Army Transport Truck Model Kit: Design through Manufacturing

The army transport truck model kit I designed many years ago will be reviewed today at CNCROi.com as I update the 3D assembly animation of it.

Watch this video showing you how I went about cutting this model kit with our CNC router and then put it all together.

This 3D assembly animation shows you how the parts all come together for the army transport truck model kit.

We are able to cut it using a variety of technologies, CNC laser through router, it all depends on the end result you wish to achieve.

CNCROi.com had its beginnings in the same garage as these photos way back in 2012, what was way before I got my Austrian CNC laser and founded this company. Back then, I designed kits that were sold digitally all around the world for other CNC shop owners.

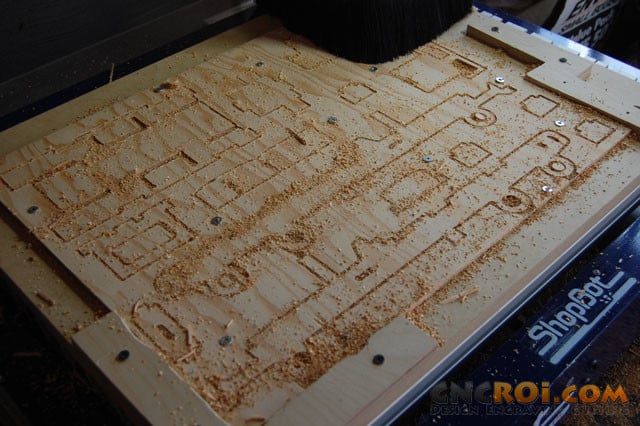

This ShopBot Desktop was our very first CNC machine, I cut my teeth on this machine and it taught me how to apply my designs towards custom engraving and cutting processes.

Cutting with an industrial CNC router is similar in some ways to our industrial CNC laser, there is a lot that goes into designing an army transport truck model kit or any other project for that matter.

With a CNC router, you have bits, pushing and pulling pressures and material hold-down issues to contend with.

While CNC laser cutting an army transport truck model kit is somewhat different, where we use a beam of energy that cuts and engraves through the base material.

CNC lasers are a no-contact cutting method compared to CNC routers but they are still very much a different machine, not any better or worse, just different in a production environment regarding capabilities.

For instance, we can use a vacuum table or screws (in these photos) to hold the plywood down onto the bed of the CNC router, otherwise, it would fly off the bed due to the spinning bit cutting through the board.

For this army transport truck model kit, it required a few sheets of plywood, if we were to use a laser to cut this kit, it would be all cut from one bigger plywood sheet.

The reason is simple, notice the wide spacing between the different parts on the above army transport truck model kit picture?

Well, we need to give room for our industrial CNC router’s bit to move around and enough room so the parts can be held in place until all the cutting is done.

With a CNC laser, this isn’t required as there isn’t any contact on the piece of wood, there is no need for tabs either to hold the piece in place while other parts are being cut, again, because there is no contact.

The importance of prototyping is shown in these two photos, no amount of digital proofing is equal to making a real model and assembling it yourself.

This is why at CNCROi.com, for some of our projects that have lots of pieces that come together, a prototype is required before going into full production.

For this army transport truck model kit, the only error I found was in two pieces, they were just a little bit too wide, it was, of course, in the digital model but just not noticed until actual cutting and assembly of it was performed.

Luckily, fixing these models is very easy, just fix the digital file and then go ahead putting it together again.

Here’s a comparison of our CNC laser cut army transport truck model kit compared to the larger CNC router version.

CNCROi.com model kits scale perfectly, want it bigger? Since I’m both the designer and “cutter/assembler”, there are infinite material and sizing options when it comes to producing these.

I’ve designed, cut and assembled hundreds of custom CNC models, all this experience goes into each model we create for our customers, from making custom corporate awards through to 2D designs.

This shows you the amount of engraving detail we can achieve using our industrial CNC laser, while with our CNC router, other options are possible like v-carving of custom models.

So, if you wanted a model kit (or anything else you get CNCROi.com to custom design) to have a beveled edges, depending on the design, our CNC router may be a better option.

After this army transport truck model kit was done drying (from the glue), it was time to go play with it in the forest to get some wonderful pictures done for promotional purposes.

If the model looks a little rough, it’s because it wasn’t sanded, with our Austrian CNC laser, the edges are all “burned” so there isn’t any roughness while with our CNC router (material depending), additional sanding is sometimes required.

I really like the look of natural materials, rough or otherwise, I think it adds character to a model but some of our clients have another stream of thought and want their work from us to be more finished.

As a result, that’s why we do all our work to spec and can offer that to our customers. CNCROi.com is a custom production shop, we make things to YOUR specs using YOUR material for YOUR application.

This army transport truck model kit is incredibly strong, the interlocking of the parts which you can see in the 3D assembly animation are what give it a lot of points of contact between each individual part.

Thanks to interlocking, each part helps to support other parts, at different angles, as a result, this model I designed will last a very long time even under abuse.

Although this army transport truck model kit wasn’t painted, it’s quite easily done and the results would look awesome but I really enjoy just having things natural.

Plywood is a wonderful material but that’s just where CNCROi.com begins, we can make these custom model kits out of any material, solid wood veneer through to lamacoids.

These models are all pretty simple to me, I’ve designed enough of them to just know how they should go together and what works rather than what doesn’t.

This self-taught knowledge has provided very helpful for many custom project we do at CNCROi.com.

I also published many books on the subject of making custom models like this army transport truck model kit to share with others how this is done as I never had resources to explain to me how to go about making models of anything.

It may sound odd but all that experience designing and building custom models in my early years is what gave me the confidence to start CNCROi.com and offer such a huge variety of services to our clients.

I really enjoyed designing this army transport truck model kit, from the first pixel to the final bit of glue, every part of it is clear in my mind as if it was yesterday, not over 4 years ago!

I owe a lot to ShopBot Tools, out of North Carolina, their ShopBot Desktop allowed me to proof my models and learn even more about custom designing.

I gained even more knowledge about my passion that’s directly applied towards what CNCROi.com has become today.

Most of these photos from way back when I’ve never shared online or in my books, like all the photographs and videos you see on CNCROi.com, a lot more is taken and then I pick through the best shots to share with others.

The other nice thing about custom model kit production, this army transport truck being no different, is that these toys don’t age.

They look as great now as they did back then, unlike plastic toys that tend to show their age quickly after a year or two. Being solid wood, they are also incredibly easy to fix!

Although all these pictures of my army transport truck model kit are in wood, it could have been just as easily made using acrylic for instant colorization of it, or just elements. The video below gives you an idea of what’s possible using plastics.

If you are wondering about how much of a load this small army transport truck model kit could actually carry, I could put my foot in the back and all my weight and it would almost act like a roller skate!

Whether I’m designing simple models for wholesale or complex projects for my clients, I’ve always tended towards overbuilding them strength wise rather than not enough as I’d hate something to fall apart on my watch and I know my clients would hate that all the more.

If you want to read more about how I actually went about designing this army transport truck model kit, check out my CNC Book Anthology, you’ll see how it was built step by step, design through manufacturing.

Of course, if you have a custom project, contact CNCROi.com right now!