CNC Fiber Laser Cutting & Annealing Stainless Steel

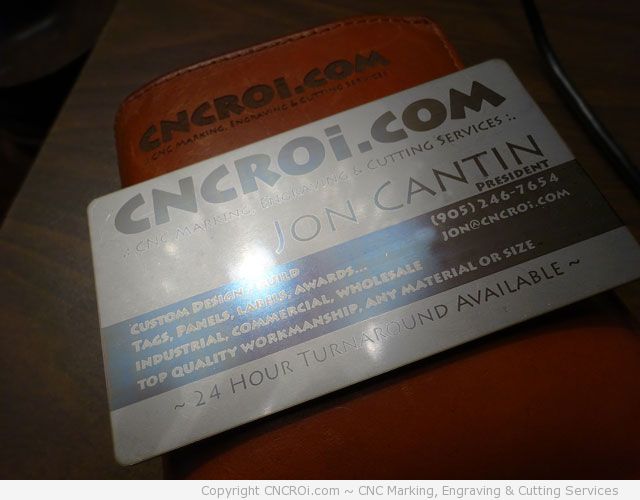

It’s amazing how much stainless steel metal projects CNCROi.com has pushed through the shop in the past two weeks, we literally did more during this time interval than our first six months in business over two years ago! Here are some common questions we get from customers and ‘soon to be’ customers alike.

How durable is stainless steel fiber annealing?

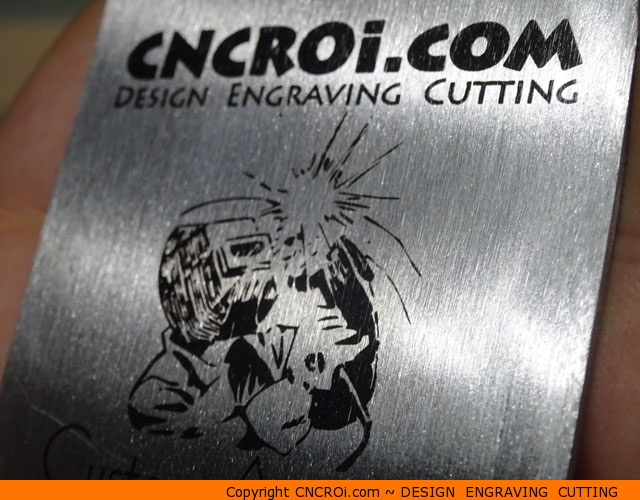

CNCROi.com utilizes a fiber laser source, not ceramic bonding paste, not UV printing or any other sublimation or imprint process. Why? Because it’s PERMANENT. How permanent is permanent? Well, I routinely challenge customers to remove the fiber annealed information we put on their custom plates!

At first, they are gentle, just scraping it lightly against something else that’s metal or concrete then they go right into the heavy-duty stuff. I edge them on to keep on trying! Why? Because I know that short of using a sand belt to remove the ENTIRE SURFACE, our fiber laser annealing on stainless steel is NOT EVER COMING OFF. It will not fade, crack, peel or be affected by temperature.

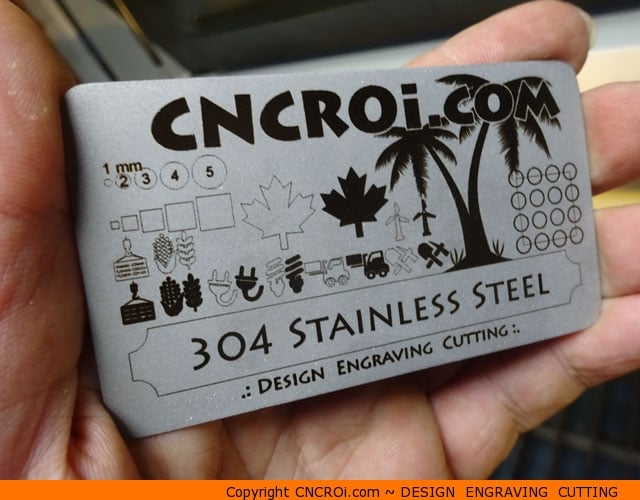

That black you see on the stainless steel in these videos and photos, that’s the annealed part. We routinely make these for heavy industry, from welding tags to machine electrical plates and everything in-between from metal business cards to luxury drink coasters.

Can you anneal onto stainless steel images and text?

Yes, with up to a thousand DPI, we can anneal in black just about any information you want, whether that’s images, text or any combination. For the best results though, we do need those images to be vector based, the reason is we want to have nice round corners and SHARP text or details, images that aren’t vector based tend to be jagged and not with a clean finish.

What are your custom stainless steel plate options?

We keep a tight selection of “custom standard” plate sizes in the shop but as we are a custom CNC shop, about 99% of our stainless steel is to order. There are just so many different gauges available, surface finishes and metal alloy combinations that keeping all of these in stock would make our shop the size of a small city.

For instance, this week we had a customer order a bunch of custom fiber laser cut 11 gauge plates from us which we then permanently annealed the information they wanted onto it. There are various off-cuts from this process that we keep but due to the cost of production, we try to use as much as possible and even mix projects from various customers together to get the best process forward.

How do you get custom metal plate fabrication started? Send us a drawing, generally DXF with a few measurements for reference along with material details and how many you need. They can all be the same or different, it makes no difference to us as we make everything to order.

Why do you fiber laser cut your stainless steel (or any metal)?

One of the many tricks to proper and consistent annealing is making sure the surface is completely FLAT. The tolerances are incredibly tight when it comes to fiber laser annealing and the flatter the base metal, the better the results and the faster we can move.

As a result, through extensive experience with plates cut using various materials, those cut with a fiber laser tend to work best, waterjet, plasma and CO2 laser also do a great job, but the decision on which produces optimal results depends on the gauge, application and the material composition we are contending with.

For example, if a customer wants to get custom blanks cut out of aluminium, we often tell them that waterjet won’t work if they then require them powder coated or anodized as there won’t be enough electricity binding on the edges. So, it’s the little things like this that can make or break a project that CNCROi.com has learned the hard way not to do again.

Do you use 316 or 304 Stainless Steel?

We can work with and a host of other metal alloys, what we generally tell customers is that unless the application involves a marine or extremely corrosive environment, go with 304 stainless steel instead of 316. Why? Well, it will generally save you 20-25% in material costs!

There are so many variations when it comes to metal, from the high grades use for surgical equipment (yes, we anneal that too) down to the rough stuff some of our customers love to sell as ornaments at the local flea market. We’ve also worked with brass, copper and lots of other materials but our default option is generally stainless steel with a brushed finish (#4 is especially nice) or anodized aluminium, gauge doesn’t matter.

Stainless Steel: Special Design Considerations

There are a few issues that come-up that designers sometimes forget about that are unique to stainless steel which I’d like to share with you, our awesome reader. If you don’t work with metal too often, this will save you lots of problems.

Round your outer corners!

When we custom fabricate plate, I always ask the designer to round the corners. Why? Well, those things are sharper than your sharpest knife otherwise! With plastics, woods, composite materials and fabrics, it generally doesn’t matter (though Corian is pretty sharp too!) but I’ve lost track at how many times I’ve cut my hands on stainless steel-cut 90 degrees or less on outside corners while packing it for shipping.

The corners also don’t need to be ROUND, they can be as little as 1/32″ or less than a mm. The same holds true with anodized aluminum but that’s far lighter so it doesn’t have the digging power that REAL stainless steel or iron has on a hand.

Lots of fiber annealing? Go as thick as you can!

The annealing process using our fiber laser is incredibly hot, depending on the design, I actually have to leave some of our customer’s plates on the bed of our laser to cool down before picking it up. Yes, along with losing track of how many times I’ve cut myself on stainless steel, a close second to that statistic is how many times I’ve burned myself on stainless steel picking it up!

Stainless steel doesn’t glow red when annealing though I’m pretty sure I could manage to do it, it looks the same hot as cold and it’s amazing at how hot the entire plate gets just from a little annealing on the surface! This heat also causes issues on very thin plates, we literally bend it! So, for customers, thicker is better depending on the application.

Stainless Steel is HEAVY and STRONG!

Somewhat related to the above but in an inverse fashion, stainless steel is heavy, we routinely make custom stainless steel business cards and even at thin gauges, you feel the weight. We also make lots of custom machine plates using 11 gauge (roughly 1/8th inch or 6 mm) and you KNOW its metal just by the weight.

If you are coming from the wood or custom mill work industry and aren’t familiar with the strength of custom metal fabrication, try to think of it this way, you can get away with a fraction of the overall surface area using metal than you can wood. It’s an incredibly durable, strong and heavy material which is why your car engine is made of metal and not wood. Keep that in mind when you go into having us custom fabricate something for you out of this material.

I hope this helped you understand better what we can do for you specifically dealing with stainless steel, there are of course lots of alternatives, anodized aluminium, metal laminates and brass but we’ll deal with those in a future blog post.

Need custom metal plates produced and annealed? Contact CNCROi.com right now!