CNC Laser Marking Metal: RAW & Coated Aluminum Plate

CNCROi.com pushes through lots of stainless steel plate as well as anodized aluminium but raw aluminium plate… that’s something we are just NOW starting to get into. We showed-off our RAW brass abilities a few blog posts back so we won’t review that again here.

Metal Differences: Stainless Steel VS Anodized Aluminium VS Raw Aluminum

Stainless steel is the strongest of these three metals, the results are BLACK if annealed or brown/white depending on settings and application requirements. For instance, using our Austrian CNC Trotec Laser, we can fiber anneal black or fiber polish the metal to almost a mirror (depending on grade). We can also engrave into the metal so if you want a surface that’s rough or smooth, we can do that too.

Anodized aluminium is another animal, we just vaporize the top coating completely, revealing the aluminium underneath using our CO2 laser source or “whiten” it using our fiber laser source. We have a machine that can do both so it depends on the application at hand!

The advantage of aluminium plate is you can get it in pretty much any texture and color, sure, technically, we could apply a coating of paint over the stainless steel but it already has an awesome finish, why cover it up? Aluminium is a soft metal compared to Stainless Steel, it likes to scratch and so the coatings (powder or anodized) protects it and gives us the canvas to perform our art onto.

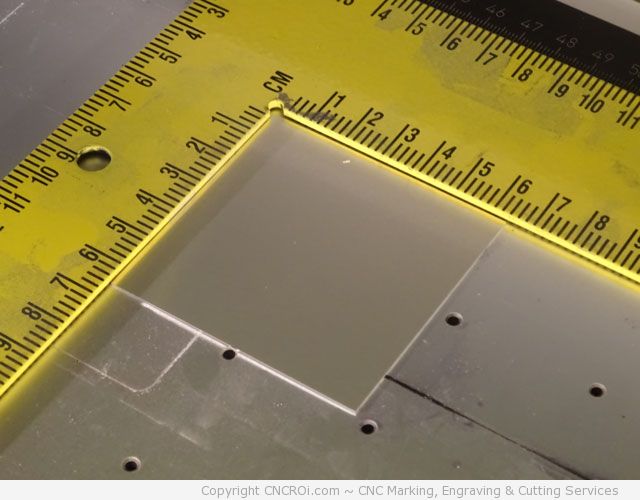

I had a client ask me to make some samples uses aluminium so we began testing away, these are some of the results we achieved with both raw 3000 series and coated aluminium. The thickness of both are 1/8th inch and yep, we can cut and bend that to any shape within the bounds of physics.

CNC Marking (Engraving) Results: RAW Aluminium

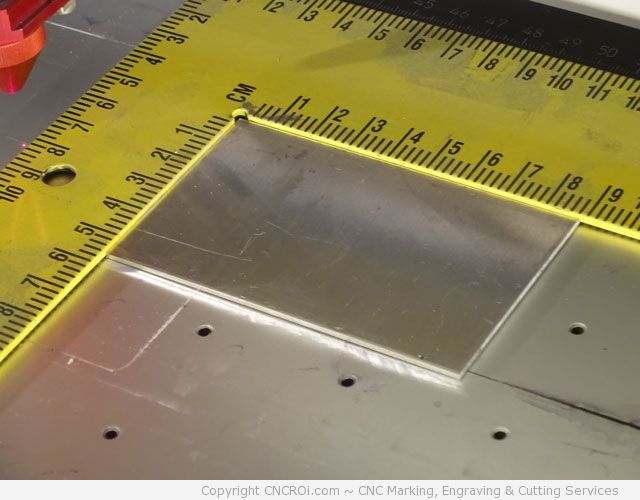

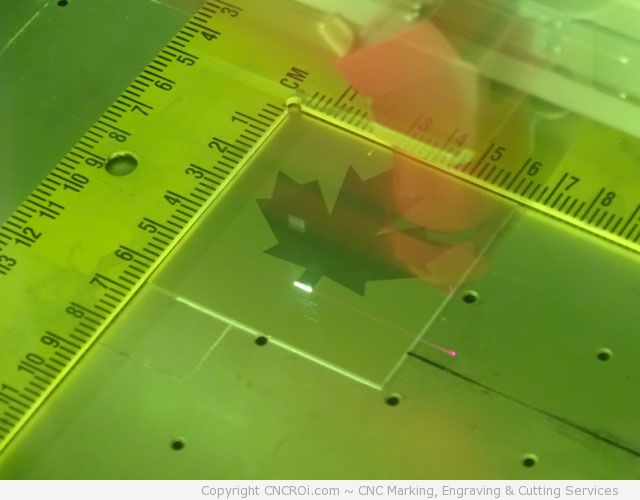

The “tough” part with aluminium is that it likes to melt and scratches so easily, it’s also wonderful for dissipating heat even when it’s highly focused like what CNCROi.com‘s CNC laser produces. We cut these plates to a smaller size using our metal guillotine which we acquired a few months back to complete a project for an aerospace client.

You can already see it’s been scratched! These are offcuts from a project we did earlier so no need to mask it, we keep these as clients sometimes need samples to show their engineering or executives a preview of what they will get with their production.

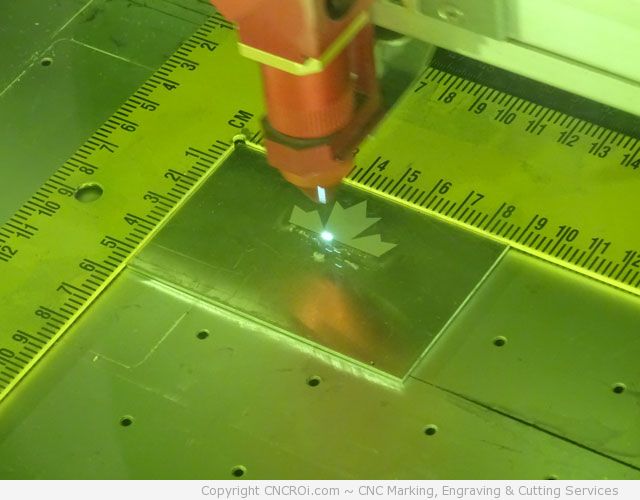

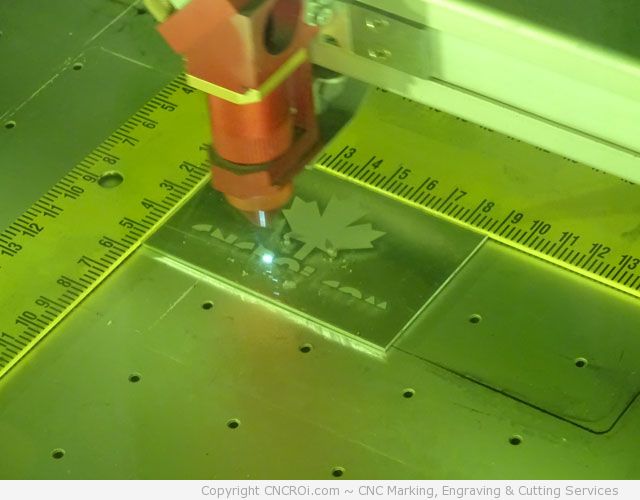

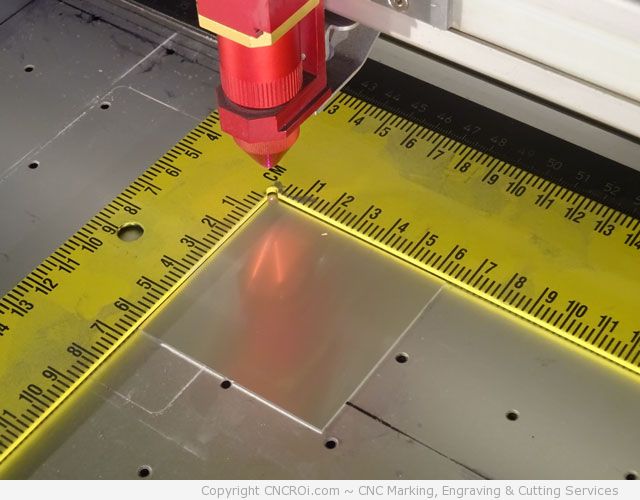

After dialing-in our settings, it was time to start engraving. Although we have a fiber lens, we used our flexx lens in this case using our fiber laser tube. This is just fiber marking and with aluminium we have A LOT more tolerance than with stainless steel so this is more than fine to do the job.

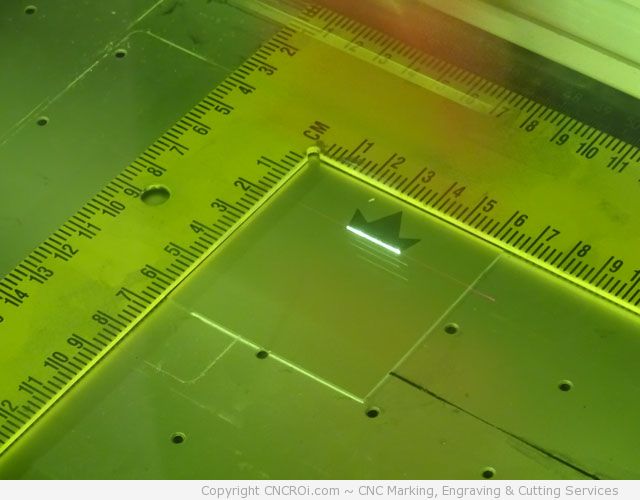

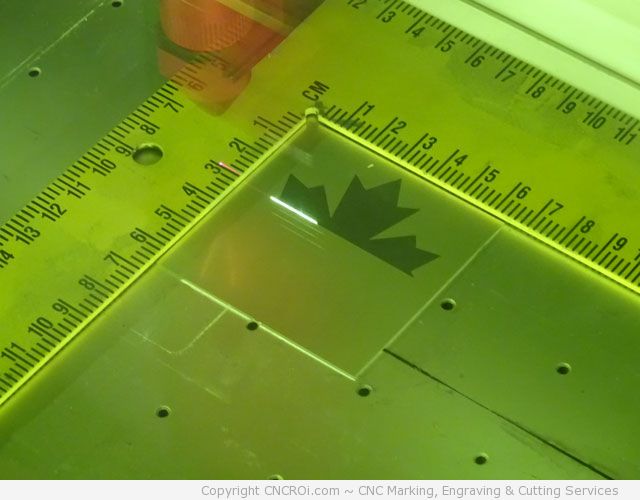

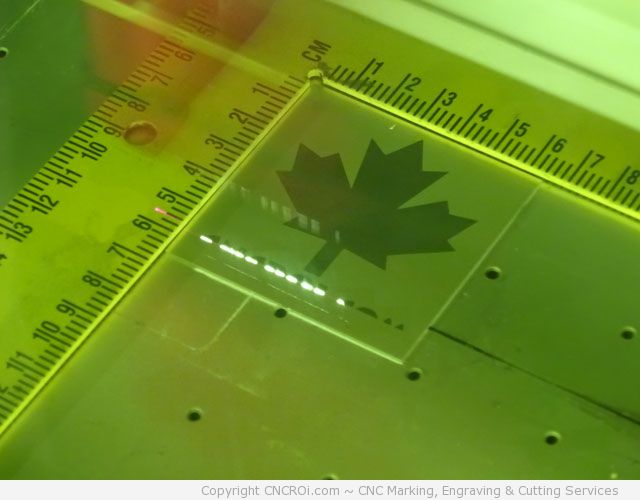

You can see our fiber marking of the aluminium plate is actually engraving into the surface slightly, the debris you see is just aluminium powder.

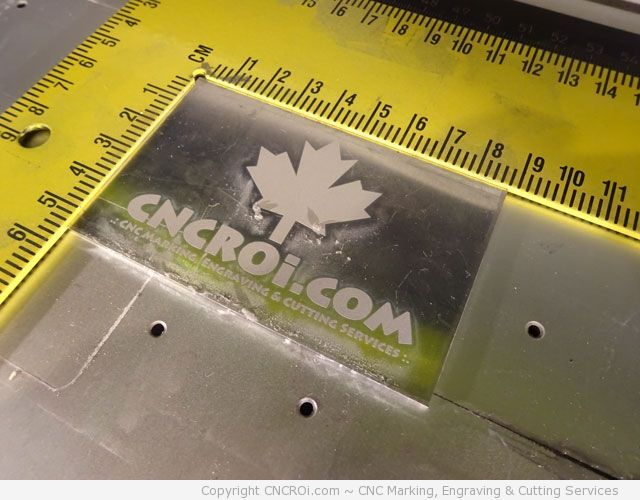

Taking accurate pictures of aluminium (or any metal) is actually quite difficult, so I took pictures with the light reflecting off the aluminium in a few different angles so you can more clearly see the results.

Straight off the bed above, cleaned below (light making it look “black”). Cleaning metal is pretty easy as nothing we use, including incredibly corrosive stuff, will damage the surface unlike “metal looking laminate” which although cheaper, is easy to scratch.

The results are clear, consistent and endlessly repeatable!

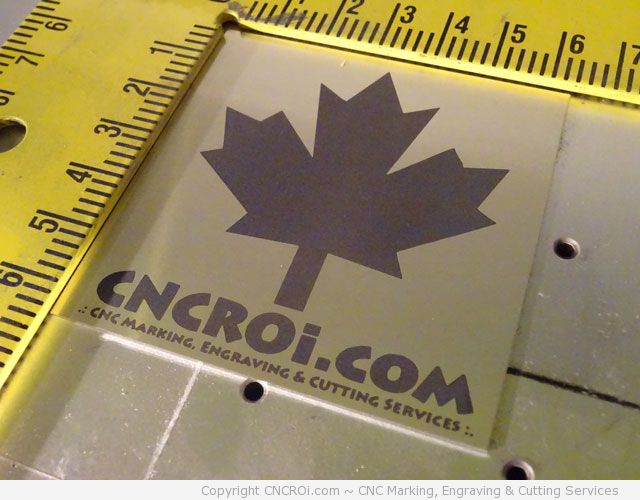

CNC Bonding Results: Coated Aluminium

CNCROi.com has put part numbers and logos on a lot of different types of aluminium, sometimes the client wants a clear “white” marking while other times, they want a dark one. In that case, we can coat the aluminium and produce a result that achieves that… yep, you can have BLACK on aluminium too though it requires a bit more work.

The advantage of creating a “black” marking on aluminium over stainless steel is that the resultant project weighs a lot less and is non-magnetic… think aerospace and military applications mostly where anodizing or powder coating isn’t required or needed but a highly visible marking is.

My CNCROi.com suitcase keeps getting heavier and bigger so I’m starting to make my “show and tell” samples smaller as a result, I got to squish a host of laminates, steels, woods, plastics and other stuff.

In this case, we used our CO2 laser source instead of fiber – unlike annealing stainless steel where its straight fiber heat treating the metal, in this case we are using a bonding agent onto the aluminium to achieve the blackness.

Unlike stainless steel, this stuff produces no sparks so it’s like looking at grass grow.

The resolution you get on coated VS raw is pretty much the same, technically the RAW will give you more resolution but you really have to look at it extremely closely to notice any differences.

The cleanup of these parts is easily done, and looking at it from different angles gives you a better idea of the results we can achieve.

Take a look at the video of both being produced so you can see the difference, we had some focus issues with the coated metal, the light is so intense it screws-up the automatic focus on our camcorder but still worth a watch.

CNC Fiber Engraving RAW Aluminium Plate

CNC CO2 Bonding Coated Aluminium Plate

Looking for a company with experience marking any metal out there regardless of the application? Contact CNCROi.com right now!