CNC Laser Engraving & Paint Filling Custom Corian Signage

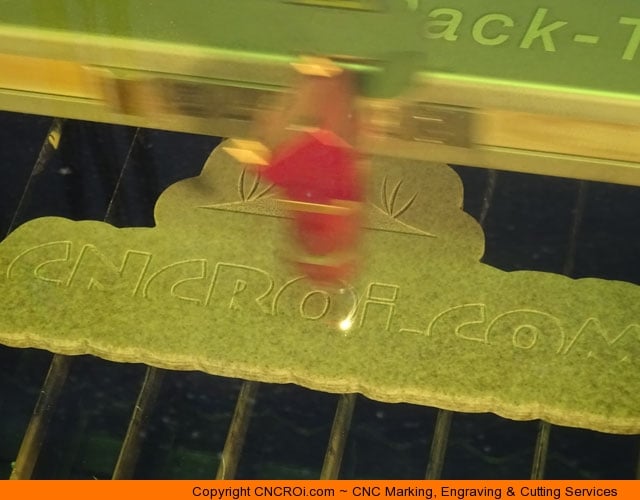

Custom Corian signage is something CNCROi.com does a lot of, among many other neat things, in the previous blog post (CNC Router V-Carving Custom Corian Signage) demonstrated us making a sign using our CNC router, in this blog post, the concentration will be on doing essentially the same thing but using our Austrian CNC laser instead.

To make optimal use of this sample that I show clients, I decided to mirror the image that was V-carved on the other side of this piece of Corian so the same design is on both sides to help illustrate to customers the various options that they have available to them when it comes to custom Corian signage, wall plaques and anything else made out of Corian.

Keep in mind that although this post is focused on Corian, the same essentially holds true with wood, stone and a host of other materials we use here on a regular basis at CNCROi.com for our customer’s applications.

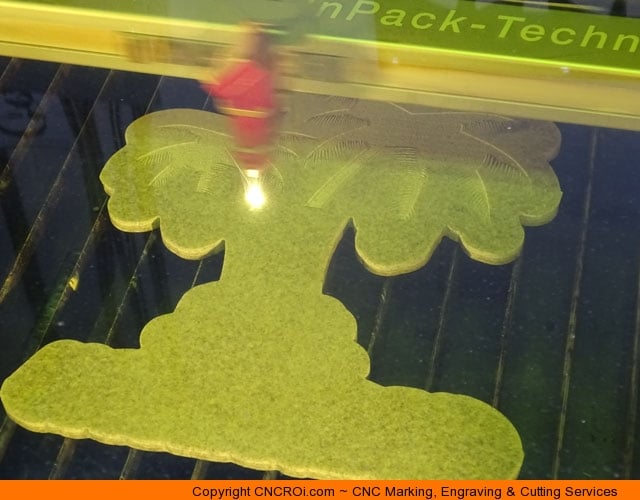

I strongly encourage you to review the video (link at the top) of the first part of this two-part blog post so that you understand how this cool shape came into being. It will help you make more sense of what’s going on in this blog post regarding this CNC laser engraved Corian.

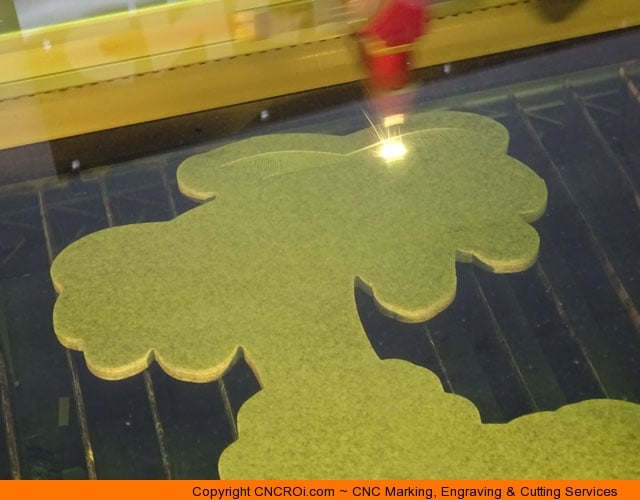

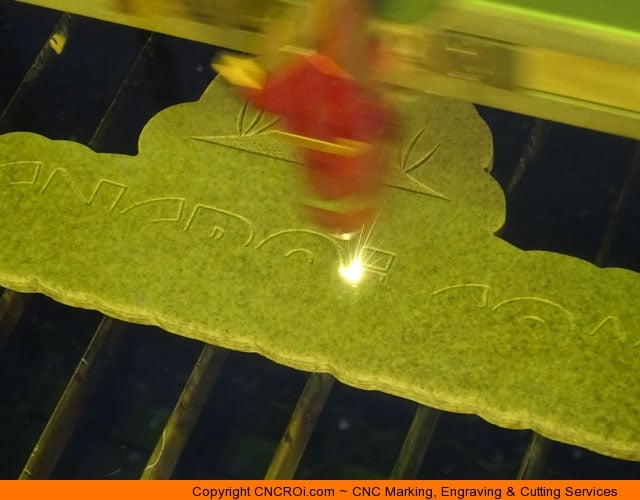

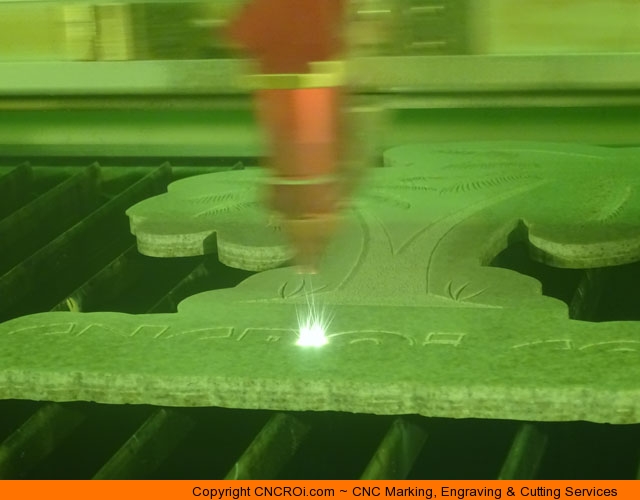

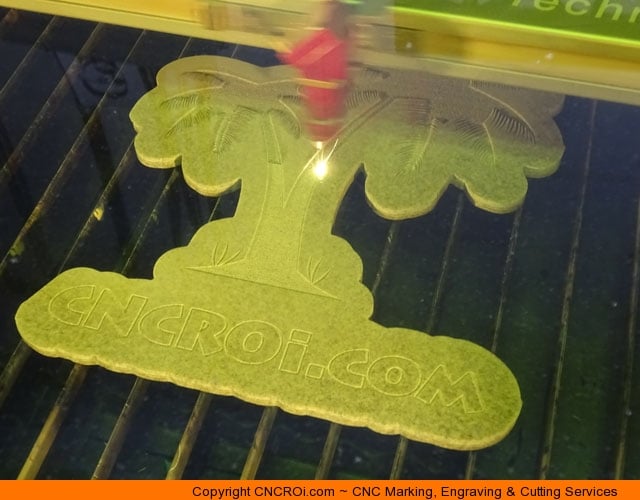

There is quite a bit of dust produced by the CNC laser engraving into this Corian signage, the difference is the chip size, while with the CNC router, you can physically hold the chips, with the laser, it’s a very fine Corian dust that’s produced.

Depending on the design, CNC laser engraving Corian signage may or may not be faster than CNC routing Corian signage, there are a lot of optimal settings across both machines to produce a final physical design that have to be taken in account. Luckily, you don’t really need to know all this as we can help you produce optimal results for Corian signage.

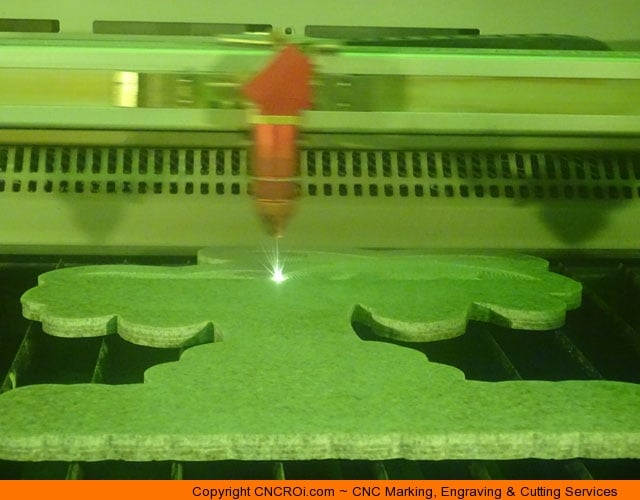

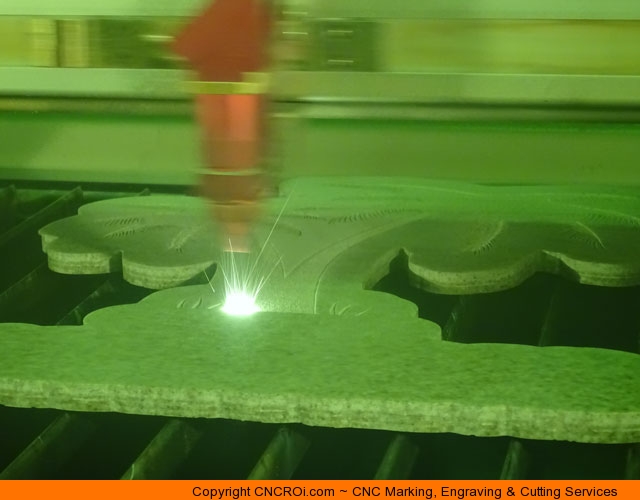

As you can see, there are sparks produced when our 110W wide format Austrian CNC laser engraves into this material. Generally, we engrave about 1 mm per pass, we can do more, but the results start to be inconsistent regarding depth qualities. Why? The laser is always the same, the densities of the various “things” that make-up Corian start to be more pronounced.

Slow and steady wins the race when it comes to custom CNC Corian signage, regardless of the technologies we use. For this project, I wanted about 2 mm of depth (less than 1/8th) so that’s why you see the laser going over the same place twice in the video and why it seems like we are repeating laser passes in these custom Corian signage photographs.

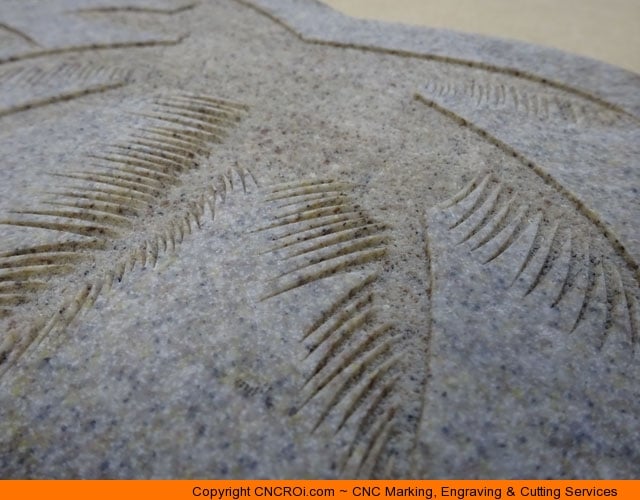

The advantage to using a CNC laser for custom Corian signage (and other things) is the amount of surface exposed by the process itself, it’s wonderful for paint adhesion, where the CNC router produces a nice smooth finish, the CNC laser produces a Corian surface similar to sand paper.

The other advantage to the CNC laser engraving Corian over CNC routing it are that no hold down is required. Watch the other video in the previous blog post and you’ll see screws holding down this piece of Corian and essential NOTHING in this one. There is no physical contact between the laser and the Corian other than the bed.

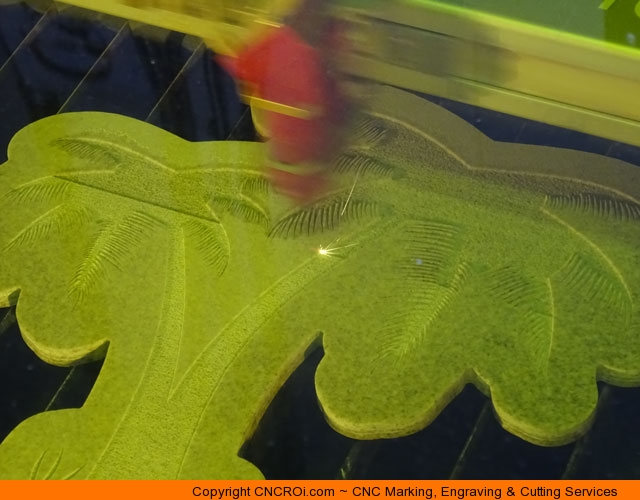

Fine details achieved in CNC lasering Corian are also apparent rather quickly, while with the CNC router you are limited by bit size, the smaller the bit, the more prone it is to breaking and the slower the engraving happens, with a CNC laser, you are limited by the width of a beam of light. Not much of a limit!

Regardless of what technology we use here at CNCROi.com for custom Corian signage, one thing holds true. Precision. We have top of the line CNC machines for their class, they are accurate within nanometers (not a typo) which means we can do neat things like going over a material again and again and still be dead-on. Look at the Corian we are engraving with the laser, the laser is passing over the SAME SPOT… time after time.

The challenge with custom Corian signage is actually narrowing down exactly what the customer wants, just like wood and other materials, there are endless combinations and options. Corian itself is available in hundreds of different colors and shades! Throw-in that we can use CNC routers or lasers to produce effects on the Corian and then endless paint filling options, and the Corian options list gets rather large quickly!

Luckily, we have lots of experience with Corian, we will produce an optimal results for your design! Some customers know exactly what they want down to the Pantone shade while others give us an open slate to work from. Both are fine!

As you can see, “raw” CNC laser engraved Corian doesn’t produce the best results regarding contrast, Corian is the same “throughout” the material so contrast must be created in other ways. Either paint filling the Corian or painting the Corian itself then engraving through the paint and Corian and/or combination of the two.

Looking at the CNC laser engraved Corian sign at another angle, after cleaning it, the contrast isn’t as bad but still not the best. If you wanted a custom Corian sign like this as/is, having it in a water fountain looks awesome but “dry”, there just isn’t much contrast by its nature.

Looking at it close-up, you can see the sand paper texture the CNC laser produces when custom engraving the Corian sign. It is consistent, it’s 90 degrees straight in and incredibly precise, just look at the “i” spacing, there is less than a third of a mm there and it’s still standing strong! Corian is awesome!

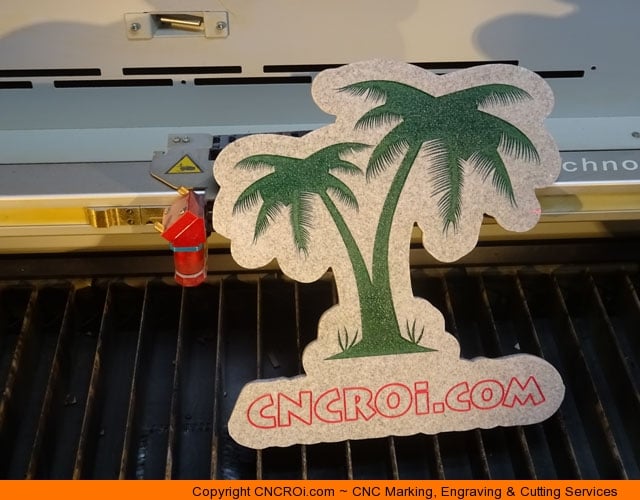

Look at the detail achieved in this custom Corian sign on the foliage of the palm tree, again, incredibly precise and clear!

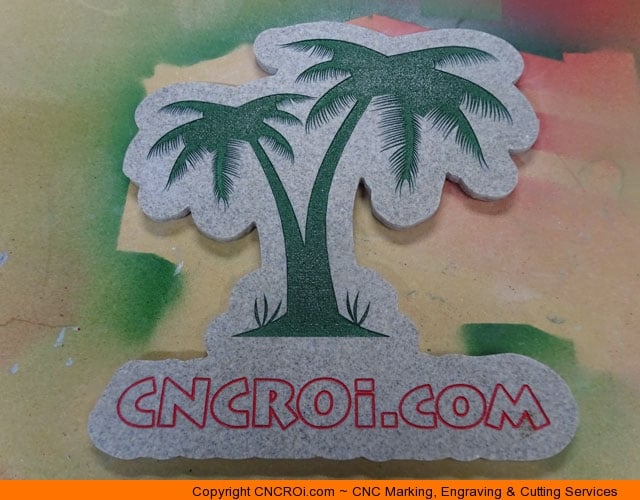

Next step was paint filling the custom laser engraved Corian sign. I decided on a gray metal looking color, although there are many methods to doing this, for this specific sign, I decided on painting essentially the whole thing and then sanding the Corian surface (removing the paint in the process).

The results look pretty good but the contrast sucks! Well, that isn’t an issue, the surface is still incredibly rough so this Corian can be paint filled AGAIN! This time, a bit more contrasting material will be used on the Corian sign!

This time, another paint filling process was used, instead of a paint brush it was sprayed on. This custom piece of Corian signage will now be easily read and will stand-out!

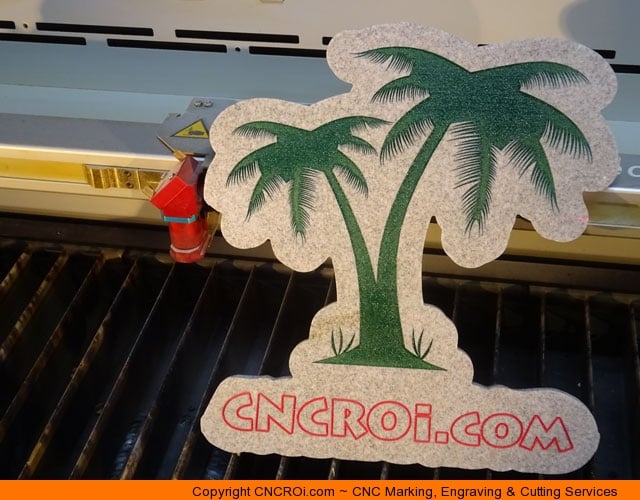

After allowing the custom Corian sign to dry, the surface was then painted and the results look spectacular! Of course, we seal this after then a bit more sanding.

And that’s how CNCROi.com makes custom Corian signage, start to finish! Custom contoured using our CNC router and then profiled or using our CNC laser, engraved (we can also engrave using our CNC router by the way).

Looking at this from another angle, you can see the sine that’s achieved but regardless, this custom Corian sign looks fantastic!

Have some custom Corian requirements from cutting boards through signage? CNCROi.com can do it for you! Contact us today!