Clay Embossing Stamp: Laser Engraved & Cut 1/4″ Acrylic

Need a custom clay embossing stamp? CNCROi.com makes them using any material you want but generally, we make them out of acrylic.

Acrylic makes for the perfect custom clay embossing stamp because the clay doesn’t stick to it as readily as other materials, such as wood or rubber.

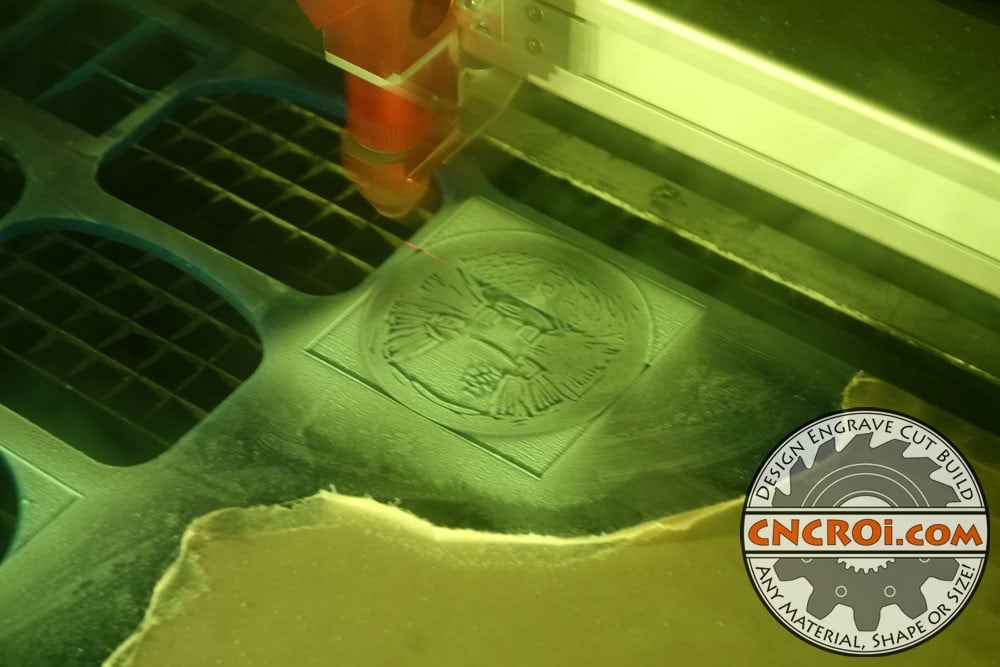

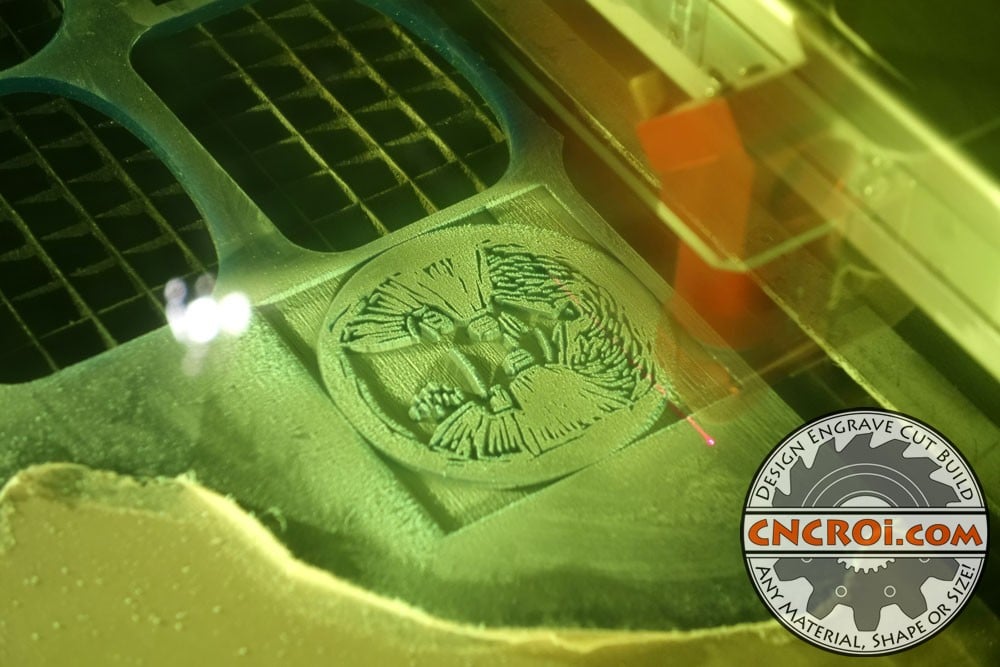

When it comes to making custom clay embossing stamp, the only real limitation we hit generally are details that are too small for the clay to accept, remember, we are dealing with a fine clay, not ink, as such, you don’t get as much detail with a solid as you would with a liquid.

You want to send CNCROi.com black and white vector images to have the highest quality imprint, we can do greyscale but you have to keep in mind, with clay, you want a deep embossing or no embossing, or laser on and off, as a result you get a more striking stamping.

In addition to having larger and more noticeable details in your design, you also want to allow plenty of space for “flat” embossing, as you have to keep in mind, the flat is what produces the contrast in the design, so if you don’t have enough of it, you just end-up muddying the resolution.

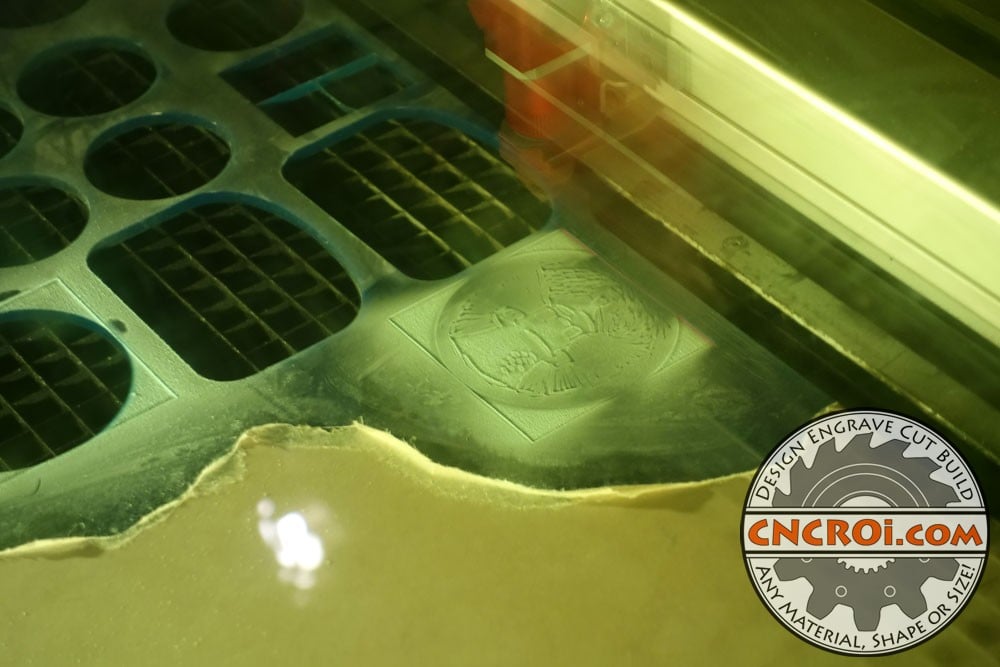

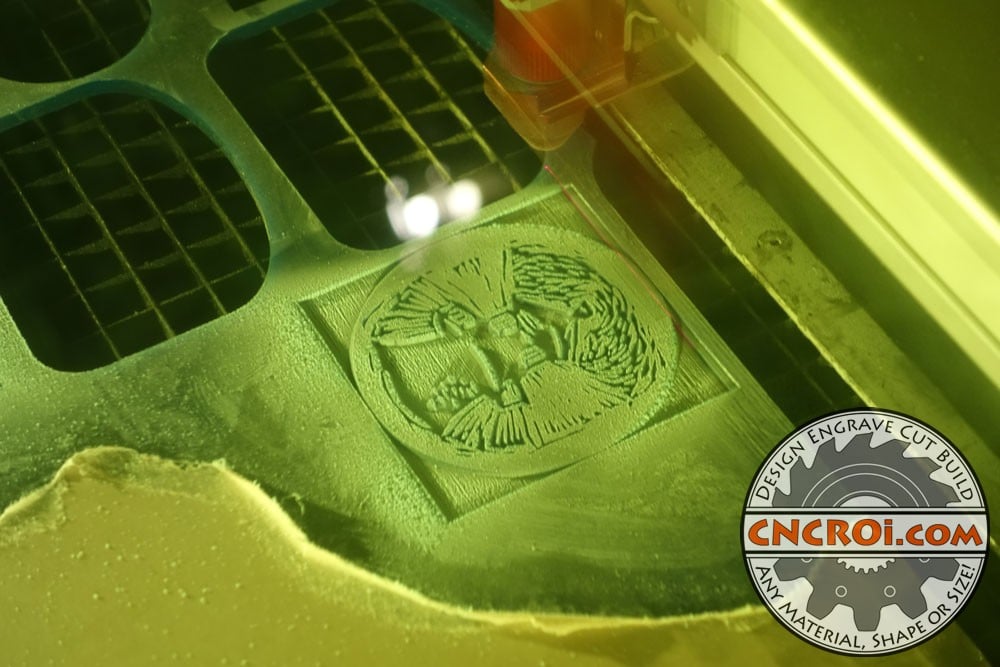

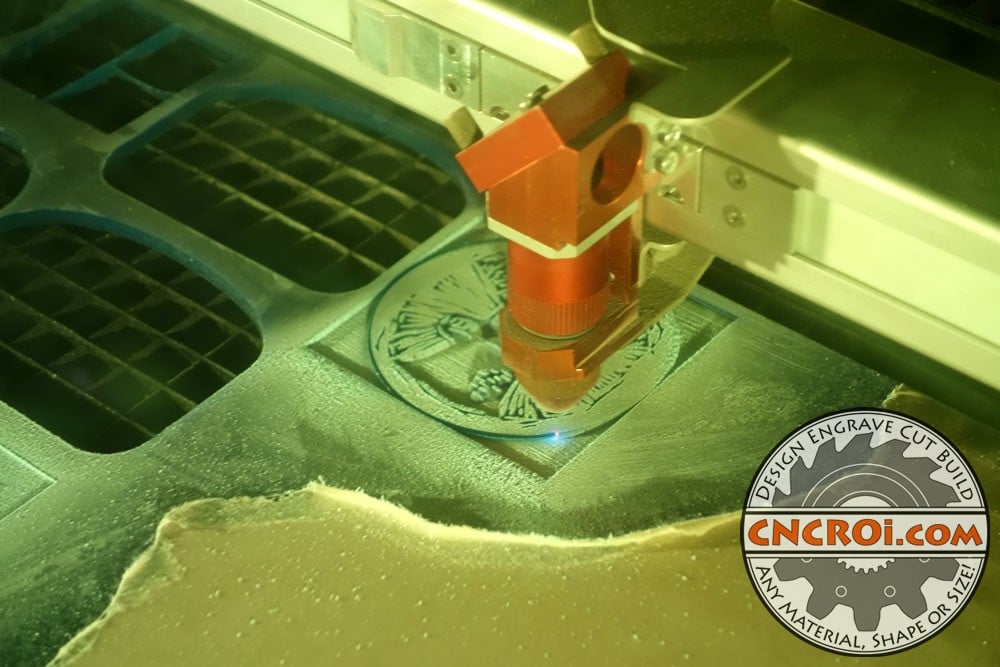

For these custom clay embossing stamp, I performed multiple passes on the acrylic, this ensures the highest quality possible when it comes to sharpness and a good shoulder in the design for the best possible embossing results.

Not sure why, but generally, the acrylic I use for embosers is blue.

The dust you see building-up on the surface and around the custom clay embossing stamp is just vaporised acrylic, it comes right off, it’s just a fine dust, no different than when CNCROi.com engraves custom rubber stamps.

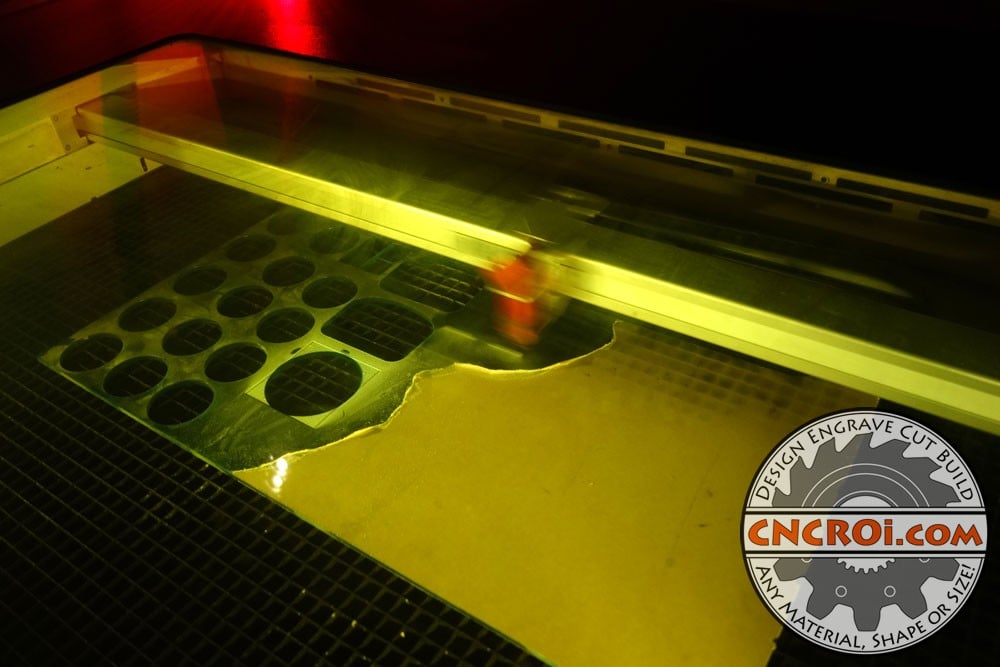

The paper you see on the front of this acrylic (also on the back unseen), is a protective masking to ensure the acrylic doesn’t get scratched-up before CNCROi.com does something with it.

Just about any design is possible with lasers, at any scale, so if you wanted the same design to be on a 1″ diameter embosser and on a 1′ embosser, CNCROi.com can do that no problem.

Fine (thick) lines tend to work best than a series of ultra thin lines, you have to keep in mind, that we are melting plastic and there is just so much heat it can take before melting.

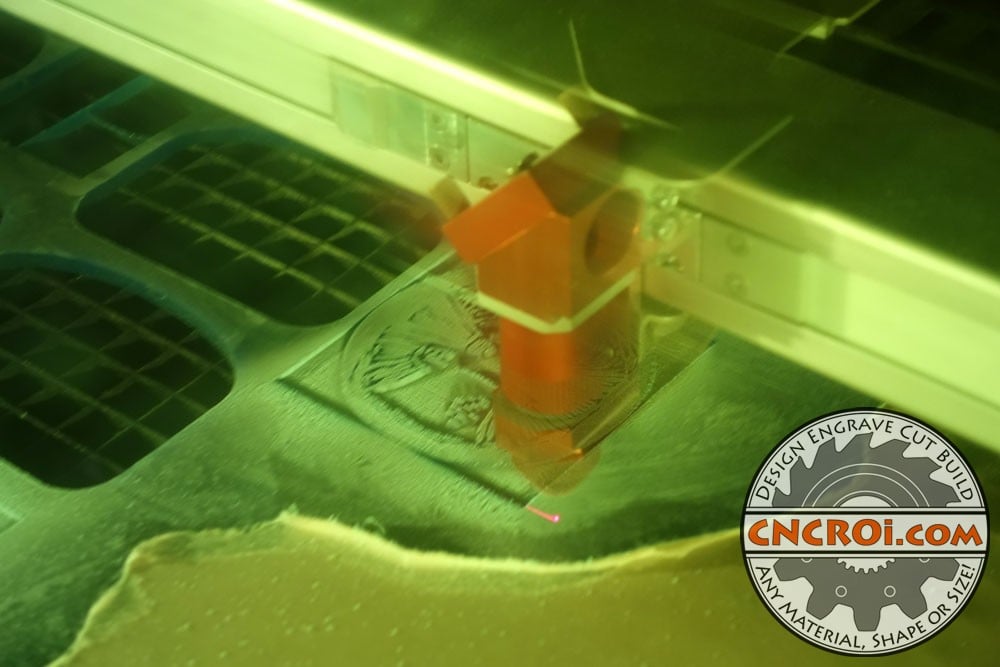

It’s important to perform the laser engraving first before the cutting, especially for custom clay embossing stamp, because any shift might double-up the details, causing a far less than optimal embosser.

There is no absolue control regarding depth using lasers, unlike our routers, there is nothing touching the material and at the same time, there is no feedback regarding the depth of the engraving, so everything for this custom clay embossing stamp is a guestimate at CNCROi.com.

For more specialized applications, CNCROi.com can employ thicker and more rigid materials such as HDPE and Corian or even Acetal.

Your application and production volumes will best dictate what materials your custom clay embosser will be made out of.

Acrylic is a very tough material but also brittle, as clay is a soft material, there are no issues, but you wouldn’t want to drop this custom clay embossing stamp on the floor because it can be prone to cracking or shattering.

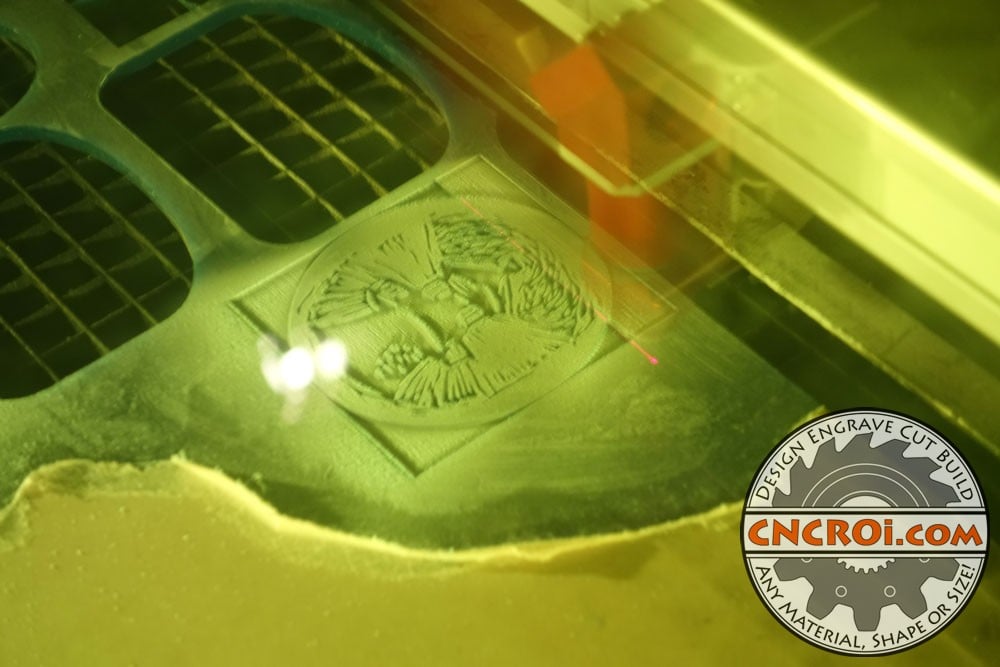

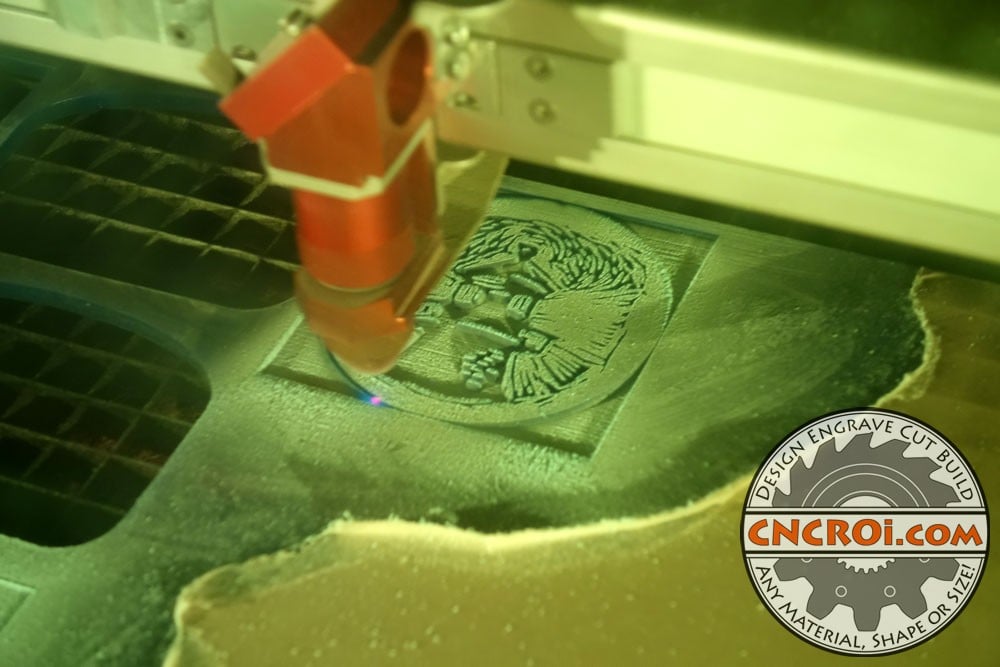

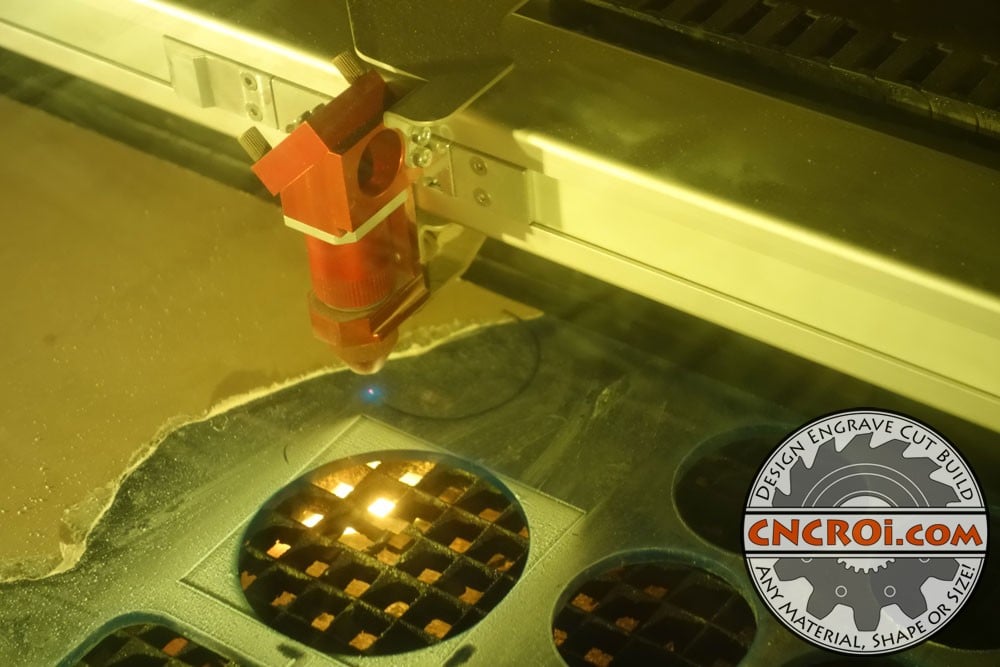

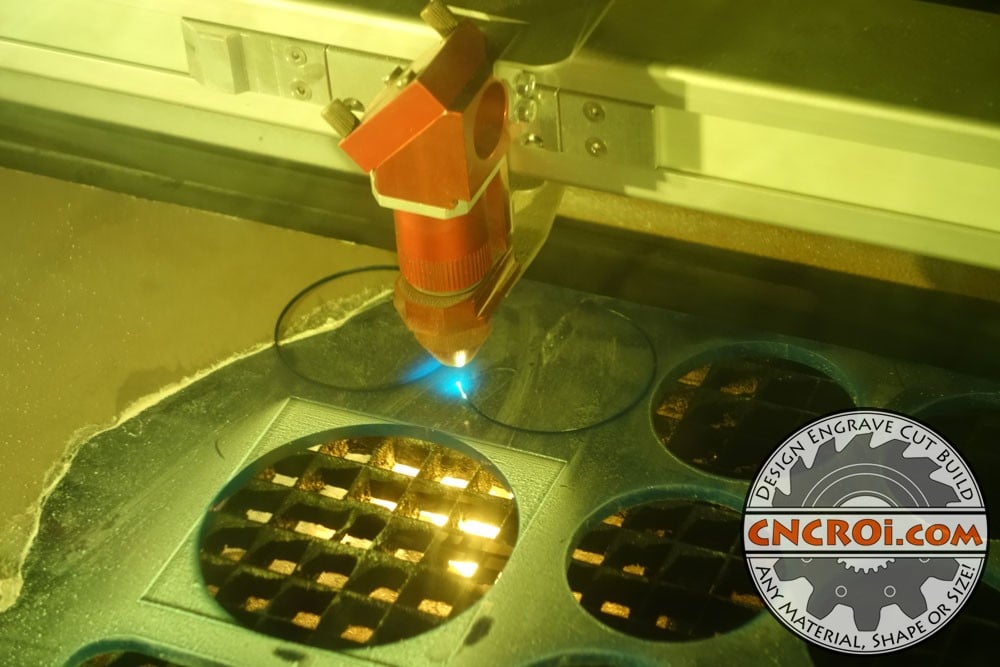

There is fire when the laser cutting is being performed because there is more directed energy shooting through the acrylic, while engraving, it’s more on and off, with a powerful jet of air shooting down from the heat to extinguish any small flames immediately.

As this acrylic is opaque, you can’t see through it, you don’t see the huge flame shooting underneath as essentially, the laser is igniting a petroleum product that’s highly flammable.

The embossers that CNCROi.com makes for seals can absolutely be used for clay, but generally the thickness isn’t enough, hence moving to quarter inch thick materials.

The clarity and quality you see on this seal embosser is very close to what you’d get on acrylic, it’s just that acetal is more resilient to pressure than acrylic, which tends to shatter if too much force is applied to it.

Before above, after clean-up, below… night and day but you can see the clarity and definition that the laser performs on the acrylic, in this case, the acrylic was quarter inch thick.

Acrylic can be had in lots of different colors, so if you prefer another color, that isn’t an issue.

For this custom clay embossing stamp, due to it being rather large with a 3″ diameter, I made a little handle, using the same acrylic as the embosser itself, so that there was a slight stand-off for easier holding.

Generally, the more pressure and use a embosser will be subjected to, the smaller it needs to be unless we upgrade to more resilient materials.

Like the custom molds we make for customers, there is definitely a progression from cheap materials to more expensive ones as the application and tolerance requirements become more rigid.

Need a custom clay embossing stamp? Contact CNCROi.com right now!