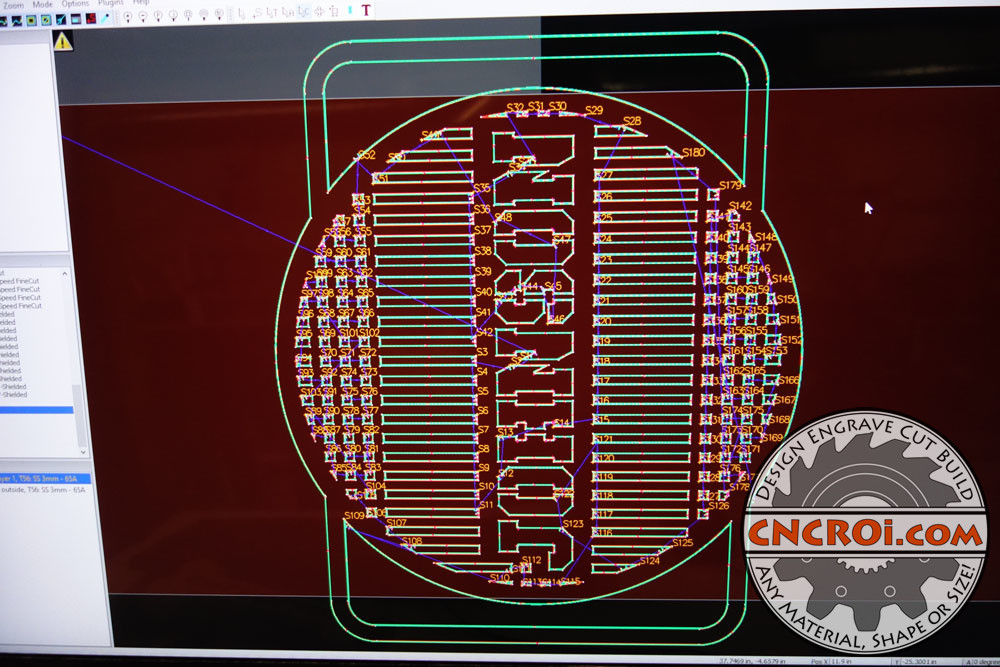

BBQ Grill Prototyping

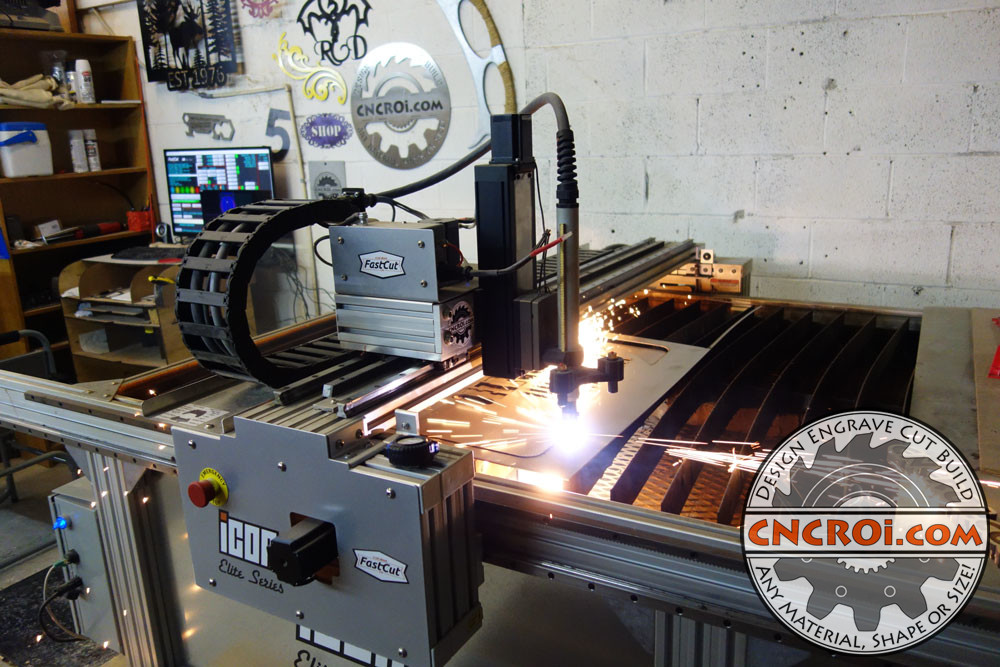

BBQ grill prototyping might sound like an odd thing to do but this was by far the tightest and most number of cuts I’ve ever done in such a small space so before going into production, this was the best way forward and a lot was learned!

https://www.youtube.com/watch?v=nqGlD94761c/

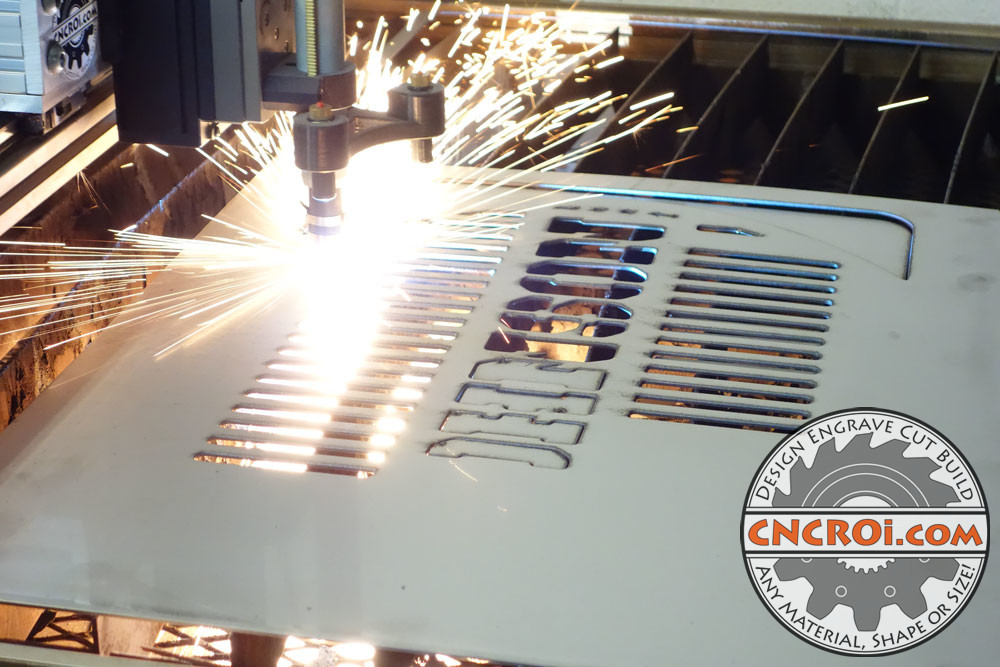

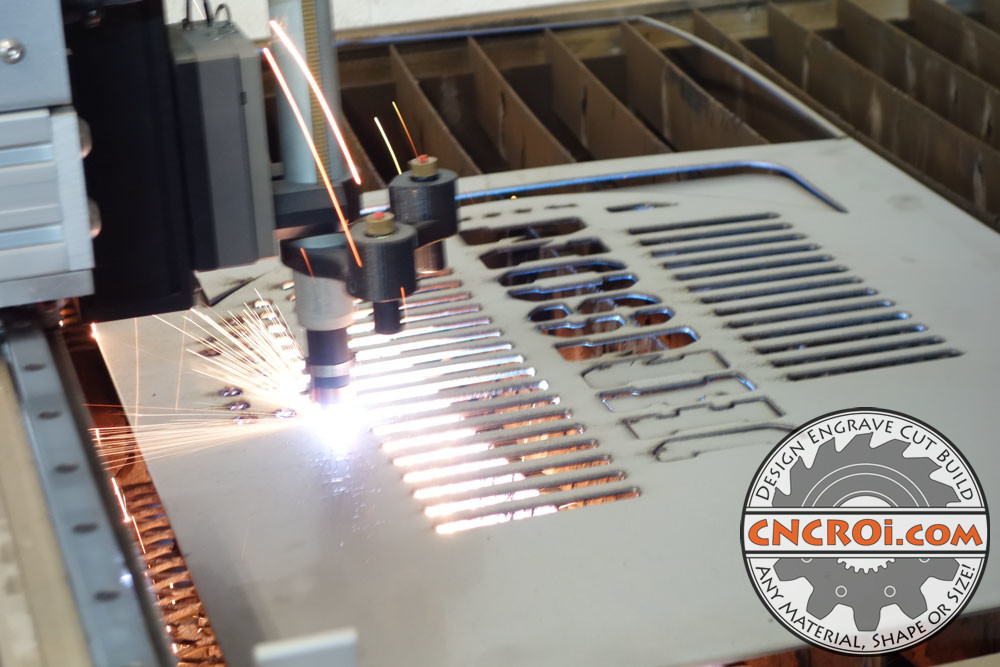

By far the biggest issue with plasma (any plasma) is heat, it’s 5x hotter than the Sun and all that heat has to go somewhere, much of it goes into cutting but there is a lot of residual that’s also held by the stainless steel, as you saw in the video above.

What heat does is warp metal, now, before you say, I should use a water table so that it isn’t an issue, that isn’t true, the heat is so hot, that air is actually a superior method of cutting and far less messy with a lot less clean-up, which is why CNCROi.com when this route, but you still get warping no matter what type of table you have.

So, what’s the easiest fix to all the warping you saw in the cutting process when CNCROi.com cut this BBQ grill prototype?

GO THICKER! And that’s exactly what I will do in the next round of this BBQ grill prototyping, thicker metal warps less even if more power is needed to cut through it, but 5x hotter than the Sun is still 5x hotter than the Sun regardless.

Another major way to reduce warping of materials, especially stainless steel, is to space-out the cuts.

https://www.youtube.com/watch?v=kpTA718xa5I/

The vast majority of the work that CNCROi.com does is like the video above, straight tags that are fiber etched, not exciting but it pays the bills.

You’ll notice when CNCROi.com cut this BBQ grill prototyping, a lot of the cuts were side by side, which means that the heat has time to build-up higher and higher in the metal, spacing out the cuts greatly reduces this from happening, and I use this technique with my laser all the time when cutting polycarbonate.

The nice thing about video, which you don’t really notice when you are right next to the machine or in photographs, is how much warping actually happens during the cutting process.

If it wasn’t for the Johnson you see across the BBQ grill prototyping, it would have been very hard to see that something went wrong at CNCROi.com while cutting this stainless steel.

https://www.youtube.com/watch?v=NEPeWpEYiOg/

Of course, cutting projects that are essentially flat sheets see no warping at all, again, most jobs go along this route than the BBQ grill you see in this blog post so these issues never really come into being.

I personally didn’t notice the mistake at all until a while after making this BBQ grill prototyping, that’s when it popped-out at me, but looking closer, you can see a few other very minor ones caused by the heat generated and kept by the stainless steel during the cutting process.

The time I really noticed a lot of warping was when larger pieces of the BBQ grill prototyping was happening, you could actually see the sheet raising off the bed of the plasma cutter which is never a good thing.

You an actually see a bit of this in these photos, but the video really shows the song and dance that’s happening and it’s quite a bit more noticeable over time lapse.

https://www.youtube.com/watch?v=BEIzFHDronM/

Additionally, small items don’t have warping issues at all either, it’s generally large items with lots of holes that cause issues like you saw with this grill.

So, next round of this BBQ grill prototyping will be using thicker stainless steel and spacing out the cutting processes, this along should dramatically reduce the amount of warping happening during the cutting process of this project at CNCROi.com.

A lot of companies don’t want to share their failures, but I really enjoy failing because it teaches me how to do things properly next round, and being self-taught at CNCROi.com is how I got to this point and now I know from experience what works and what doesn’t.

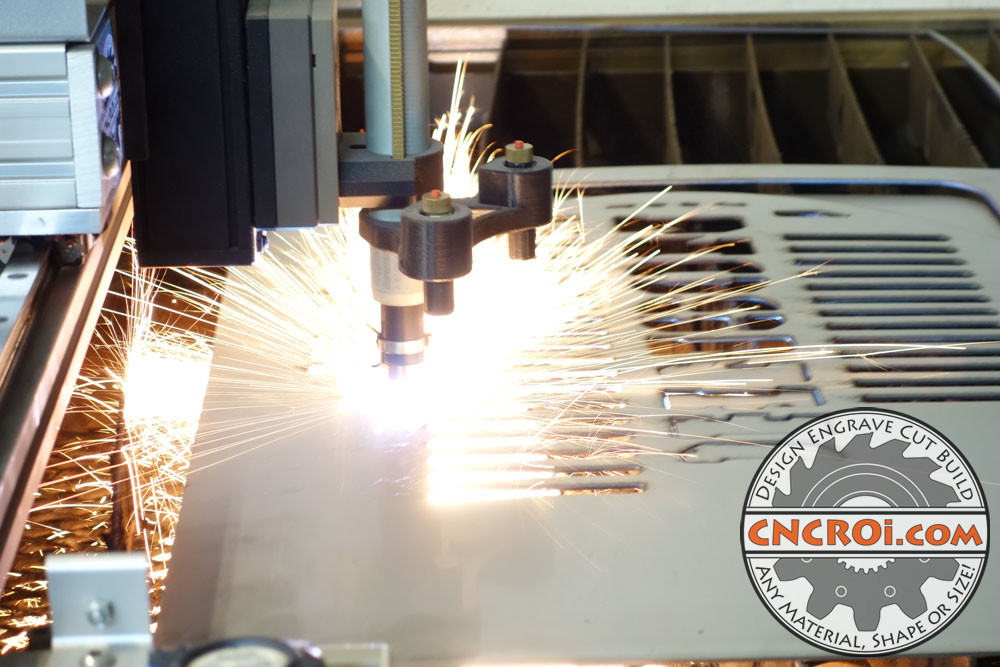

In the picture below, you can really see the warping happening as the outline was being cut of the BBQ grill prototyping CNCROi.com project.

The reason why I didn’t notice this previously is because the warping is minor and goes away very fast, and there is a lot of other things that I need to watch for at CNCROi.com during the cutting process than just the cutting head.

https://www.youtube.com/watch?v=j91BQbrrsLg/

Literally any shape or design works, I just have to be careful in the future about items that have so much holes that the steel has time to build-up heat and get super hot, which is what causes the warping as one part is hot and the other part has had time to cool-down.

When it comes to plasma cutting, it’s an awesome tool, it cut this project dramatically faster than the waterjet, but there are things to watch for, the nice thing about waterjet cutting is that you don’t have heat affected zones, bad thing is it’s incredibly slow.

You can really see the first “O” in the plasma cut BBQ grill prototyping is slightly raised, by about 1/8″, which isn’t much but it is there!

Regardless, this is why prototypes are made, to learn what works and what doesn’t when it comes to any process, and CNCROi.com is a custom fabrication shop where learning is a vital part of the job description.

https://www.youtube.com/watch?v=W1eJ0VT8wWM/

This item had zero warping, it’s thick and few cuts, so no problems there!

Relatively small projects like this BBQ grill prototyping have as much to teach as bigger jobs that we make at CNCROi.com and I enjoy them all.

https://www.youtube.com/watch?v=fsXTxcW_juQ/

Plasma is a wonderful and necessary tool at CNCROi.com, I love using it for these types of jobs for customers across North America and the Caribbean.

The next step on this project, regardless of how the plasma cutting went (remember, I didn’t notice the warping until after all this was done) is to sand both sides of this BBQ grill prototyping.

Sanding makes this project really pop with a lot more beauty and detail as all the dross and stains are removed from the BBQ grill prototyping.

And you can see the finished BBQ grill prototyping job below, next round CNCROi.com will address every issue this brought-up and rectify them for a far more precise cut.

Need a custom BBQ grill? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=StBesadXpkw/