CNC Laser Cutting & Engraving Sir Richard Branson

Sir Richard Branson, one of the few entrepreneurs who admits how much luck, not just hard work and brains, got him to where he is at today. It’s time to honor him by cutting him out with our Austrian CNC laser here at CNCROi.com and learn a few things along the way!

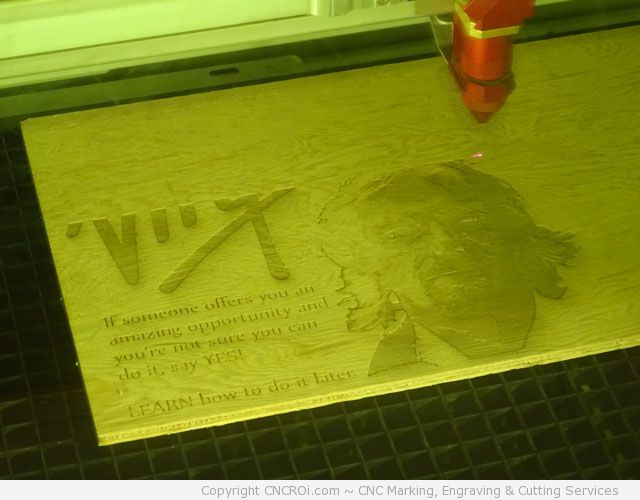

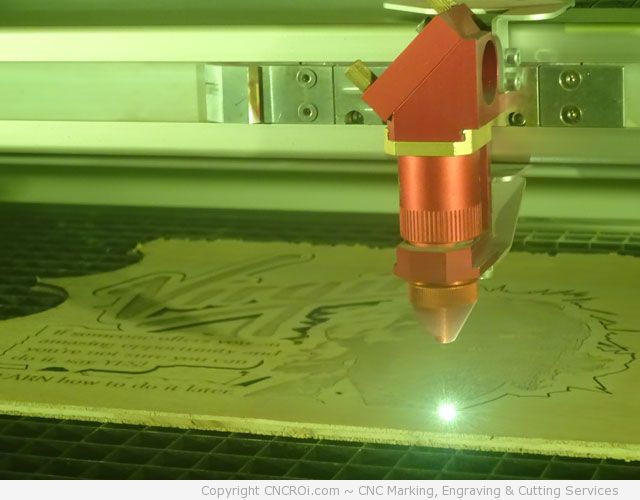

The first thing we need to do is engrave Sir Richard Branson onto the plywood, going down to up helps reduce the amount of cleanup required when this plaque is done as the material is whisked away into the extraction system using the gas kit our Austrian CNC laser has.

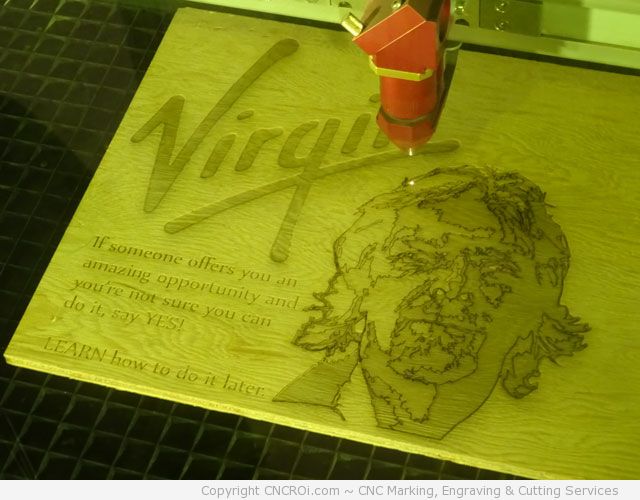

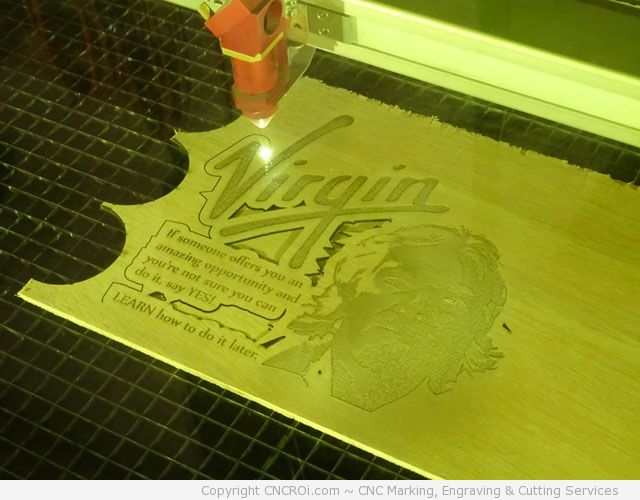

After engraving the entire board, it’s time to do another pass, this time, adding details by “cutting” into the material but not all the way through, these lines of definition double the production time (and cost) of the entire project but it’s well worth it as you’ll see lower down on this blog post.

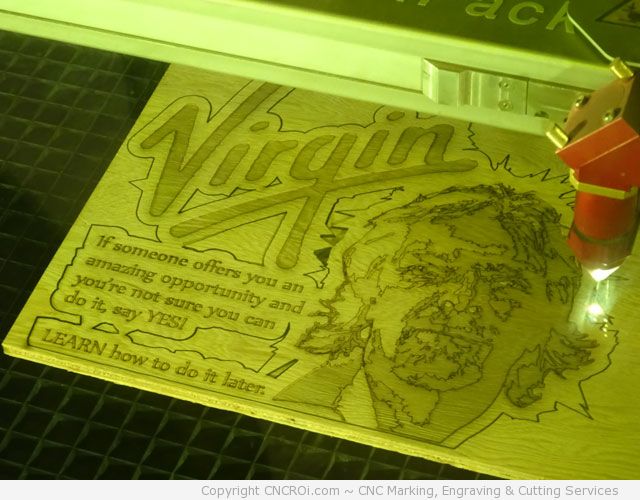

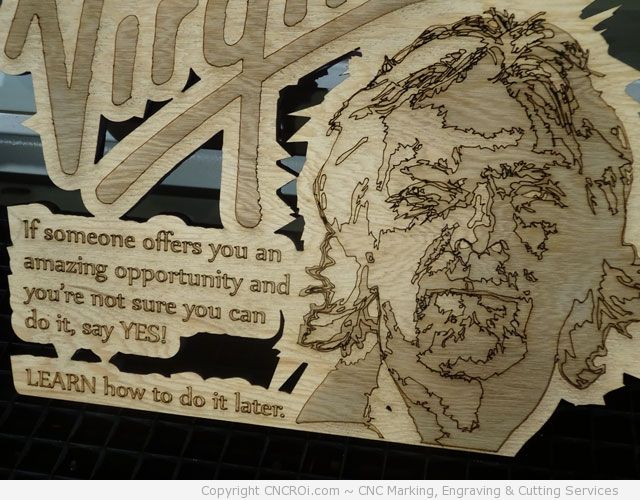

Looking at the above picture, you see the value of outlining things in a second pass, just in the lettering alone, there is far more clarity than leaving the board empty. By the way, depending on the material, this may or may not be necessary – it depends on your production requirement and final application. Budget will dictate the approach taken.

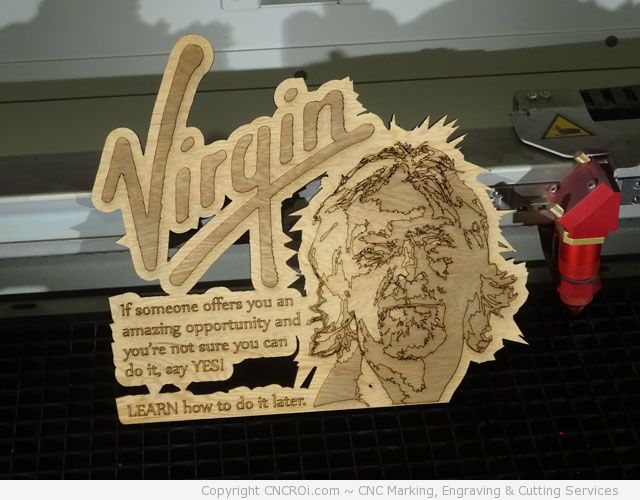

After adding definition to the plaque, it’s time to cut Sir Richard Branson out of the plywood board for the whole world to see!

That looks pretty good, I’d probably do a few more refinements here and there but overall, pretty happy with it. This isn’t high quality plywood or wood for that matter, just scraps from the CNCROi.com shop. The reason why we use scrap to showcase most of the work on this blog is simple, it’s easily available and if we can make cool stuff on scrap, imagine what we can do on the good stuff!

Watch the video of the above being made… this can be done across a variety of materials by the way from stainless steel to acrylic, paper to formica. You tell CNCROi.com what you want and we will engrave, cut and build it! That’s what a custom CNC shop does, transform your dreams into reality!

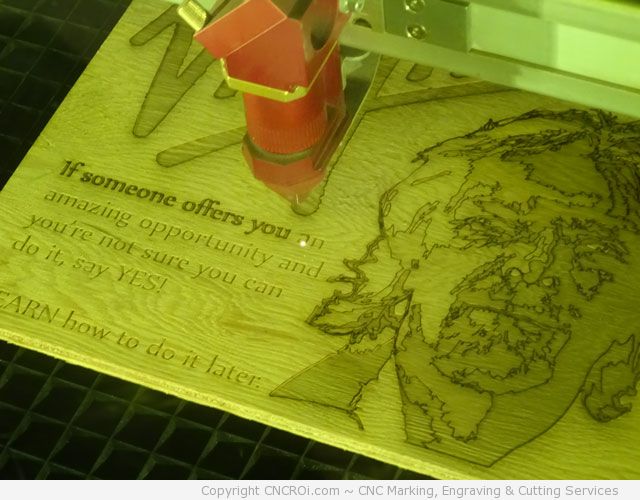

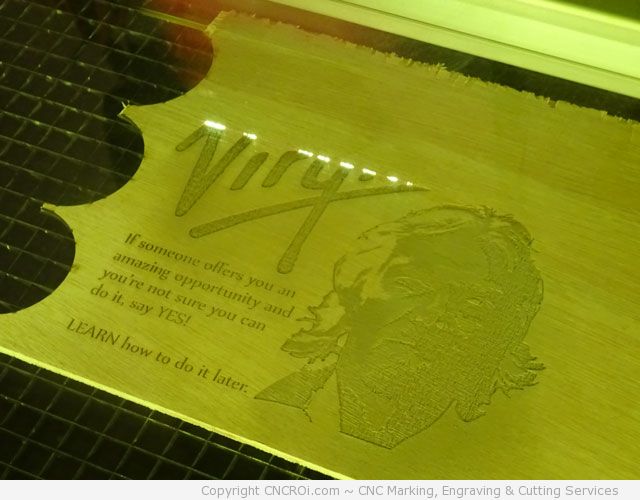

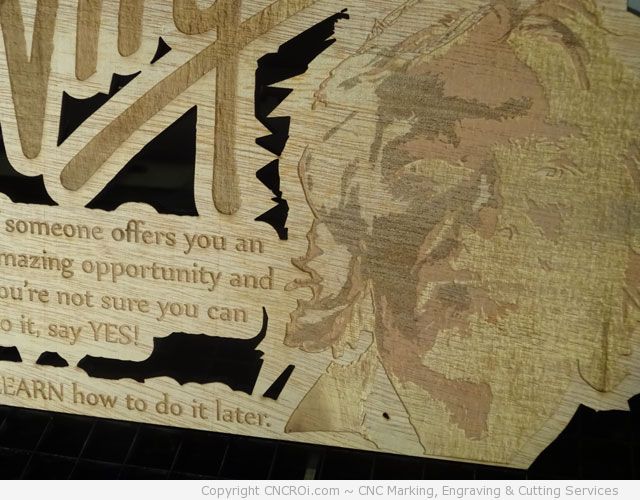

Now for the learning part, what if we did this project without doing another pass to add definition? Let’s find out on another piece of scrap plywood. This board was a bit smaller than the previous one so I had to scale everything down slightly.

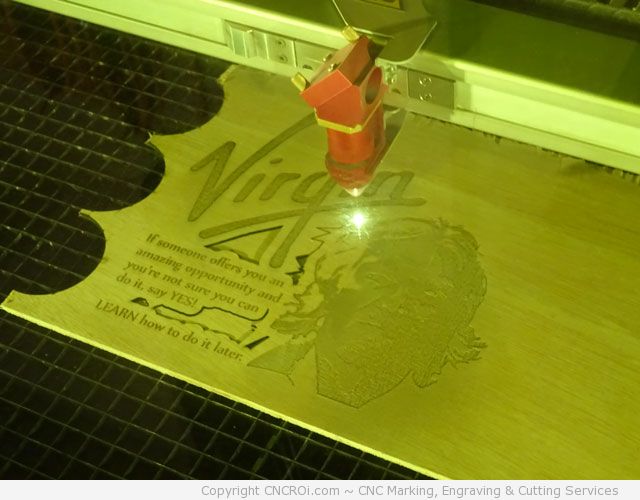

Just like the last board we CNC laser cut and engraved Sir Richard Branson onto, we will first do a pass involving only engraving.

Looks neat to see the vaporizing of the wood and under that, a face and words emerging!

The dust you see all over the board comes off easily so it isn’t an issue on this plywood which is why it wasn’t masked. Some woods we can get away with doing this, others, with high resin content, we cannot.

Remember, we aren’t doing a secondary pass to add details onto this board, just straight engrave and cut. I hope you already see the difference in quality!

The two designs are identical by the way, just this one is a bit smaller to fit the board.

Cutting plywood is always fun, after that, we push it through an air compressor curtain and it comes out all clean!

Watch the video of this Sir Richard Branson engraving and cutting!

Time to compare the two results. On the left would cost twice as much to produce as the one on the right, the quality is dramatic as is the impact. On the right, it looks faded while on the left, the logo, words and face of Sir Richard Branson pop-out!

If I were to make additional changes, I’d have a few less lines going through Sir Richard Branson face, I went a bit overboard on details.

On the other board without the secondary pass, Sir Richard Branson’s face just doesn’t come out very well at all. I think having a middle ground on these two boards would be ideal.

Looking for an awesome company that can design, cut and build using a variety of materials, processes and equipment? You’ve found CNCROi.com – contact us today!