Arcade Bartop Cabinet: Routering MDF

At CNCROi.com, the team embarked on an exciting project: building a custom arcade bartop cabinet. This wasn’t just any DIY — it was precision-crafted using CNC routing and high-grade materials like 19 mm (3/4 in) and 12 mm (1/2 in) MDF (medium-density fiberboard).

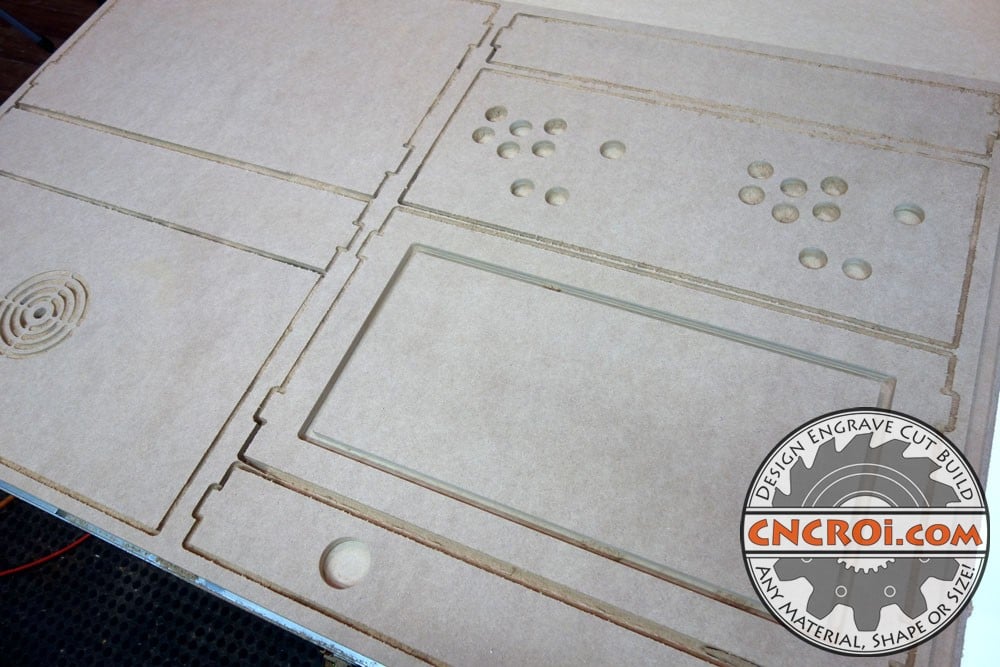

The arcade bartop cabinet was designed to house joysticks, buttons, screens, and all the electronic fun a customer could want, but importantly, CNCROi.com ensured it was delivered flat-packed so the customer could handle the internal electronics without the headache of disassembly.

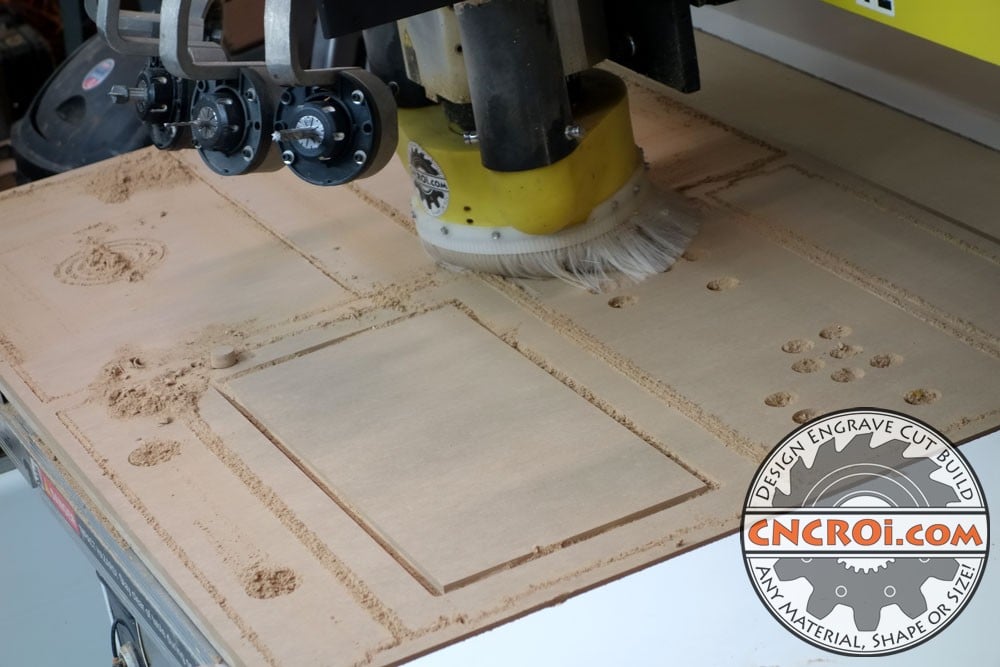

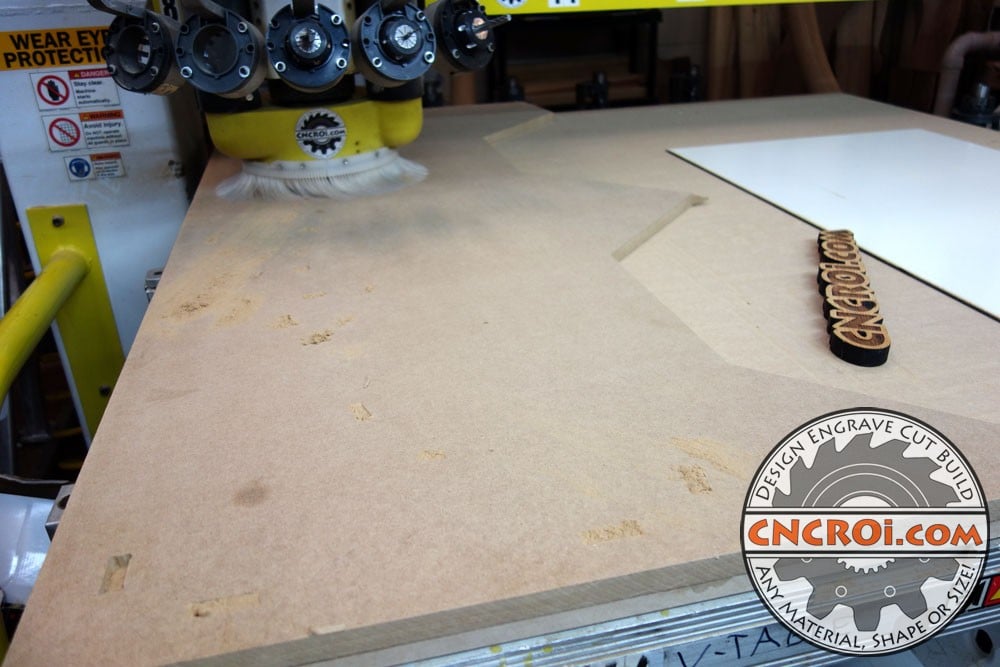

The process started with careful material choice. MDF was selected because it’s easy to cut, sand, paint, and adjust, making it perfect for projects like this arcade bartop cabinet. Jon and the CNCROi.com crew understood that MDF can create an incredible amount of fine dust, often leading to what Jon humorously called the “MDF headache.”

Thankfully, their shop was equipped with an industrial vacuum system attached directly to the Thermwood CNC router, pulling down the MDF sheets and sucking up most of the dust right off the table.

Additional vents and fans around the shop helped keep the air breathable — though, Jon admitted, sometimes finishing work still kicked up enough dust to trigger the occasional headache.

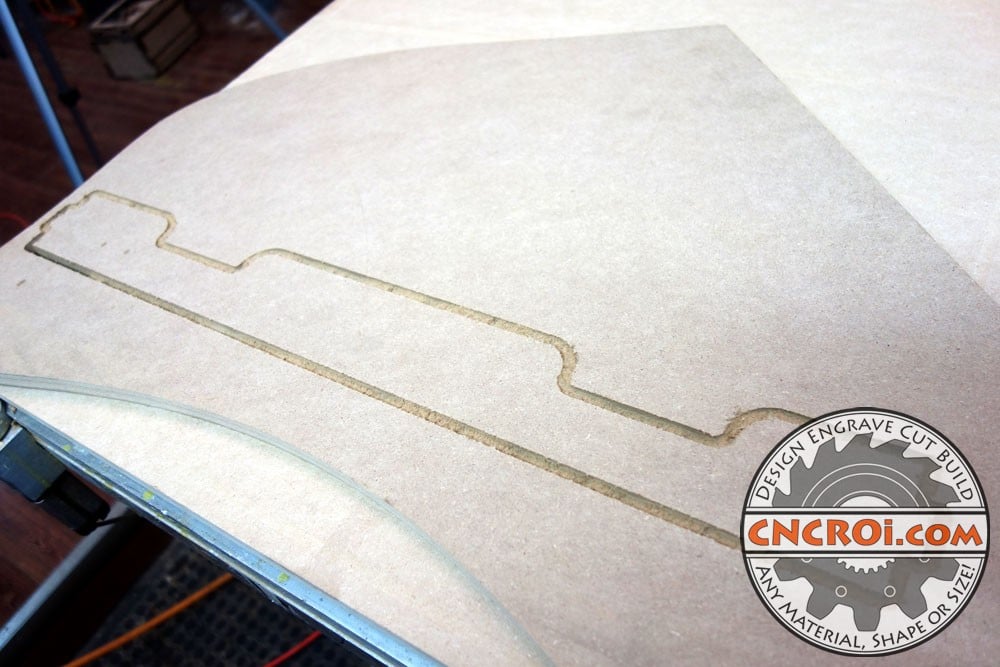

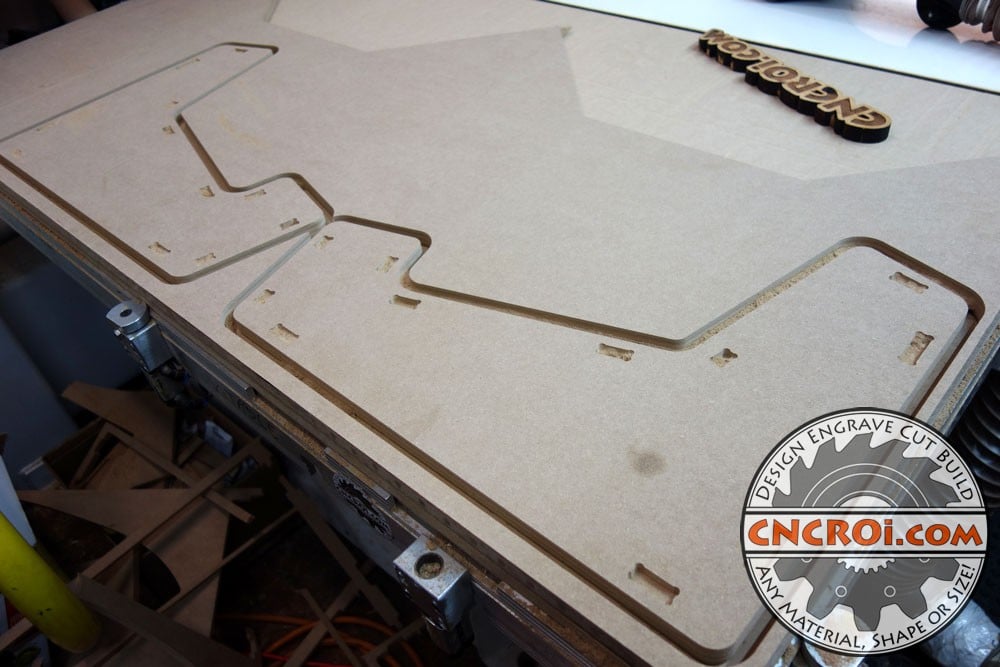

The CNCROi.com team took extra care when cutting the MDF panels. They wanted the arcade bartop cabinet to fit together perfectly, but they also needed to make sure the customer could handle final assembly easily. That’s why they didn’t glue the pieces together in the shop.

If everything had been pre-assembled, the customer would’ve had to tear it apart just to install the electronics, and nobody wants to risk loosening precision parts. Instead, they shipped it as a perfectly milled kit, ready for the customer’s magic touch.

MDF was a great material choice, but CNCROi.com is far from limited to wood-based projects. Jon often reminded customers that the same arcade bartop cabinet could be built from stainless steel or mild steel — and in those cases, it would be welded, not glued.

Sure, there would be some design file adjustments to account for the different material properties, but CNCROi.com had all the machines, tools, and skills needed to switch seamlessly between materials and processes. They could easily swap MDF for acrylic too, using the correct CNC bits to avoid melting or burning the edges.

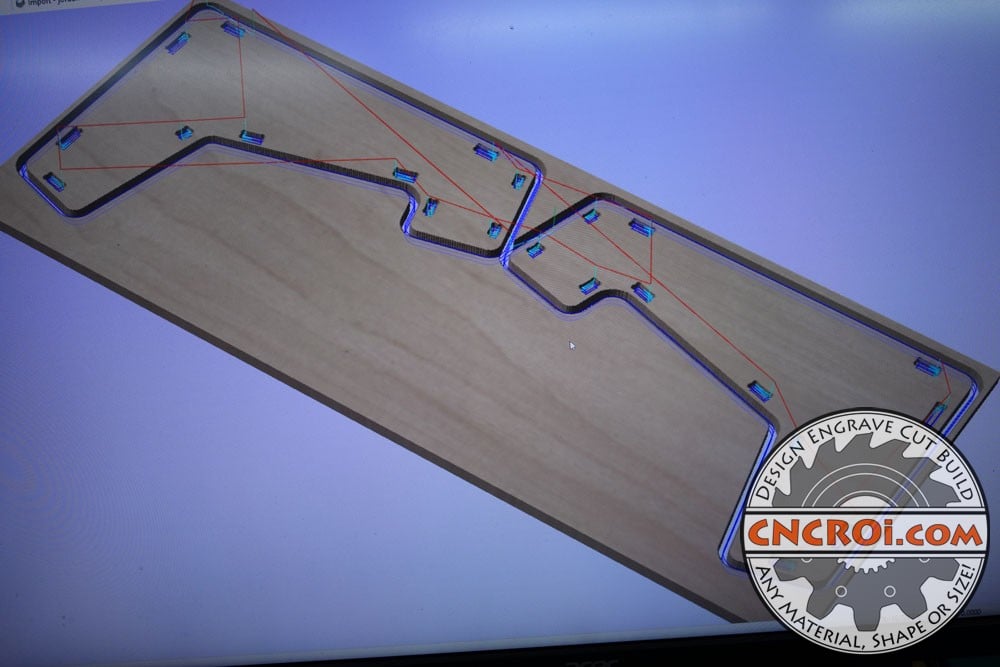

One big advantage CNCROi.com offered was scalability. The arcade bartop cabinet, or any project, wasn’t tied to a fixed size. Thanks to digital design files, everything could be scaled up or down without losing precision. Want a miniature version? No problem.

Want a towering full-size arcade cabinet? Easy. CNCROi.com worked digitally, so they were material-independent, machine-independent, and size-independent. Customers just needed to send their design specs, and the team could make it happen.

While cutting the MDF, the Thermwood CNC router underwent several tool changes, but Jon preferred to keep those to a minimum. Tool changes create small pauses in production, so CNCROi.com focused on maximizing efficiency for every project. This way, they could produce customer orders faster without sacrificing quality.

One technical challenge in CNC routing was inner corners. Unlike a laser cutter, which could create perfectly sharp inner corners, a CNC router used round bits. You can’t cut a square corner with a round bit — it’s simply not possible.

That’s where dog bone cuts and overcuts came into play. By slightly extending the cuts beyond the design’s exact line, CNCROi.com ensured all the slots and tabs fit together flush and tight, even if the corners were inherently rounded. Without these overcuts, assembly would be a nightmare.

After the pieces were cut, they would typically be glued together and tapped into place with a hammer to ensure a firm fit. Clamps would hold everything steady for a day, ensuring a rock-solid final assembly.

But again, for this particular arcade bartop cabinet, CNCROi.com left the final glue-up to the customer so they could handle their internal wiring and electronics hassle-free.

The shop’s workflow wasn’t just about woodworking. CNCROi.com often mixed materials and tested prototypes in various ways. For tricky designs, they’d first 3D print a model to check the fit and function.

Once everything was confirmed, they moved to MDF, then to the final material if needed — whether that was stainless steel, mild steel, or acrylic. This layered approach saved time, money, and headaches by solving problems before committing to expensive materials.

Jon liked to joke about MDF being a flexible material, perfect for quick fixes and small tweaks. If a slot was a little tight, you could just sand or chisel it down. But stainless steel? That’s a different story — there’s no casual sanding down a steel panel.

That’s why CNCROi.com emphasized precision in every material they worked with, ensuring the digital file was right before making the final cuts.

The arcade bartop cabinet CNCROi.com crafted was a great example of how adaptable the company was. Whether a customer wanted one in MDF, acrylic, or steel, or whether they wanted it tiny or massive, CNCROi.com could deliver.

Their shop was fully equipped with the tools and know-how to handle projects of all shapes, sizes, and materials. Customers just needed to reach out with their ideas — CNCROi.com loved a good challenge.

Even the bits used in the CNC router varied depending on the material. MDF needed one type of bit, acrylic another, and steel yet another. Using the wrong bit could cause burning, melting, or poor cuts, so CNCROi.com took great care to match the right tool to the right material.

That kind of attention to detail made all the difference, especially when scaling designs or switching materials.

One key takeaway from Jon’s process was that digital design files ruled everything. Whether a customer wanted a small change or a complete material swap, CNCROi.com could adjust the digital blueprint and get right back to production.

This flexibility made the company a great partner for anyone looking to build something custom — including those gorgeous arcade bartop cabinets.

CNCROi.com’s workspace was set up for maximum dust control. With strong vacuum systems and smart shop design, they minimized the mess that came from cutting MDF. But Jon admitted, no matter how good the systems were, some dust always made it through — especially during final finishing work. That’s just part of the game when working with MDF.

Efficiency mattered a lot to CNCROi.com. Every extra tool change, every pause in production, was time they could save with smart planning. That’s why they streamlined the cutting process and designed projects to minimize unnecessary complexity. It wasn’t just about getting the job done — it was about doing it better and faster for every customer.

While many think of CNC routing as a woodworking tool, CNCROi.com was quick to remind customers that they could handle much more. Steel, acrylic, composites, and more — their machines were ready for whatever the project demanded. And if a customer didn’t have a digital file ready, no worries — CNCROi.com could design one from scratch.

The arcade bartop cabinet project highlighted CNCROi.com’s strengths: precision cutting, material flexibility, and customer-first thinking. By shipping the cabinet flat-packed, they made life easier for the customer, who could focus on the fun parts — adding joysticks, wiring up the buttons, and bringing the arcade machine to life.

Jon’s shop wasn’t just about machines; it was about process. Whether scaling a design or switching materials, CNCROi.com focused on delivering consistent, high-quality results. That meant checking every step along the way, from digital files to final cuts, so customers got exactly what they wanted.

One of the shop’s clever tricks was using dog bone cuts to overcome the rounded-corner limitations of CNC routers. By carefully overcutting key slots, they ensured that panels slotted together perfectly, making assembly smooth and solid. It’s one of those little technical details that made a big difference in the final product.

Customers working with CNCROi.com didn’t have to worry about technical headaches. The team handled all the tricky bits — from tool paths to material selection — so customers could focus on their vision. Whether it was an arcade bartop cabinet or something entirely different, CNCROi.com had the tools and talent to make it happen.

Jon always emphasized that if you can dream it, CNCROi.com can build it. The digital nature of their work meant projects weren’t locked to one material, one size, or one machine. Customers just needed to reach out, share their ideas, and CNCROi.com would handle the rest, shipping a custom-made masterpiece right to their door.

Even when working with challenging materials like stainless steel, CNCROi.com approached each job with care. They knew when to test in MDF first, when to move to prototypes, and when to go full-steel production. That kind of thoughtfulness saved time, money, and hassle for everyone involved.

In the end, the arcade bartop cabinet was more than just a fun gaming project — it was a showcase of what CNCROi.com could do. Precision cuts, smart design, flexible materials, and customer-focused service all came together to create something special.

CNCROi.com made sure that every project, no matter how big or small, got the attention it deserved. Customers looking for custom arcade bartop cabinets — or anything else — were encouraged to get in touch. The team was ready and eager to help bring new ideas to life.

So whether you’re dreaming of a custom arcade bartop cabinet, a steel sculpture, or an acrylic display, CNCROi.com is your go-to partner. Reach out today, share your project, and let the CNCROi.com team turn your ideas into reality — all with precision, humor, and top-notch craftsmanship.

CNCROi.com didn’t just cut and ship parts — they thought about the whole user experience. For example, when designing the arcade bartop cabinet, they considered how the customer would interact with it once it arrived. By flat-packing the pieces, they gave the customer full control over the assembly and electronics, making sure nothing was damaged or loosened by premature shop assembly.

This kind of thoughtful planning set CNCROi.com apart, ensuring each arcade bartop cabinet project landed safely in the customer’s hands, ready for its final personal touches.

Beyond arcade bartop cabinets, CNCROi.com worked on a huge variety of custom CNC projects. Whether cutting elaborate signage, precision industrial components, or intricate decorative pieces, the team handled it all with the same care and precision.

They loved working with customers who had bold ideas and were always ready to suggest the best materials or processes to get the job done right. With every project, the goal was the same: deliver top-quality, custom-crafted results that fit the customer’s exact needs, shipped directly to their door, and built to last.

If you’re sitting on an idea — whether it’s a sleek new arcade bartop cabinet, a large-scale metal installation, or even a detailed acrylic display — CNCROi.com wants to hear from you. They’re eager to take on custom projects of all kinds and have the tools, machines, and experience to bring your vision to life.

So don’t hesitate; reach out to CNCROi.com today and let them transform your creative spark into something tangible, durable, and precisely made.