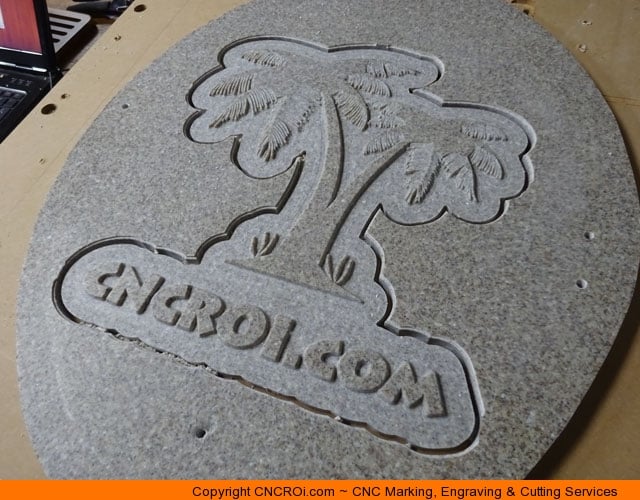

CNC Router V-Carving Custom Corian Signage

CNCROi.com does a lot of custom Corian work as much of our work is NDA, I finally found time to do something to showcase just a glimpse of our internal capabilities from custom Corian signage to wall plaques… the list goes on!

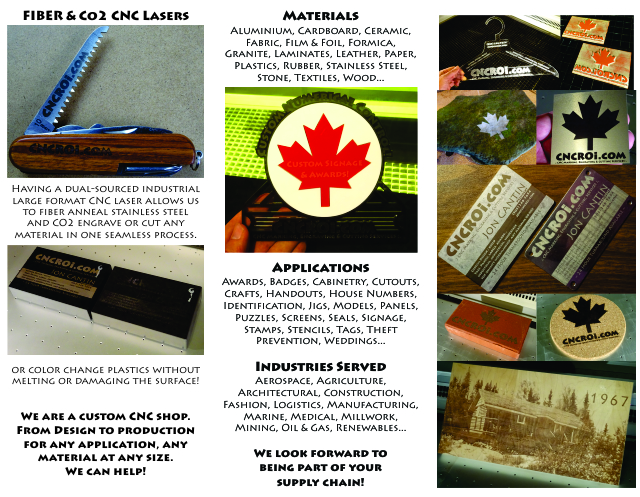

We work with an ever-growing list of materials here in the CNCROi.com shop, one of which we’ve been exploring more heavily recently with our customers is custom Corian signage. What are the advantages that we provide your business specifically relating to Corian? Let’s fine out!

Many of our projects are done on scraps that would have otherwise been thrown into a landfill, this saves you money (Corian isn’t a cheap material by any means!) and for most purposes where the scales are small, a perfect solution for everybody involved.

We can handle Corian projects of all sizes with both our CNC laser and router, which technology we use and in what combination depends on the spec work you require us to do. Whether it’s a custom Corian sign several feet long and wide or a small Corian wall plaque, we make it custom to your needs.

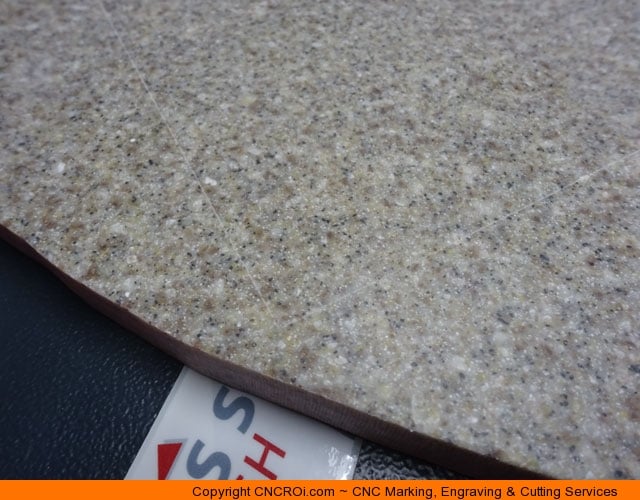

One of the advantages CNCROi.com has is that we have many technologies at our disposal, this allows us to be efficient and flexible to your custom Corian needs. For instance, to save time, we generally use our industrial CNC laser to create an outline on the Corian that will be used as placement and reference points on our CNC router. Why?

We want to use as much material as possible in our production as efficiently as possible, sure, we could make the outline in pencil (or marker) but our CNC laser is 100% precise down to the nanometer, it will make the dimensions EXACTLY PERFECT for optimal CNC router placement afterwards. Overkill? Absolutely!

That’s how much care we put into our work and our clients appreciate this insane amount of detail we put into our production, regardless of material, application or scale.

Our zero (X=0, Y=0) was dead-on using the reference points made with our Austrian CNC laser, thus screwing it into the bed and positioning left nothing to chance. Line-up the points the laser made with the homing of the router and something that would take generally a little longer to do is done perfectly the first try.

The bit we used on this custom Corian plaque which we are also V-Carving is a 1/8th straight double-flute bit. Yes, there are specialized bits for every material but we’ve found this to be the most flexible across all our material production needs. The V-Carving bit (that creates the fine details) is a 60 degree carbide. Again, nothing special but it gets the job done! Corian is a tough material on the machine and bits, by using standard technology, we keep production costs low as breaking a bit is a great way to have a negative ROI.

There are, of course, a bunch of more specialized bits we use depending on the goals our customers wish to have, such as a nice rounded profile for custom Corian cutting boards to hold down the juices while cutting or unique profiled edges but for this project, we kept things nice and simple.

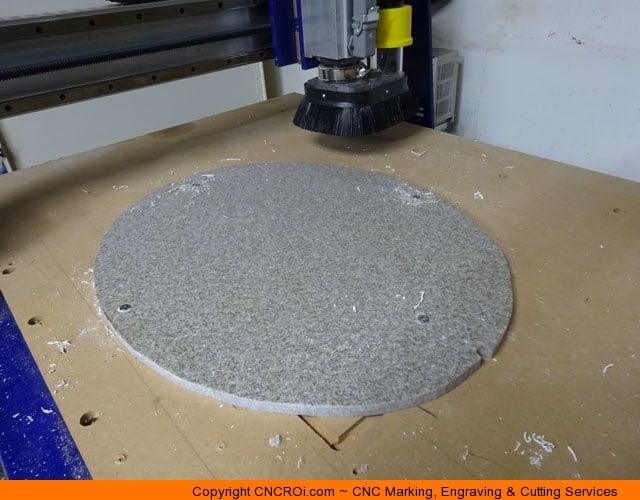

Although many of these steps are interchangeable depending on the project and application this Corian will be used in, for this project, the first step is removing the excess Corian from the surface, creating that “3D” extrusion you see on the finished custom Corian sign.

This is a tedious process, which is why using a CNC router with an industrial spindle is so great, we can make one or a thousand of these and it’s the CNC machine making it, not a person bent-over hand carving Corian.

The excess is removed only where the plaque is, there is no point in surfacing areas that aren’t part of this custom Corian plaque, that would be a waste of time and resources. The CNC router as a result just goes back and forth an endless number of times until the entire extra material is removed.

The finished results are starting to take shape, the next step is creating a 60 degree profile on all the parts, this again, is a very tedious process that is wonderful to automate. This will make all the edges change from 90 degrees to 60 degrees while adding additional details into the custom Corian to really make this stand out.

Creating a profile in custom Corian creates a lot of chips, I forgot to bring the skirt down when the bits were changed, hence you seeing it float above the Corian with few of the chips being picked-up but this has no bearing on the finished quality of this custom Corian job.

As you can see, creating a profile (there are almost endless options) in the Corian dramatically changes the look and feel of the finished product, which is why we do it!

The resolution and production capabilities of CNCROi.com across a wide variety of Corian is unmatched, we are able to secure Corian in well over 100 different colors! You want your custom Corian to be black, white or blue? NO PROBLEM!

The advantages of Corian over wood are numerous, it’s dramatically stronger and more resilient, incredibly durable both indoor and out AND can be paint filled or Corian filled (flush finish after polishing).

To help make the possibilities more straight forward, just about any application where wood is used can also be done using Corian! If you want custom furniture made out of Corian, we can do that too! You want something bent, yep, we can do that too!

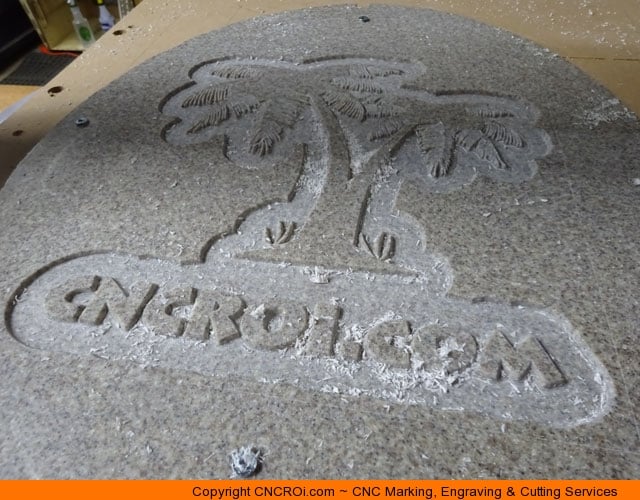

Although the profile may be hard to see on the Corian making-up our company name, if you look at the leaves found in the palm tree above, you can clearly see the work being done by our CNC router. This is where experience and passion for our work comes out the most!

Now that all the custom Corian is properly profiled with absolute precision using our ShopBot Desktop CNC router, it’s time to cut the entire wall plaque or sign out of the Corian.

To achieve this, the bit goes around and around until the finished piece is removed from the Corian. We’ll keep this piece for additional work as we can make custom coasters, key chains and even name tags using the scrap from this custom Corian project. At the end of the day, the less scrap that leave the shop, the happier the environment and our customers ROI on custom Corian projects.

The material you see building-up along the edges is basically chip fragments and dust that build-up within the cutting hole, it presents no danger in the shop (some people think Corian is a hazardous material) because nothing ever gets into the air, the vacuum system sucks all the fine dust and particulates and filters it out. We love our shop, we don’t want the optics of our industrial CNC laser to be filled with particles!

Removing some of the dust, you can see how clean the finish is on this custom Corian project. It can then be lifted out of the scrap Corian we made this project on and showcase to our customers far and wide!

How strong is this custom Corian sign or wall plaque? We can drop this on the floor and it won’t dent or be damaged, the worse that can happen is that it chips. When ever we do work like this using our CNC router or laser, we always pack it extremely well for shipping making custom MDF boxes so no matter how badly the packaging is treated, your finished custom Corian piece arrives safe and sound.

Looking for a reputable company that’s passionate about custom regardless of material, challenge or volume? Contact CNCROi.com today!