CNC Fiber Engraving Plate Metal

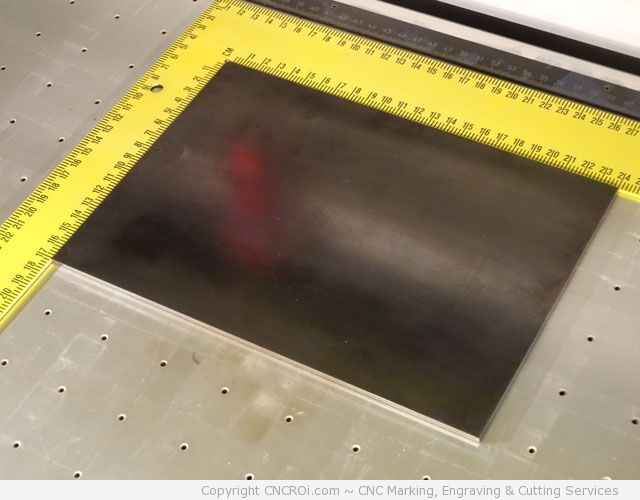

I’m unsure what type of metal this is but it’s dark, it’s heavy and although we could anneal it, there wouldn’t be much contrast, same with marking… so let’s engrave into it using our CNC fiber laser source but using a different tolerance that engraves into the metal rather than anneals the surface. Engraving plate metal produces a rough result while annealing a smooth one.

We used our CNCROi.com fiber lens on this along with our fiber tube as it provides the best results for metal. After placing it on the bed of our Trotec Speedy 400 flexx, it was time to start engraving plate metal into it using our laser.

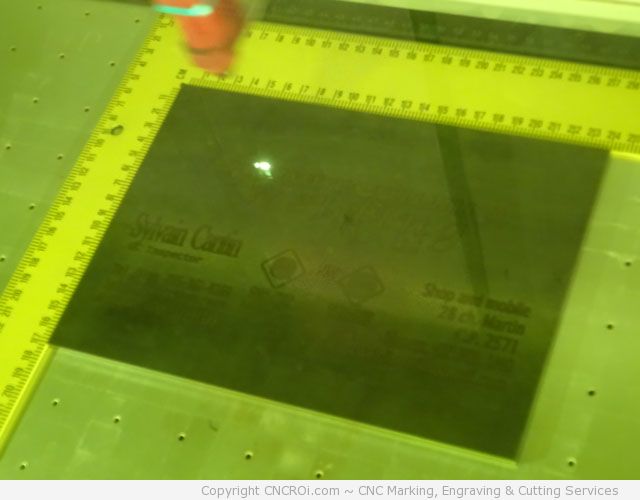

Annealing would give it a “black” mark which just doesn’t provide enough contrast while marking it would cause a similar issue, without contrast both of these methods just don’t work very well so engraving into it, which takes lots of power and precision to pull off was done instead. Some of our customers prefer a very rough result while others prefer a smooth one, we can do both no problem.

The results look great, in hindsight I’d probably apply an enamel paint FIRST then vaporise it to give better contrast but this was a fun test to see what kind of results can be achieved. Although it looks “rusted”, it’s actually quite a consistent result once everything is cleaned-up after engraving plate metal. This would be great for paint filling due to the surface depth.

I probably wouldn’t bother using this method over using our CNC router (blog post about that later) for metal engraving simply due to the time involved but like the cowboy sign, something to keep playing around with till the results are what I want.

Contact CNCROi.com for all your custom engraving, etching, annealing, marking and cutting applications – regardless of material.