CNC Cleaner: Live Edge & MDF Cleaning

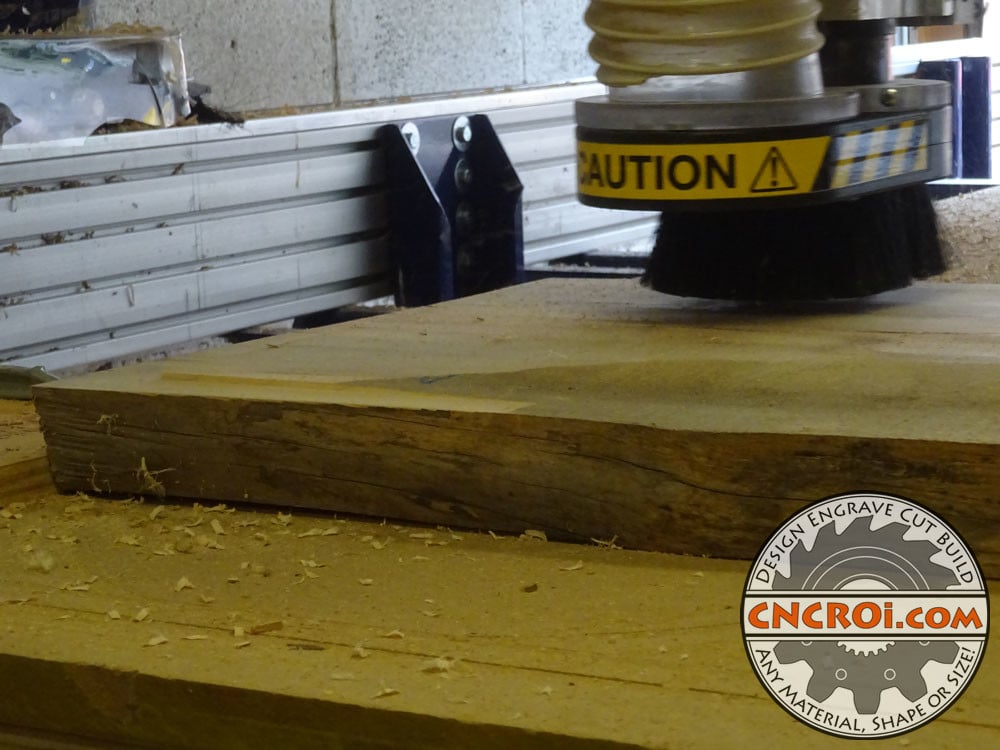

CNCROi.com uses our CNC cleaner to both flatten and clean-up live edge and MDF sacrificial boards, it does a wonderful job as you’ll see.

https://www.youtube.com/watch?v=Ps6AE1GY-f0/

It’s pretty impressive how wonderful our full sheet CNC router is when it comes to being a CNC cleaner as well as making boards totally flat regardless of the species or wood composite.

When it comes to flattening, you may be wondering why we do so much of it at CNCROi.com with our live edge material, this video will help explain the process and reasoning as to why it’s so important.

https://www.youtube.com/watch?v=1ODtKCwwDmk/

When it comes to flattening, I’ve lost track of how many live edge board and slabs we’ve made parallel for a variety of applications, from custom corporate awards to house number signs and even furniture.

Although my hold down methods for holding down boards has evolved over time, with live edge slabs, whether I’m just CNC cleaning them or making them parallel for other projects for customers at CNCROi.com, I’ve found that generally the live edge doesn’t want to lift so really holding it down just required X and Y and not vertical holds to keep them in place during the flattening process.

Another nice thing about live edge slabs is that they are heavy, as such, their weight alone keeps them from moving around on our CNC router so there really isn’t much pressures pushing and pulling on the overall board.

Regardless of how many thousands of times I’ve flattened boards and MDF spillboards though the years, I find it a fascinating process and I really enjoy doing it.

https://www.youtube.com/watch?v=wt2bBRtEIHY/

Each board is unique, each produces a finished result that customers and projects that I work with on a daily basis come out great upon.

One of the most common uses of flattening live edge boards and CNC cleaning is actually house number signs, the board needs to be FLAT for the best results possible.

https://www.youtube.com/watch?v=SZbDwgCE8iw/

Regardless of the species involved, flat is flat and having something parallel helps wonderfully when it comes to sticking the house number sign on a post or a wall of a home.

I find the CNC cleaning and flattening process to be one process, two different results achieved at the same time that make sanding and other post applications so much easier on other machinery, it’s really hard to describe just how wonderful having something flat is when it comes to general woodworking.

Once a board has been CNC cleaned and flattened, it can be transformed into literally anything, from custom house number signs to even shooter trays!

Although technically CNCROi.com can make custom shooter trays using wood that isn’t flat, it’s tough because it wants to wiggle around and an uneven surface can cause production issues on it’s own.

When I was flattening this piece of live edge board, I did have my dust collector a little high on the spindle, so it caused a bit of a mess with the wood chips flying all over the place but with live edge, it really isn’t a big deal, but when it comes to MDF, it’s a fine powder that that takes quite a bit of cleaning-up as it flies everywhere.

Here’s a video showing more live edge slabs being CNC cleaned.

https://www.youtube.com/watch?v=kDinzYsr8io/

Considering how sped-up the video is, you get to see the finished result in a fraction of the time it took me to see it real-time.

If I only flattened one side of the live edge slab, it would be flat on one side but not the other, and thus, not parallel, so the board needs to be flipped around, and this is the secret to it all, not doing this produces OK results but parallel is really the way to go.

What else can be made using CNC cleaned slabs? How about dog bones!

https://www.youtube.com/watch?v=67DOfMCacBk/

There are really endless product possibilities when it comes to making custom woodworking jobs come to live at CNCROi.com.

The reason I say we do a lot of CNC cleaning is demonstrated in the picture below, you can see how rough, stained and Sun bleached the wood is in the photo and where I revealed the true beauty of the wood, so instead of using a power washer or extensive sanding, CNC cleaning does just that, reveal a brand new fresh surface to the wooden live edge slab.

What’s really fun though is when CNCROi.com puts together different slabs to make a totally flat surface, so at first, you flatten individual boards, then you chop it up and then glue them together with biscuits or dominos depending on the size.

https://www.youtube.com/watch?v=1ODtKCwwDmk/

So even with slab specs that are out of budget or range, CNCROi.com can make them using multiple boards with an almost seamless and timeless look to them.

Lots of wood chips being made, these are used later in our fire pit to make some wonderful food, so nothing is wasted.

You can see how wonderful this slab looks, just a few minutes of sanding and you end-up with an amazing board to do just about anything from.

My other goal that day was to do some CNC cleaning of the MDF sacrificial board under all this live edge work, CNCROi.com recently finished a custom melamine cabinetry job and it was time to return the table to both flatness and to give the vacuum system an easier job of holding items down.

In addition to live edge, CNCROi.com does lots of woodworking for other industries from aerospace to millwork and literally everything in between.

https://www.youtube.com/watch?v=uvHMBQN0-sI/

Big jobs, massive jobs and small jobs, we do them all!

If you are wondering how a vacuum system looks like, here’s a video I made showing how the table was put together when it was time to clean-up the sacrificial board and put on a new one.

https://www.youtube.com/watch?v=A3R9u_DI5IE/

In a custom fabrication shop, there is never nothing to do.

Live edge flattening is exciting work to do, giving new life and stories to the wood but when it comes to MDF, it’s more an erasing of the history that was performed on it to be able to create new items on it’s surface.

Need some custom CNC work performed?

Contact CNCROi.com right now!

https://www.youtube.com/watch?v=oPnWLWwNDeQ/