American State Cigar Ash Trays: Alabama & Texas in Cedar

CNCROi.com can produce custom American State cigar ash trays at any size, shape or material but today we’ll focus on Cedar which makes a wonderful smell when the customer uses it for these Alabama and Texas shaped trays.

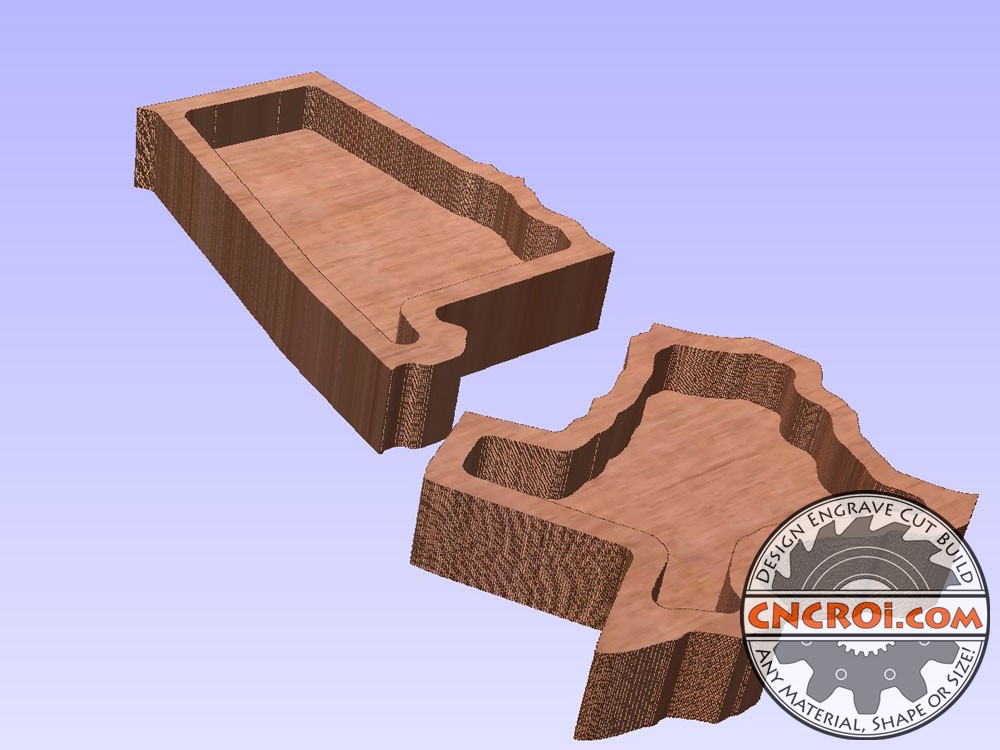

The process is essentially the same regardless of which state, country or universe CNCROi.com makes custom American State cigar ash trays, it all begins with a digital simulation to make sure the design makes sense and will be usable by the customer for their intended application.

Although we can make these custom cigar ash trays out of any wood species, Cedar is very hard to beat, it has a perfect weight to strength ratio for this applications, smells great both while we make it and the customer uses it ans most importantly, has a natural preservative in it that gives it a great shine with incredible resilience from rot.

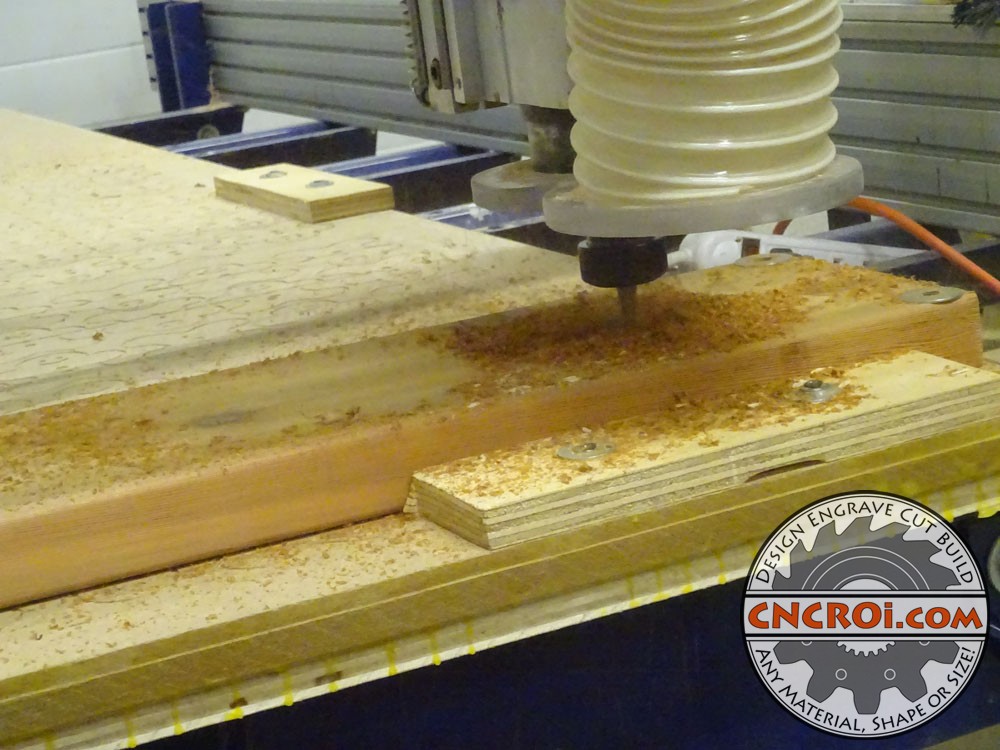

To make this these American State cigar ash trays don’t move, they are bolted to the surface of our full sheet CNC router, CNCROi.com is going full speed through this board for the rough cutting and hollowing out then a kiss cut to smooth out the roughing introduced during the initial production of the trays.

How custom can CNCROi.com produce cigar ash trays? We can even make them based on letters from the alphabet!!!

There are additional hold-down boards around the Cedar board just to make sure nothing moves if a screw gets loose as again, we are really going fast and furious through this to produce the optimal chip load, which means we don’t wear out our CNC router bit from the heat generated from cutting through Cedar which is a very dry wood.

Hollowing out the American State cigar ash trays is a fun process, the smell of Cedar almost hits the shop immediately and although the results look rough initially, Cedar sands wonderfully after the fact.

If you are wondering what a production run of custom Texas cigar ash trays looks like, watch the video below.

The other massive bonus of Cedar are the knots, our CNC router cuts straight through them and our CNC laser engraves into them with relative ease but they add tremendous character to each and every American State cigar ash trays we produce at CNCROi.com.

You can see the Cedar chips produced by our CNC router really look great, if we went slower, they would be a powder like substance and going too fast would break the bit… it has taken us a long time to optimize our settings to produce the best quality American State cigar ash trays possible.

What else does CNCROi.com use Cedar for? How about custom house number signs!

For all the wonderful qualities of Cedar, it does have one drawback, it’s a little brittle to shock, so sometimes our aggressive approach produces a less than stellar American State cigar ash trays but no worries, we can always cut another one if something didn’t work out.

Here you can see the initial roughing pass in the image below from our CNC router, the reason the American State cigar ash trays didn’t move is because CNCROi.com left about a 1/8″ 3 mm strip of material in the board, this is easily cut out using our bandsaw and sanded down.

Having more than one machine allows CNCROi.com to offer incredible flexibility when it comes to making custom Cedar house number signs or custom Cedar cigar ash trays in any shape, size or within any branding requirement.

There are a lot of dynamic pressures put onto the spinning bit as it cut through the Cedar in the initial pass, this leads to some bit deflection where it isn’t always exactly 90 degrees to the CNC router surface, as such, removing about a fraction of a mm of material by going over it a second time assures that this time around, it’s perfectly 90 degrees and as such, produces a nice smooth polished finish.

Although you still see the machine marks in the image below, you can see a bit of shine and far better clean-up of the bottom of the American State cigar ash trays than the photograph two images up from the one below.

If you are wondering what kind of resolution CNCROi.com can achieve on Cedar board, here’s a great video showcasing just that, this is before any sanding.

Next step was to liberate these two American State cigar ash trays from the Cedar board, our bandsaw does quick work of this, the goal isn’t to produce a flush cut, it’s just to roughly take it out of the Cedar board and then sand the resultant cut-outs flush.

The reason why CNCROi.com sands flush rather than bandsaw flushes the American State cigar ash trays are because Cedar is easily sanded and the edges need to be sanded anyways, the bandsaw might cut into the side requiring a lot more sanding so by doing things this way, it leads to a more efficient production of the custom cigar ash trays.

CNCROi.com can make pretty much anything out of wood, here’s some custom cottage signs but those could have been made out of Cedar just as easily.

After an initial sanding, you can see how the edges that were one pronounced are almost all gone, CNCROi.com then sands the other spots the initial sanding belt couldn’t with a spindle sander.

The results are looking spectacular, it’s amazing what can be produced using just a CNC router, bandsaw and a little sanding!

Next-up is to stick both these custom American State cigar ash trays into our wide-format industrial CNC laser for the personalization on the back, again, the smell is great in the shop when we do this!

CNCROi.com is even able to make custom cabinet fronts using our CNC laser for branding all around the house.

Where our CNC router wins in speed, our CNC laser wins in resolution, any font can be laser engraved by CNC router onto these American State cigar ash trays including imagery if you wanted.

The results on the back of these American State cigar ash trays look amazing like the front, it’s really a lot of fun to see how we transform a board into something this beautiful that will be appreciated for decades to come!

If you want a custom cigar ash tray (we strongly recommend going with Cedar), contact CNCROi.com right now!