CNC Laser Engraving and Cutting Felt Fabric

CNCROi.com can engrave felt? Yep… and we can cut it along with a host of other fabrics too! When you have a contact-less production system, there is very little you can’t do given enough time, expertise and quality Austrian equipment.

We’ve done lots of blog posts here across various fabrics but it has mostly been centered towards leather. This time, we’ll do something a bit more fragile. Felt! Here is the design we will cut out.

I know, it belongs on a Roppongi advertising billboard in Tokyo but for our purposes, we’ll just put it on normal felt. We are doing two contrasting colors as well, this is a great case study to show the precision of our Austrian industrial wide format CNC laser too because, we should be able to put the cut-out from one color into the other colored felt and it should fit PERFECTLY!

This felt was acquired from the dollar store, just to show you how you really don’t need to spent a fortune on materials to prove a point nor need to invest a lot of money to make something awesome… we deal with high-end materials all day here at CNCROi.com HQ, it’s nice to play with stuff that’s “cheap” for a change.

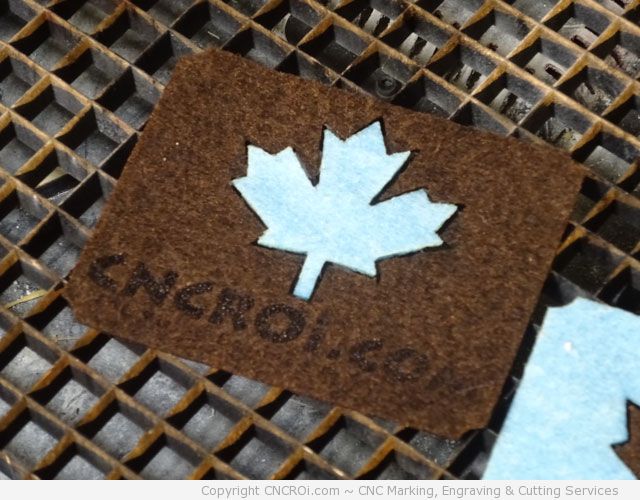

The engraving process is calibrated to remove roughly half of the felt depth, this can be augmented (which we did during material testing) to either go all the way through or do very little. It’s all in the settings!

Once the engraving is done, it’s time to cut out our maple leaf. CNCROi.com is based in Canada but services the world!

The results look pretty good, the smaller writing is a bit harder to work-out due to the lack of font thickness and the angle of the camera but if you look closely, you should be able to work it out just as well as the bigger CNCROi.com lettering.

The fabric color makes a big difference as well, as you can see, there is no burning or smoke damage on the up-side of the felt. We can also apply double sided tape BEFORE production if you wish, this would allow the resultant felt pieces to be stuck onto anything.

The two pieces are cut identically, this could have been just as easily a thousand pieces and the results would have been the exact same.

Looking at it closer, you can see how consistent the cutting and engraving is. You wouldn’t get this from a smaller or cheaper machine, the price of CNC lasers is dictated by the laser tube more than anything else. More consistent power bands cost dramatically more but you can see the difference it produces.

As you can see, the pieces are completely interchangeable, for all your fashion needs, you want something consistent, you’ve now found a way to achieve this efficiently… contact CNCROi.com!

Looking at it closer, less than a mm of material was vaporized during the CNC laser cutting process of the maple leaf. This is the same regardless of fabric, even for thicker fabric, where more power is required, there may be a bit more vaporizing happening simply due to the higher power requirements needed to get through the material.

Think this looks awesome? It looks even better with a slightly stronger material like leather or denim! Contact CNCROi.com for all your fashion cutting needs, we are able to handle everything from pattern cutting (each can be different, makes no difference to our CNC laser) to mass production accessories and jewelry.