Blank Wooden Firefighting Plaque

CNCROi.com produces lots of wooden blanks for customer to use as a foundation for their woodworking projects, in this case, we are making a wooden firefighting plaque using a square piece of Maple.

https://www.youtube.com/watch?v=1K3kfcfW8kI/

When it comes to blanks, CNCROi.com can make the out of any material, size, shape or design profile you want, as you’ll see with this wooden firefighting plaque, it has the inside part carved out for resin work (to be done by client) and the shape they can’t achieve using their own woodworking equipment.

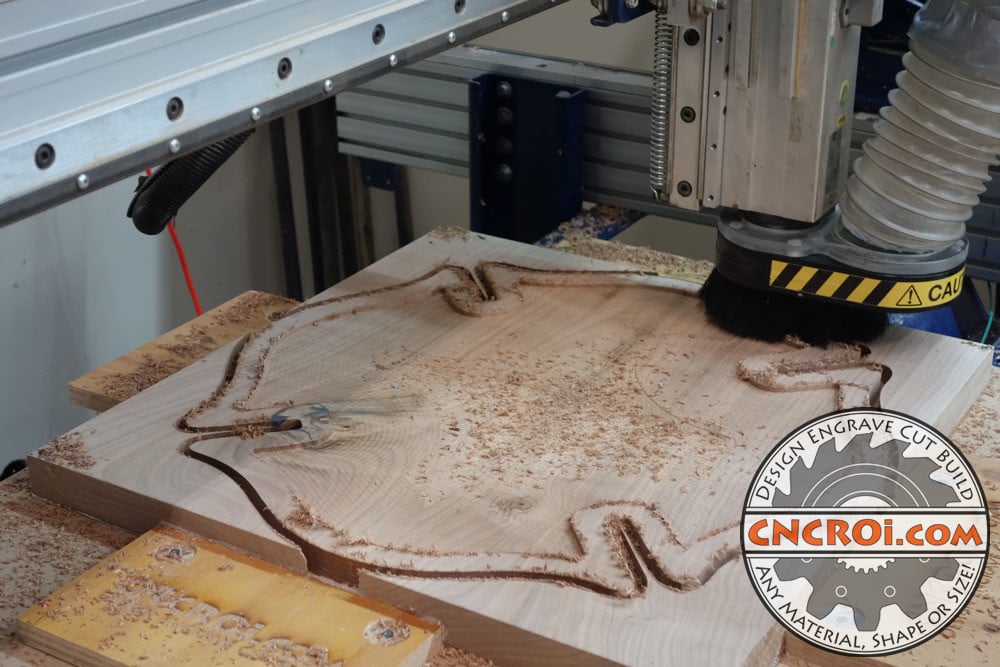

The toughest part of this job was trying to figure out a way to hold this wooden firefighting plaque down so that nothing moved during production at CNCROi.com, if you look at the photo, you can see a mix of glue along the edges (to improve vacuum hold-down), wooden supports on all four sides and of course, screws in each corner and actually turning the vacuum table on.

This may seem like overkill, and it probably is, but I’m literally cutting it all around totally which undoes most of this and so the goal is to always have a backup to make sure if one fails, another hold-down method will pick-up the slack.

Carving out the inside of course doesn’t introduce that many forces, but when I’m cutting this out, there will be a lot of forces introduced on all 3 axis of this part and any vibration or kickback will literally cause this wooden firefighting plaque to be thrown into the fire pit.

If you want to see an extreme example of what CNCROi.com can produce carving wise, here’s a great example using MDF but that could have just as easily been Maple or any other wood species you can imagine.

https://www.youtube.com/watch?v=ppbDvVOadcI/

When it comes to producing blanks using wood, especially live edge, there are internal stresses that our CNC router sometimes releases during production and you can see a prime example of this in the carving out, there is a slight relief of vertical stress about 1/16″ where it pops upwards then downwards… it’s easily sanded out BTW and for this job, this will be filled with resin anyways, so it won’t be seen.

Regardless of the shape, our CNC machine can carve, texture or cut it out, in this case, it’s a maltese cross shape which is no different or anymore complicated for our robots than a circle or a rectangle of the same spec.

As pushing forces are always front of mind for this wooden firefighting plaque, I took things really easy at CNCROi.com for carving this out, I could have easily doubled or tripled production speed for this entire job but again, if something gets loose, the whole job is scrap, so slow and steady wins the race for this job.

I’ve also done a lot of jobs using a lot more complex mix of pieces, so just a flat piece of wood isn’t anywhere near the limitation of what can be produced by CNCROi.com.

https://www.youtube.com/watch?v=943SSQyBHa4/

As I’m carving OUT material, I used an upcut bit, as you can see from all the raised wood along the edges rather than a downcut bit, which wouldn’t produce this but this is easily sanded off so no big deal for a greatly improved removal of Maple chips.

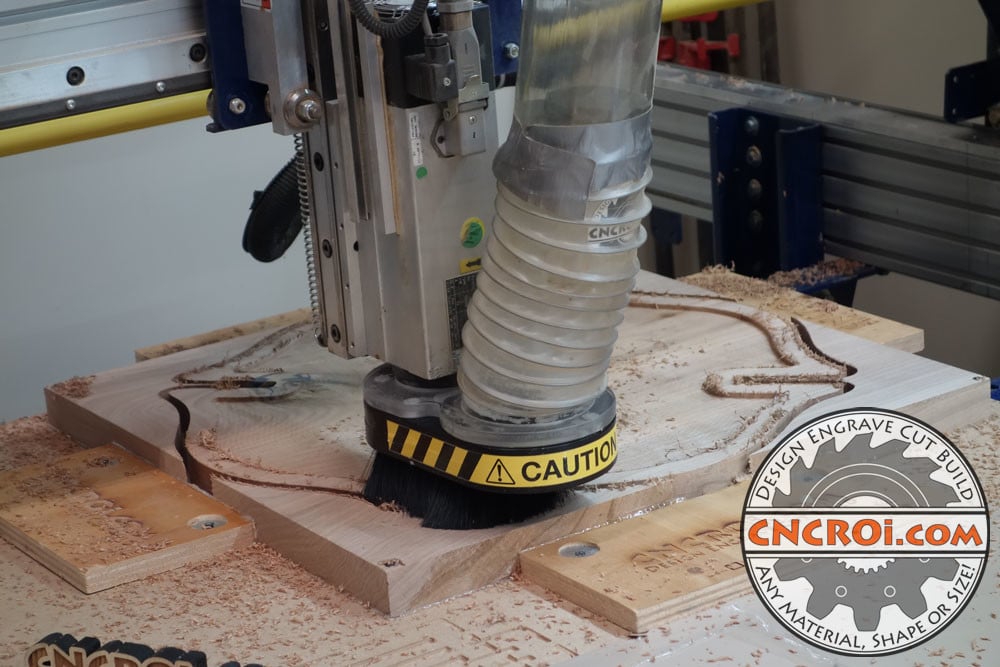

After the carving out process is done, roughly a quarter inch deep from the surface of the square piece of Maple, it’s time to cut out the actual shape of the wooden firefighting plaque, which is where I will negate the screws, four boards all around and the glue sealing the vacuum at CNCROi.com so I’m literally left with only a somewhat “OK” vacuum to hold it down during the final pass.

When it comes to cutting out the maltese cross shape, again, going slow to reduce the cutting forces on the piece as much as possible, by slow, I don’t mean we are reducing cutting speed, just not going as deep as I could to make sure chip evacuation is easy and little forces are pushing in any one direction of the Maple.

You’ll notice that once all the corners are cut out, they are utterly useless to hold anything down, I even cut into my support boards on all four sides, not a big deal, that’s what they are meant for.

CNCROi.com can also laser engrave wood for you, so if this job needed that added to the blank, on either surface, we could have done that as well.

https://www.youtube.com/watch?v=A6nKh6UKxMk/

You can see in the picture below just how much I’m cutting this out, the overall piece of live edge Maple is 24 inches square, the wooden firefighting plaque is 23.5″ so I have a quarter inch all around to account for things not being totally square.

This wooden firefighting plaque is starting to look good, the shape is coming together very nicely, a little sanding and this will turn into a very nice blank for the customer to continue on after CNCROi.com finishes our end of the project.

There were a lot of wooden chips produced in this blank wooden firefighting plaque, it’s surprising just how much is made considering so little is showing, you can see the reason for this is the inch and a half thickness of the Maple cut all the way through and the shape itself that lends to a lot of cutting at CNCROi.com.

Keep in mind that CNCROi.com could have cut out this maltese cross from any other wood species out there, from Walnut to Basswood, Cherry to Alder.

Of course, if you want just a template or a finished product to work from, CNCROi.com can produce that as well using any material you can imagine.

https://www.youtube.com/watch?v=sxcm_u0TVzg/

You can see in the image below where the stress was removed from the wooden firefighting plaque happened, right in the middle, again, this makes no difference as the resin the customer will use isn’t transparent, this will never be seen and actually gives the resin more surface to adhere to, so I left it there.

Otherwise, if this was going to be visible, then I would have run through this about 1/16″ deep again and that would remove it right away and give the surface area a totally flat appearance.

You can now see the blank wooden firefighting plaque, it looks great, and technically, I could send this to the customer as/is but I wanted to clean it up a bit with some sanding.

You can now see the maltese cross after sanding, it looks great, and I’m very happy with how it turned-out at CNCROi.com and our customer absolutely loves this, try doing this with a band saw, jigsaw or skill saw!

Need a custom shape cut out of wood or any other material? We also make templates… contact CNCROi.com right now!

https://www.youtube.com/watch?v=LPG8rwvgG-c/