Change Happens

Regardless of how long you’ve been in business, the only constant that seems to exist is that of change. You either change and adapt to new circumstances or you fall by the wayside.

CNCROi.com has grown tremendously since its founding, while a year ago, we’d get a metal OR acrylic OR wood order, this is now occurring on a weekly basis and the volume is exponentially higher as well.

With growth comes change, new equipment requirements like our newest industrial air compressor and smaller things like a 4″ lens for our Austrian CNC laser. Some things are noticeable while others aren’t as much unless you are looking at the right area.

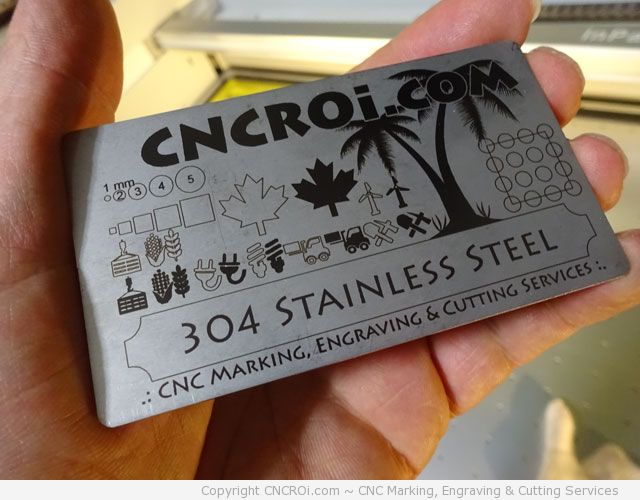

In the metal division of our company, it has never been stronger – annealing stainless steel through anodized aluminum is something that’s always going on an upwards trajectory. Why? Because companies are starting to see the incredible versatility and durability of our capabilities.

Sure, vinyl and inkjet tags are cheap, but they won’t outlast your grand-children. Ours will… and if you have an especially corrosive environment, we can even get them powder coated clear to outlast when the dinosaurs come back on Earth.

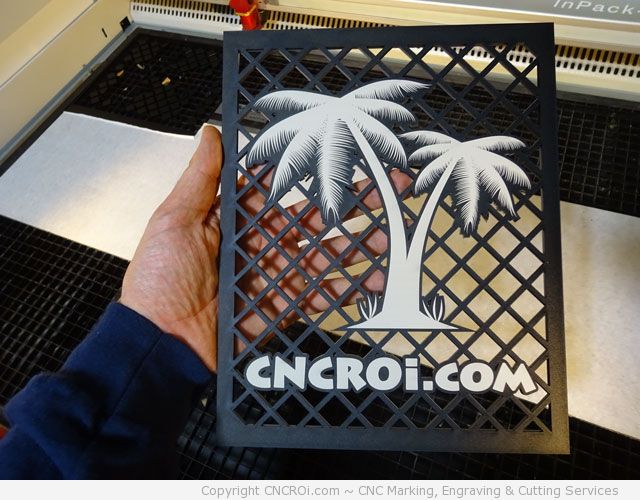

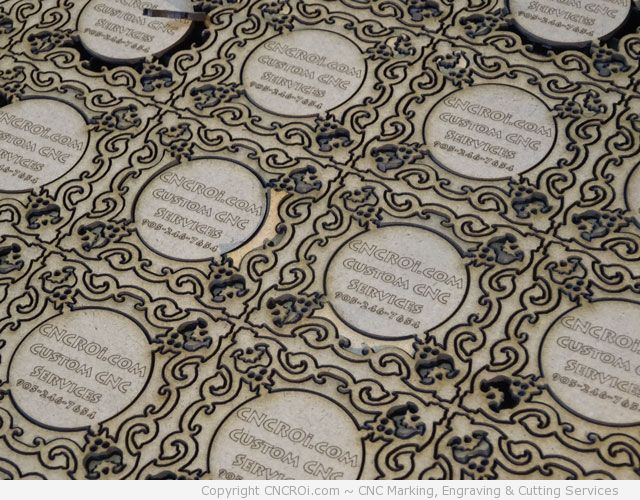

Our wood division at CNCROi.com is also going gangbusters. Why? Well, we can handle sheet sizes that simply don’t fit in “regular” CNC laser machines. The incredible repeatability and precision we also offer, although overkill from a technical standpoint when referencing wood, is greatly appreciated. From the onset, I set-up the production of CNCROi.com to be industrial in scale, meaning if you have thousands of units, it’s not a problem. We have the equipment that can handle that and then some.

We just completed a massive acrylic job as well for one of our clients, I don’t care to count the number of units we cut out but there were PILES of them in the shop that had to be classified, sorted and bagged. Was lots of fun and our Austrian CNC laser didn’t even break a sweat!

It’s incredible what we can do for fabrics using our industrial laser, but it’s a section of the company I’d like to develop further. Fashion designers around the world are using lasers to make incredibly accurate designs that aren’t possible using any other method but we haven’t done as much in this area as I’d like. Not sure why we haven’t been able to break into this market as easily as we have the industrial and mill working ones but will keep trying!

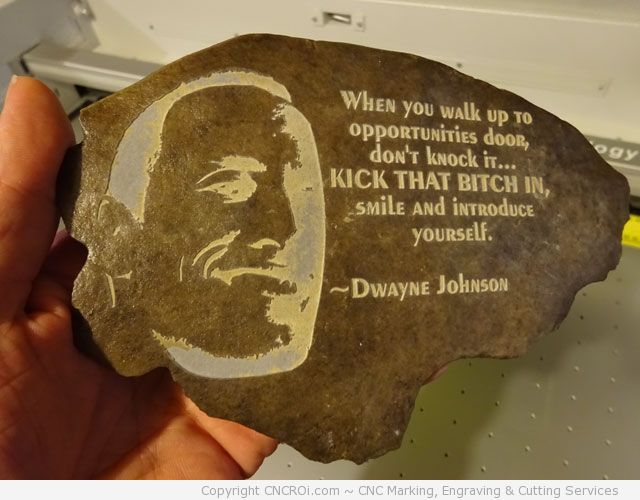

As for stone and concrete, we’ve done a fair bunch of work for customers across North America. It’s always fascinating to me how the same laser that can engrave a fraction of a mm off paper can also vaporize the hardest layers of rock to reveal their subsurface attributes.

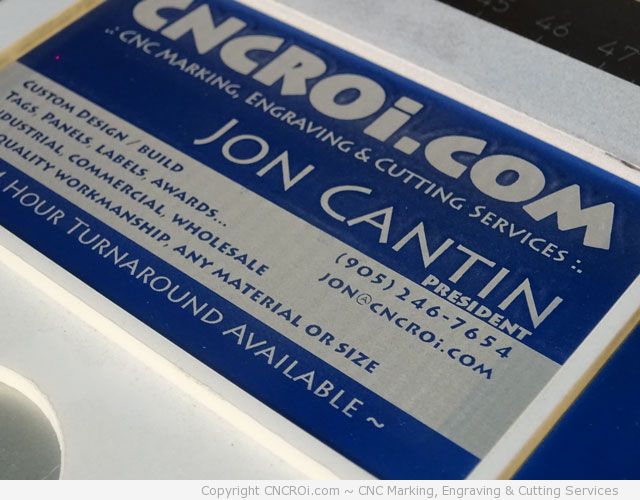

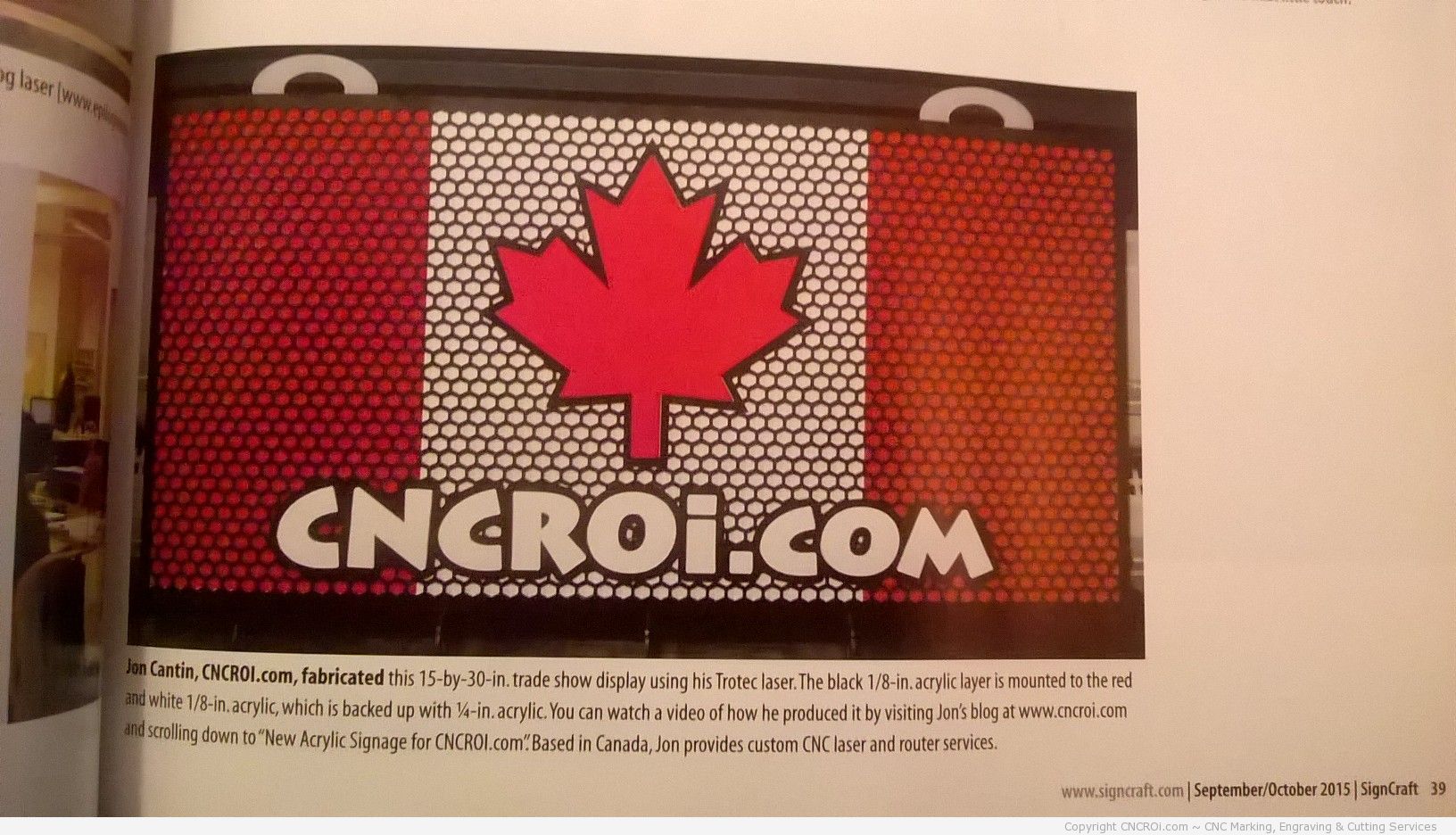

I put laminates with acrylics and plastics generally but this is an area that is experiencing some significant growth of its own here at CNCROi.com. Why? Well, the endless creative possibilities from signage to displays. It’s relatively cheap, has far more presence than the printed equivalent and the endless color combinations has helped it to become recognized by our client base.

I’ve been so busy with managing the change at CNCROi.com that I haven’t had much time to do some new models, it’s fun to take a break from production demands and just make things because I can. I look forward to doing a lot more of this in the near future.

Making rubber stamps and stencils, that’s a growth area but it’s on and off, we’ll get a ton of it, then nothing, then the cycle repeats. I think people just don’t understand the capabilities we can provide their company with these solutions. There is no reason why every company doesn’t have a custom stamp or stencil from CNCROi.com… and I’m working hard to make that a reality.

There you have it, a quick snapshot of what’s happening here as we grow in capacity and capability. Looking for a custom CNC shop to make something awesome for you? Contact us today!