Autodesk 3DS Max: Our Design Software of Choice

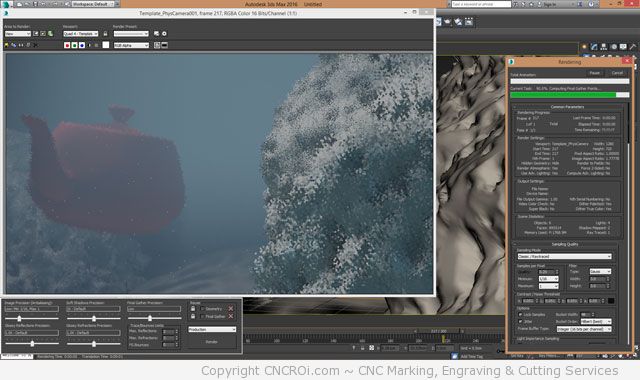

What does CNCROi.com use to design our projects with and animate visuals for our clients? Autodesk 3DS Max 2016!

Our beginnings were in creating industrial 3D animations (solutions) for manufacturers almost 20 years ago. Back then, industrial workstations cost as much as a car and were as slow as a mopped. We also use other software to help us in the design process and are expanding our CAD/CAM capabilities as well to improve our sheet metal cutting, bending and welding quoting process.

It was a great time, the .com boom was in full effect, 3D was nowhere near the buzzword it is today and we were doing projects around the world. i3DS International Corporation (parent company of CNCROi.com) had downtown St. Catharines offices and things were looking up after years of investment designing websites to support our 3D endeavors, we were finally turning a profit with little competition.

We did projects for Disk Brakes Australia and a host of other companies to help them save a bundle at trade shows and to give their sales people cool visuals to explain their unique product line. Manufacturing was having challenges but generally, they were coasting along thanks to globalization.

The skills I learned during this time have served myself and our clients well since, although the 3D visualization market has bottomed out, there is still a need to show clients work without actually DOING the work beforehand. It costs less moving pixels than cutting generally more complex projects we take on.

Today (many of the above animations were transferred from VHS hence the low resolution), we can render at full 4K resolution and although the rendering times are still slow, the quality per cycle is many fold better. There wouldn’t be a CNCROi.com if it wasn’t for our early beginnings in the industrial 3D field nor would there be a CNCKing.com with books and CNC projects being sold all around the world without it either.

If you have a need for custom designing, we have the experience, contacts and equipment to pull it off, both in the real world and the digital one.

There is a tremendous amount of capability present at CNCROi.com with experience to back it up. This year, I really hope to expand this blog tremendously to showcase more of it, we do far more than just laser work and designing for them… from CNC water jet and plasma to a vast array of materials including hot stamping – with related delrin or rubber mold engraving in-house!

I know you are dying to see what the render we did in the top of this article looks like complete, this is an animation frame so it’s blurry on purpose… if we can make a tea-cup swim underwater, imagine what we can do with your stuff!

Contact CNCROi.com today using the form on the right hand side, let us know what you need done, budget and timeline and we’ll make it happen!

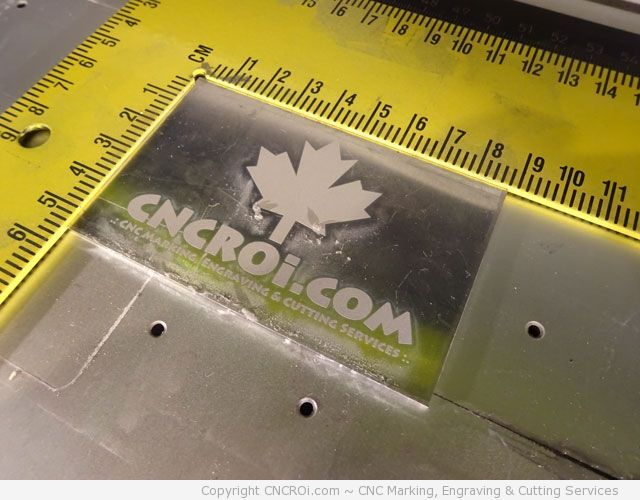

CNC laser marked 3000 series aluminium, cut in-house.