CNC Laser Engraving & Cutting 3 mm Mirrored Acrylic

Mirrored acrylic is at the top of my “most favorite materials” list here at CNCROi.com. It cuts great with a nice flame polished edge using our Austrian Trotec Speedy 400 flexx CNC laser and the results look great regardless of where it’s placed.

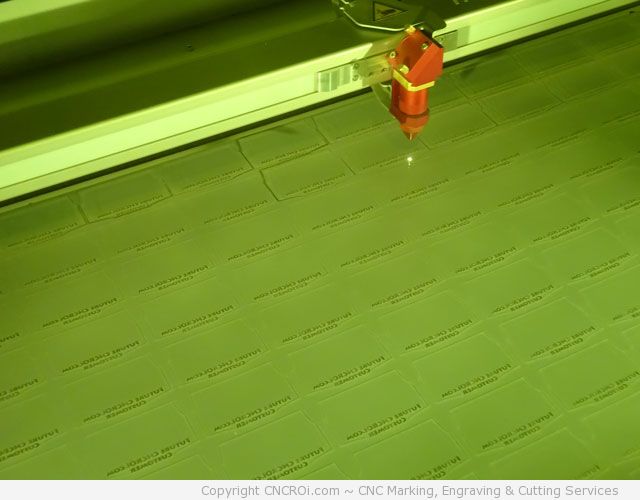

CNC laser engraving mirrored acrylic – face down.

Using our brand new acrylic cutting table, I decided to give it a test using a 1 m x 60 cm (39 x 24 inch) sheet of mirrored acrylic. This is the first step in which the text to appear on the mirrored acrylic is reversed engraved (on back not front like last time). In the previous sample, I did it mirror face-up to prove that this was possible but this time around, I wanted to do the engraving and cutting with the mirror face down.

Adding embellishments around the inside edge.

After the engraving was finished, it was time to do the embellishment that’s a cut line that goes along the inside edge but doesn’t actually go through the acrylic (on purpose).

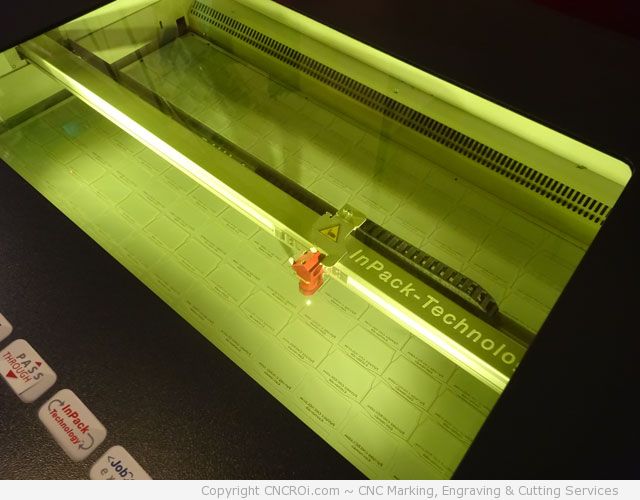

Cutting through the mirrored acrylic, all process done using our CO2 laser tube (we also have a fiber laser tube).

Next on the list was actually cutting out the small mirrors, one at a time. As I tell many customers, the life of a CNC laser is boring, in this case, spending a good period of the night engraving and cutting out over 150 mirrors.

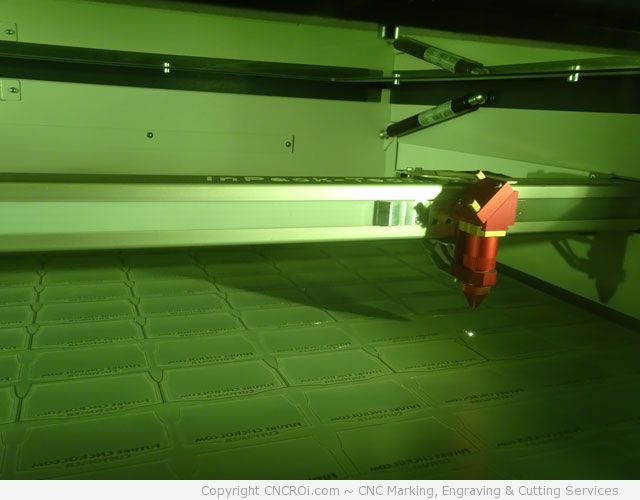

We have TONS of clearance! 22 inches worth if needed… our table can go down to suit any project size.

Having a massive bed size allows for some serious production to happen in the shop! One day, I’ll do a full sheet of this to show how massive a job we can actually do with this Austrian CNC laser marvel!

Overhead action show of our Trotec Speedy 400 flexx engraving and cutting out sample mirrors!

So far, the largest project we’ve done was over 3 meters long… being able to open the front and back to feed through a project has advantages that aren’t noticeably at first blush but it’s a feature that has won us some very good clients and continues to impress!

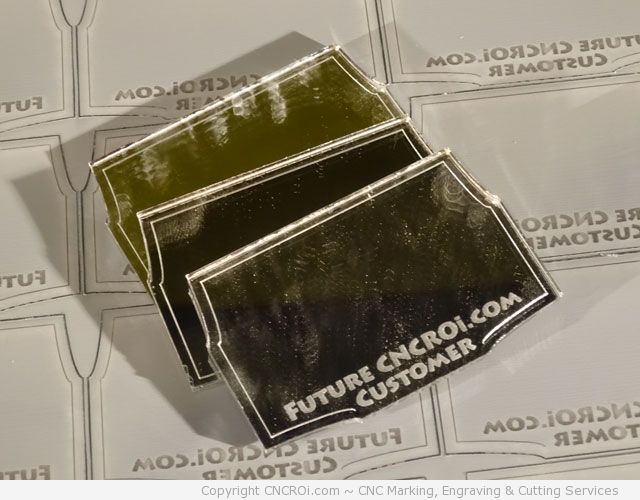

Over 150 individually engraved and cut little mirrors.

The sheet is all done, the amount of wastage has been significantly reduced with the redesign of this sample, compare it to our old design. Not only are we getting MORE samples out of this sheet but the recycle bin is filled-up even less with what’s left over!

Previous mirrored acrylic sample, our newest design produces far less waste and more per square foot of material.

The end result is looking very good – this was taken before the cleaning process, hence the dust and finger prints all over the surface.

End result… yet to be cleaned.

Here is a video showing the entire process from start to finish… it starts with the engraving “Future CNCROi.com Customer followed by the thin cut line (not going all the way through) then cutting out of each individual mirror.

CNCROi.com has large production capabilities so whether you need to mark/produce hundreds or thousands of units, we can do it quickly, efficiently and professionally regardless of material or application. Contact us and allow us the opportunity to apply our skills to your projects!