Cable Tag Jig: Repeatable Stainless Steel Etching

I wanted to share how CNCROi.com makes a custom cable tag jig, our evolution in jig production, being our own customer more often than not for this specific application really allows me to keep experimenting and trying new construction and production methods for increased reliability.

https://www.youtube.com/watch?v=ULJFaa6s4oU/

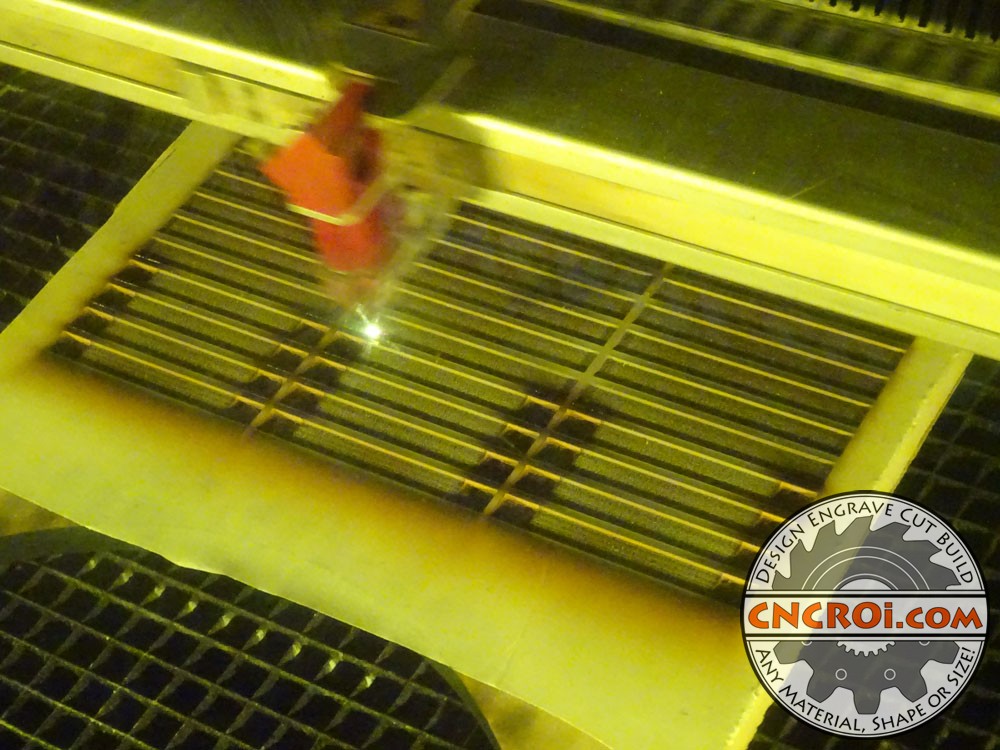

Stainless steel cable tags are a little special in that they have a part that sticks out at both ends, if it wasn’t for that, then any layered jig would do but due to the tight etching tolerances, that wasn’t an option as those jigs are always slightly off by their very nature.

For this specific cable tag etching job CNCROi.com had to perform, we needed the jig to come from one solid pieces with zero room for error, and we needed to make two units that were IDENTICAL.

Again, the more layers something has, the more error will be present regardless of how carefully we make a jig, going solid is really the best method.

How durable is fiber etching?

https://www.youtube.com/watch?v=w2fhPBwSEMs/

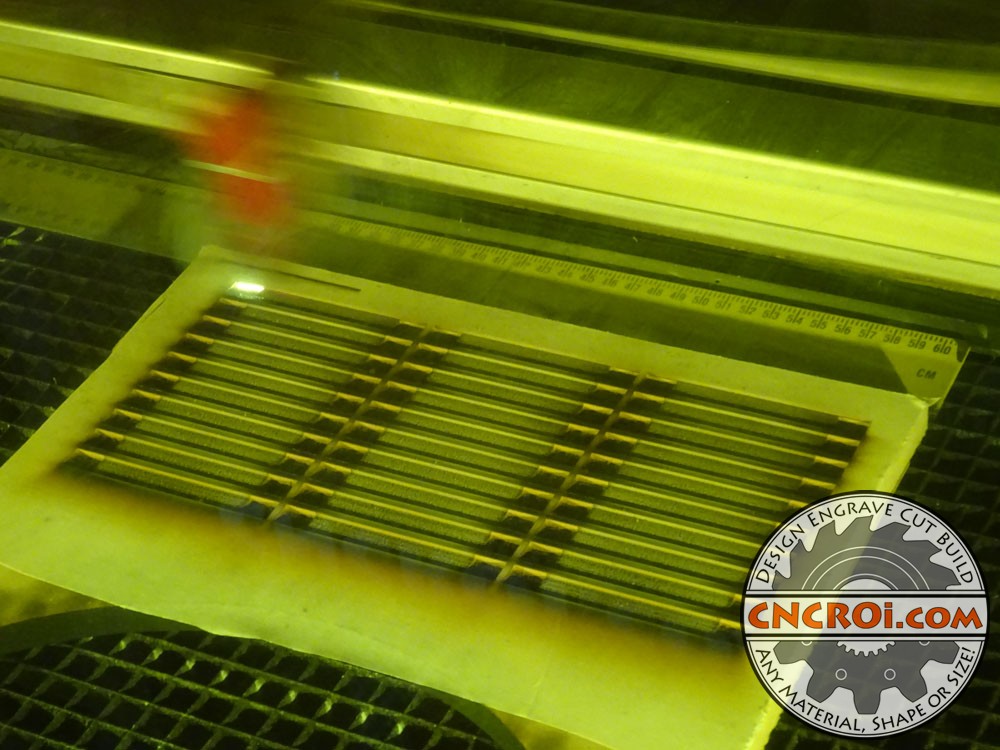

Unlike acrylic or just about any other material we could have used at CNCROi.com, MDF, especially thick MDF, starts off flat and STAYS FLAT, another very important feature as any slight variance in etching focal length will become annealing with the fiber laser.

This is why, for instance, making jigs for anodized aluminium, where we have a very wide amount of focal tolerance is so easy but for stainless steel, not so much, especially over a larger surface area.

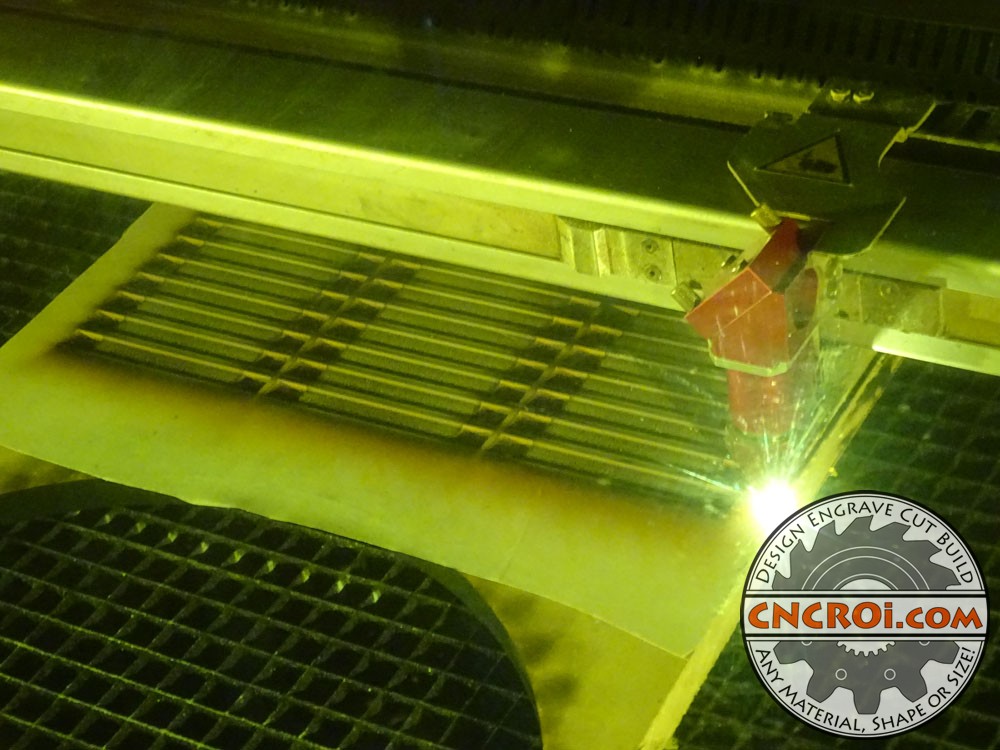

CNCROi.com now has a plasma cutter, this allows us to produce tags in larger quantity and faster turnaround time than our waterjet ever could.

https://www.youtube.com/watch?v=EdEIRd9_c4w/

This cable tag jig was made using a process I haven’t shown before on this blog or video, the reason is it’s a very inefficient and costly process, but the results are spectacular, basically, it’s expensive and slow verses just about any other production method.

CNCROi.com also has two CNC routers, technically this would have been fine with that technology except for one small issue, the jig, to hold the same number of stainless steel cable tags, would have to be bigger to account for the dog boned corners which would slow the etching process because the wider the area, the slower fiber etching is.

So, either CNCROi.com makes a quick and big jig using our CNC router then loses production time with each use or we just laser engrave MDF SLOWLY and then etch faster.

Steel is a wonderful material, but we can achieve two different processes using it, they take the same amount of time, just one is sometimes preferred over the other for our customers.

https://www.youtube.com/watch?v=ZC0sGZB2b9U/

With stainless steel tags, it’s really a race to the finish regarding laser etching them, hence going with the slow jig production method to gain back our time on the etching process.

Etching stainless steel, especially thin cable tags, is also a careful process because the metal is so thin, too much heat, they warp and guess what, go right out of tolerance.

I’ve been making jigs for years, each material has a plus and a minus, as does the production process.

https://www.youtube.com/watch?v=Petz7b5x52o/

Due to the factors involved with cable tag etching, jig to finished production, this was really the best method to use to make a custom jig at CNCROi.com.

The advantage of fiber laser etching is that it’s a PERMANENT process, it will not crack, peel or fade over time, unlike UV printing, ceramic bonding or screen printing.

NOTHING beats fiber laser etching stainless steel, there are NO alternatives other than going into the surface, like CNCROi.com does.

Acrylic is wonderful for larger, more spaced-out production with a material that engraves fast.

https://www.youtube.com/watch?v=55Z4lMT3E4c/

MDF is a very consistent material, there are very few variations in density of the material itself, as such, it’s perfect jig material for this, acrylic is very consistent too, but warps from heat.

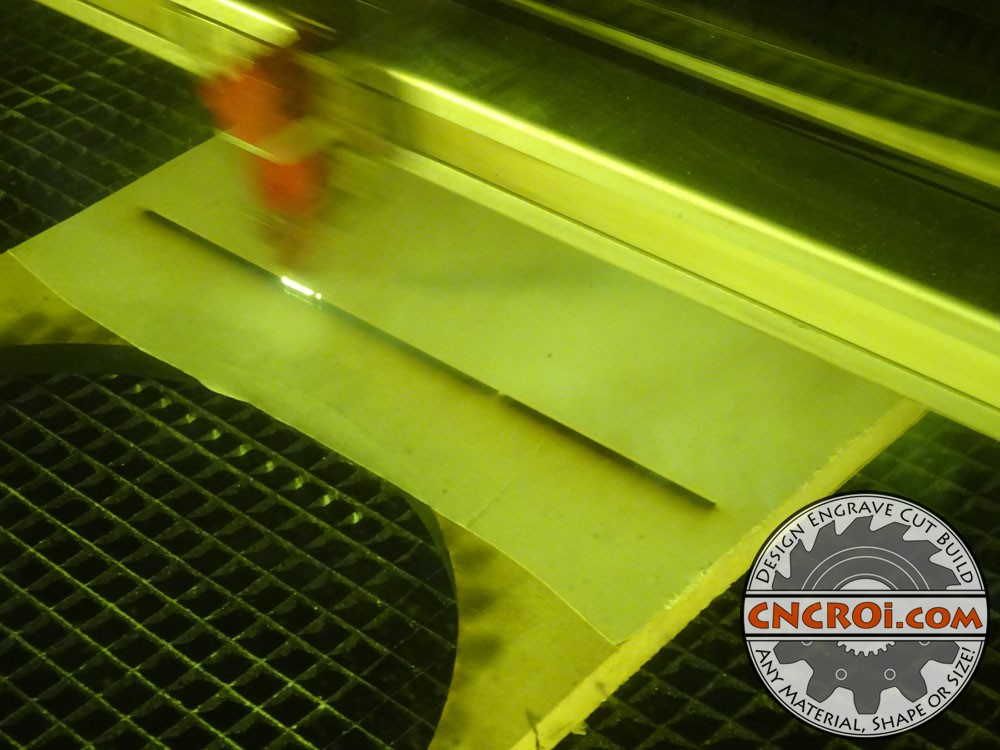

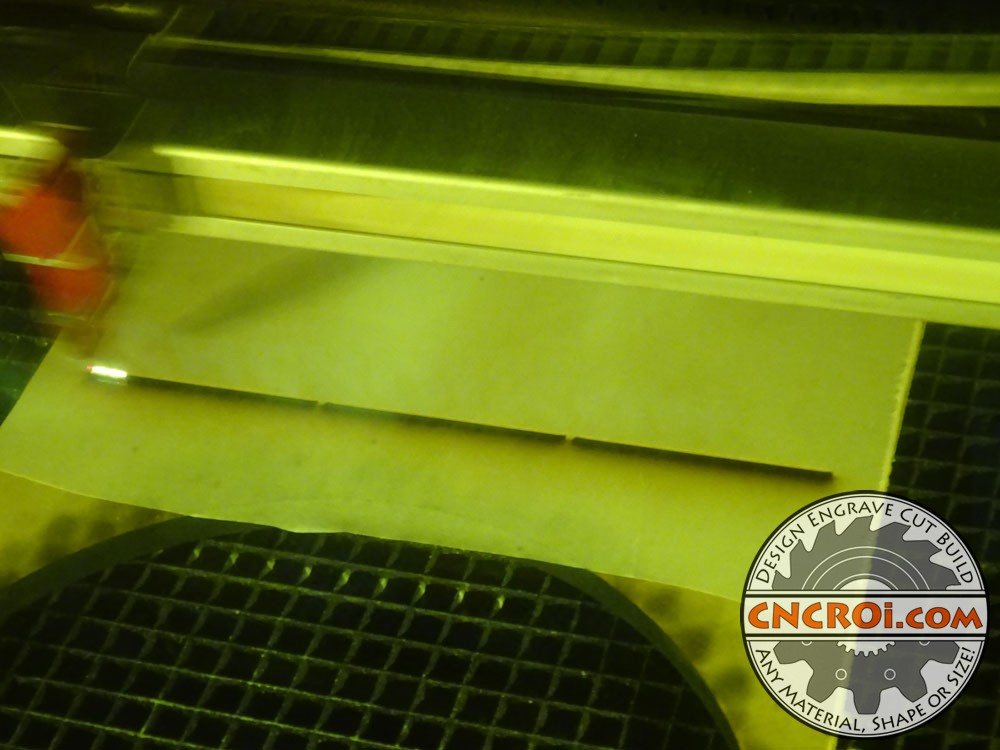

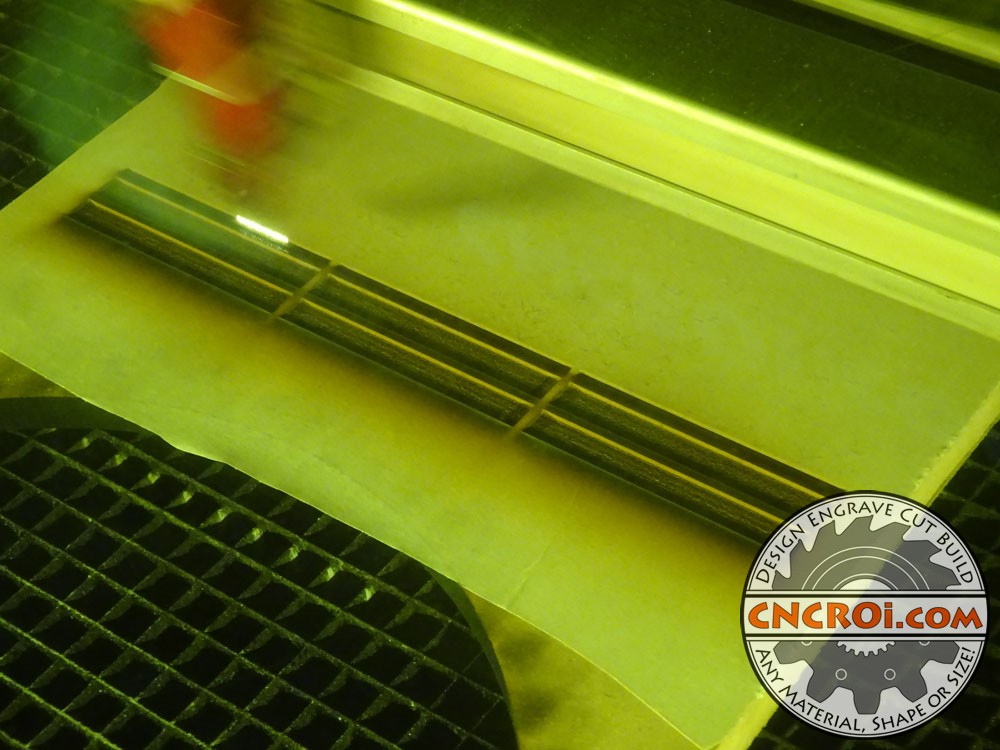

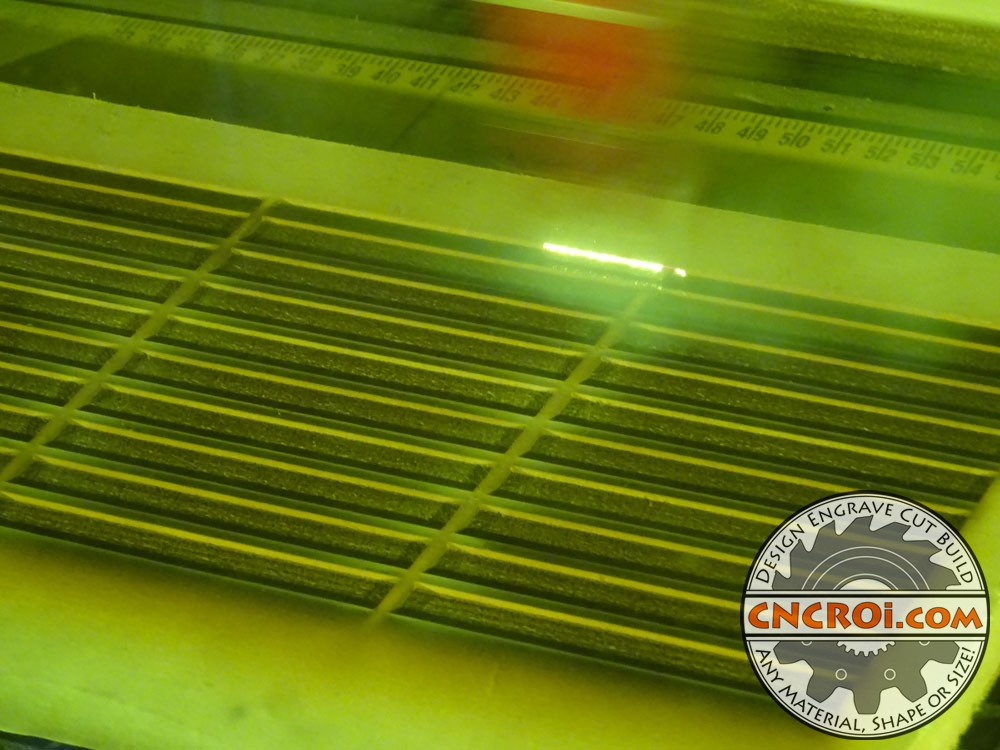

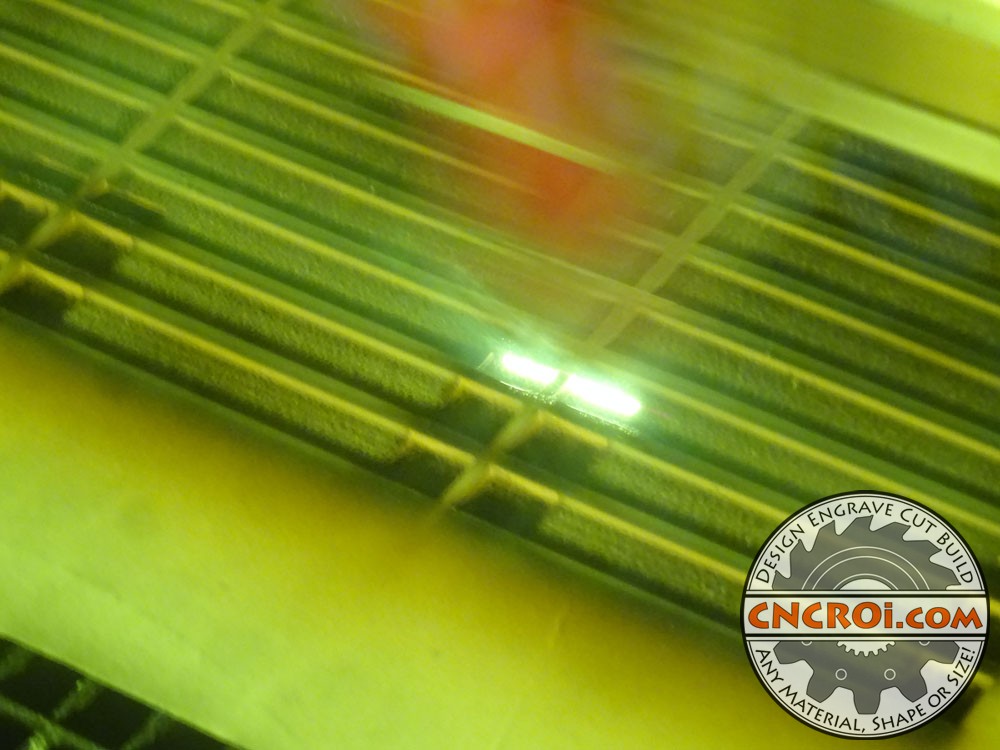

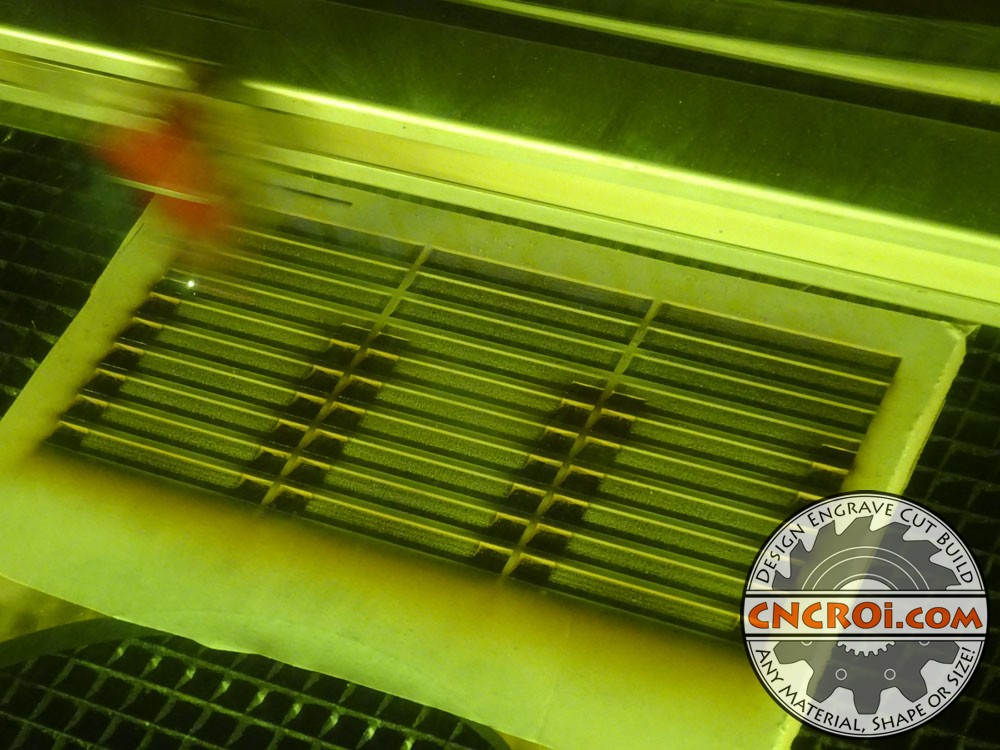

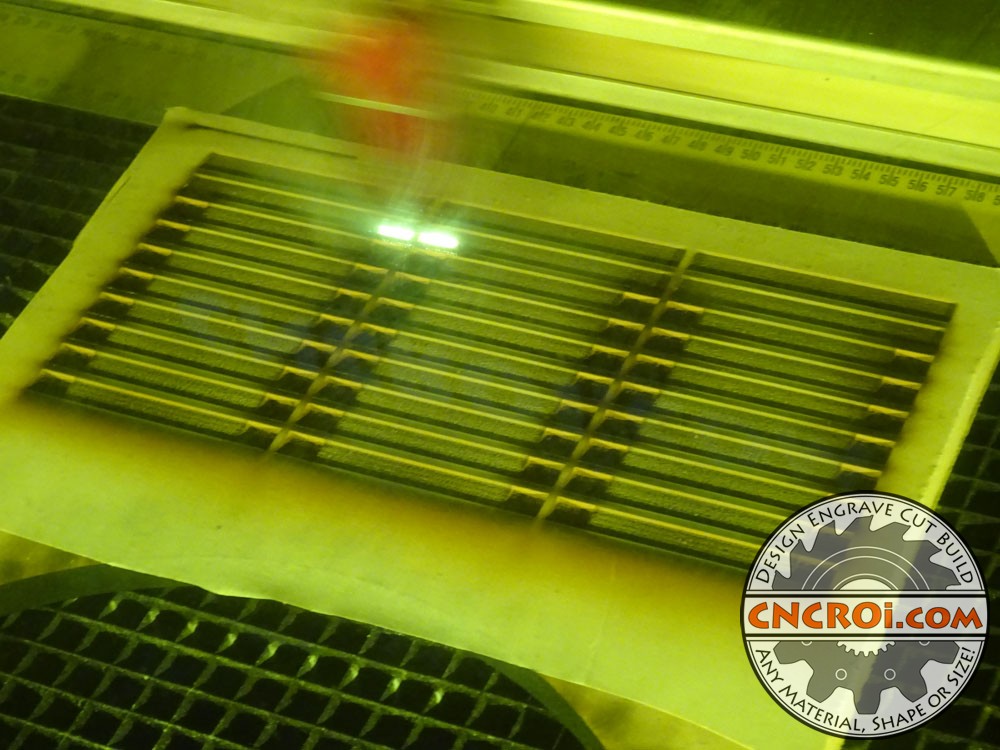

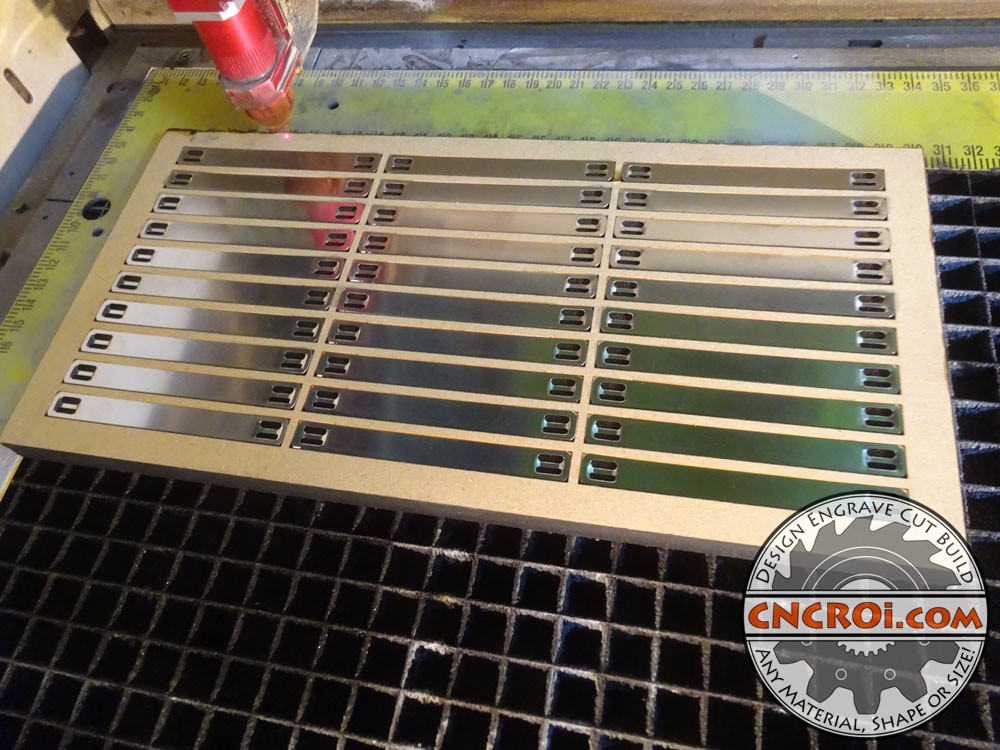

You’ll notice I made two passes into this MDF, the first was to get the depth of the stainless steel tag itself, the second, to get more depth at both edges for the little protrusions that are below (when flipped) of the tag edges itself.

The speed of the laser to make both passes is the same, whether there is empty space or not, the laser takes the same amount of time, this happens with fiber laser etching too, which is why you really want to have as compact a jig as possible for fiber laser etching stainless steel cable tags.

Here’s a very small jig I made, in hindsight, I should have made this the same way as I made today’s stainless steel cable tag jig.

https://www.youtube.com/watch?v=fzQYELFabSc/

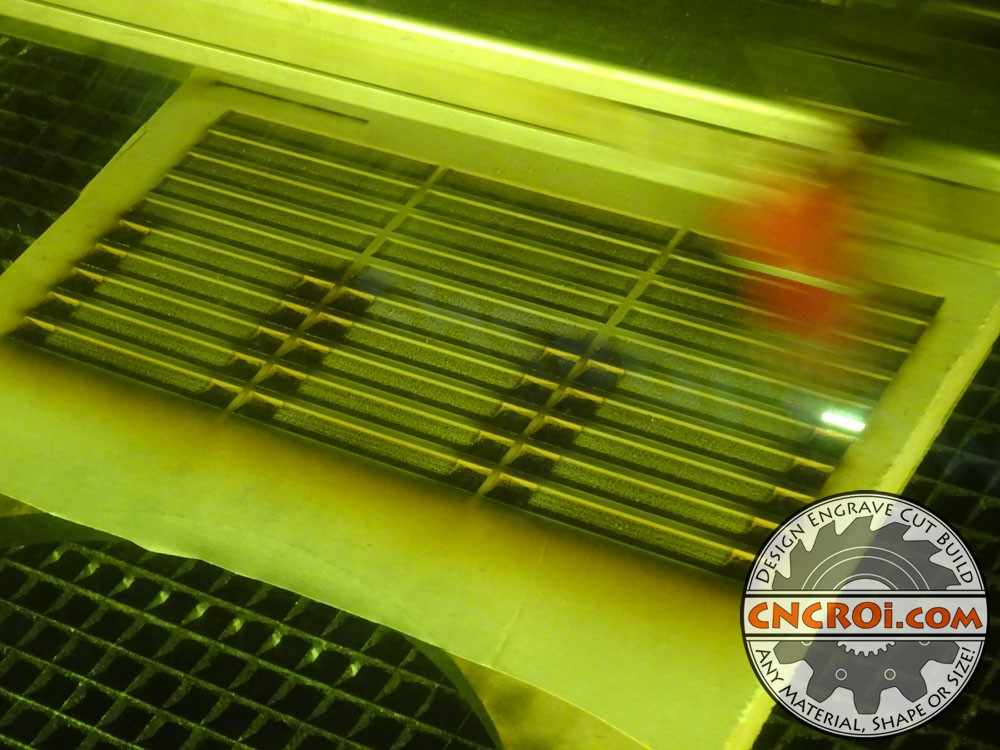

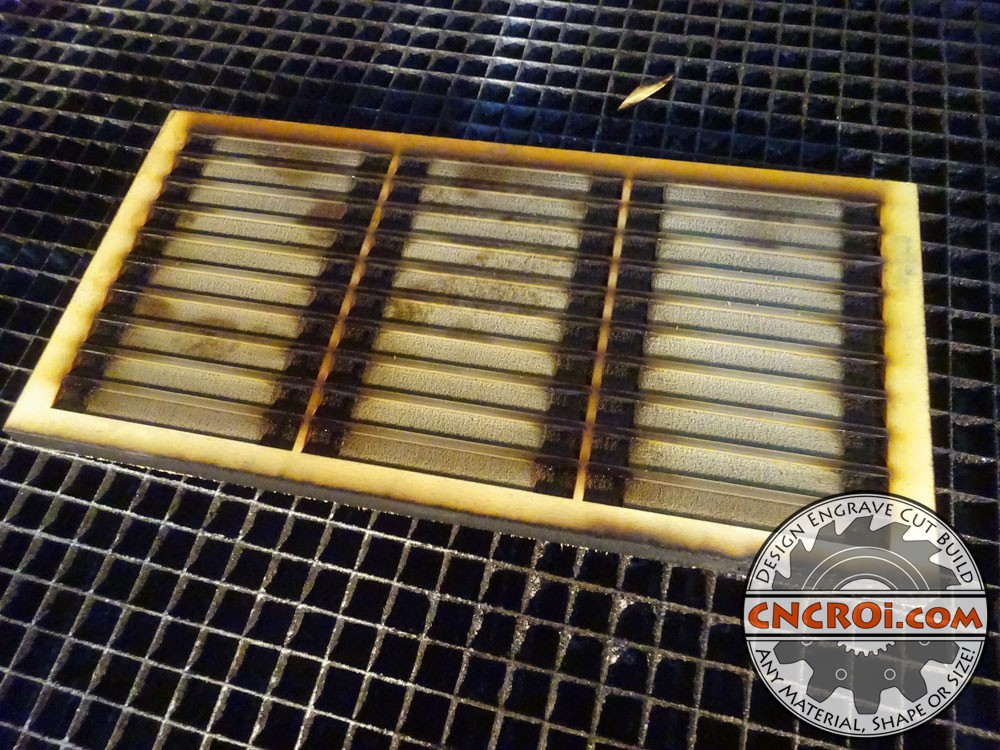

The end results aren’t pretty, but I thought in advance, there is a masking on both sides as I really don’t want to waste time sanding this, one it takes time but more importantly, it may change the depth and placing characteristics during production if I don’t sand both units the same way.

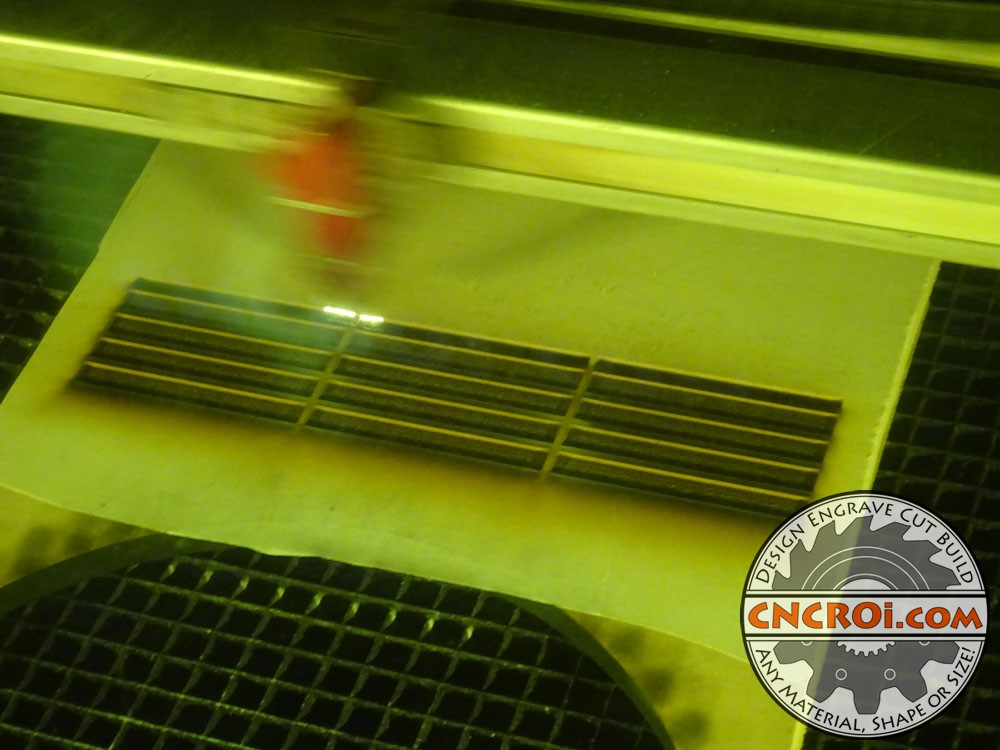

You can see how wonderful this jig looks now, the precision of lasers is hard to beat.

For a test fitting, you can see how little space is wasted along the X and Y axis, again, this is done for speed and precision purposes.

Need custom steel tags etched or anything else, contact CNCROi.com right now!

https://www.youtube.com/watch?v=vnh5YSgshZE/