CNC Fiber Vaporizing Behind a Mirror and Color Changing the Back

CNCROi.com has shown-off its mirror etching and engraving expertise in the past but let’s try something really neat, fiber vaporizing “behind” a mirror and color changing the plastic on the other side. I noticed these cheap mirrors at the dollar store and thought they’d do a wonderful case study as to what is possible using our industrial Austrian CNC laser!

REAL glass front and metal backed mirror.

Why FIBER vaporizing behind a mirror?

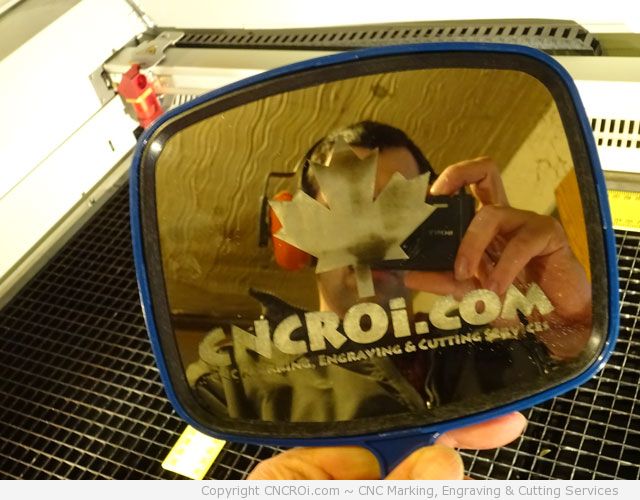

Well, if you don’t actually engrave or etch the mirror’s surface but coating (in this case foam in between the mirror and backing) then you have a smooth surface with won’t have dust or buildup. It’s tricky but based on the focus you assign to a material, pretty neat to see it happen with the proper settings!

Thanks to our fiber laser source, we aren’t actually doing ANYTHING to the mirror, what you see is the mirror backing being melted away, not the mirror itself being touched!

As to why I used my fiber laser source instead of the CO2 our Trotec Speedy 400 flexx also has in the box, CO2 would just burn the surface (this is very cheap plastic after all) so the mirror would become a fire hazard in the machine and the results would look horrible. This cheap mirror test would NOT be possible without a dual sourced CNC laser.

Fiber on the left, CO2 on the right.

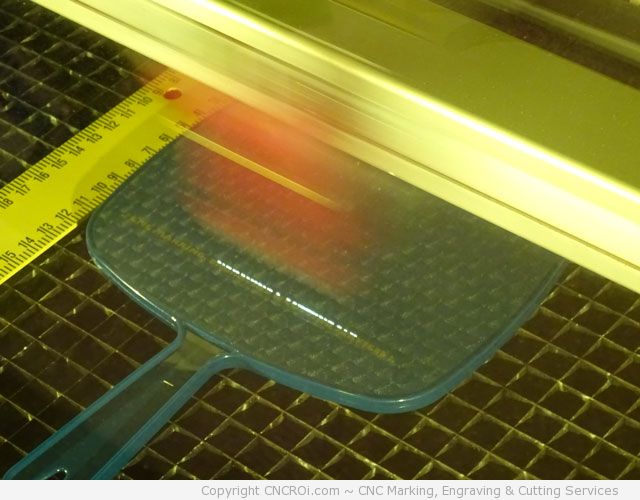

Fiber Vaporizing the Front

One of the challenges that comes-up and this picture clearly demonstrates is the smoke build-up… you’ll notice that it’s especially noticeable just above the leaf stem and below the leaf top but over the rest of the mirror, relatively consistent.

The easiest solution to this is dialing down the power and/or increasing the speed of our 5G CNC laser so there is less material burned-up between the backing and the mirror itself. The smoke has nowhere to go, vacuum table and gas kits are useless in this case. Another solution to this would be to build-up the image using slight but multiple outlines. It’s like cooking an omelet, there are a dozen ways to achieve the same results depending on budget, time and specs.

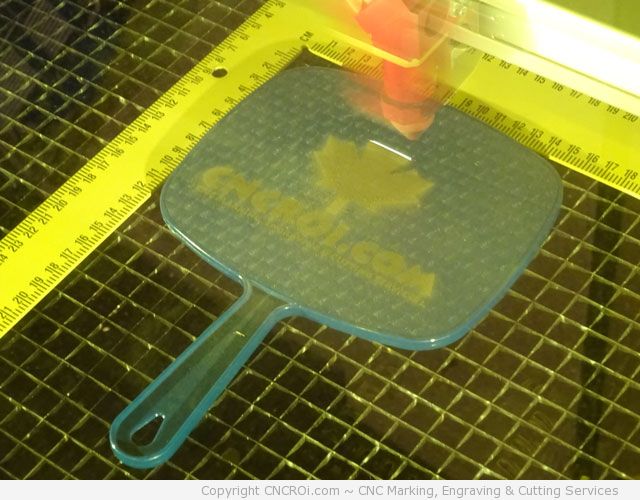

Color Changing Plastic

The backing of the mirror is anything but smooth, it has a deeply marked back so I wasn’t sure what the results of pushing fiber onto the surface would do.

You can see a slight gray is quickly being established on this blue plastic, it isn’t flat so that’s why you get inconsistent results though what is color changed smooths out slightly.

There is a lot of debris being built-up in this case which gives the backing a fuzzy look but that’s easily removed.

The results aren’t bad, I’d maybe reduce the power settings slightly to see if I could somehow manage to keep the groves in the backing while color changing the plastic, in this case, we vaporized more than color change I suspect but again, this material isn’t flat and we don’t have much tolerances when it comes to fiber color changing something where price dictated materials rather than quality.

Taking a look at the front again, you can see that, like the back, there is room for improvement.

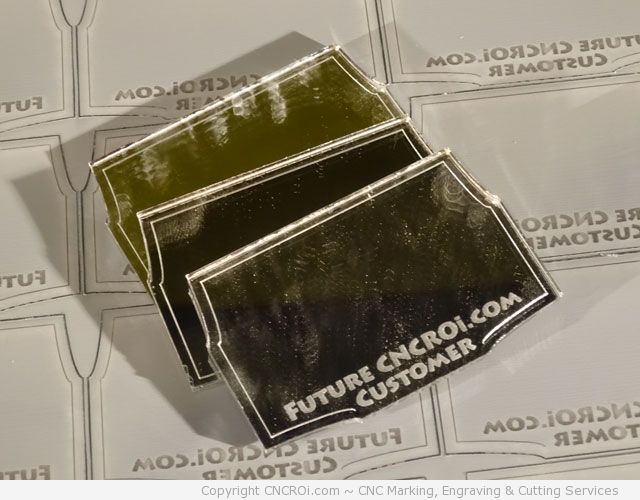

Material Testing is Important!

CNCROi.com had some fun with a cheap mirror, the results look promising and this clearly demonstrates why material testing is required for most custom projects. Cutting plywood or annealing 304 stainless steel is one thing, getting a random piece of plastic in the mail or in this case, from the dollar store, is quite another. Luckily for us, most of our work is industrial so we can play with one widget until we got the settings dialed-in and then we are off to the races.

Sometimes we are lucky, we can get away material testing a small area of a widget and the results stand across the material but as you see in this case, the smoke damage between the layer wouldn’t have been noticed on only a small area being fiber vaporized nor would the inconsistencies on the back been realized either. This is why I generally ask clients to give us a full scrap piece for doing a full-sized test run as part of our material testing just to make sure nothing was overlooked.

Imagine if we would have filled out huge bed with about 50 of these mirrors, pressed a button and then one it was done, realized the error of our ways… a headache easily avoided by taking things slow the first time around. Watch our 701’th video, front to back!

Contact CNCROi.com

How do you become awesome with an industrial CNC laser? You play, play and play some more with it… the benefit is that you can discover approaches and efficiencies that lead to innovative solutions for our ever-increasing customer base!

Acrylic mirror, CNC laser engraved and cut by us!