CNC Laser Cutting 101

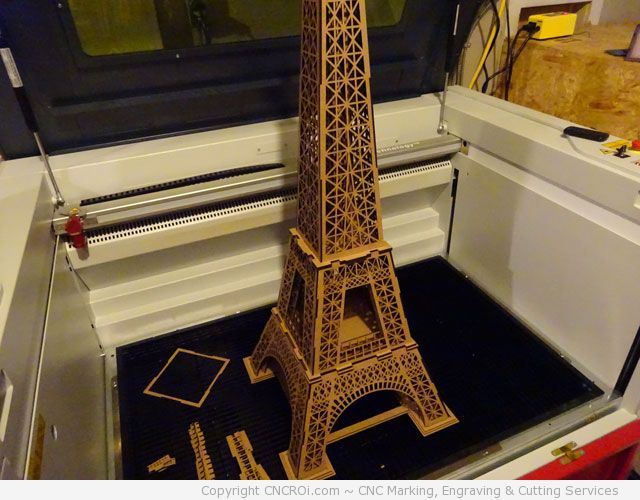

With a massive production bed, our Austrian CNC laser is able to quickly cut, mark, etch, anneal and engrave just about any material we’ve come across and then some. Our bed is so big that the Eiffel Tower can fit inside of it with plenty of room to spare!

The advantages of CNC lasers are many but here are some of the main features.

- Eliminates the need for edge sanding and produces a nice charcoal on woods or flame polished contrasts on plastics.

- Compared to a CNC router (which we have as well), you can get a lot more parts done on any given amount of material, greatly increasing output ROI.

- Repeatability, compared to non-CNC approaches, a CNC laser will cut the same material day in and day out without any wear (like a CNC orbital knife) or tearing into the material (like a CNC router).

- Incredible material availability… the only thing that can’t be processed using a CNC laser is vinyl as it releases Chlorine gas but everything else is fair game.

- Unlimited design possibilities, you can pretty much create anything using a CNC laser!

The disadvantages of CNC lasers.

- You can’t create pockets as the laser beam can’t gage depth like you can with a CNC router.

- You can’t undo what you did, all the processes are permanent when you screw-up though this is also a good thing for theft prevention for instance.

- They are by far the most expensive of the CNC options both in power requirements and capital costs.

Where CNCROi.com fits in

We began from a purely design background, learning how to create just about anything using CNC lasers, CNC routers and by extension, CNC water jet and CNC plasmas. It’s one thing to get a CNC laser, quite another to understand its quirks and design around them efficiently to greatly increase ROI in both time and monetary measures.

Yep, that’s our machine, our Austrian Trotec Speedy 400 flexx is an awesome machine and we use it to full capacity as much as possible. What makes a flexx a flexx? Well, we are the only company in Canada with this machine, it isn’t cheap but CNCROi.com believed there was a huge market that needed what this CNC laser can provide. Here are a few reasons behind this large capital expenditure:

- Dual-laser sources, meaning we have both the capability of a CNC fiber laser and a CO2 laser in one machine without any of the disadvantages. In the CNC laser world, having multiple tubes is a huge benefit!

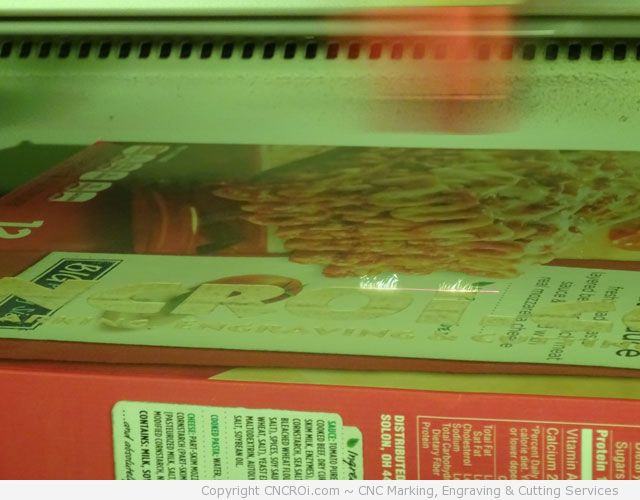

- Pass through ability, meaning we can open the front and back (and top) to put in huge, long and odd pieces quickly and efficiently. From a bowling ball to a door, we can get it in there!

- FAST! Our CNC laser head moves up to 3 meters a second and has up to 5G acceleration… it’s so fast that our camera has trouble seeing it when we take pictures!

- Gas kit and powerful extraction, this means far less vaporised material ends-up ON your material, greatly increasing ROI as we aren’t wasting our time cleaning things after our CNC laser is done with it.

- Rotary kit, we didn’t just invest into the best machine in the market, we also got all the bells and whistles with it including a rotary kit to handle cylindrical and round objects so we can engrave around a baseball bat for instance or wine bottle.

How to take advantage of this capability?

No need to go out and spend a King’s ransom for this capability, that’s why we bought this machine, so you can have all the benefits without the costs. Give us a call or send CNCROi.com a message using our online form and we’ll produce some awesome CNC laser products that you will be proud to show to friends and business associates!