Challenges of a Custom CNC Shop

There are a lot of challenges around owning and operating a custom CNC shop, from competing deadlines through to equipment purchases, it’s never a dull moment at CNCROi.com!

Running any business is like a puzzle, you try to see what processes, projects and procedures work best together and then optimize to produce the best ROI. In our case, there is an incredible diversity in projects that we handle which make it all the more challenging.

Where a typical business specializes in one area, say, millworking, and buys all the tools necessary to build, say, kitchens. There is a set number of tools, budgets and ladder to climb. You know you need a CNC router, a bandsaw, various power tools, table saw and a hell of a lot of clamps.

For a lawyer office, you need a set of books from former case law (though this is more for decoration nowadays and available digitally), a coffee machine and a nice looking office! You then specialize in the type of law you are performing and then start climbing the ladder.

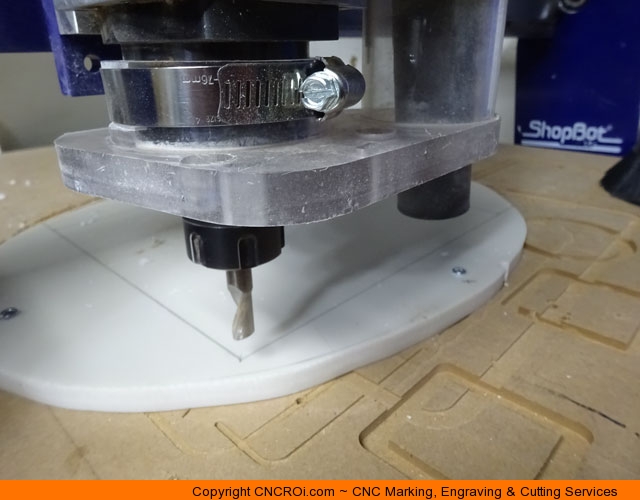

For us, it’s a bit different. We do a lot of woodwork, which necessitates what a typical millworking shop would have and then throw-in a lot of metal work, again, with specialized equipment to fulfill that need and then we do a lot of foam work, again, specialized tools and techniques and the list goes on.

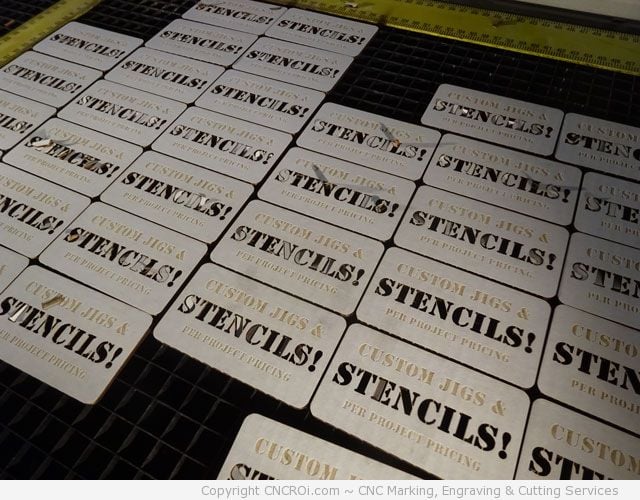

Then you throw-in material, for instance, we do a lot of work with Corian making everything from custom signage to smaller items, same goes with wood, metals of various types.

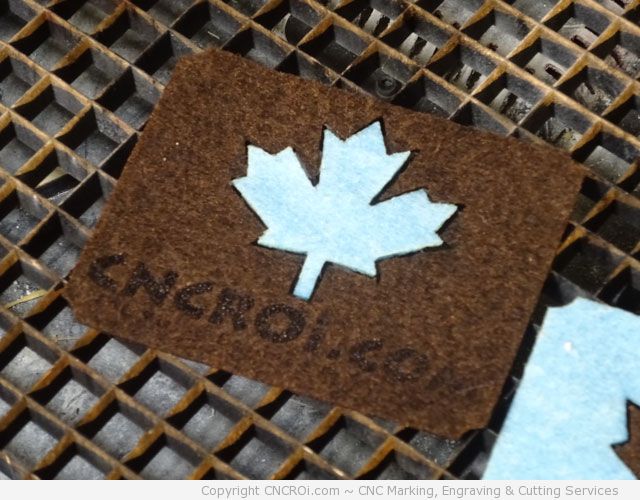

This incredible diversity is a massive plus as techniques used for one can be generally applied to another with a few modifications.

It also leads to a lot of competing challenges where basically with many of the projects we take-on, it requires us to buy equipment to fulfill it properly.

Sometimes it’s pretty easy stuff and other times, it’s learning hands-on using scrap until you have something DOWN and then focus on getting the work done for the customer.

For example, we have lots of specialized wood bits for our CNC router but you can’t use wood bits on metal, something else we are doing more of these days, so it means buying some lubrication, optimizing cutting and climb speeds as well as RPMs and the like.

Some of these, like the lubrication on the surface to prevent overheating of the bit isn’t necessary with a proper bit onto wood but almost mandatory for steel.

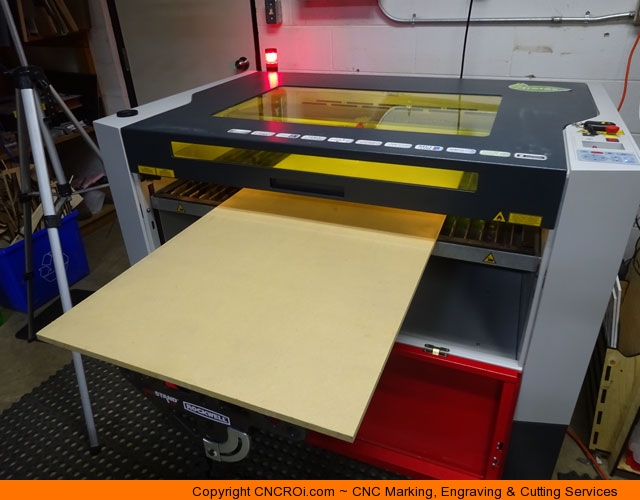

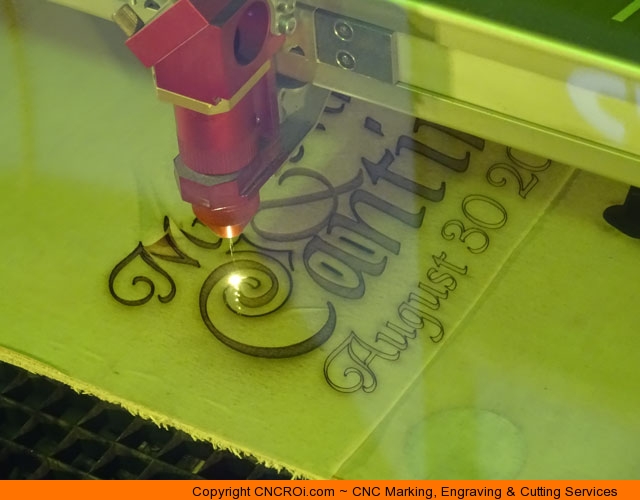

Then on another front, we have our industrial laser that can handle lots of different applications and projects on its own, but even then, there is optimization as, for instance, you can’t laser engrave concrete at the same speed as you do foam.

This makes coming to the CNCROi.com awesome fun as each day is literally completely different than the other when we aren’t doing massive unit projects.

We’ll do some wedding things in the morning on plywood, metal work for a manufacturer in the afternoon and then at night, either learn something new that we can show customers, build samples or do video.

For instance, we recently got a job that involves sanding LOTS of wood, so, as part of the project, we had to go to the hardware store and buy a bunch of different industrial grade sanding equipment and related accessories.

Another project involved lots of stamping so we had to source optimal raw resources to make that project possible under the time and financial constraints of the customer.

This is why it’s vitally important for us to have top of the line equipment, a typical “consumer drill” for instance, is tested and optimized for 10 hours of use a YEAR! That’s why it’s 10 dollars. We’ve had project where literally we do a years worth of wear in one day so short of heading to the store everyday to replace equipment, you spend 10x more and get something that can not only handle the job, but is overpowered and overbuilt.

It means when we plug something in, it works and can keep on working!

Overall, running a custom CNC shop is great fun, the diversity of the clients and approaches to provide the optimal ROI for any given projects is really a thinking game that makes chess look easy.

CNCROi.com has grown tremendously over the past two years, each piece of equipment that I look at I can describe the project we got it for and the subsequent things we did for that client. The fun never stops!

Back to work!