Aluminium Tag Marking… and Galvanic Corrosion Issues

Can CNCROi.com make Aluminium Tags? That’s the question I got the other day while on a sales call… the answer is…

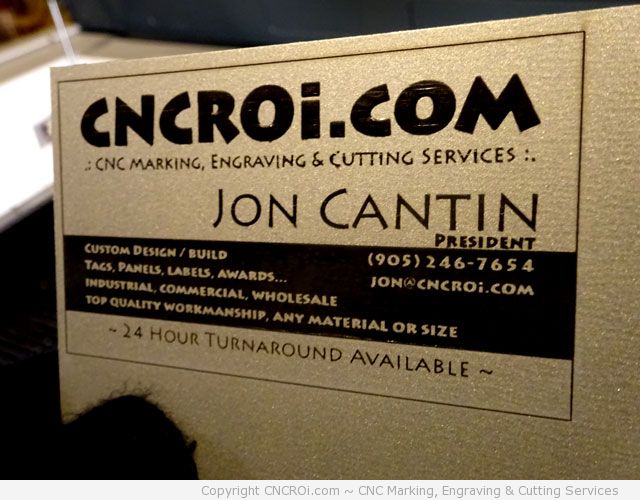

Fresh from our Austrian CNC laser… still needs to be cleaned-up a bit. Cut lines are shown around the card.

Although the sample above still needs to be cleaned-up and cut out, you can see the incredible contrast we can achieve on a variety of aluminium that has been specially coated to be marked using our Austrian CNC laser.

Stainless Steel VS Aluminium

Although I far prefer to use stainless steel or even anodized aluminium over this specialty aluminium, the results are far better than what can be achieved with sublimation or screen printing as it can be completely customized one-offs, the process is comparatively fast and the results are far more permanent.

There are a few reasons why I try to steer customers towards stainless steel (304 at a minimum), although the cost is a bit more and the processes take a bit longer, you get something that will still be readable with the dinosaurs once again take over the Earth… you can’t say that about these aluminium plates. They will degrade and pit.

Stainless steel is also far stronger, you can whack it with a hammer, ram it with a forklift and you’ll still have it mostly in one piece (though a bent and dent quality). I can’t say the same about aluminium… the nice thing about aluminium is that it’s very light but as most of our clients use these plates to attach to their steel machines, they introduce a major issue by using these plates. Galvanic corrosion.

Stainless Steel in the middle surrounded by Anodized Aluminium plates.

Beware of Galvanic Corrosion

Of all the clients CNCROi.com has currently, very few of them make any kind of equipment out of aluminium. Most of them make their stuff out of various grades of steel but mostly it’s 304 stainless steel, so adhere our custom 304 stainless steel tags using rivets or welding them right onto their products. Try that with aluminium tags onto their products and you’ll end-up with galvanic corrosion which happens when you put two different kinds of metals or alloys together, one will act as an anode, the other a cathode due to their different electrode potentials. The anode metal will slowly dissolve into the electrolyte and that will collect onto the cathodic metal. Basically, where the two different metals meet, you end-up with accelerated corrosion because you created an artificial battery.

Ways around Galvanic Corrosion

There are a few ways around galvanic corrosion, the easiest is applying a coating so there isn’t metal on metal contact, another is using rubber stoppers in the screw holes and so forth. Basically, you just don’t want the two different alloys or metals to touch so the electrolyte has no way of taking from one and depositing onto the other… but why bother? Just let CNCROi.com make tags in the same metal you are using at the point of fixation and you won’t have problems. It’s quicker and more efficient for everybody.

Engrave or mark the WHOLE part

Things brings-up an interesting situation, something I’ve been telling more and more customers about… why bother making tags at all? Just give us the part and we’ll engrave, anneal, mark or etch it directly. YOU DON’T NEED TAGS! Because we have a massive bed capable of sliding pieces several meters long by a meter wide, we are in a unique position to do this.

CNC fiber annealing on the left, CNC fiber marking on the right.

For some applications, this is well worth it as there are no material costs at our end (passed onto you) and no extra production steps at your end. This works great in the military and aerospace applications side where the added weight and tolerances created with affixing a metal or aluminium tag add extra burden that’s best avoided. Engraving, annealing or marking the part directly doesn’t increase weight, is just as permanent as a tag and can be done even at a microscopic level if needed, like adding unique part numbers or customer order codes.

So if you are looking for a company that’s capable of CNC laser marking, engraving, annealing, etching just about any material, give CNCROi.com a call!

Oh yeah, here’s the video of the aluminium tag being made with our Trotec Speedy 400 flexx dual-source laser… the only one in Canada!