CNC Fiber Marking & Engraving a PCB Board

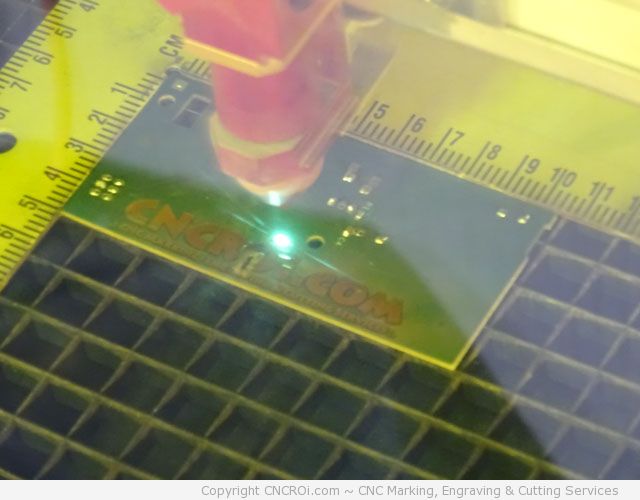

Although there are a number of ways to permanently marking or engraving PCB boards, by far the best is using a fiber laser tube onto the green part of the PCB board. Watch the CNCROi.com video to see why.

The major advantage to using a CNC laser over just about any other process out there is lack of contact. Using a CNC router or peen will vibrate the PCB board which may cause damage. Using our method, with a fiber laser tube, we can mark each board identically or uniquely using QR codes through alphanumerics run through a database so each component(s) can be tracked easily.

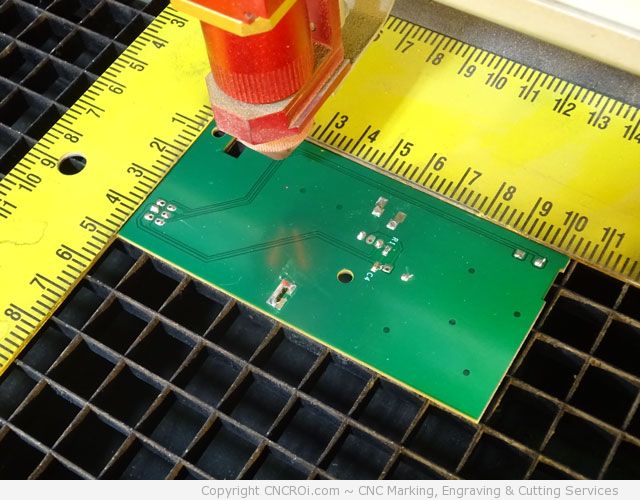

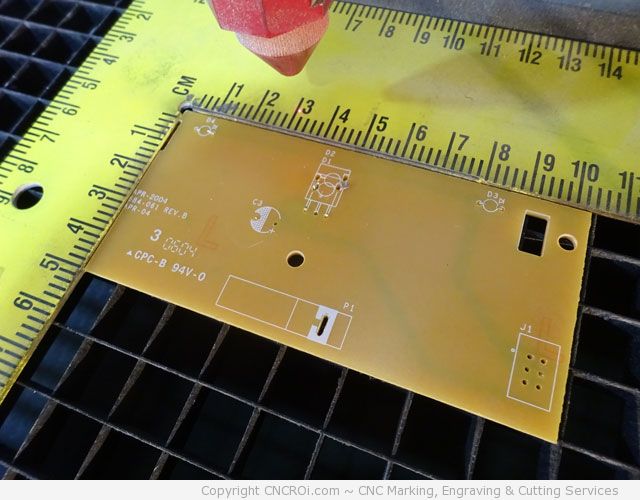

In this case, we recently completed a project and this was a piece of scrap used during the material testing phase of the PCB board fiber marking. I cut off all the circuits just for easier visuals but we have more than enough tolerance and distance to do a full board with all components without any issue.

For the highest contrast, the green side of the PCB board was fiber marked using our fiber laser tube, the other side, with a CO2 tube just to show the contrast of each approach.

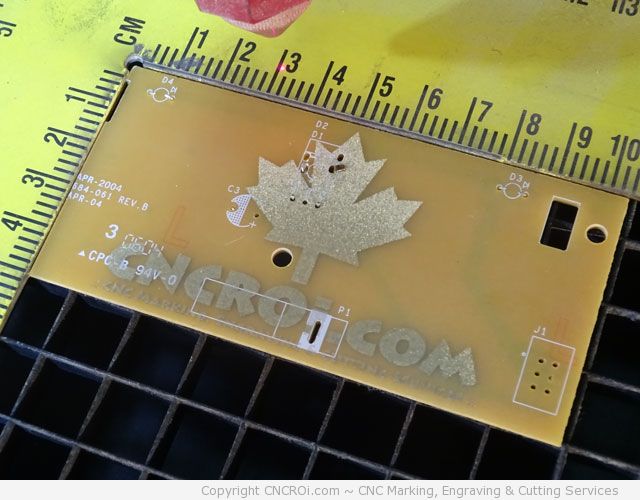

You will see a slight difference in the “C” because even with all the components cut off, the board wasn’t totally flat, hence a different amount of energy hit that part over the other parts of the board. Generally, we make custom jigs so that this isn’t an issue as part of the laser engraving or marking process.

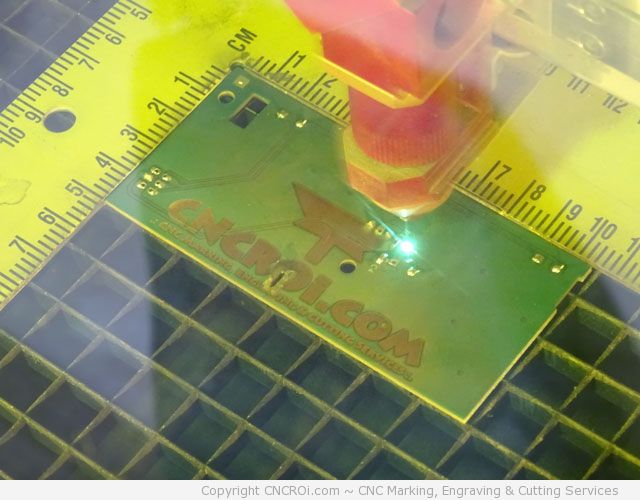

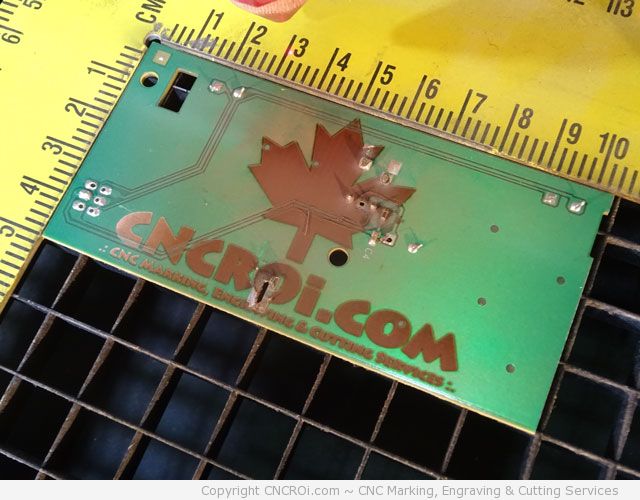

The PCB board, other than not being totally flat, came out pretty awesome! After a quick clean, the contrast will be improved as some deposits were made on the board itself during the lasering process. Depending on the power setting, we can either go straight through into the board or just do some very mild surface abrasion. It depends on the specs you wish to achieve with CNCROi.com.

Now, for the other side, it already has some markings on it done using a fiber laser so we used a CO2 instead to show the difference.

This design of the CNCROi.com logo is identical to the one fiber marked on the other side by the way.

The results aren’t anywhere near as nice, that’s because we essentially melted the plastic while on the other side, using the fiber laser tube, we heated only the very top surface enough to change the material properties. Again, different power settings will produce different results but it looks from this preliminary testing, fiber is the better way forward.

Comparing the two, CO2 above and fiber laser below, you can clearly see the better tube for this specific application. This is why CNCROi.com imported our machine from Austria, a Trotec Laser Speedy 400 flexx, because we wanted to offer our customers complete flexibility and not be locked into ONE WAY of doing things. That’s one of the many reasons customers send us awesome projects to work on!

Here is the same board at a different angle.

Looking for a fantastically passionate company to handle your next CNC laser project? You’ve found us! Contact us today!