform CNCROi.com could have used to make these custom aluminium Christmas ornaments, they would all produce some sort of dross on the underside, as a result, post-processing is required and that’s why you see me sanding the front and backside of all of these parts.

If you are wondering what waterjet cutting aluminium looks like, here you go!

You have to keep in mind that lasers are invisible, fiber or CO2, which CNCROi.com has both, so what you are seeing is the results of the laser working on the aluminium, not the laser itself, other than parts raising up, it’s a completely non-contact method of production, meaning the machine (other than the bed), never touches the custom aluminium Christmas ornaments during production.

Laser cutting aluminium is actually quite fun, we could have used our CNC router to cut this as well, but not having to hold things down and the speed of which a laser can move with little fuss makes it a dream platform to fabricate these custom aluminium Christmas ornaments.

Laser cutting custom aluminium Christmas ornaments was done in pretty short order, what took a long time was actually the pausing and resuming of the project as it was being cut because of little shards of aluminium raising-up and requiring to be removed, as if they hit the head, they would drag the aluminium sheet and thus, everything cut previously would be out of spec.

Fiber laser cutting can be done at incredible resolution but so can the engraving at CNCROi.com, of course, we can easily mix and match, so we can laser cut then laser engrave if required.

Although these different sized custom aluminium Christmas ornaments are al the same design, CNCROi.com could have done a unique design for each of them or mixed and matched the design in any which way, as you can see from the laser cutting process, each is essentially done one at a time.

The nice thing about using CNC equipment to produce these custom aluminium Christmas ornaments is that they are size agnostic, meaning that whether these ornaments are big or small, it makes no difference to the machine, same goes with quantity, the first like the last is cut to the same spec as the machine doesn’t get tired or need a coffee break.

The other thing I enjoy about CNC equipment are the tight repeatable tolerances they can maintain during a production run, some of the details on these custom aluminium Christmas ornaments are so small, even using a hand-saw, I don’t know it would be possible to do them repeatedly over time to the same quality.

The reason we use anodized aluminium for engraving rather than marking it “black” is because those processes are permanent, unlike ceramic bonding paste.

The above picture is a great illustration that no matter how much sparking you see on top of the sheet, like plasma, there is a lot more being shot down through the material during the cutting process, it’s quite a fireworks display that I get paid to produce for CNCROi.com customers!

After the production run, you can gain a better understanding at just how tight some of the tolerances were on these custom aluminium Christmas ornaments.

Of course during production, there are scratches that develop so that’s why, along with dross, I sanded both sides at CNCROi.com, it gives it a nice finish.

If you are wondering what engraving raw aluminium looks like, the video below shows you, hence why we generally work off anodized sheets for better contrast.

Below is a close-up, you can see how this job wasn’t possible using our CNC router as all those inner sharp details would be severely limited due to using a round diameter bit and plasma, well, they would have been a lot less sharp as the diameter of vaporization is a lot larger than fiber laser.

Need custom aluminium Christmas ornaments? Contact CNCROi.com right now!