CNC Laser Cutting Custom Solid Plywood Hangers

Custom designing and CNC laser cutting solid plywood hangers is pretty easy, CNCROi.com has done a lot of this… including some made out of acrylic, high density plastics and even stainless steel (we dull the edges before giving to the customer as otherwise, they’d easily double as personal protection devices).

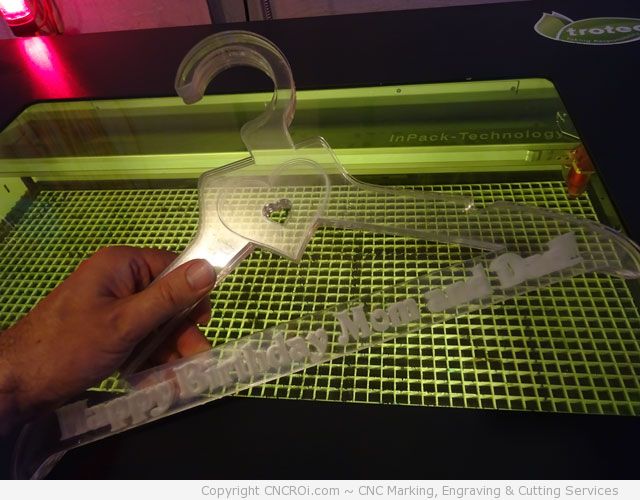

This is the two layered custom laser cut hanger we are going to make this round, compared to the thinner (due to material properties) acrylic ones we made earlier in this blog.

These aren’t as weather proof but as they were scrap headed to the fire pit, it’s good to salvage as much from material about to be burned as possible.

Looking at the two designs, due to the poor quality of the plywood (it’s scrap!), I had to cut out the inside hole to make it stronger and double them up with glue in between. This produced a far stronger hangar that otherwise, would have broken prematurely.

To save on clamps, I just layered each doubled-up hanger with another one with glue in between each second hanger. They all glued together but were easy to pry apart once it dried.

These plywood boards were a bit warped so I went extra slow with our Austrian CNC laser to make sure we cut through the wood even if it was slightly out of focus… this trick works great with wood but no so much with other materials such as foam or high density plastic or laminate.

You can clearly see a flame under the board, better there than above it! The high energy from our CNC laser cuts right through this like it was butter, the extraction above and below help keep fire damage to a minimum and compressed air gas kit pushes the flame downwards. This leave a nice finish on the “top”.

I also designed the hanger top to be 3x thicker than the acrylic one I designed earlier. Why? Strength. Again, this isn’t high quality plywood, it has holes between the layers of ply and I wanted to make sure that even if I hit those, I’d still have something “solid” to double-glue them together onto.

You can already see the plywood in the above picture popping-out of the plywood sheet due to the warping inherent in the wood that’s released once it’s been cut out.

Plywood is a wonderful material though, it’s endlessly flexible, great for a wide variety of projects and can be stained, painted and modified quite easily to suit a host of applications.

Once all the hangers are cut out using our Trotec Speedy 400 flexx laser with both a fiber and CO2 tube, CO2 is what we used to cut the plywood with btw, it was time to glue them together.

These will be placed in a closet, they aren’t showcase pieces, so I’m being quite liberal with the glue. These could be sanded, stained or painted quite easily but for my purposes, I just need some more hangers!

As you can see from the picture below, there are lots of knots and imperfections in these plywood hangers, that’s part of the charm as each is unique!

They have one good side and one bad side, I didn’t mirror them (to hide the bad side between the layer of glue) as I wanted to keep them imperfect. Something nice to make things looking natural.

Hangers, the one thing you can never have too many of!

You’ve found CNCROi.com, contact us with your custom spec, material preferences and we’ll turn your idea into reality!