Black Anodized AL Branding: CNC Laser Engraving Aluminium

Black anodized AL branding is something CNCROi.com does a lot of, in various sizes, shapes and designs for customers around the world.

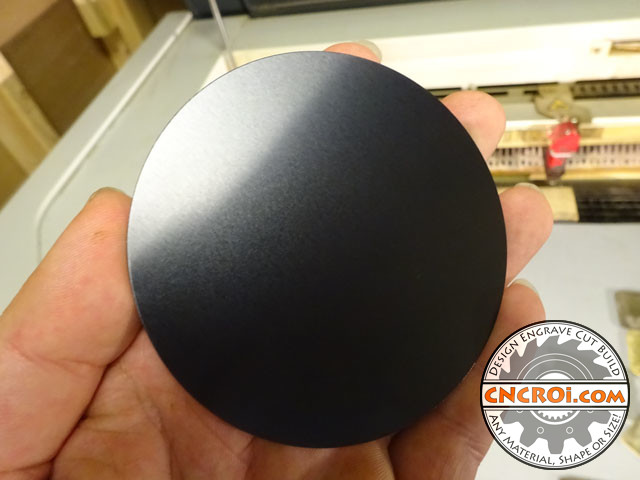

The nice thing about AL branding is that there are endless color options, though most clients stick with black for ultimate contrast and its light weight compared to their stainless steel cousins.

Compare the above production to the one below onto 316 stainless steel to see just how different the two are.

Additionally, CNCROi.com can go a lot, TREMENDOUSLY THINNER to achieve the contrasting results VS annealing the same design onto stainless steel.

At the end of the day, the application and budget will dictate what route to take.

AL branding is also a lot cheaper on two fronts, both in raw materials (once you have enough volume) and engraving wise, it’s a wonderful solution to many of our client’s custom AL branding needs!

AL branding isn’t the same product as stainless steel though, just an alternative and I’d say durability wise, they are about the same but if you want to see an extreme test that really shows just how durable the two most popular metal options CNCROi.com offers are, check this video out.

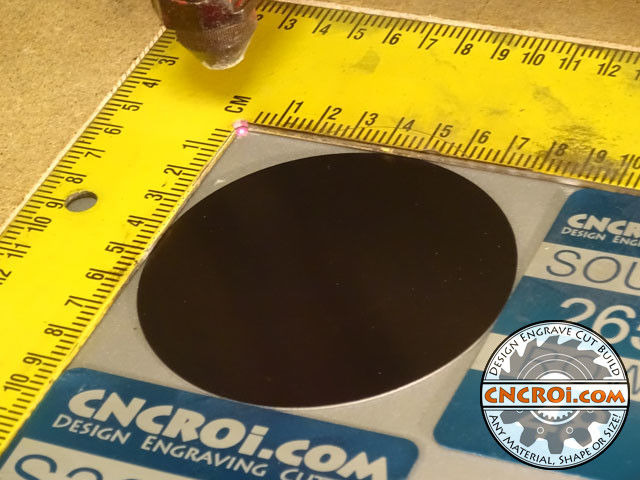

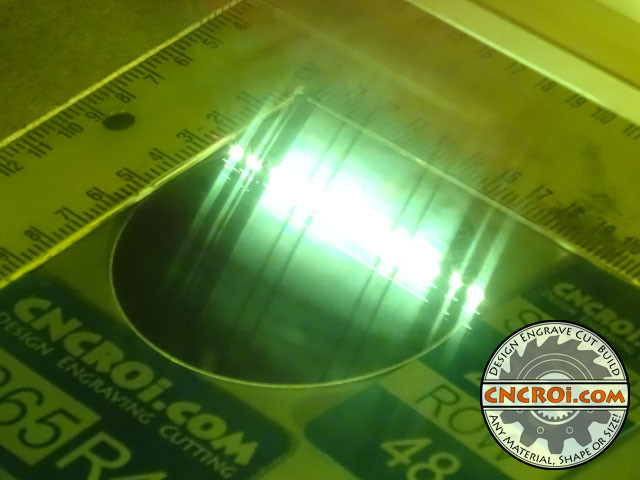

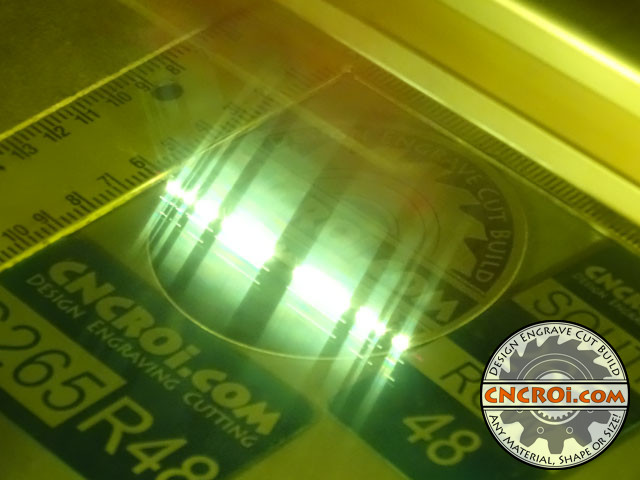

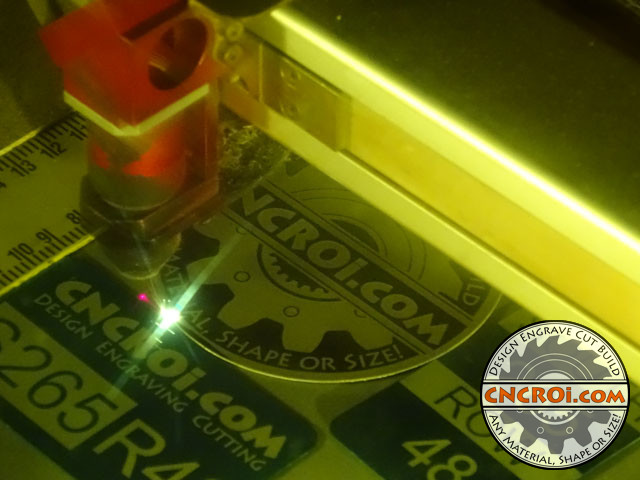

What our Austrian industrial wide-format laser is doing in these videos and pictures where custom AL branding is happening is vaporizing the anodization from the aluminium.

That’s why there is a bright light wherever our powerful laser is doing its high precision working, in this case, 600 DPI but we can go up to a thousand if needed.

If these anodized aluminium coasters look familiar, it’s because CNCROi.com did a video about these a while back, this is something we keep in stock as clients like to get a head start on receiving AL branded items (in stainless steel too) while the rest is in production.

With stainless steel, not every design works, I know right now that the design of the CNCROi.com logo will not work on this thin gauge metal, not because the metal is inferior but because there is too much annealing (turning the surface black).

Our laser is HOT, when we perform annealing, the plate gets HOT and actually bends if the gauge (thickness) isn’t low enough (or high for inches / mm) which causes annealing to become etching or nothing at all.

With anodized AL branding, there is heat, but the aluminium doesn’t absorb it and the process is so fast, there isn’t as much highly focused heat in any one area when compared to annealing or etching stainless steel.

As I tell my customers, each product as a cost and benefit, it’s the application that will dictate which is best, for instance, custom name badges, go with something colorful for sure!

Thin, durable and colorful, in this application, AL branding beats SS any day of the week!

But if you want to weld these to your work, stainless steel is the way to go, especially if the base metal is also steel.

There is no one material that’s better than another, for instance, if you only have ONE unit (or incredibly low volume) of something like a custom metal name badge, we can do it at a fraction of the metal price by using a metal lamacoid.

I wouldn’t stick this lamacoid in the back of an industrial machine working deep in a mine shaft, but for a name badge, this is beautiful, cost-effective and illustrates qualities that are the best of stainless steel and anodized aluminium.

When it comes to custom AL branding solutions, CNCROi.com is here to help you!

There are so many applications dealing with metal and more specifically, anodized aluminium, it’s mind-blowing.

If you are wondering about the clarity on even very find details, here’s an example of bar codes laser engraved onto anodized aluminium.

And yes, you see these in today’s post as I use them to keep the camera in focus when trying to photograph a lot of our laser work, reason being, bright flashes cause havoc on our equipment and I’ve found that these cards do wonders to keep things in perspective, literally!

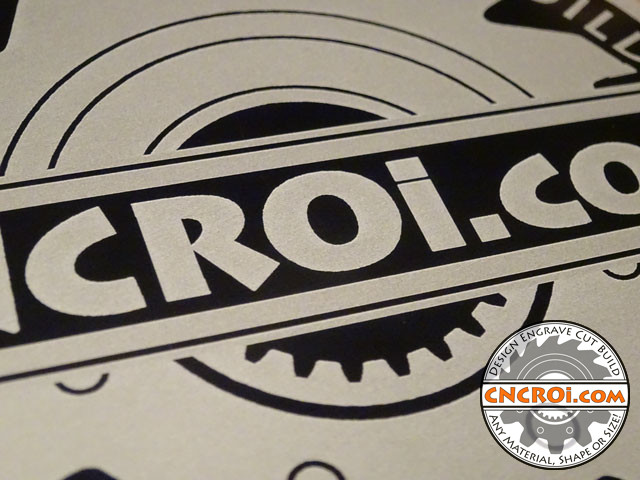

There is a fine coating of dust on this anodized AL branded coaster, it’s easily removed and the surface is nice and even, smooth like stainless steel annealing but without the heat warping that necessitates CNCROi.com moving to a thicker plate to compensate.

Another popular example of what we use anodized aluminium for are business cards, CNCROi.com has a ton of these in stock and people love these!

We’ve used them for everything from custom measuring sticks to gauges and machine tags… and yes, you saw them also being used as name badges in the video higher-up on this CNCROi.com blog post.

How long will this coaster last outside in the elements if not exposed to harsh chemicals like chlorine or sea salt?

I’d wager it will outlast the customer who uses this on a daily basis throughout all four seasons.

If that isn’t long enough for you, we can make this custom coaster in 316 stainless steel and you’ll be able to pass it down for generations.

If you are curious as to design options, endless coaster options exist and coasters within coasters too can be custom fabricated by CNCROi.com to mix and match just about any AL branding requirement you may have.

This is a Maple coaster, totally beautiful though a little scuffed-up from being in my sample suitcase for YEARS!

Nothing a little sanding can’t remove.

And the same coaster into a Corian fabricated coaster holder, again, hundreds of options with the Corian option, just like the wood species type above.

Need custom coasters or literally anything else custom manufactured to your specifications?

Contact CNCROi.com right now!