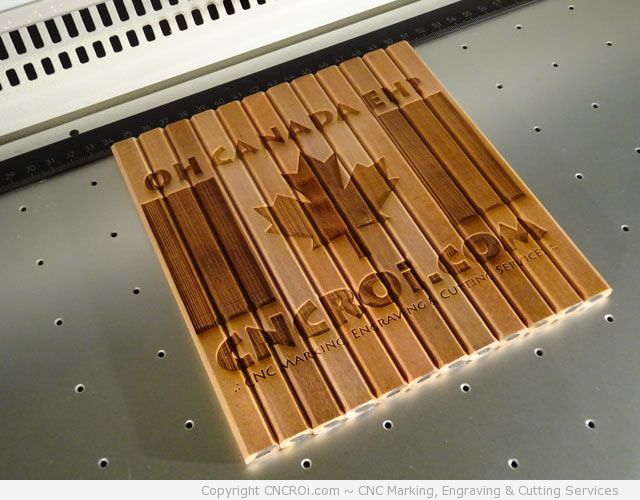

CNC Laser Engraving Carpenter’s Pencils

I lined-up some carpenter’s pencils in our Trotec Speedy 400 flexx on our solid aluminium table. We use these wooden carpenter’s pencils for a wide variety of tasks across many different materials from Corian through to Formica and even wood.

The process for making these was rather straight forward, the first step was lining them up on the bed, as the Trotec Laser never touches the source material, there was no need to hold them down like I would have to if we used our ShopBot CNC router though I did put the compressor down a few notches.

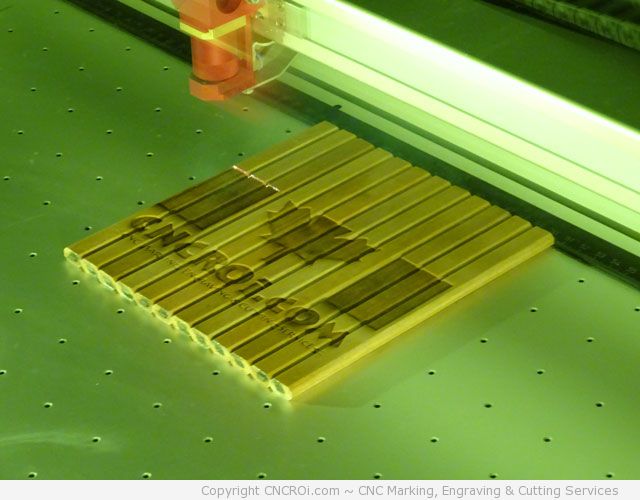

There is a lot of power in our equipment and sometimes dialing things down produces a better result than cranking things right up. Our industrial laser has a gas kit which would quickly blow these pencils off the bed and our extraction may also do the same. This is important so that our results are clean as this soot can build-up.

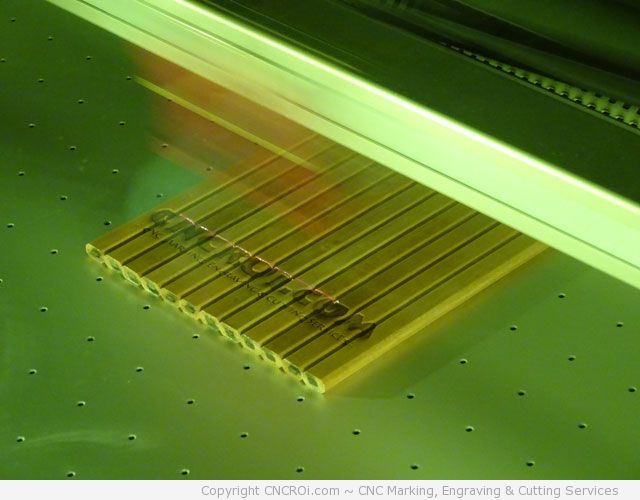

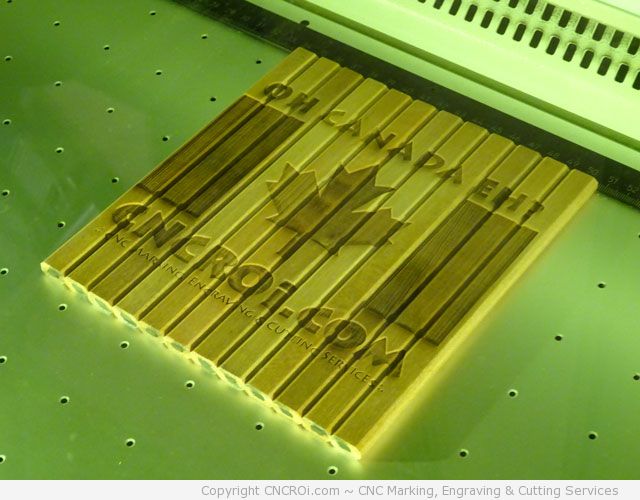

Once the pencils were lined-up, the material testing was done (backside of the last pencil to the right) and things were ready to roll, the laser was activated and it removed a good mm off until my finished design was engraved. You see a green tint because our Trotec Speedy 400 flexx has both a CO2 and Fiber laser source which means we can just as easily anneal stainless steel as we can remove a thin laser of paper from a sheet of paper.

Due to the nature of these pencils with ridges going up and down between them, we couldn’t mask this material so in this case, a combination of vacuum table and compressor shooting smoke away from the material ASAP after vaporizing helped drastically reduce the amount of soot that would have otherwise built-up.

If you are curious to see a video of this being done – look no further than down below!