CNC Router Services: Design through Build

Our CNC router services are as vital as things we do using our other equipment, including our laser, sand blaster and so today, we’ll focus on what can be done specifically using our industrial CNC router.

If you aren’t familiar with the differences and similarities between different type of CNC machines, watch this video to get you warmed-up.

Now that you are expert in all things CNC, let’s dive a little deeper as to why we use one machine over another or in conjunction with when it comes to CNCROi.com‘s CNC router services.

.

CNC Router Services: Thick Material

Our industrial Austrian CNC laser is amazing, the precision we get out of that is essentially the same as our industrial American CNC router, there really isn’t any difference on that front.

They are just very different machines optimized for specific tasks, where our CNC laser uses a highly focused beam of energy to cut, engrave or etch, our CNC router uses a bit or diamond tip.

There are some materials our laser is faster than our router in (if you including finishing requirements) and there are also some materials where the router blows the laser away, generally this is related to material thickness.

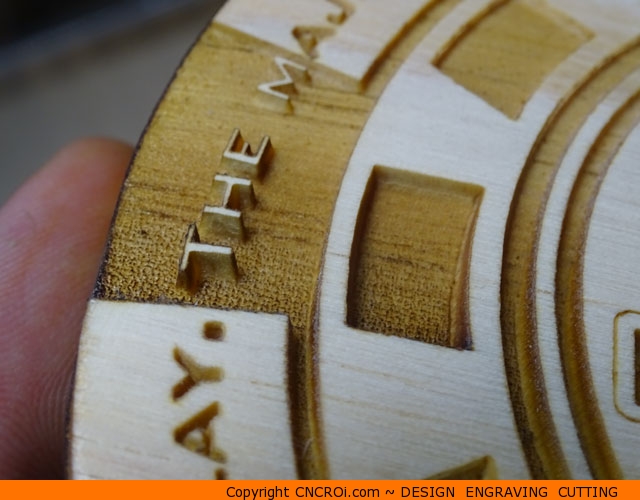

A great case study to outline this is the above sign, this is very thick cedar, I could technically cut it out like this using our laser but it would take dramatically longer to do and the end results wouldn’t be as nice due to burning.

Generally, the thicker the material, the more in the direction of our CNC router services that I lean while the thinner the material, the direction is towards our CNC laser instead.

In this case, I used the power of both machines to produce the optimal result, CNCROi.com‘s CNC router to create the profile and bevel, our CNC laser to engrave SHARP letters into the cedar plank.

It was then paint filled just to add a lot more contrast, so rather than the dark brown the CNC laser produces, using black enamel paint really made the name pop far more.

.

CNC Router Services: Hard Material

CNC routers excel in materials that our hard, the reason being is that CNC lasers work off material density, the denser a material is, the longer it takes to cut through it or engrave in any given depth.

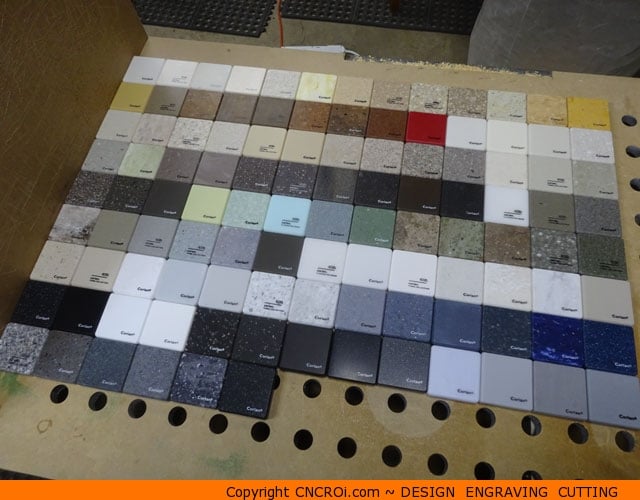

While the “problem” with the above sign was the material thickness of the cedar, an identical application with house number signs also used our CNC router services but for a different reason. Corian.

Corian is incredibly hard compressed acrylic, we can technically cut through it using our industrial CNC laser but yet again, our CNC router cuts through it like butter.

So, while the above example using the thick cedar, the issue was the material thickness, with the Corian, it’s the material hardness and this is where having the power of both machines available to use on-demand is incredibly useful for a wide variety of applications.

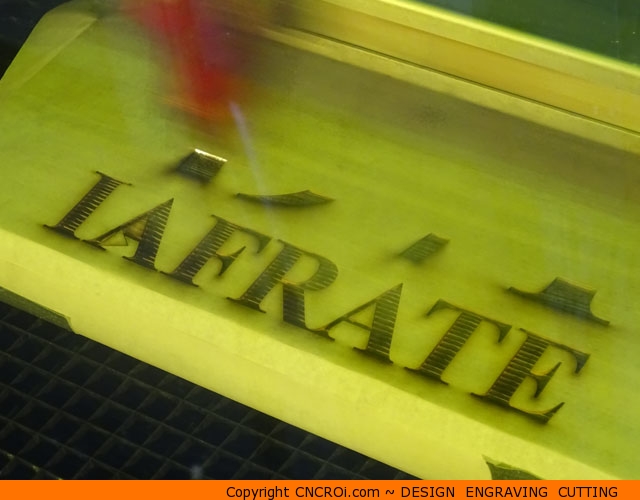

While CNCROi.com‘s American CNC router cut out completely precise and accurate profiles with bevels of the signs, our Austrian CNC laser then precisely engraved into the resultant pieces, which was then paint filled.

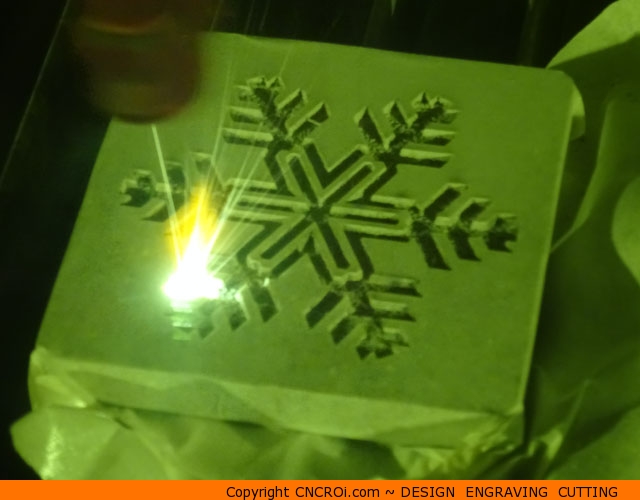

Here’s another example of what can be made with Corian using both our industrial CNC router and laser + paint filling expertise!

I want you to look closely at the inner angles of these engraving pictures and video, the reason we use our CNC laser to produce these engravings that are paint filled is BECAUSE our laser uses a beam of light.

Specifically, a beam of light is infinitely thinner than even the thinnest CNC router bit. A bit works by spinning, producing a “rounded” result, while lasers don’t have this issue.

As a result, we can produce sharp inner corners EASILY with our laser, especially nice with paint filling, that just isn’t possible using a CNC router.

.

CNC Router Services: Fragile Material

Looking at the construction of our QUALITY and TOP OF THE LINE, notice something about the gantry.

Where with a CNC router, the focus is on having a gantry that WILL NOT BEND, with a CNC laser, the gantry is focused on being as light weight as possible. Why?

CNC lasers are focused on doing things fast and precise without ever touching the material. CNC lasers are contact free CNCs while CNC routers are focused on ripping, pushing and pulling though material using a high speed industrial spindle bit.

Both our machines are steel framed ON PURPOSE! While you may think that machine rigidity isn’t important with a CNC laser, it actually is vital, you don’t want the machine to sway back and forth while engraving something at 3 meters a second!

While with CNC routers, machine rigidity is vital to make sure that both the part and the gantry remain locked in place regardless of the forces applied.

So, if the application calls for making paper stencils, a spinning bit or knife could be used but a no-contact method is best.

That’s not to say that both machines are “safe” or that one is safer to operate than the other, a common misconception.

A CNC router could easily break my arm and munch on my fingers without it affecting the precision of the work piece while our CNC laser would instantly blind me and give me deep burns.

This is why we bought INDUSTRIAL AMERICAN and AUSTRIAN equipment, it’s safe as long as you aren’t stupid with them and there is a lot of thought put into their safe operation. They cost more and are worth every penny!

But you have to keep things in perspective, I get nervous when cutting something with a kitchen knife but never once was concerned about working with our CNC equipment. Why? Because a knife is unpredictable while a CNC will do exactly what you tell it.

.

CNC Router Services: Inconsistent Density Material

CNC routers are amazing with inconsistent materials with regards to their density, while the effects of a CNC laser are based on the interaction of the laser beam with the substrate, a CNC router effects are based solely on the bit spinning through it.

Put another way, I use different power and speed settings on basswood engraving than I do on oak engraving, while with a router, it’s just speed that’s modified as the bit will always eat what’s in-front of it at the same depth and width.

Compare the two dinosaurs above, regarding surface quality. You will notice little burrs on the one cut with our CNC router while none exist on our CNC laser version.

That’s because the spinning bit in our CNC router is pushing and pulling through the wood fibers, while the CNC laser just “burns” it.

The same holds true regardless of what’s engraved or cut using each CNC machine type, in this case, a CNC laser cut CH-47 Chinook Helicopter above and similar model below using our CNC router services.

Now, what happens if the plywood in both of these 3D models (that I designed btw) was made-up of both hard and soft fibers, like tree rings. What would happen?

Well, with the CNC router, I’d just cut a little slower so I don’t break a bit during the cutting process on the higher density areas while with our laser, I’d have to “overpower” the less dense areas to make sure the laser got through the denser parts, otherwise, it wouldn’t cut all the way through the entire plywood to produce the finished flat-packed model kit!

For some applications, you actually WANT to display variances in material density, take for instance custom wooden business cards, signage and just about anything else made that you want to add a little extra free details to.

If I were to do this with a CNC router, the bottoms would be flat instead of extensions of the beautiful growth rings seen in the cedar shingle.

s

CNC Router Services: Beveling Material

A bevel is the edge detail we sometimes add to projects, it may be straight, rounded, or any combination of ornamental looks.

For instance, here’s a slight rounded edge from our Custom Corian Color Options blog post.

Here’s an offset look from our custom house number blog post, both straight 90 degrees from the surface.

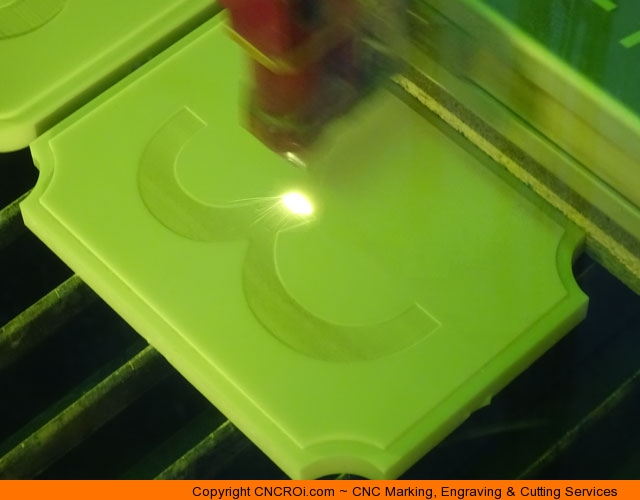

And here’s an extreme example using a V-carving bit that CNCROi.com used for a sign to show just how awesome we can work with Corian when it comes to our CNC router services. I believe this was a 60 degree angled bit.

Although this can technically accomplished using our CNC laser as well, the consistency is far better using our CNC router as any material density variances are cut out of the results equation.

What makes a bevel beautiful on a wall plaque or custom furniture is the consistency, create a bevel that’s half there and half not, and you’ll see something rather ugly.

CNC Router Services: Carving Material

Not all applications look good carving using a CNC router, for instance, this basswood plank looks great at all angles BECAUSE it wasn’t v-carved and paint filled, just using the power of our laser to burn into the material without any “artificial” looking paint needing to be used.

Additionally, the width of a beam of energy is far smaller than the smallest CNC router bit, which means even incredibly intricate details are possible, even smaller than the tip of a needle!

While if we tried the same thing with Corian, it just doesn’t come out with enough natural contrast, so it’s best to use the laser to engrave a consistent depth then paint fill.

As you saw in the Corian V-carving video above, what a laser can do and a router are two different things, each has their + and – when it comes to materials and applications.

If you notice all the pictures and videos thus far relating to CNCROi.com CNC router surfaces, they’ve all been FLAT.

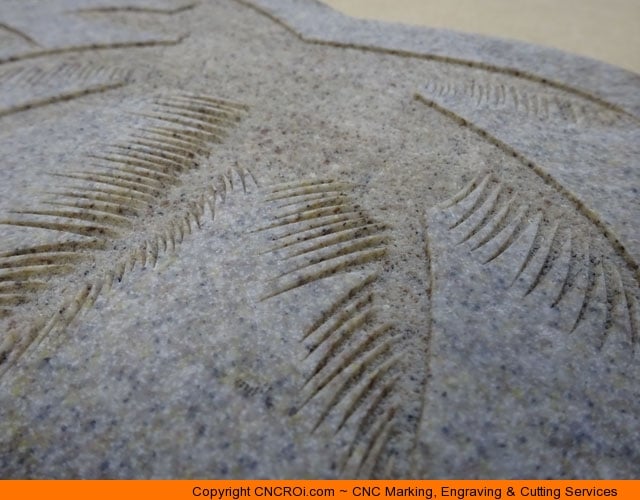

A CNC router has two way feedback, it knows EXACTLY where the bit is in X, Y and Z (height) coordinates down to a crazy number of precision. A laser only knows X and Y relative to the base.

This is an important distinction as the rock above would be just about impossible to create with a consistent depth of engraving across the surface as the surface isn’t flat but rounded here and there.

The CNC router would thus produce some engravings deeper than others as the height of the material would vary compared to the Z axis height of the bit.

It’s the same reason why this cedar shingle as you see it below just wouldn’t be possible using a CNC router with the growth areas being higher (more density) than the rest of the cedar plank.

.

CNC Router Services: Need for SPEED!

Another area of misconception when it comes to CNC routers and lasers is speed, it all depends on what you are trying to do, how you are doing it and material it’s being done ON.

Our Austrian CNC laser can move over 3 meters per second! Don’t try to follow it, it will cause you to suffer whiplash, but we certainly are not CUTTING at that speed when we produced my Eiffel Tower design!

Same thing with CNCROi.com‘s CNC router, it can move blazingly fast but rarely is that full speed used when cutting material unless I wish to break bits and cost myself frustration.

CNC lasers moving to fast do NOTHING as the energy doesn’t have a chance to affect the material under the head while the CNC routers just waste lots of time with broken bits.

For instance, you don’t get this kind of depth (precision is always the same regardless of speed on our machine btw) going full speed with our laser. Why go over something 10x to get depth when you can do it in one pass?

While with a CNC router, going too fast simply breaks bits or causes roughness on edges of material.

When you have your settings dialed right in with a sharp bit, no sanding is needed with hard materials CNC routed.

While with Corian, in this case, it’s CNC laser engraved instead of CNC routed above, going fast is fine as you are just trying to get “a little” depth for the paint to fill, going too deep doesn’t actually produce a better result for most applications.

Speed isn’t everything, it all depends on the application, sometimes going faster to save “machine time” actually costs more in “finishing time”.

.v

How do I know this stuff?

As the owner of CNCROi.com, I work with head engineers at huge multinational companies just as easily as a bridezilla getting married next week, each has their approach towards business, applications and materials.

My company doesn’t just do one thing, but a huge variety of projects, each with their own unique challenges, and this kind of knowledge is only possible with YEARS of trial and error.

I look forward to putting this ocean of knowledge for work on your specific needs, contact me and let’s get your project moving forward!